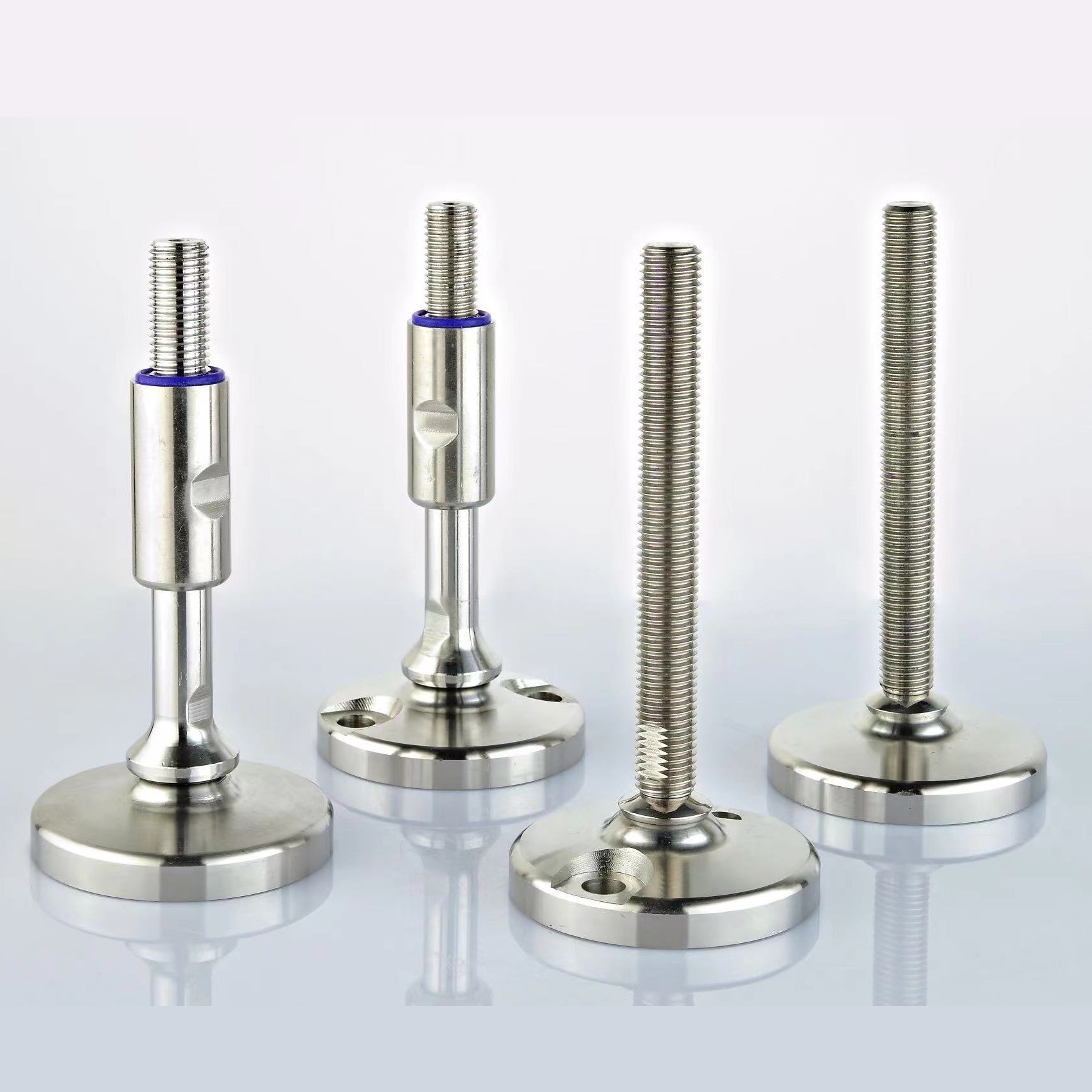

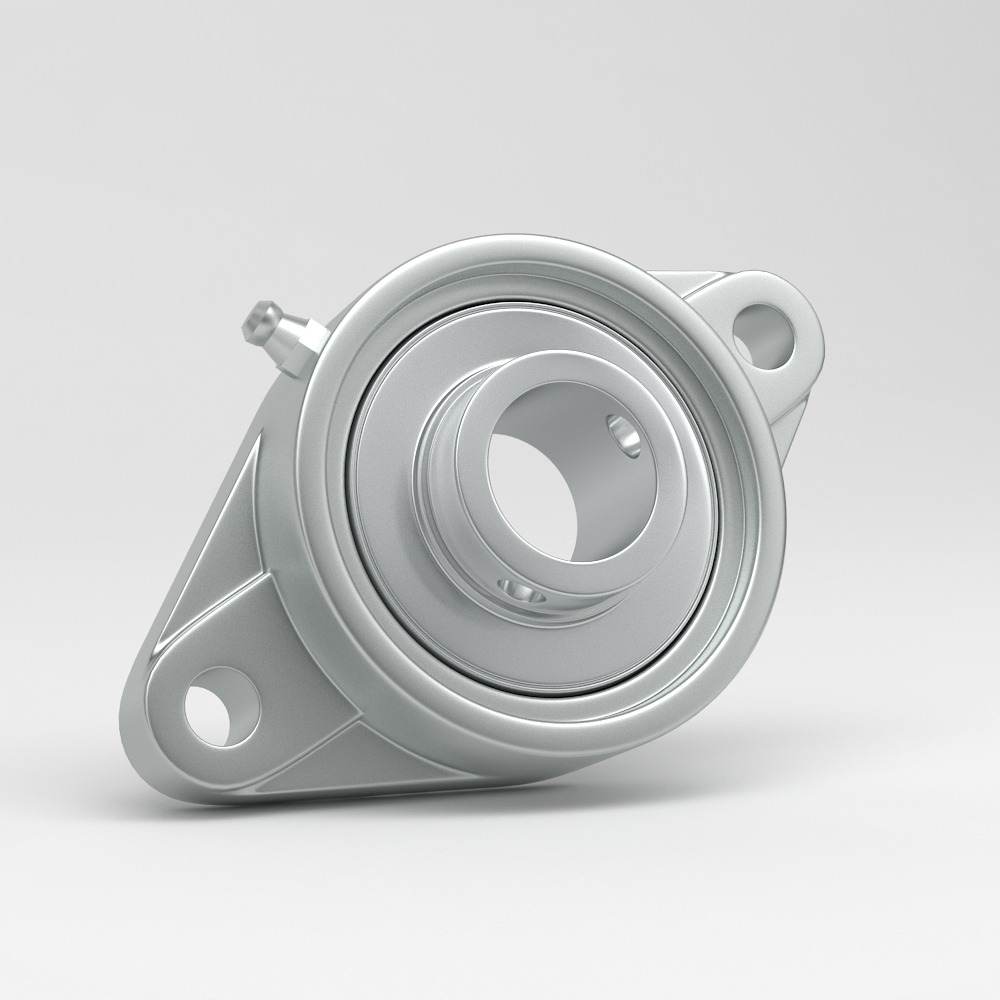

Design and Material Selection:

The design process for these leveling feet is underpinned by a thorough understanding of customer needs and industry challenges. Materials used in certified hygienic leveling feet are selected for their durability, resistance to corrosion, and ease of cleaning. These materials often include high-grade stainless steel and other non-toxic, non-porous materials that withstand aggressive cleaning protocols.

Compliance with Hygienic Standards:

Certified hygienic leveling feet adhere to rigorous standards set by globally recognized organizations, such as 3-A Sanitary Standards, USDA, and EHEDG. These certifications guarantee that the products are designed and manufactured to facilitate easy cleaning and sanitization, thereby reducing the risk of microbial and particulate contamination. The design features minimize hard-to-clean areas and prevent the accumulation of bacteria and debris.

Resource Efficiency:

By facilitating easier and more effective cleaning routines, these leveling feet help in significantly reducing water and cleaning agent consumption. The efficiency in cleaning not only conserves resources but also contributes to operational savings, lowering the overall environmental impact of cleaning processes.

Enhanced Safety and ROI:

Implementing certified hygienic leveling feet in processing equipment contributes to a safer production environment by minimizing contamination risks. This proactive approach to hygiene can prevent costly product recalls, protect consumer health, and enhance brand reputation. Additionally, the reduced need for excessive cleaning and maintenance can lead to significant cost savings, enhancing the return on investment for businesses. By selecting these certified components, companies can ensure that their processing facilities are not only compliant with current regulations but are also prepared for future standards and consumer demands.

Operational Excellence:

The use of certified hygienic leveling feet aligns with operational excellence goals, offering reliability, safety, and efficiency in production processes.

Market Competitiveness:

By ensuring compliance with hygiene standards, companies can differentiate themselves in the market, appealing to consumers and partners who prioritize safety and quality.

Future-proofing:

Investing in certified hygienic solutions prepares companies for stricter future regulations and evolving industry standards, ensuring long-term sustainability and competitiveness.

Strategic Benefits:

Certified hygienic industrial leveling feet represent a critical component in modern processing facilities, balancing regulatory compliance with operational efficiency and environmental stewardship. Their adoption is a testament to a company’s commitment to quality, safety, and sustainability, directly impacting the bottom line and enhancing customer satisfaction.