Manual Labor in Hygiene:

The hygiene industry, including cleaning and sanitation, often relies on manual labor for tasks such as cleaning and disinfection. This dependence on human workers became a significant vulnerability during the pandemic.

Outbreaks of COVID-19 among hygiene industry workers posed the risk of expensive shutdowns and contamination of facilities. Ensuring the safety of workers and maintaining hygienic standards became critical challenges.

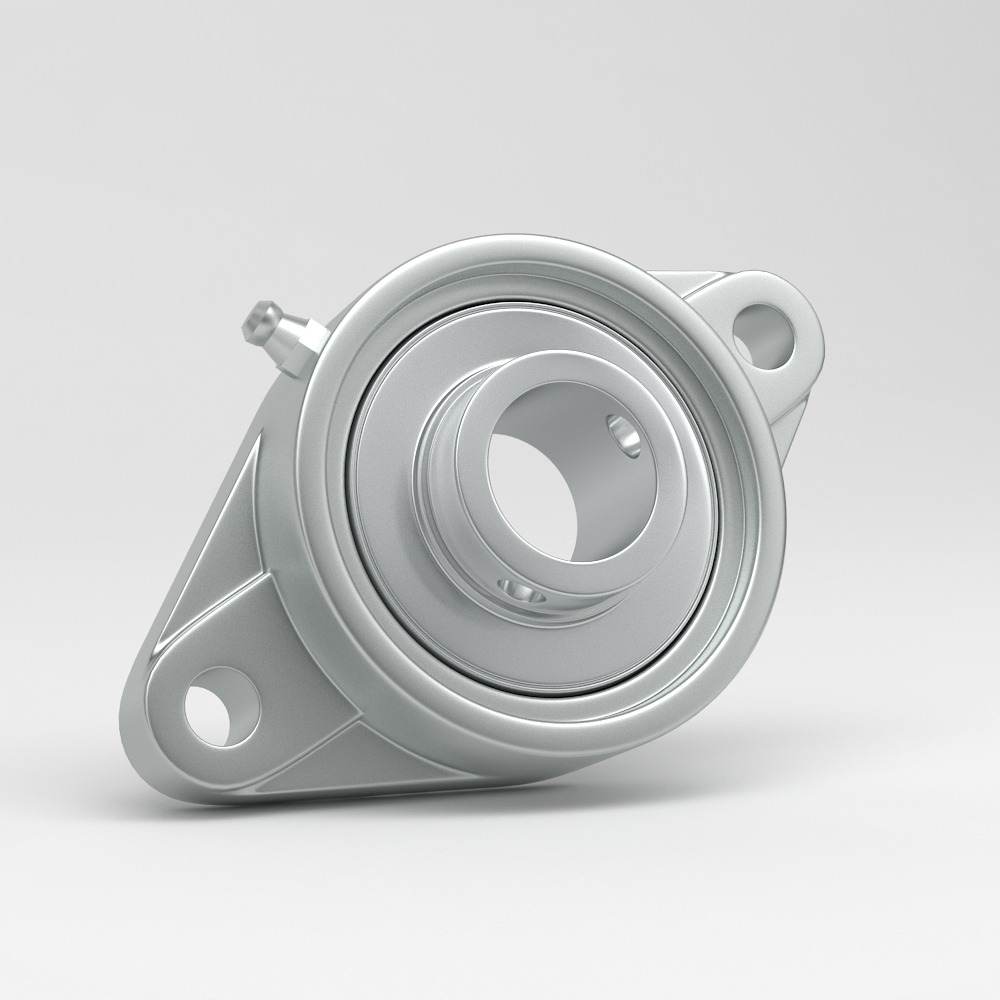

Using certified components and equipment in the hygiene industry is crucial to maintaining high standards of cleanliness and safety. Certified products are tested and approved to meet specific hygiene and safety criteria.

Automation and Technology:

The pandemic has highlighted the need for increased automation and technology adoption in the hygiene industry. Automated cleaning systems, UV disinfection, and robotics can reduce the reliance on manual labor and improve efficiency.

Certification standards in the hygiene industry, such as those for cleaning agents, disinfectants, and personal protective equipment (PPE), ensure that products meet established safety and effectiveness criteria.

Supply Chain Resilience:

Like in other industries, the hygiene industry should focus on building supply chain resilience. Diversifying suppliers and ensuring a consistent supply of certified components is essential to avoid disruptions.

Worker Safety and Training:

Emphasizing worker safety and providing proper training and protective gear is crucial in the hygiene industry. Ensuring that workers are well-prepared and protected can help prevent outbreaks and costly shutdowns.

Regulatory Compliance:

Compliance with hygiene and safety regulations is essential. Businesses should stay updated on relevant regulations and certifications to ensure they meet industry standards.

In light of these challenges:

it’s imperative for the hygiene industry to reevaluate its practices and invest in technology, automation, and certified components to reduce reliance on manual labor and enhance resilience in the face of future outbreaks or crises. This proactive approach can help ensure the industry is better prepared to maintain hygiene standards and protect both workers and the public.