The Vital Role of Hygienic Components in Food Processing Machinery

In the realm of food processing, ensuring the safety and quality of products is of paramount importance. One critical aspect often overlooked by the uninitiated is the role played by hygienic components in food processing machinery. These specialized parts are designed to meet stringent cleanliness and sanitation standards, and they are fundamental to preventing contamination, ensuring food safety, and maintaining the integrity of the final product. In this article, we will delve into the significance of hygienic components in food processing machinery.

Preventing Contamination

Contamination of food products is a constant concern in the food processing industry. Hygienic components are meticulously designed and manufactured to minimize the risk of contamination. They feature smooth surfaces, rounded corners, and minimal crevices where bacteria, pathogens, or debris can accumulate. This design minimizes the potential for microbial growth and helps maintain the purity of the processed food.

Compliance with Regulatory Standards

Food safety regulations, such as the Hazard Analysis and Critical Control Points (HACCP) and Good Manufacturing Practices (GMP), are strict and demand adherence. The use of hygienic components ensures compliance with these standards. Food processing machinery equipped with such components helps manufacturers meet regulatory requirements, thus preventing legal issues, recalls, and damage to their reputation.

Easy Cleaning and Maintenance

Hygienic components are designed with easy cleaning and maintenance in mind. This feature is essential because thorough and regular cleaning is a cornerstone of food safety. Hygienic parts are often made from materials that can withstand aggressive cleaning agents, high-pressure washdowns, and heat sterilization processes without degradation. This makes it easier for operators to maintain the machinery in a sanitary condition.

Enhanced Product Quality

Food processing machinery fitted with hygienic components can better preserve the quality of food products. These components reduce the chances of product cross-contamination, off-flavors, and spoilage. As a result, the processed food maintains its taste, texture, and nutritional value, meeting consumer expectations for high-quality products.

Extended Machinery Lifespan

Hygienic components are not only beneficial for product quality but also for the longevity of food processing equipment. The reduced risk of corrosion, wear, and damage due to aggressive cleaning agents and constant use means that machines can operate efficiently for longer periods. This, in turn, reduces downtime, maintenance costs, and the need for frequent component replacement.

Consumer Confidence

Consumer trust is indispensable in the food industry. When consumers see food products labeled as "processed under hygienic conditions," they are more likely to trust the brand. By investing in hygienic components and maintaining strict cleanliness standards, food manufacturers can build and maintain consumer confidence, which is a valuable asset in a competitive market.

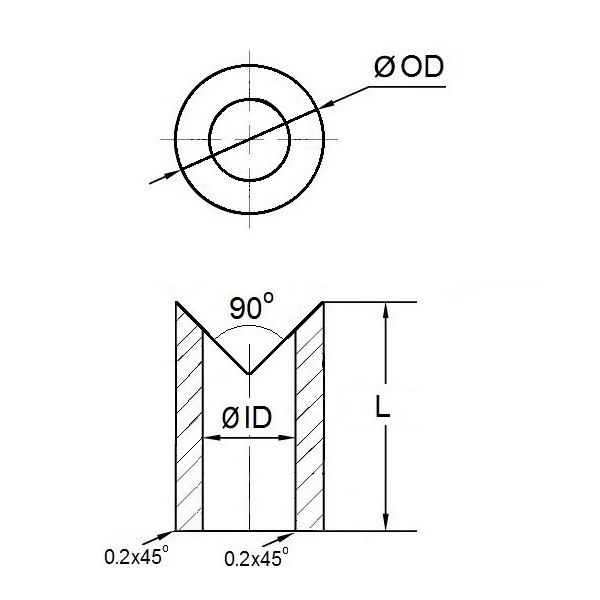

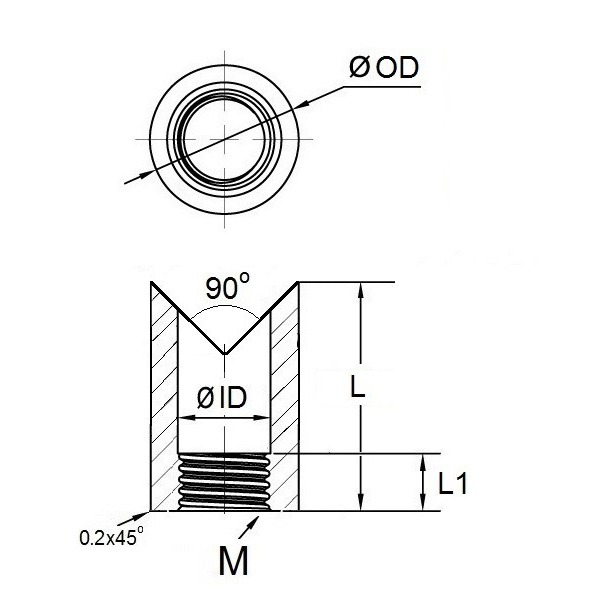

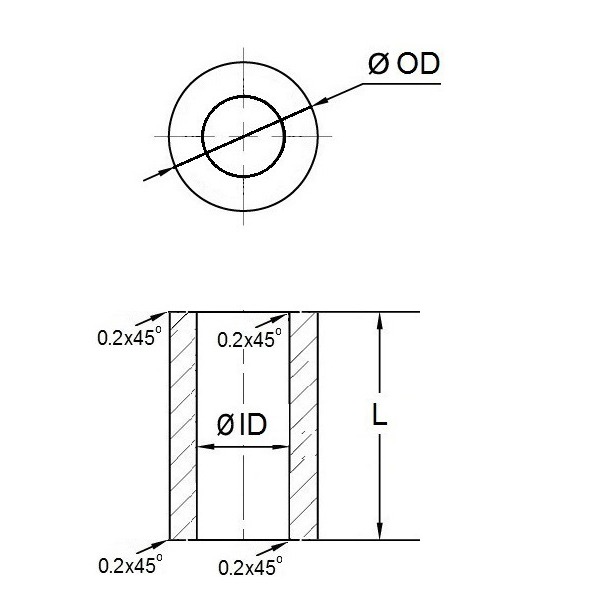

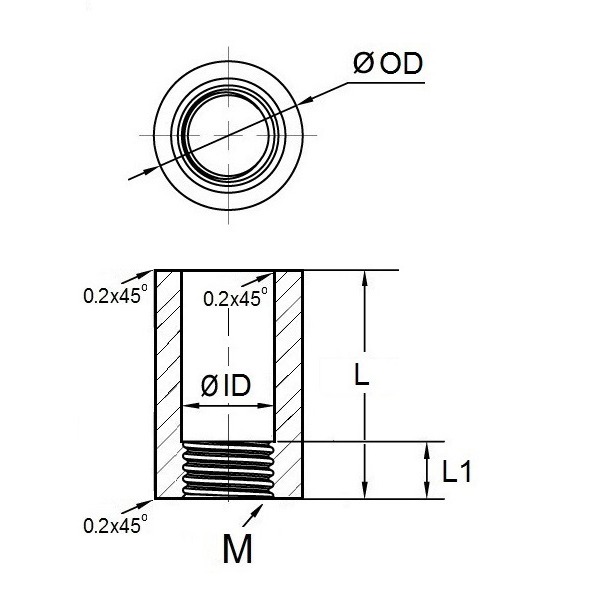

Hygienic Components and Sanitary Parts

The importance of hygienic components in food processing machinery cannot be overstated. These components are the unsung heroes of the industry, working diligently to ensure that the food we consume is safe, high-quality, and free from contaminants. By adhering to strict sanitation standards, preventing contamination, and complying with regulatory requirements, hygienic components play a pivotal role in preserving the integrity of the food processing industry. Manufacturers who prioritize the use of hygienic components not only safeguard their brand's reputation but also contribute to the overall safety and well-being of consumers. In the ever-evolving landscape of food safety, hygienic components are a cornerstone of success.

Keywords:

- Hygienic components

- Sanitary parts

- Food processing machinery

- Pharmaceutical manufacturing

- Enhanced hygiene

- Operational efficiency

- Durability

- Contamination-free

Questions and contact

Do you have any questions about our products? You are always welcome to contact us for questions about performance and solutions for your machine or anything else. You can read more about how to contact us here. You can find us in Denmark, the UK, Germany and Hong Kong.

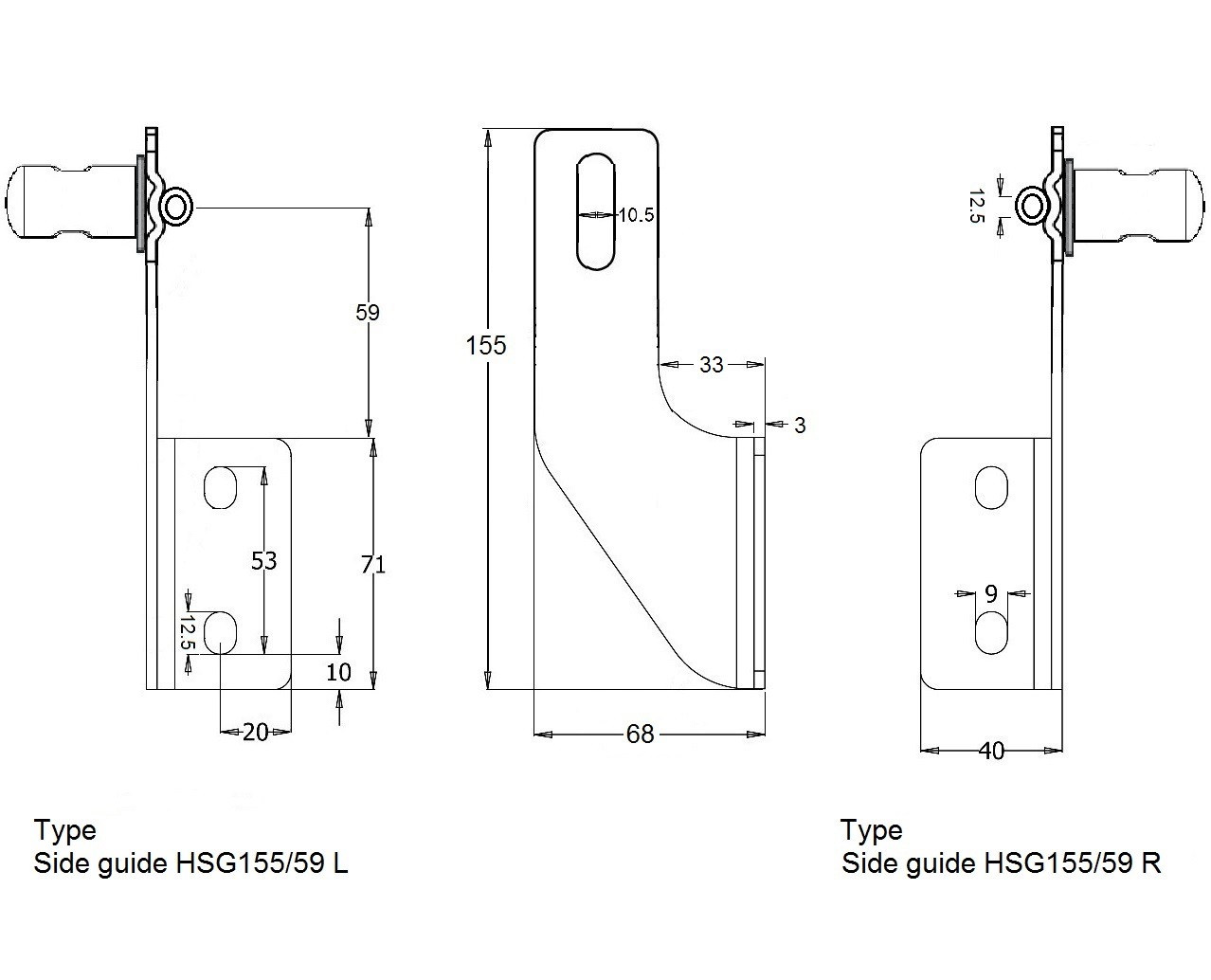

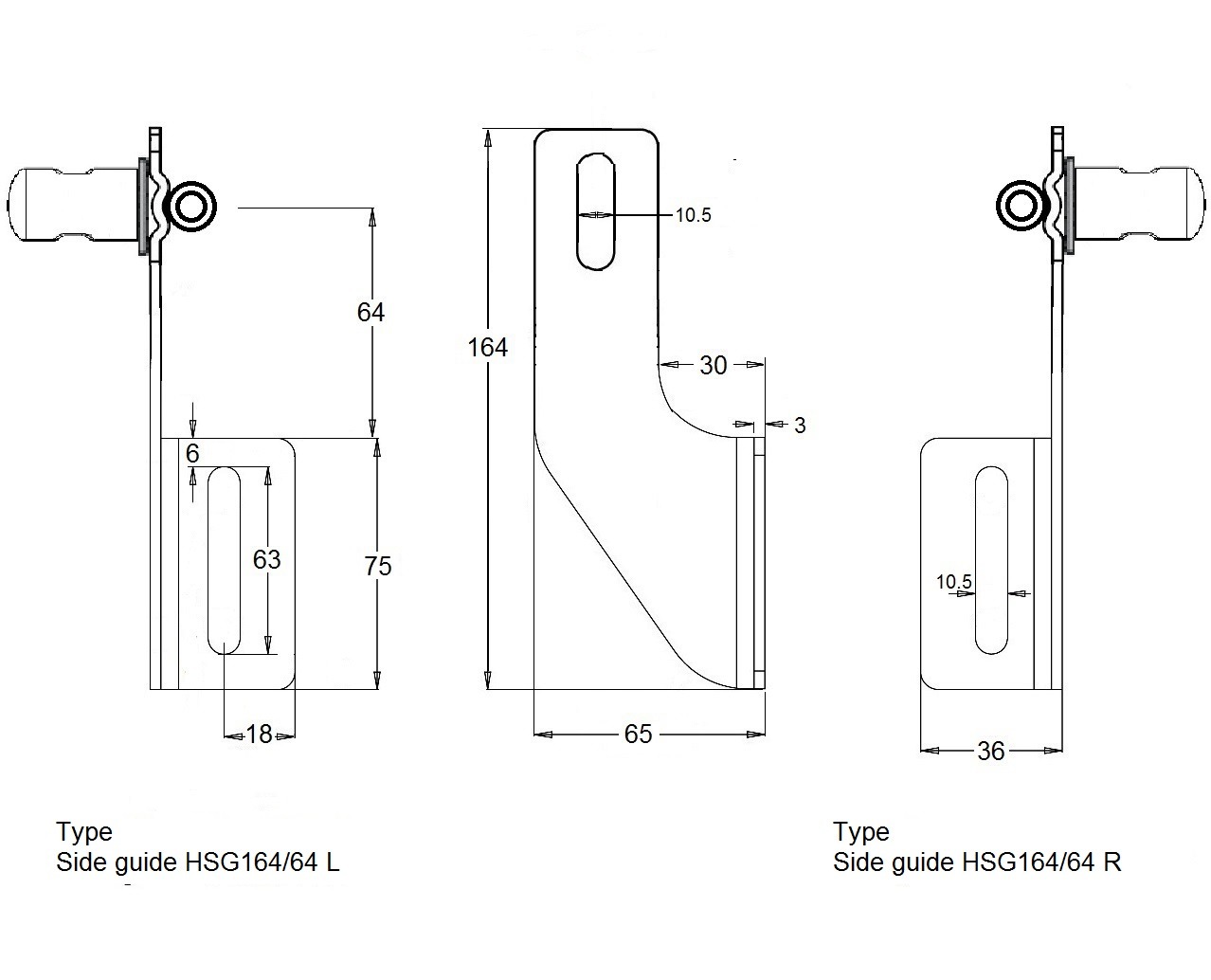

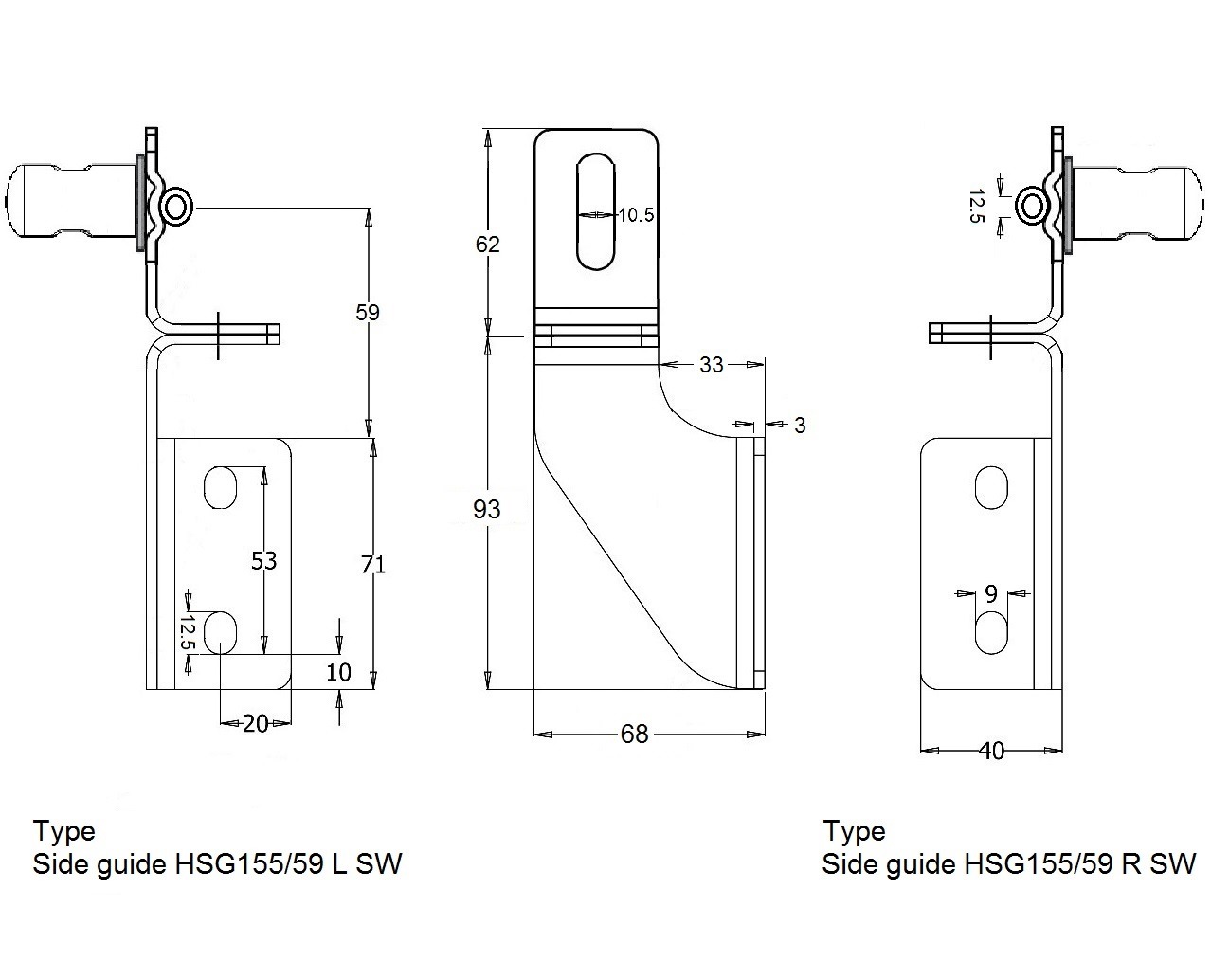

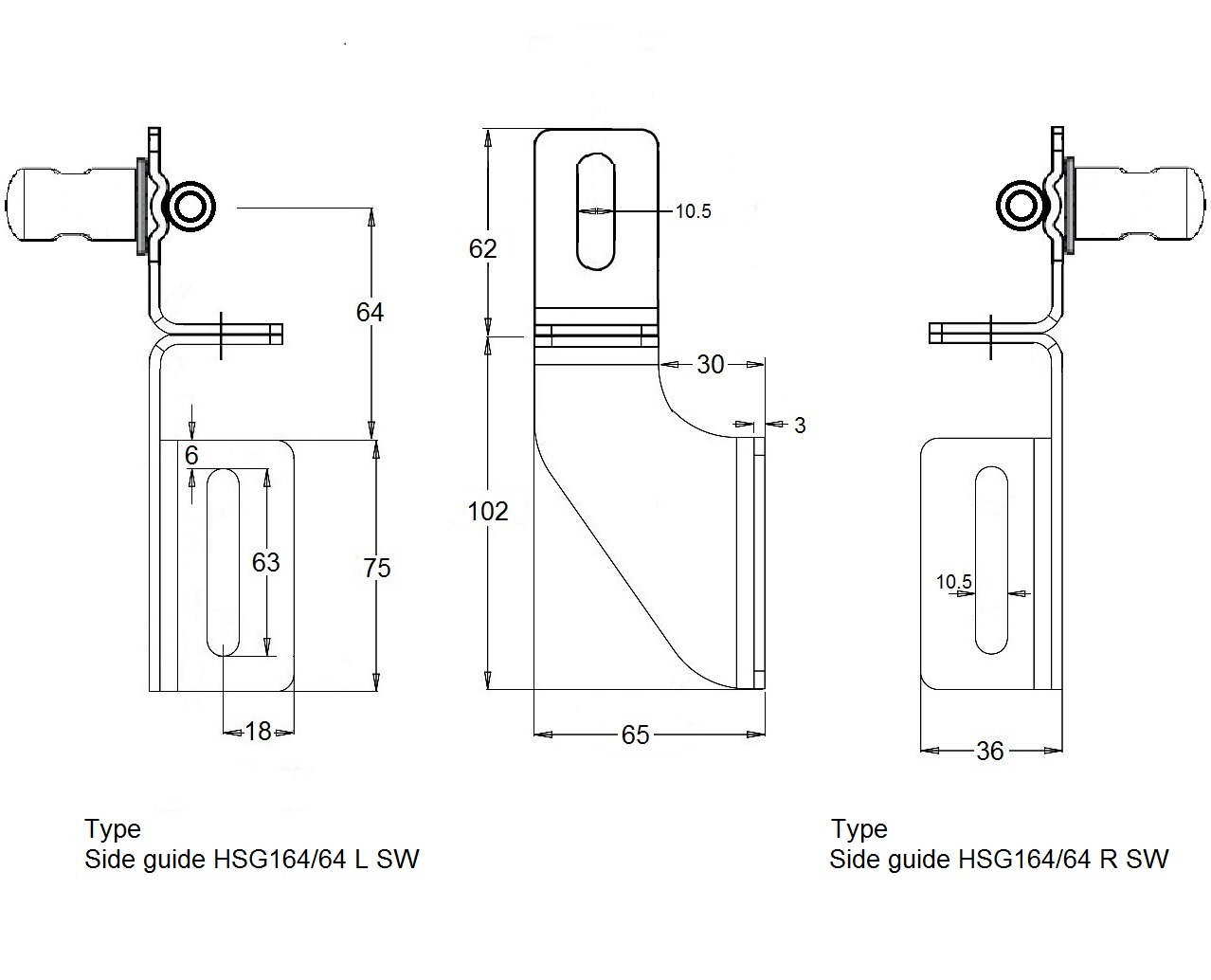

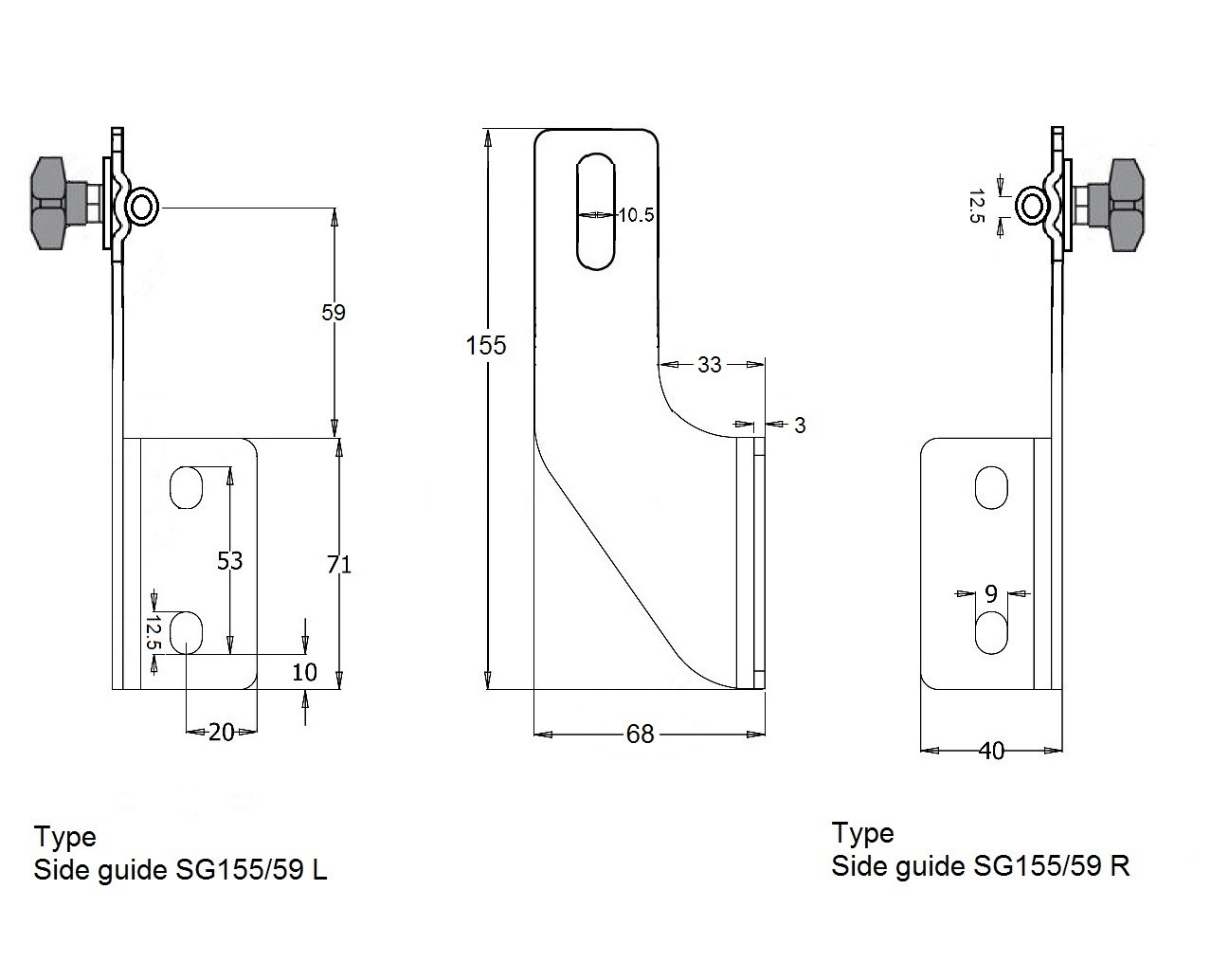

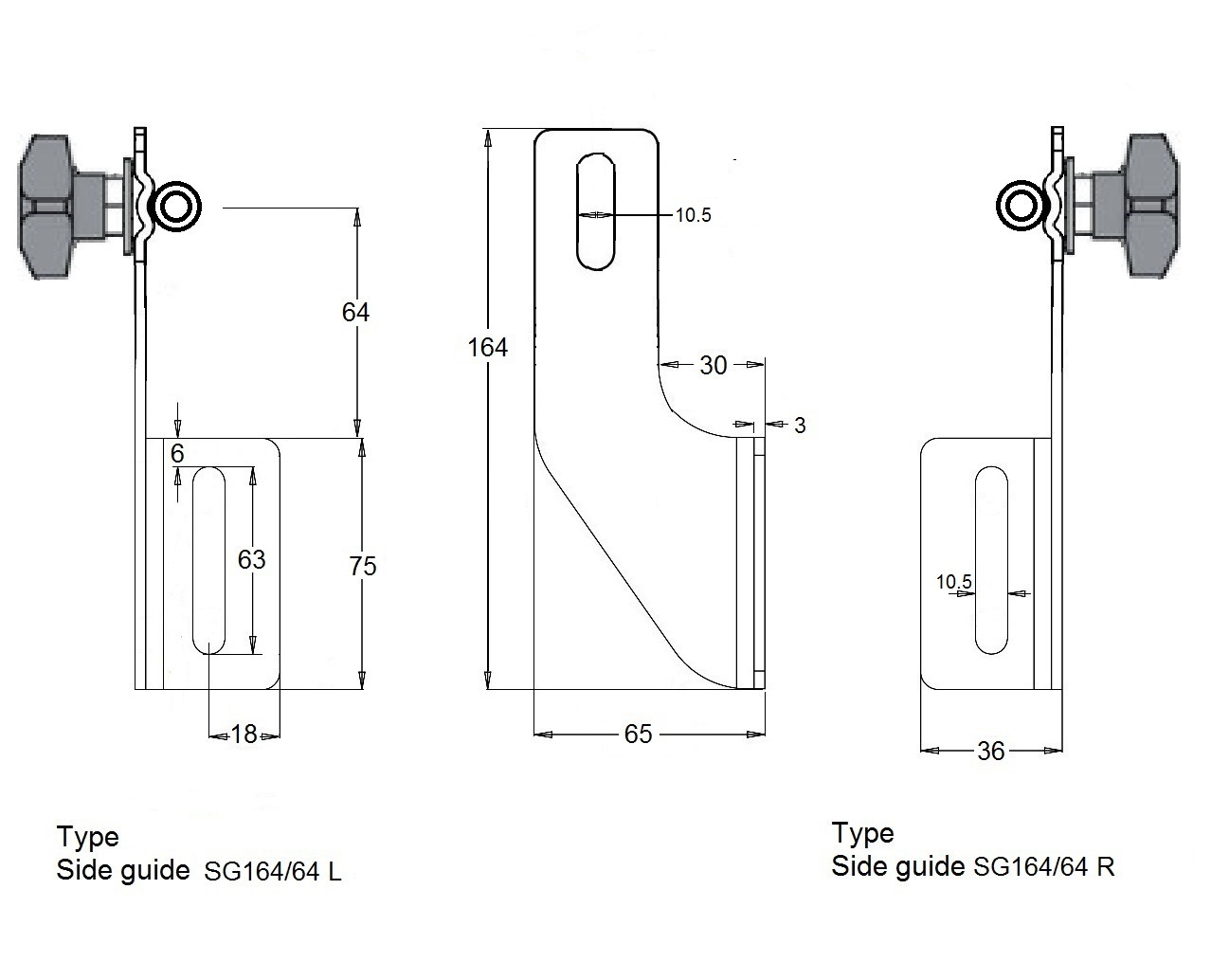

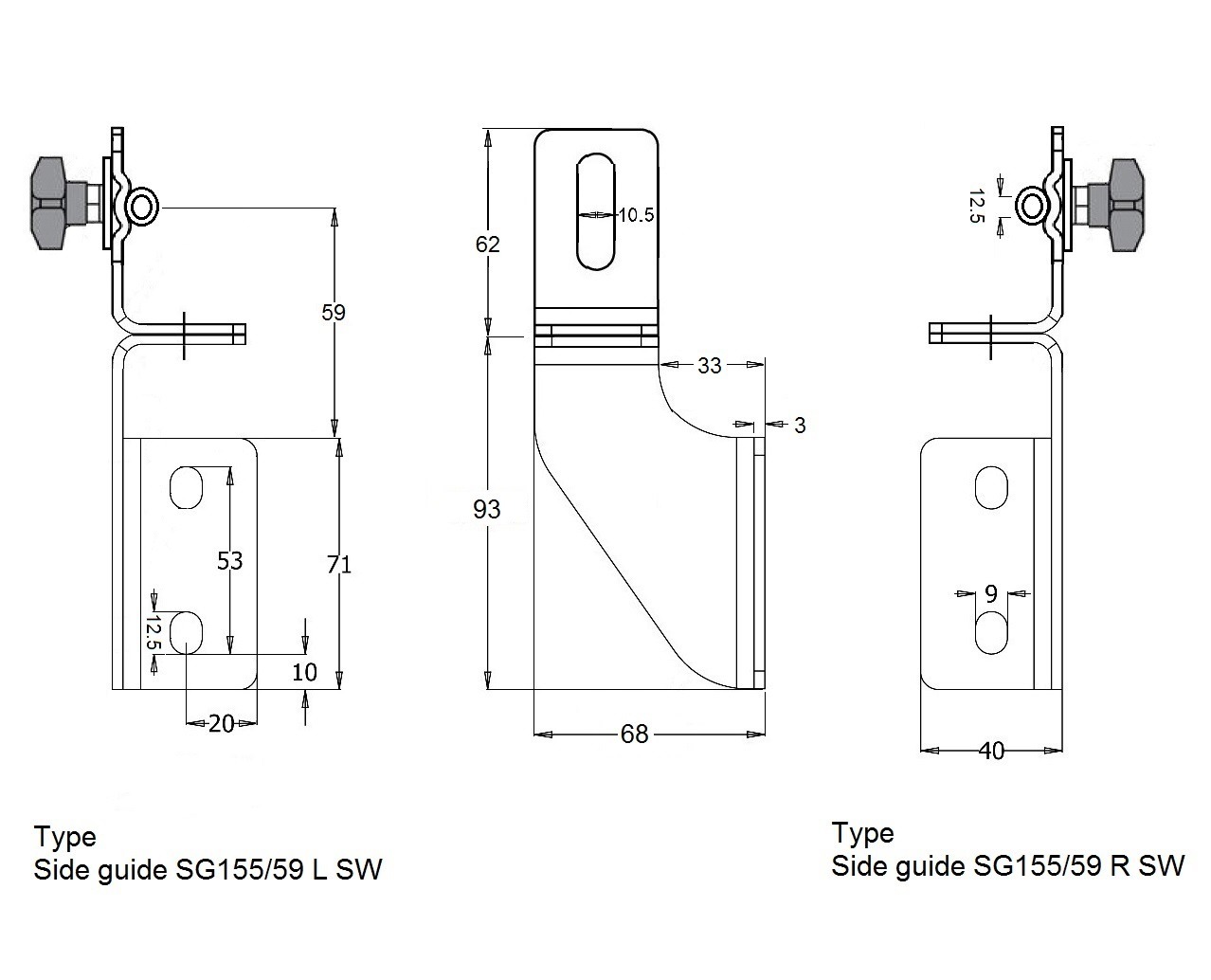

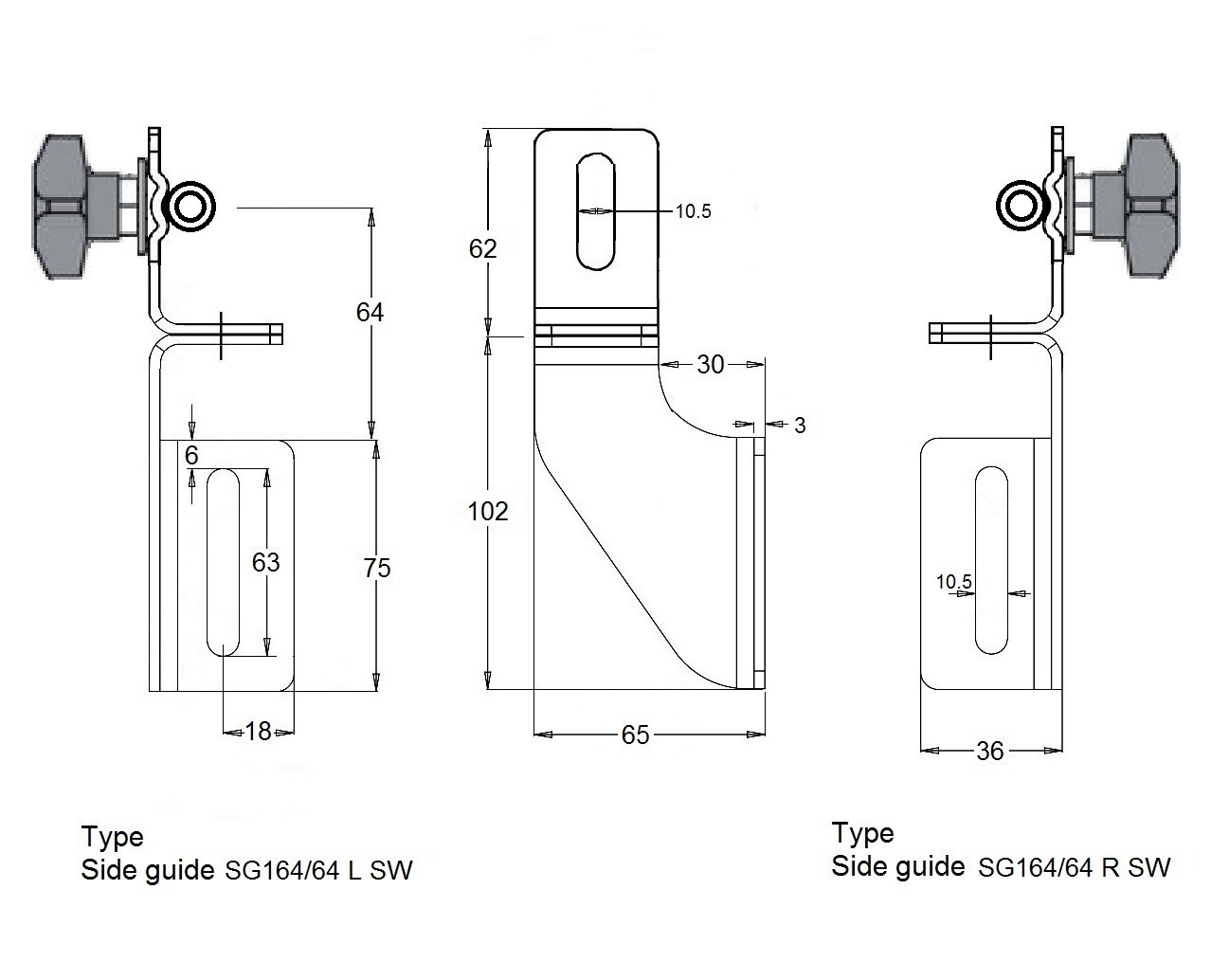

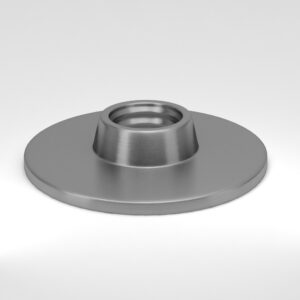

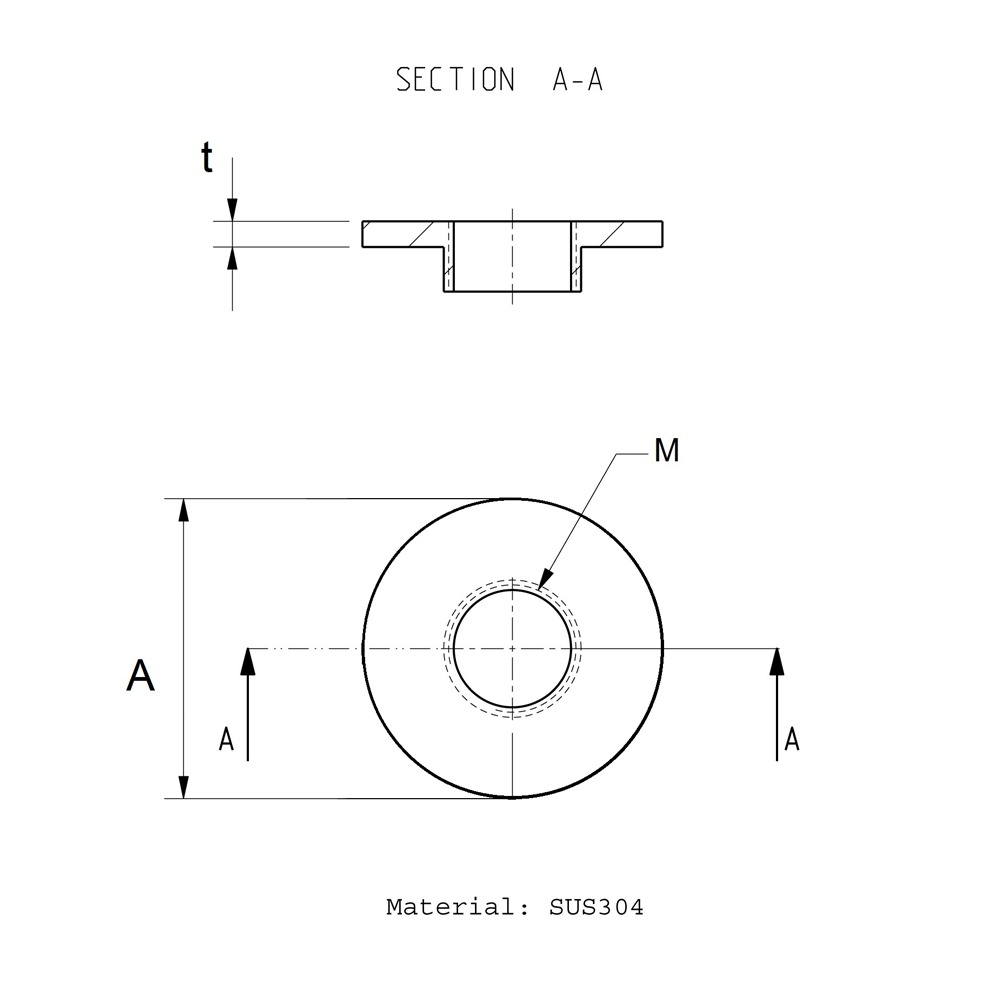

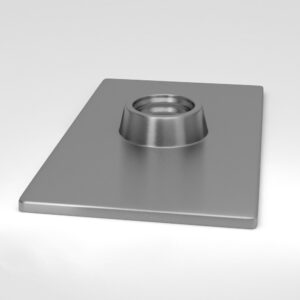

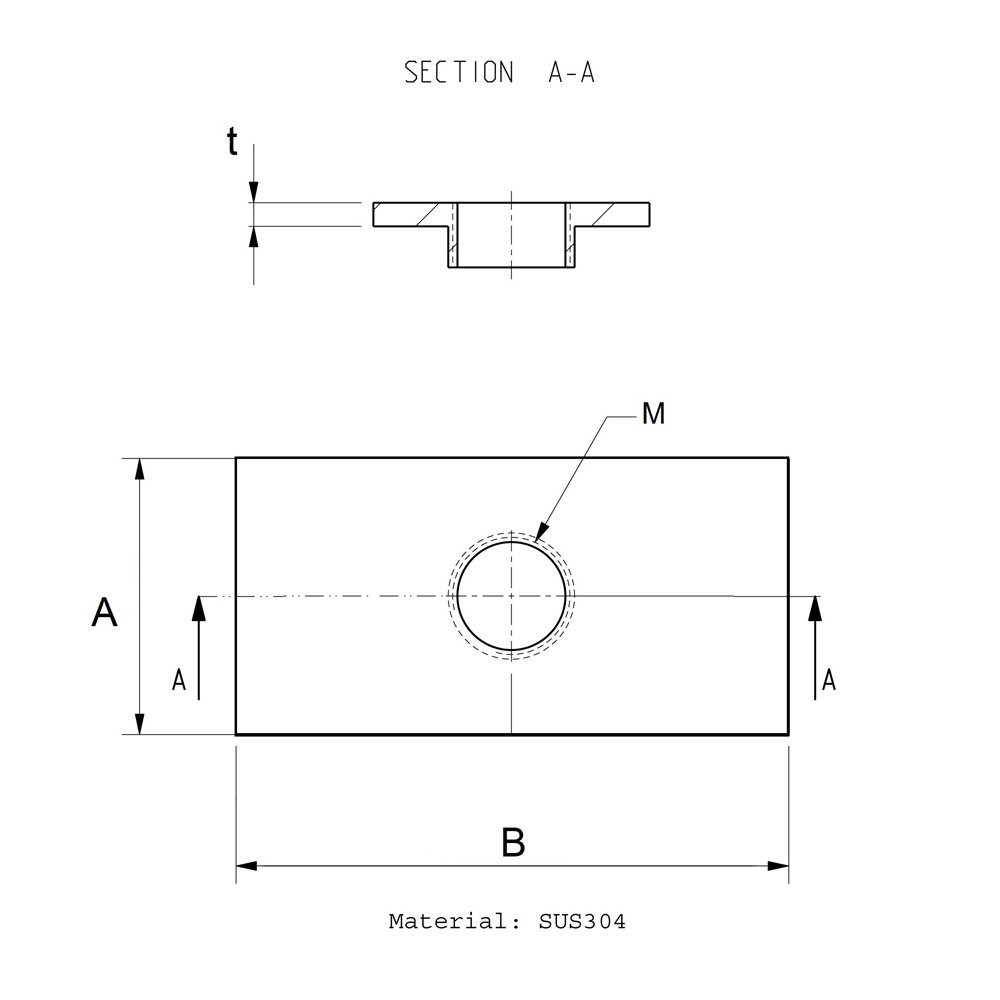

See our other hygienic components and machinery parts

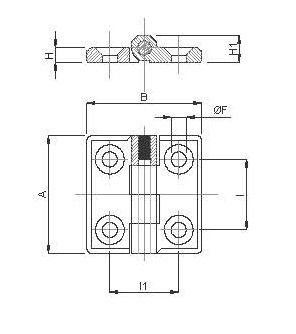

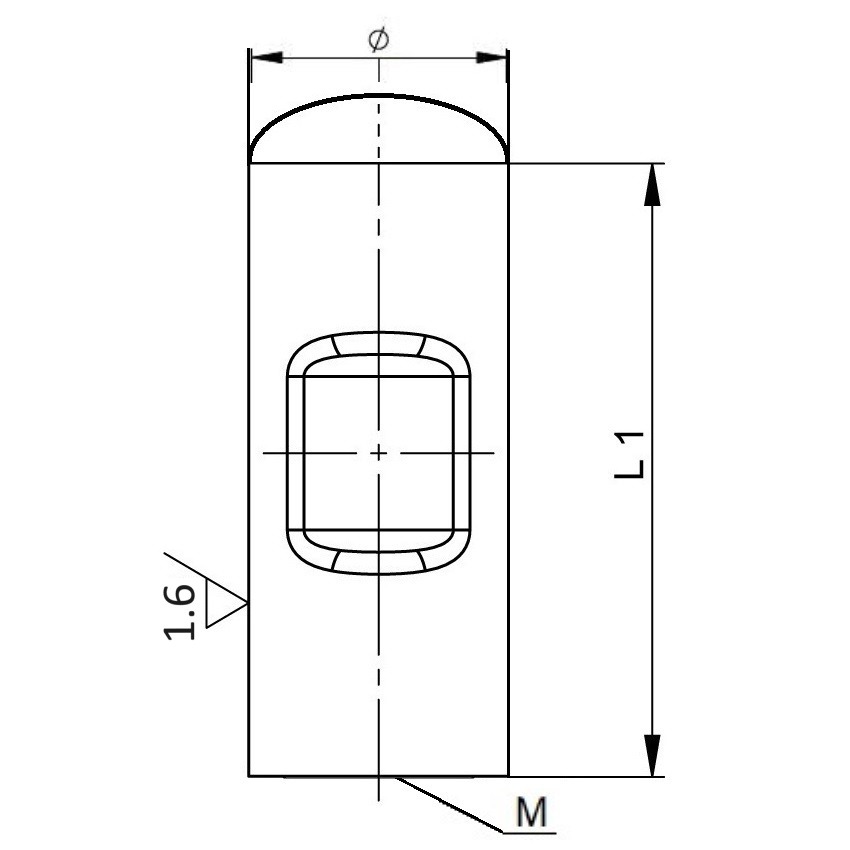

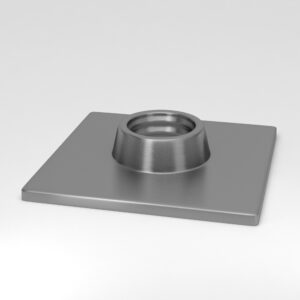

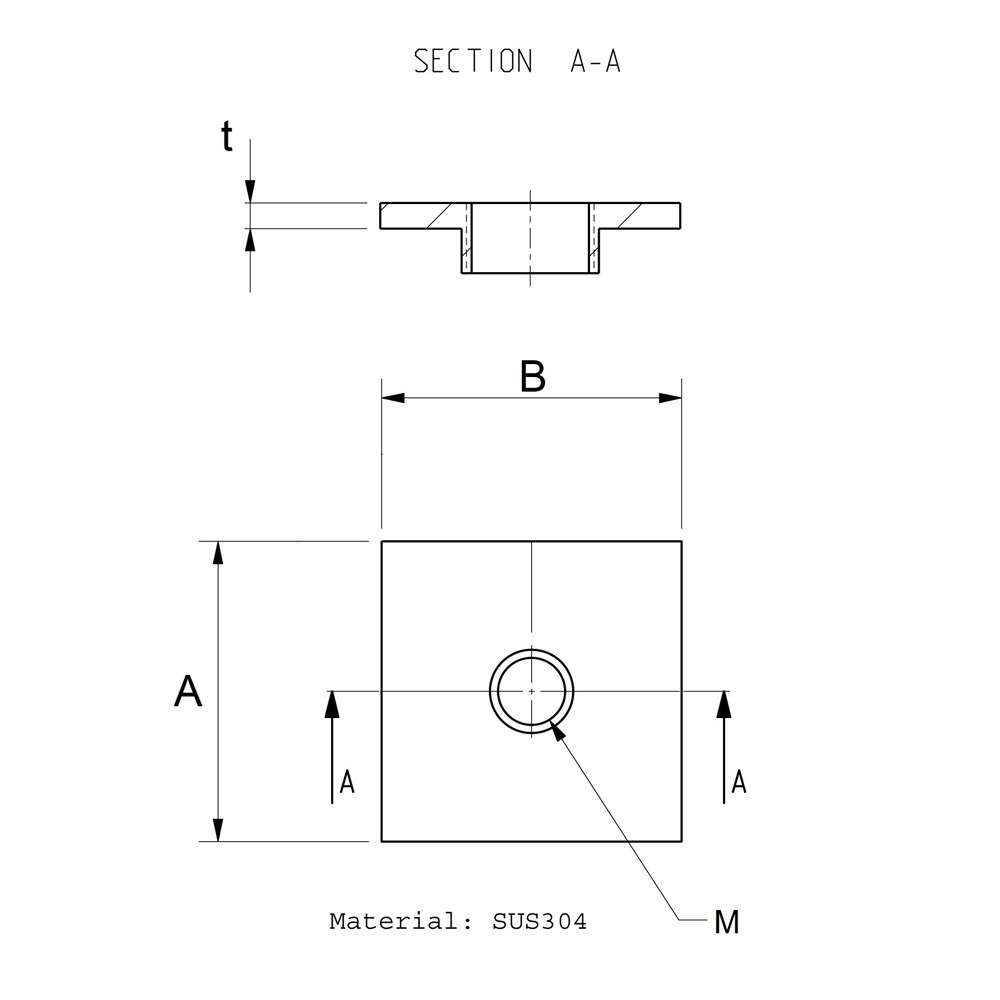

Our product range includes Certified EHEDG standard components, such as Machine leveling feet with solid base plate, Industrial machine leveling feet in stainless steel, Adjustable feet with composite material base plate and Stainless industrial caster Noise reducing castor, alongside IP67 Waterproof bearing house units, Sealed Stainless Steel Bearing Units, Bearing units in IP54 composite housing, Mounted ball bearing house units and Mini Bearing Units in Stainless Steel as well as Hygienic machinery components in stainless steel and Conveyor components and side guides, all crafted in hygienic stainless steel design for Food and beverage industry, Pharmaceutical manufacturing, Biotechnology industry, Cosmetics and personal care technology, Healthcare and medical device manufacturing, Dairy industry, Pet food processing industry, Meat and poultry processing industry, Seafood processing industry, Fruit and Vegetable processing industry, Snack food processing industry, Frozen food manufacturing industry, Cereal and grain processing industry, Baby food industry, Pastry and dough processing technology industry, Ice cream and frozen dessert industry, Coffee and chocolate processing technology, Sweets and snacks processing industry, Confectionery processing technology industry, production and packaging technology.