Understanding Business Needs

Industry Requirements: Different industries have unique standards and regulations. For example, the food industry often adheres to guidelines set by the FDA (Food and Drug Administration) or the EU’s EFSA (European Food Safety Authority), which include specific requirements for machine hygiene and contamination prevention.

Application Specifics: Understanding the specific application of the machine part or solution is crucial. This includes the types of materials or substances it will contact, the expected lifespan, and the environmental conditions (temperature, humidity, etc.) it must withstand.

Maintenance and Cleaning: Solutions should be designed for ease of cleaning and maintenance. This includes considerations for dismantling parts, materials that resist corrosion and withstand frequent cleaning, and designs that avoid hard-to-clean areas.

Technical Considerations for Hygienically Optimized Solutions

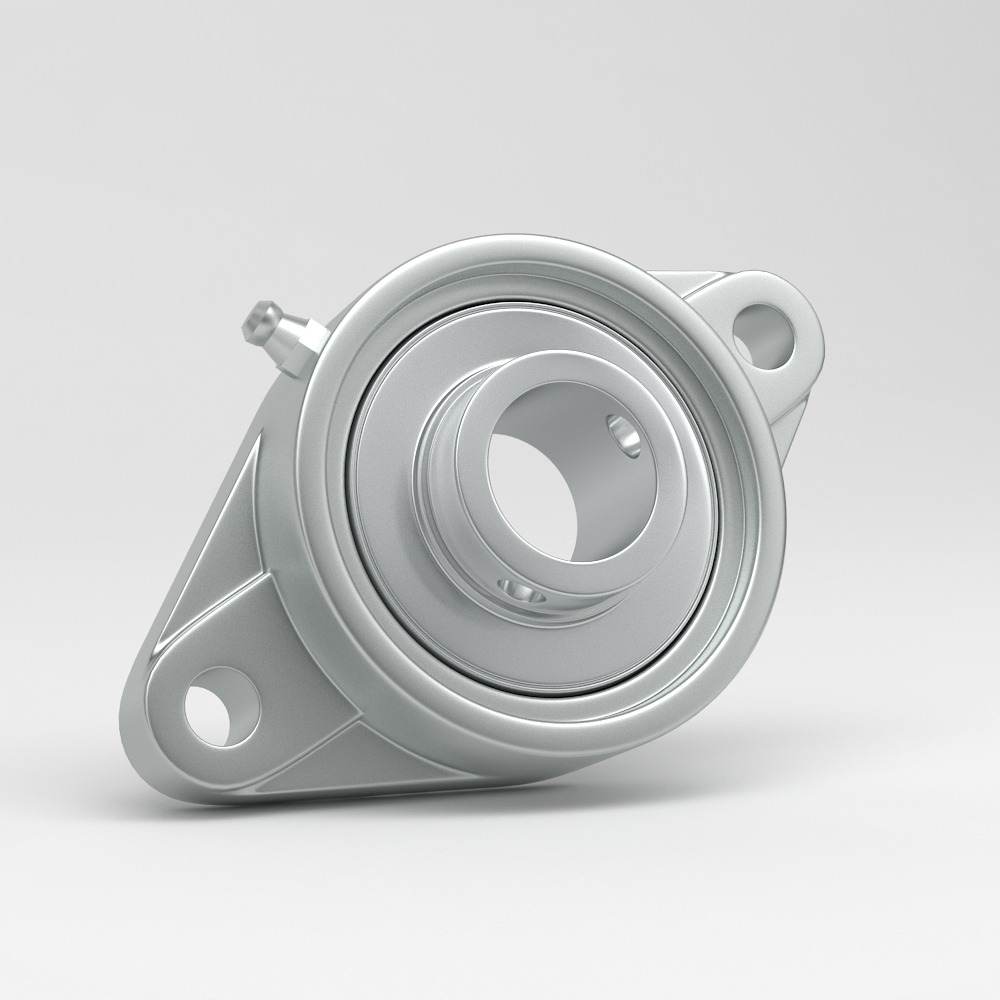

Material Selection: Materials used in parts and machinery must not only be durable and resistant to the products they contact but also non-toxic and easy to clean. Stainless steel is commonly used for its resistance to corrosion and ease of cleaning.

Surface Treatment: Smooth and non-porous surfaces are easier to clean and less likely to harbor bacteria and other contaminants. Techniques like electropolishing can be used to enhance surface smoothness.

Design Principles: Designing for hygiene includes minimizing crevices, sharp corners, and dead spaces where product or bacteria can accumulate. It also involves ensuring that liquid can drain away easily, avoiding horizontal surfaces where dust and debris can settle.

Seals and Gaskets: These components should be made from materials that can withstand the cleaning chemicals and methods used, as well as the operational environment of the machinery. They should also fit tightly to prevent ingress of contaminants.

Collaboration and Compliance

Stakeholder Engagement: Working closely with end-users, maintenance teams, and regulatory experts can provide valuable insights into the practical and regulatory requirements that the solutions must meet.

Certifications and Standards: EHEDG, the European Hygienic Engineering & Design Group, provides certifications and standards related to hygienic design principles for equipment and components used in the food, beverage, pharmaceutical, and cosmetic industries.

Continuous Improvement and Innovation

Feedback Loops: Implementing mechanisms for gathering and analyzing feedback from users can help in identifying areas for improvement and innovation.

Advancements in Materials and Technologies: Keeping abreast of developments in materials science and manufacturing technologies can provide new opportunities for enhancing hygiene. For example, antimicrobial coatings or materials and advanced sealing technologies can offer additional protection against contamination.

Striving for excellence:

Developing hygienically optimized machine parts and solutions is a complex process that benefits from a multidisciplinary approach, involving expertise in design, materials science, regulatory compliance, and a deep understanding of the specific challenges and requirements of the targeted industries.