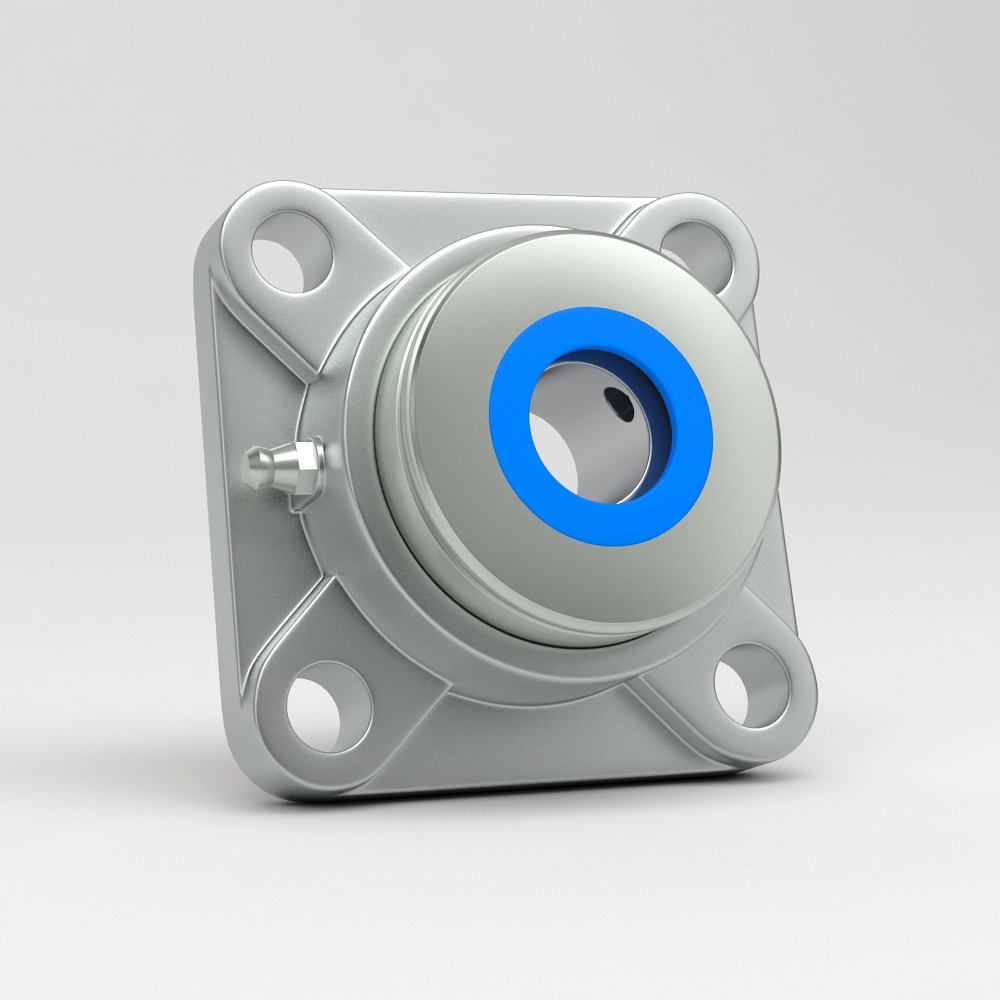

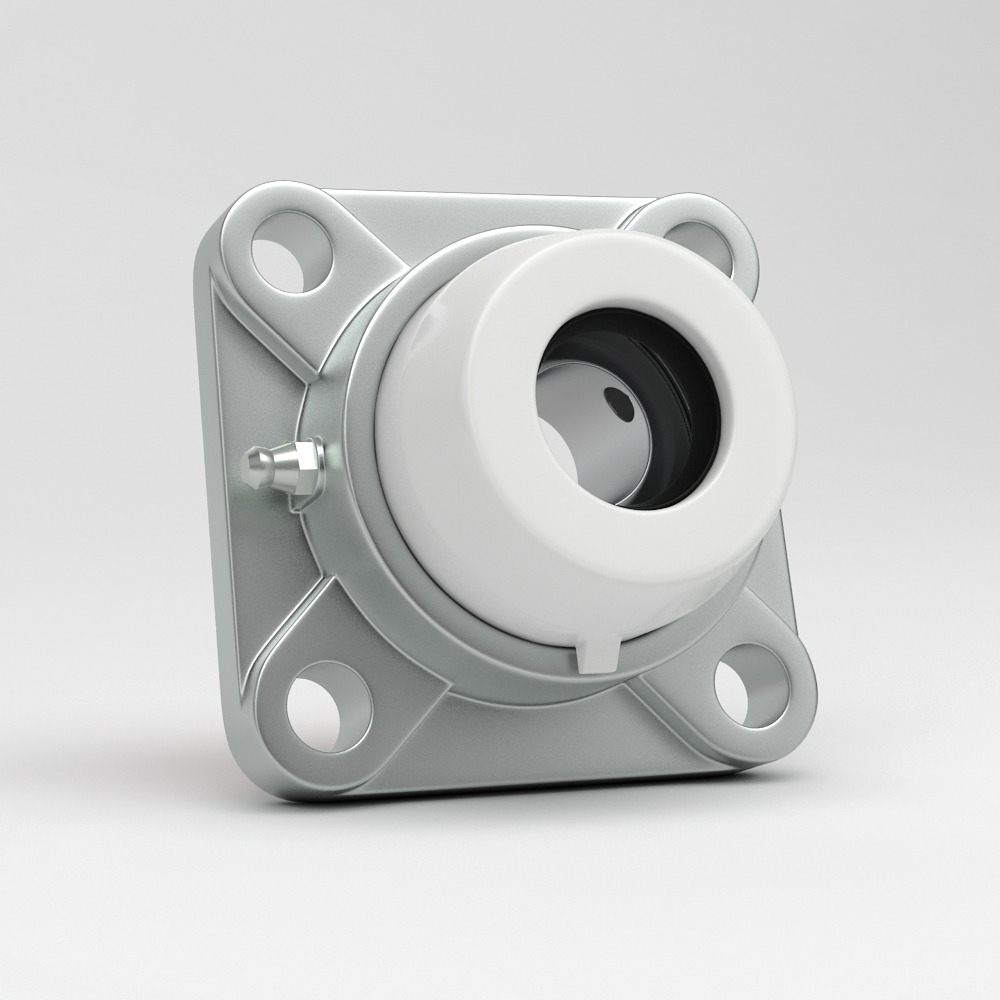

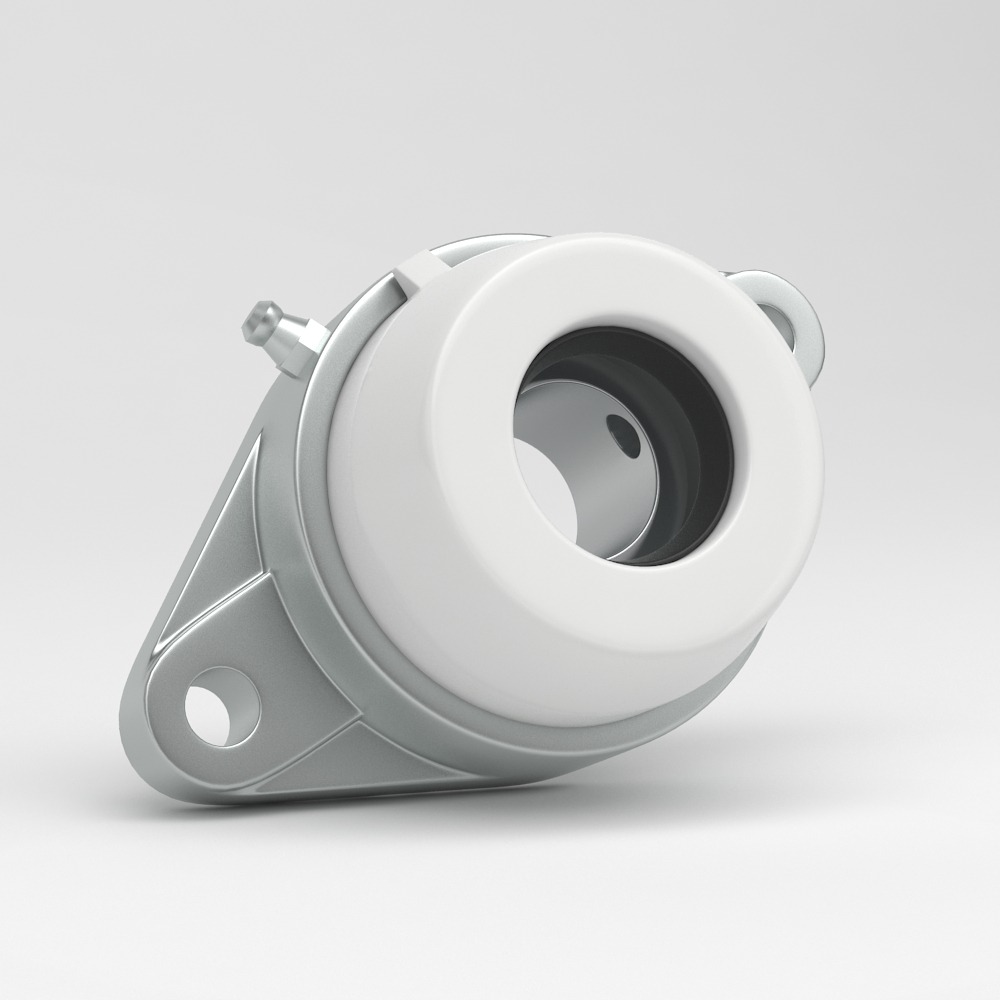

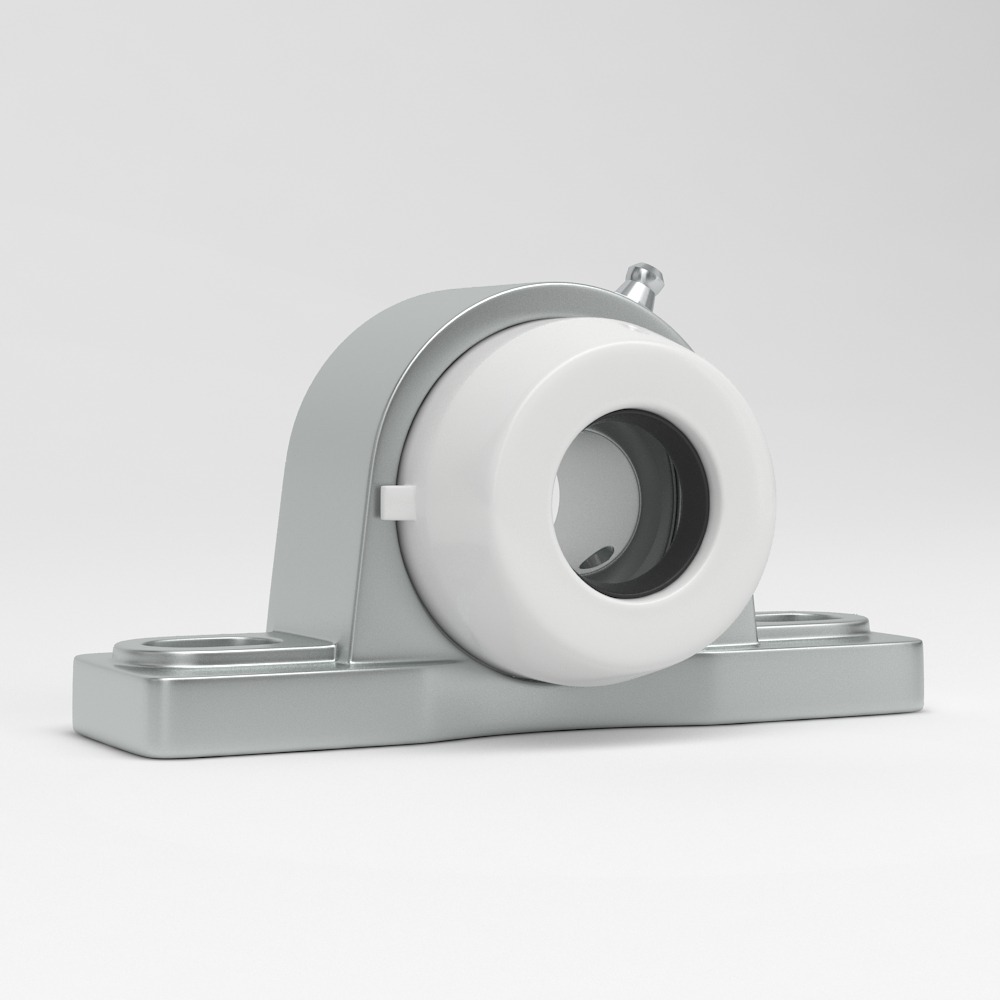

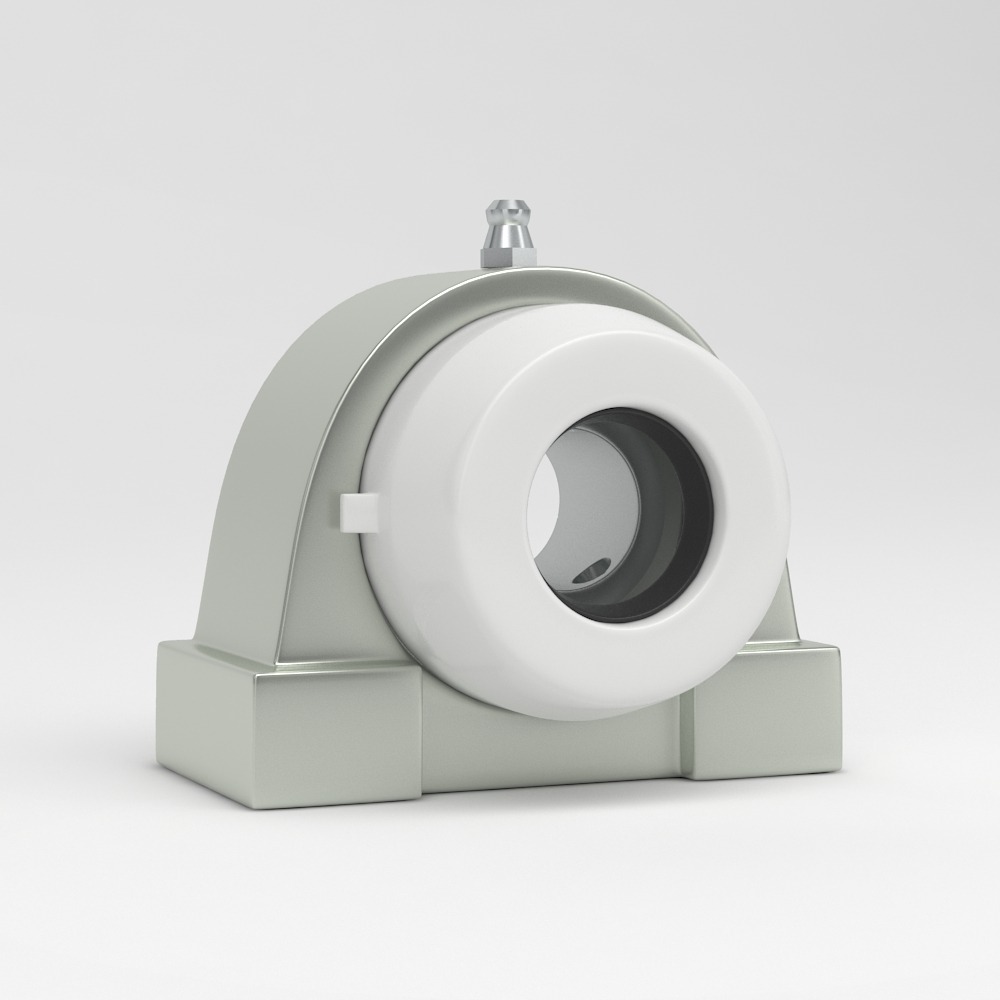

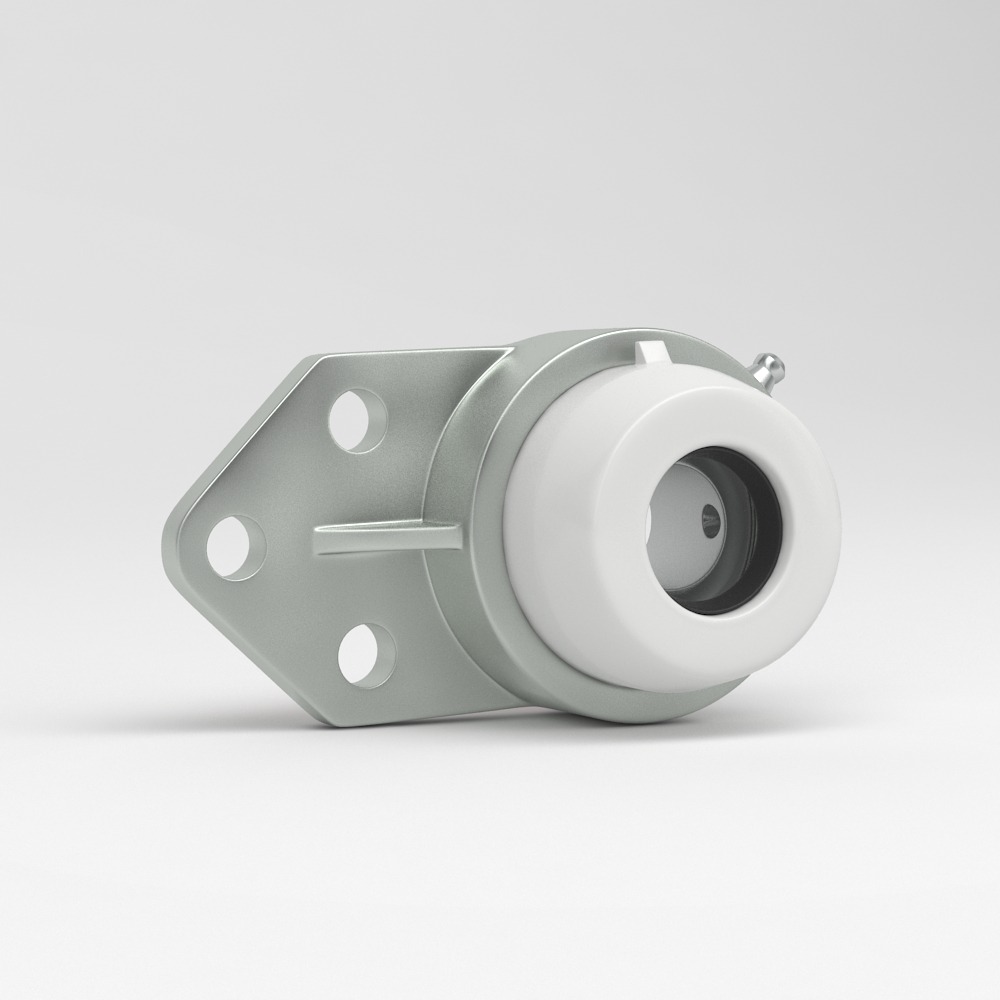

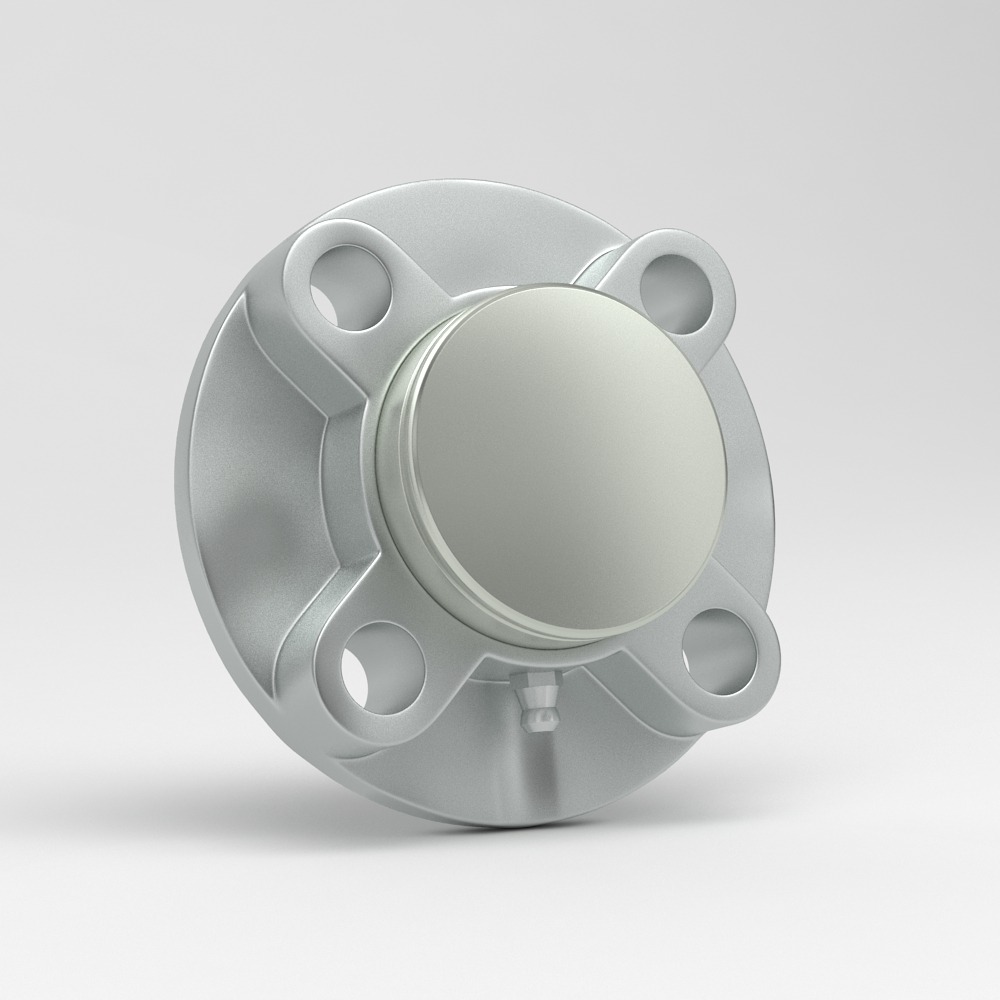

Stainless Steel 304 Housings

The use of stainless steel 304 for bearing housings is a strategic choice. This material is renowned for its excellent corrosion resistance, making it ideal for environments prone to moisture and aggressive cleaning agents. Its non-corrosive nature ensures long-term durability and reliability, essential in maintaining the integrity of the machinery and the safety of the products being processed.

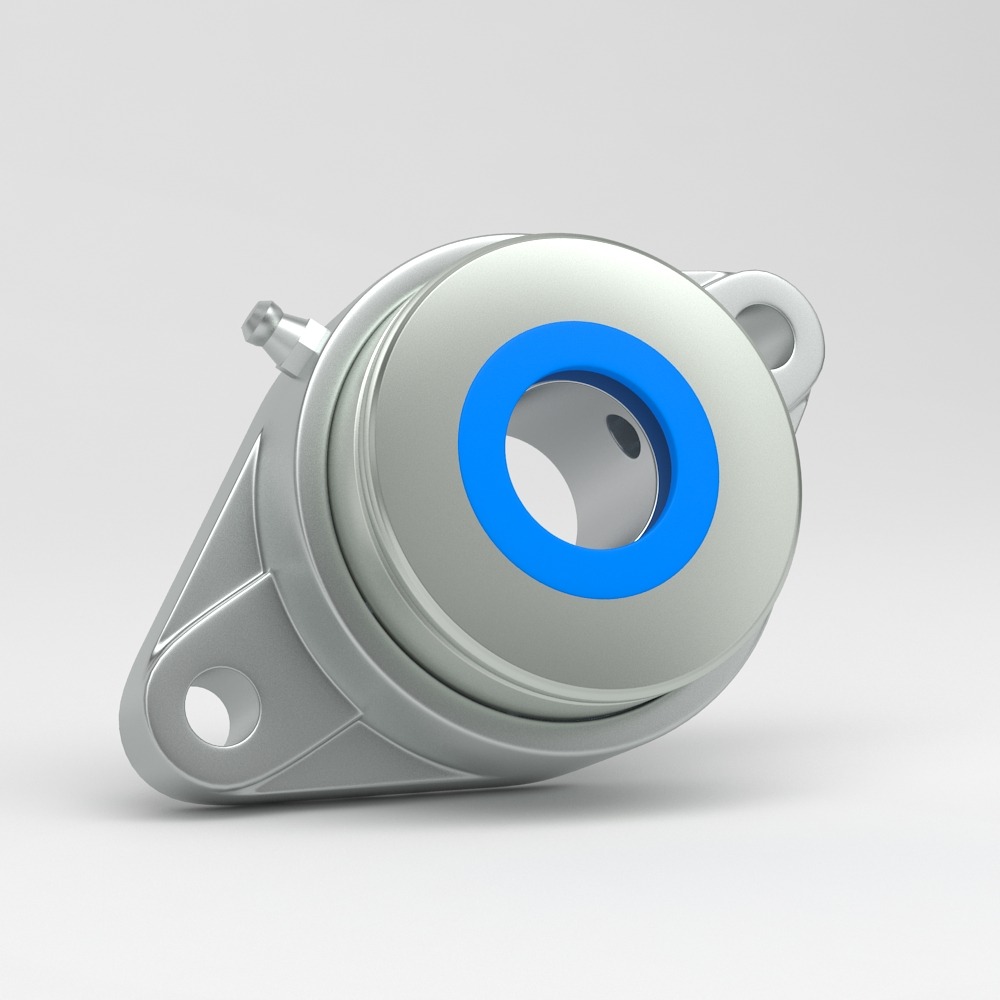

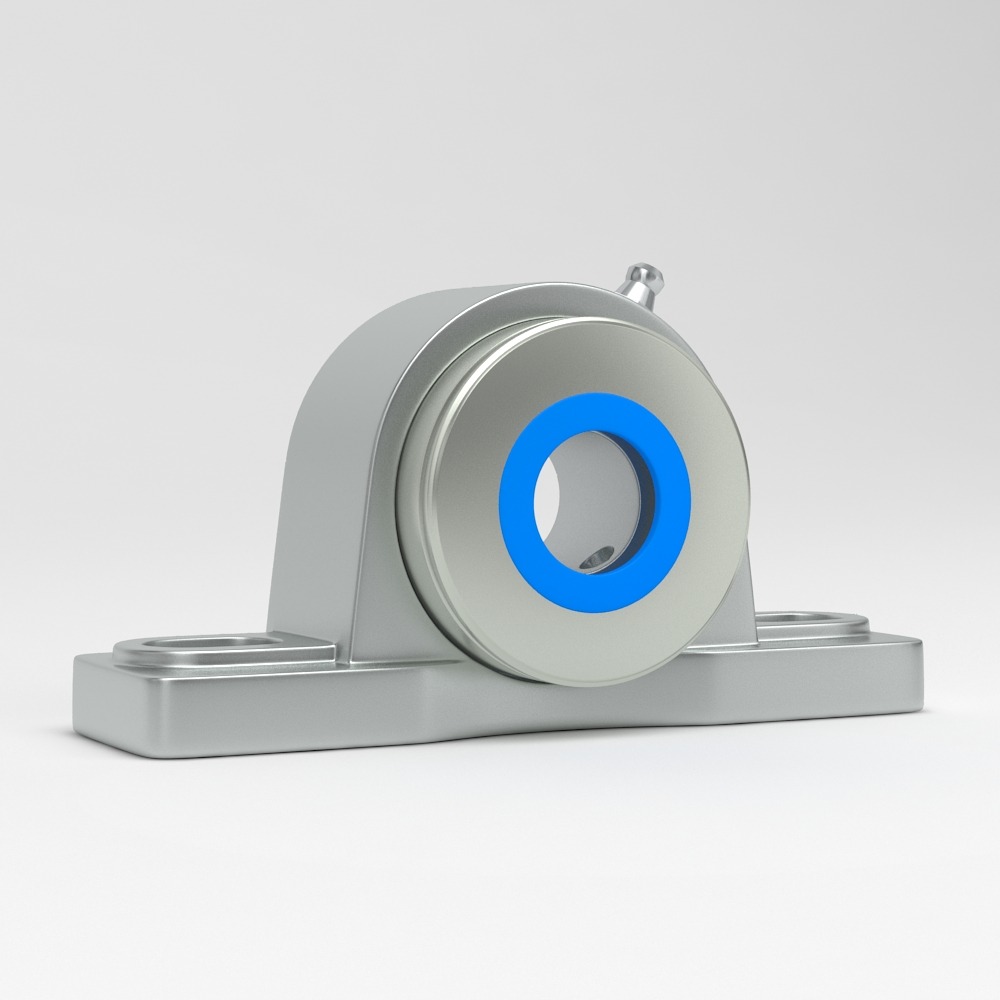

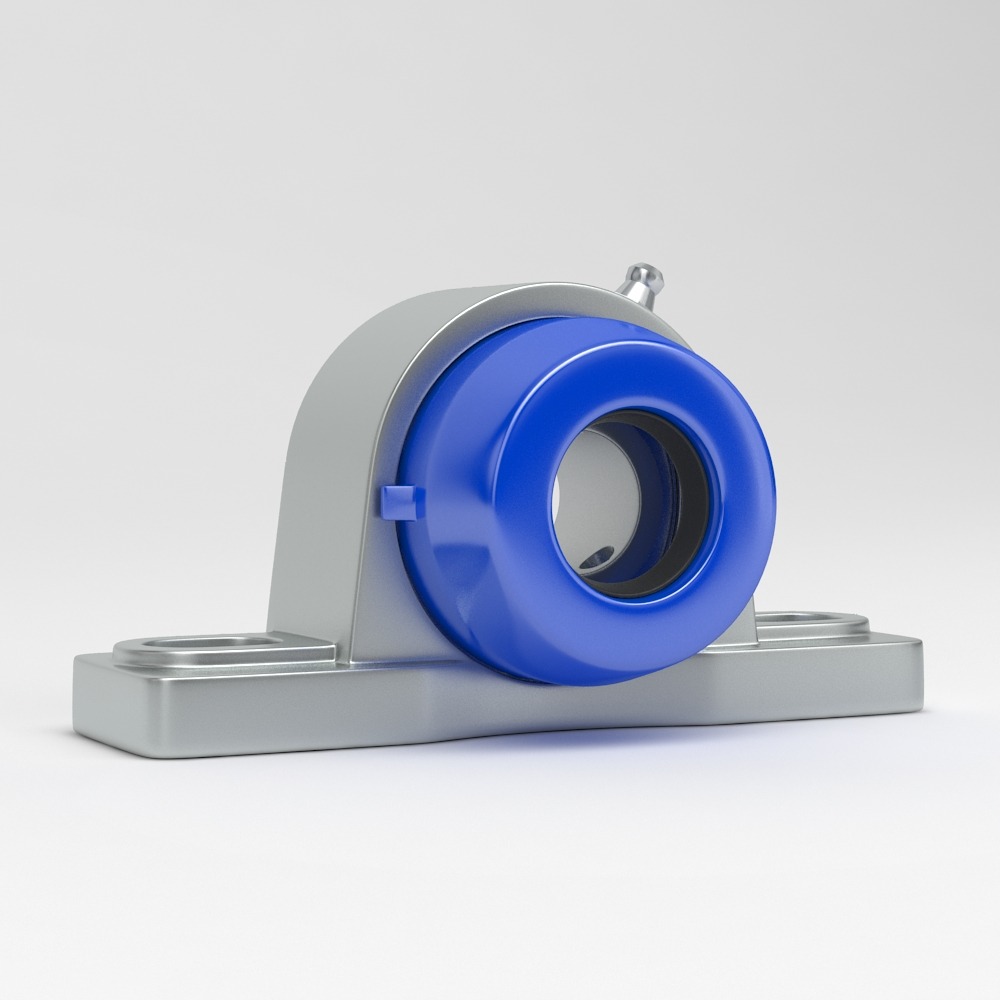

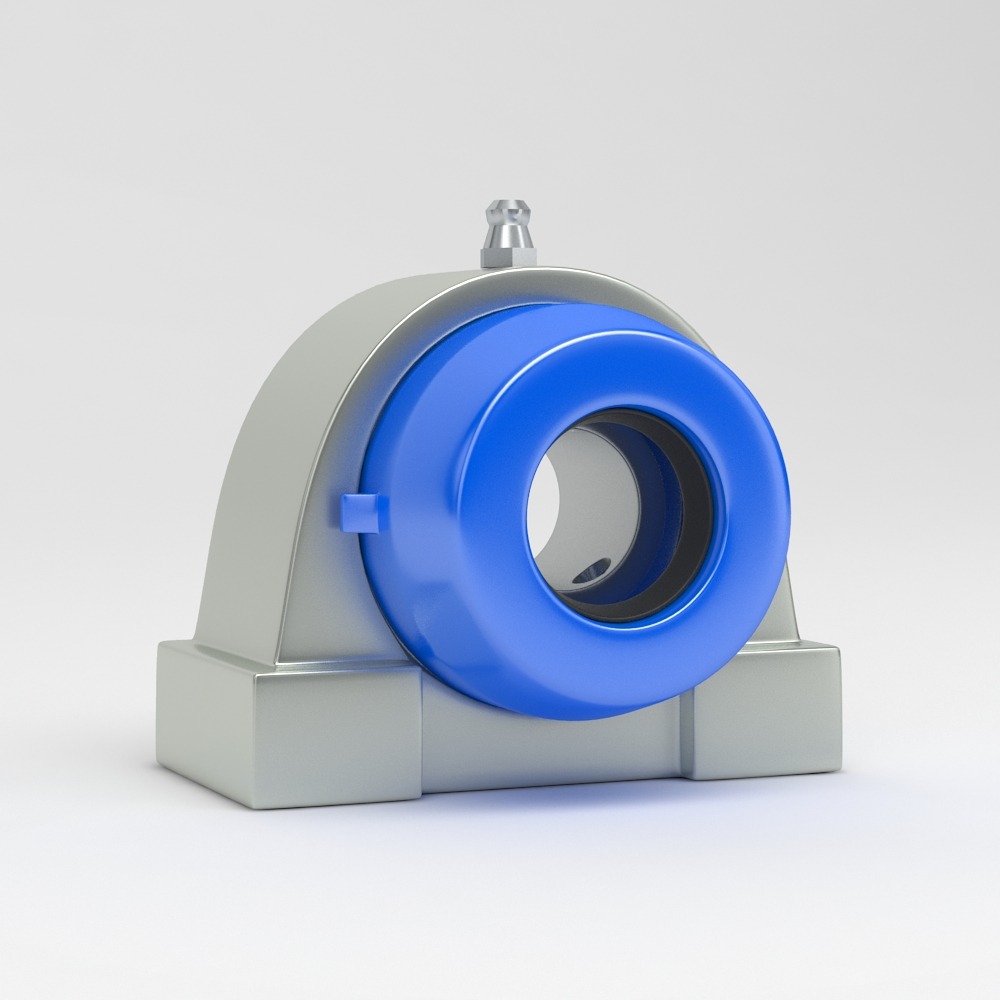

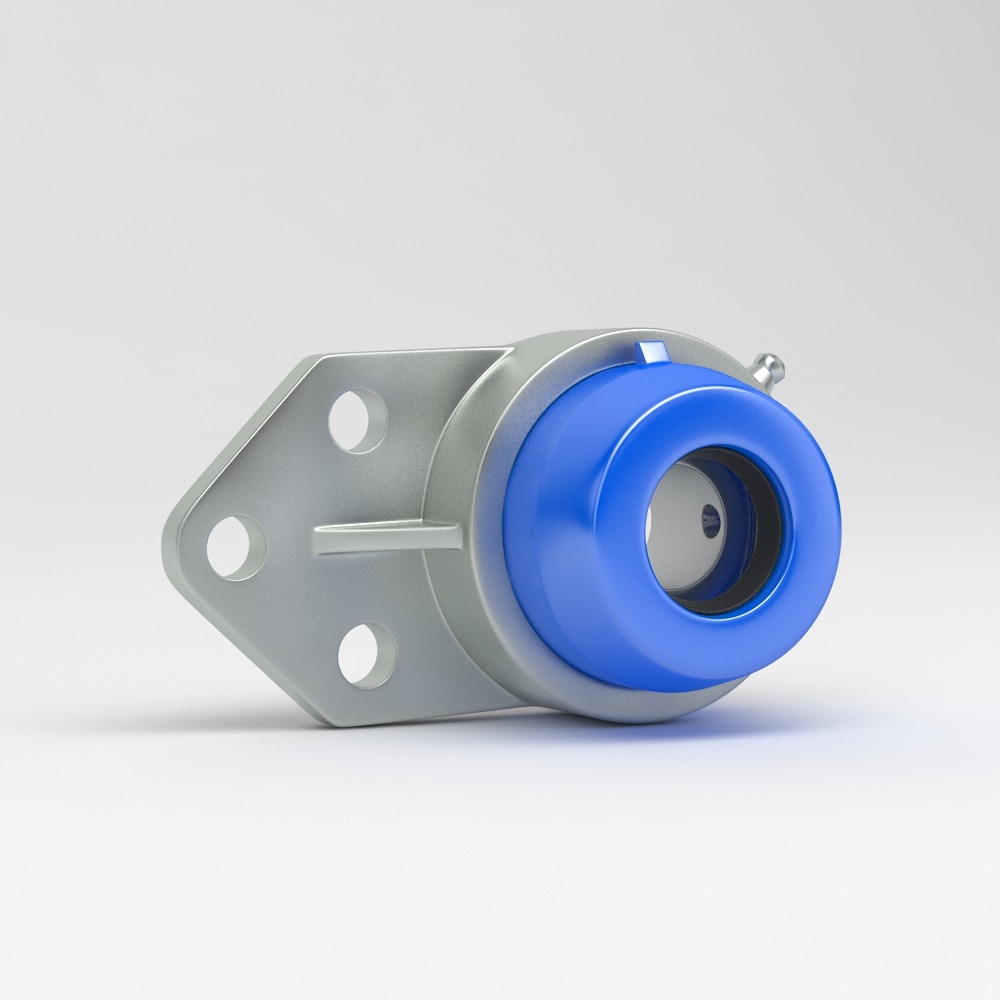

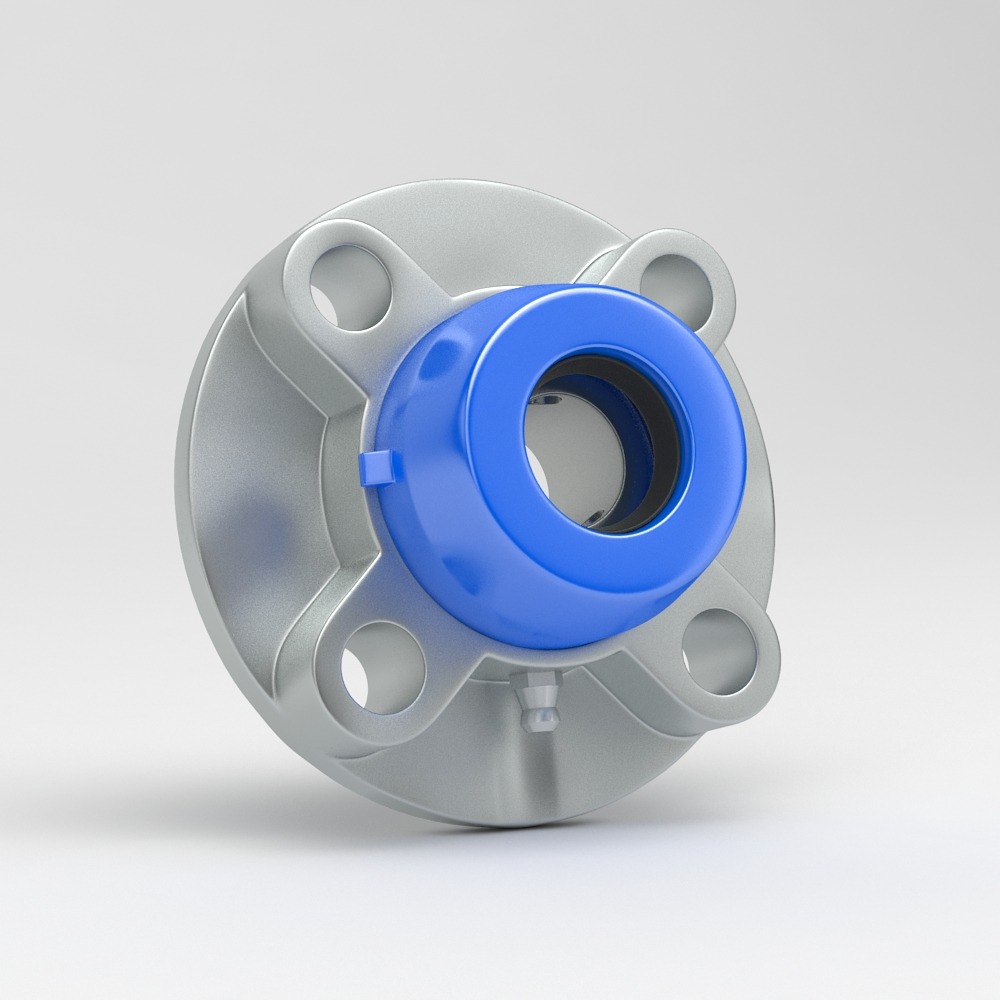

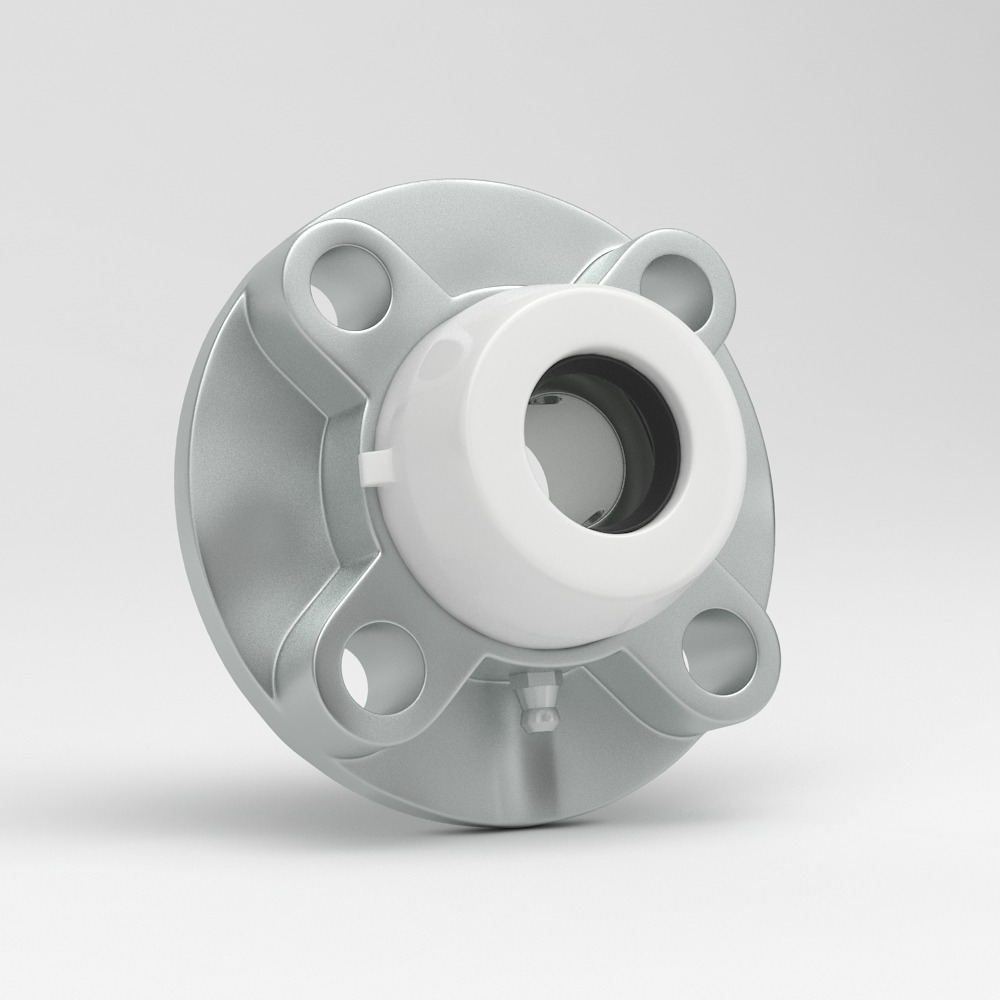

440C Stainless Steel Bearing Units

Bearing units made from 440C stainless steel offer high strength and good wear resistance. This type of stainless steel is particularly useful in environments where bearings are subjected to harsh conditions, including high temperatures and exposure to corrosive materials. The 440C stainless steel also provides a good balance between corrosion resistance and the ability to withstand physical wear.

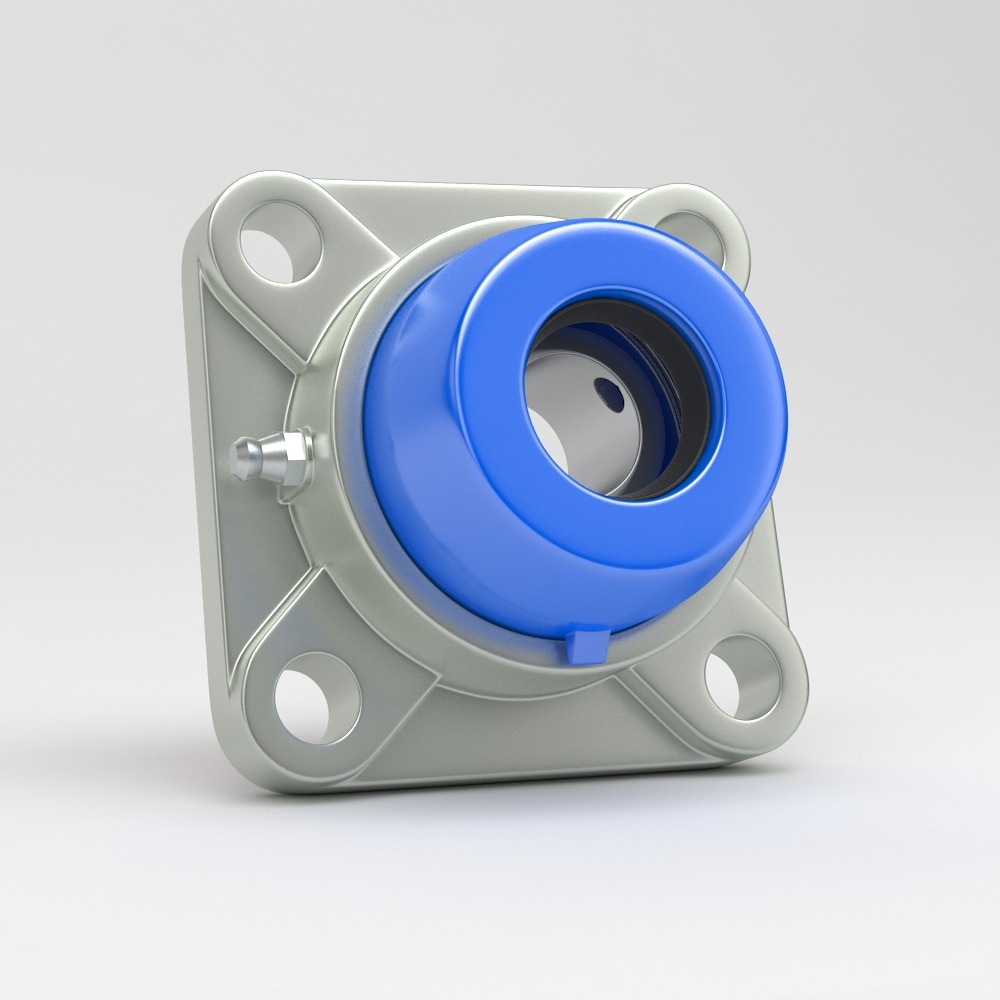

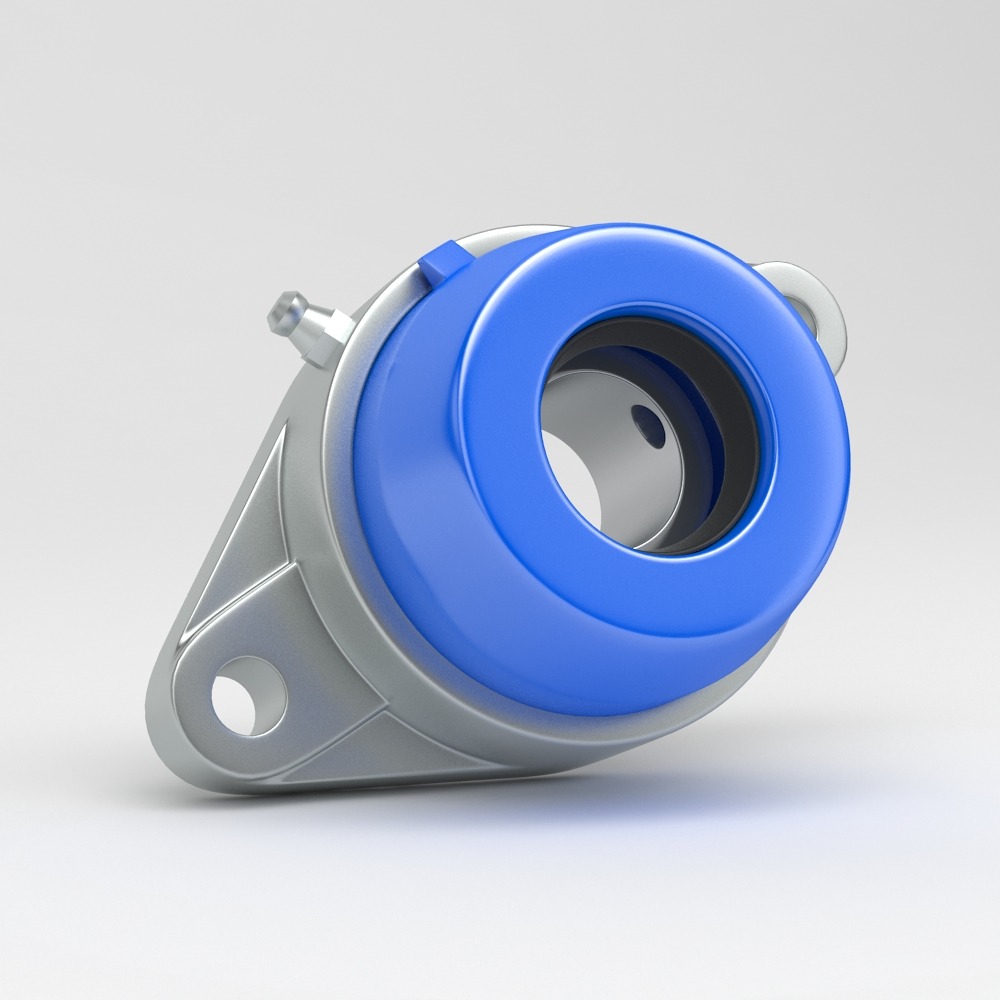

FDA-Certified Lifetime Lubrication

The integration of FDA-certified lifetime lubrication within these bearing units is a significant advancement. This feature eliminates the need for regular maintenance, reducing the downtime and labor costs associated with lubrication. The FDA certification ensures that the lubricant used is safe for use in industries that deal directly with food products, pharmaceuticals, and cosmetics, where contamination control is critical.

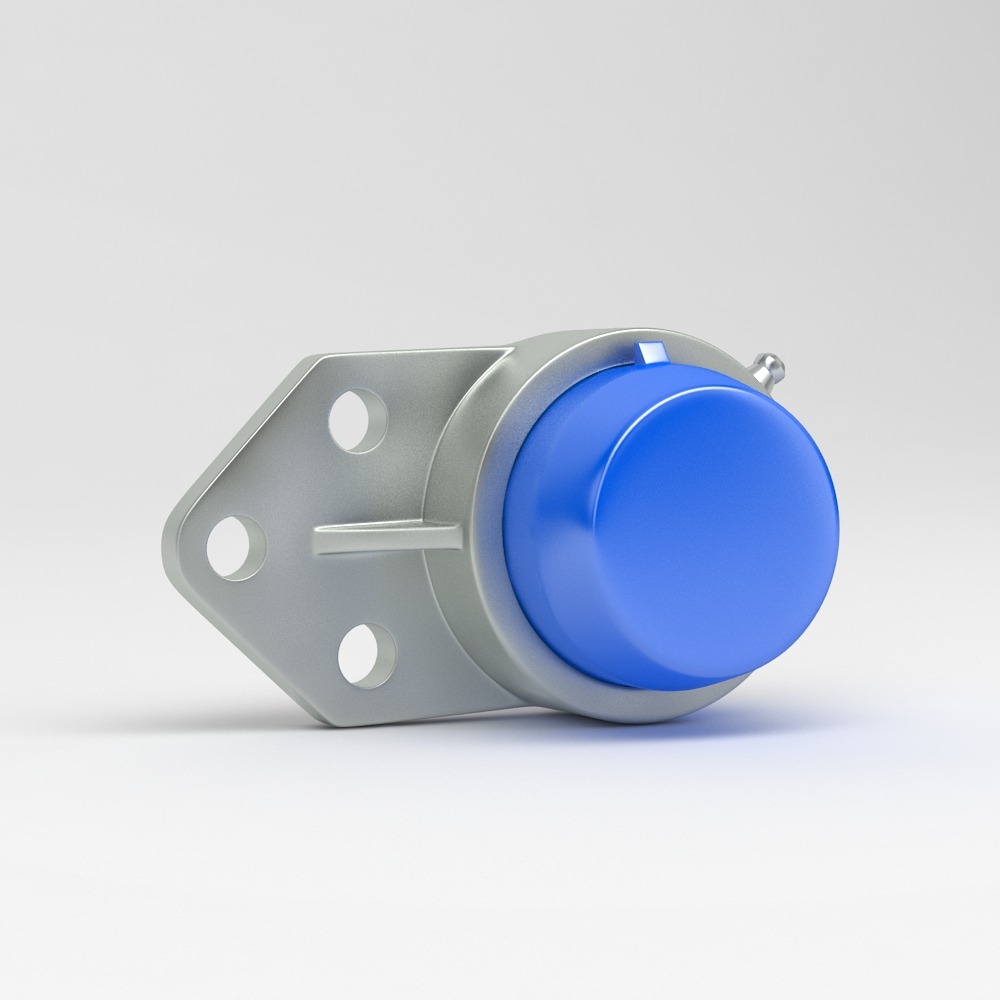

Application in Various Industries

In the food processing and pharmaceutical industries, where hygiene and contamination control are paramount, these bearing units play a crucial role. They can withstand the rigorous cleaning processes, including Clean-In-Place (CIP) and Sterilization-In-Place (SIP), which are standard in these industries. In the cosmetic, diary, butchery, and chemical industries, these bearing units provide the necessary durability and reliability, ensuring uninterrupted production processes.

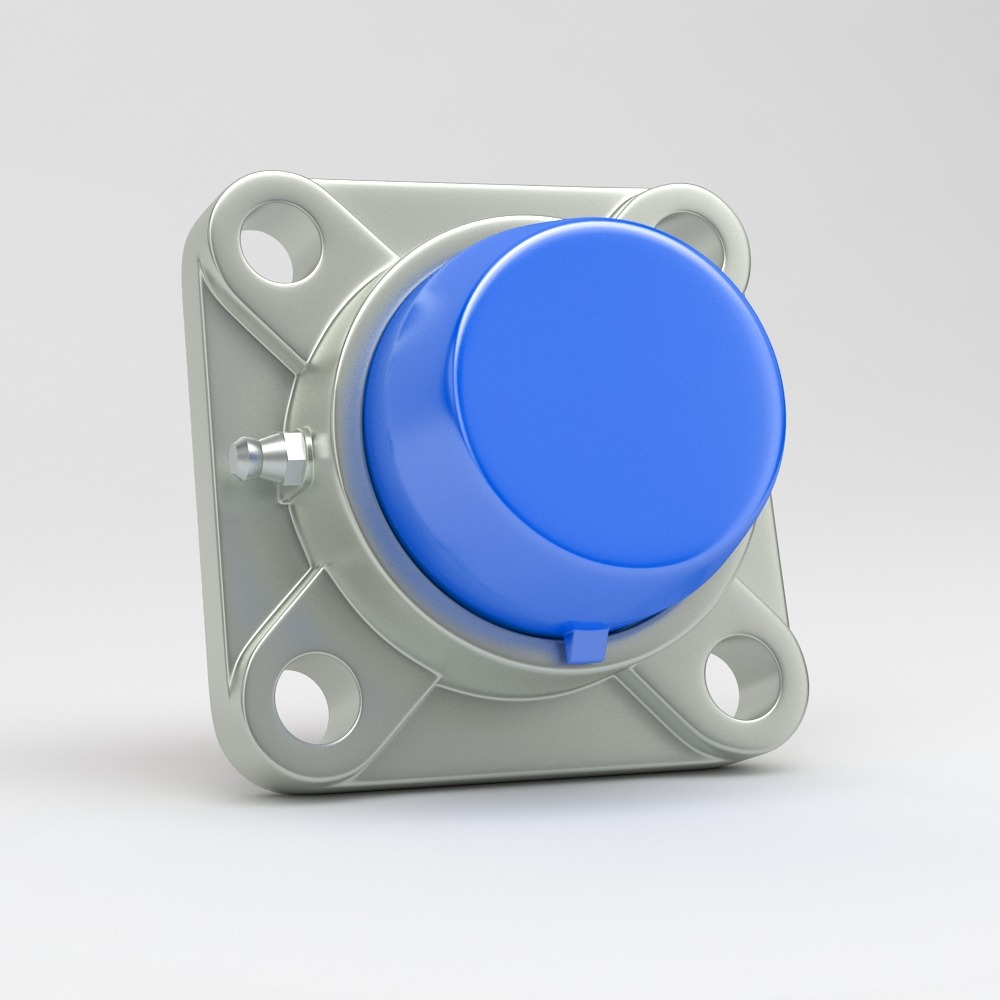

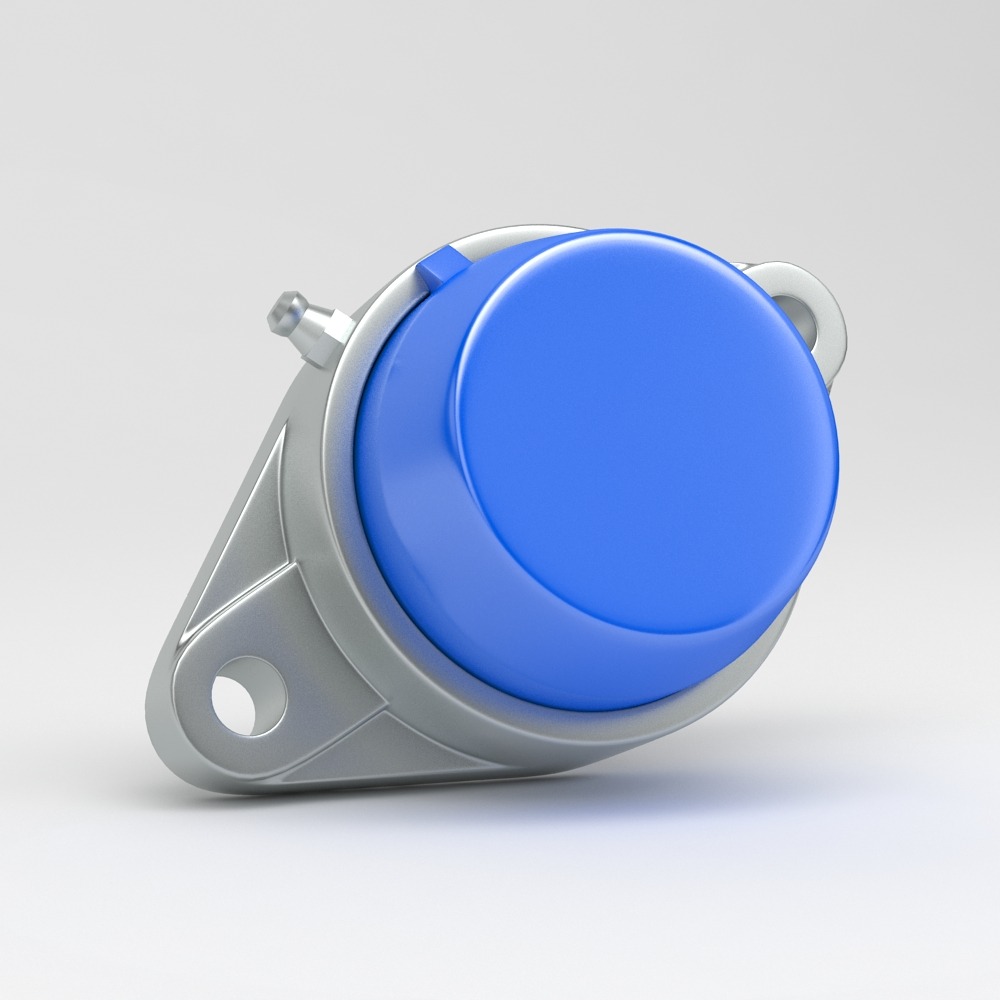

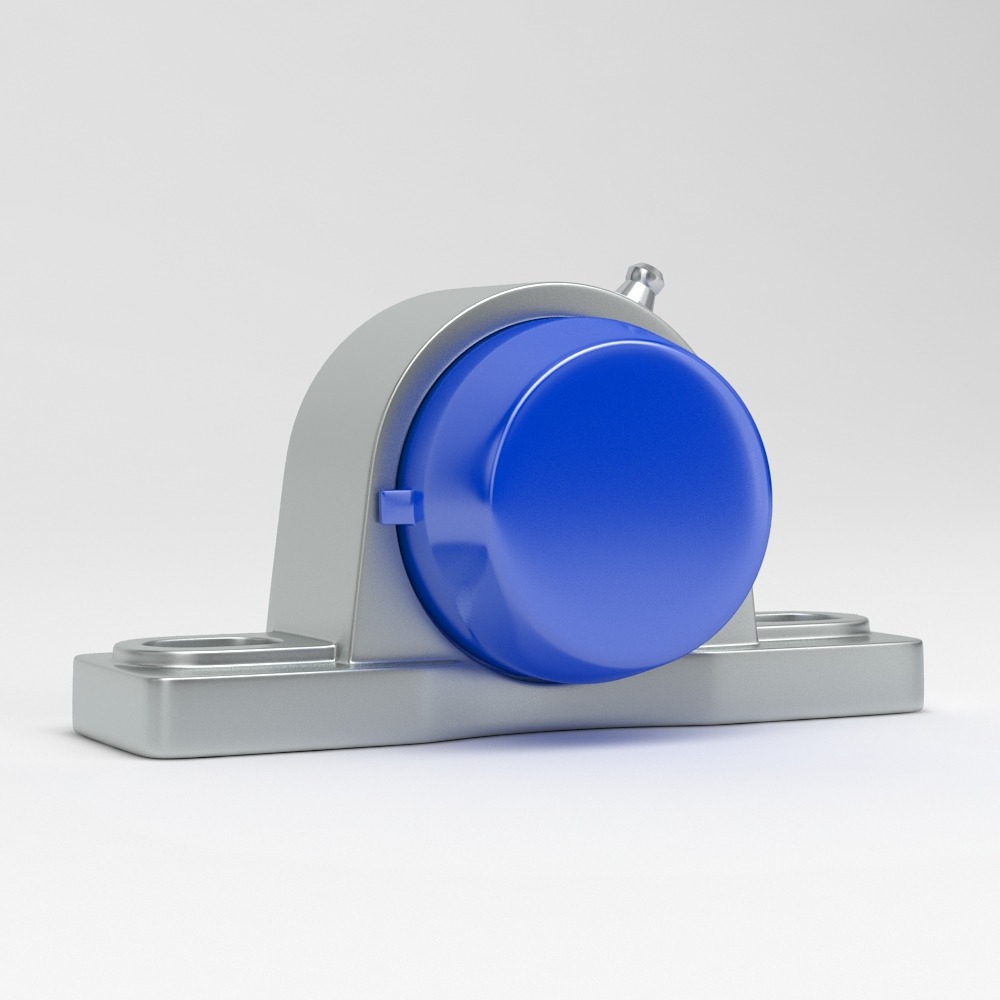

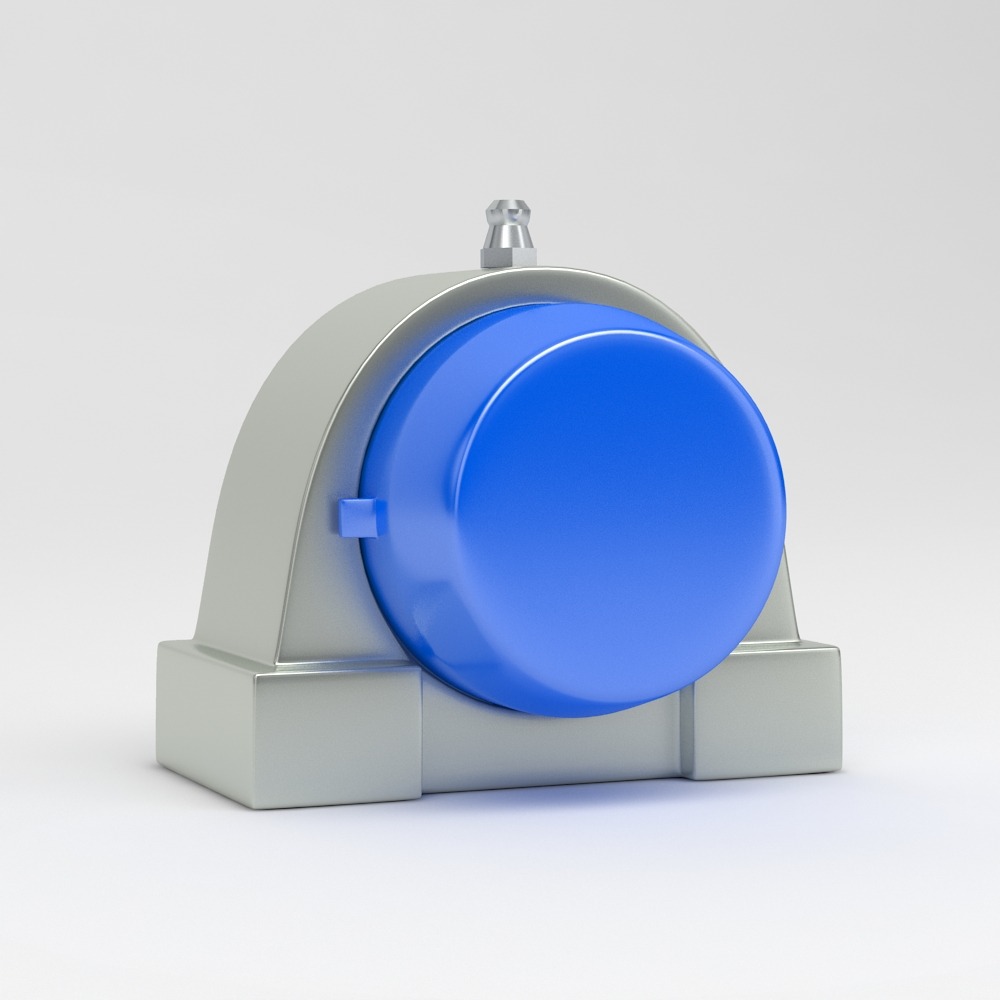

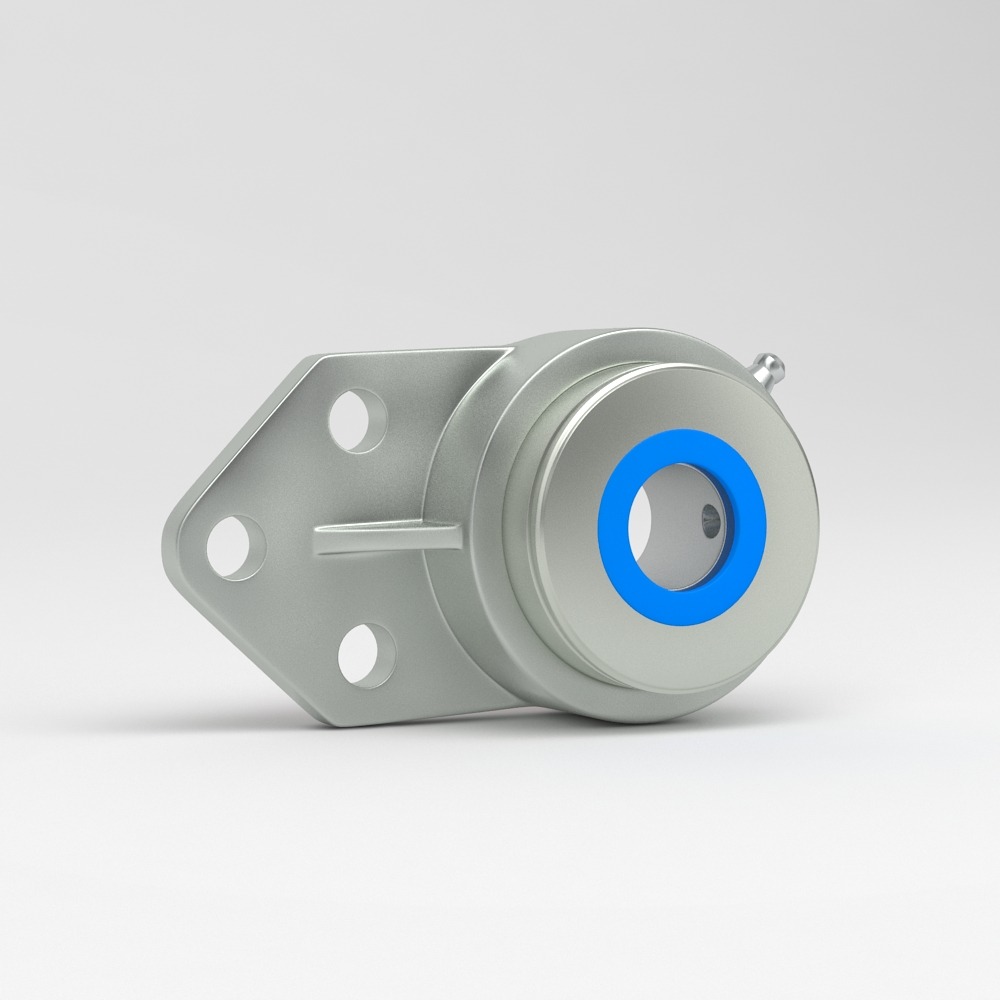

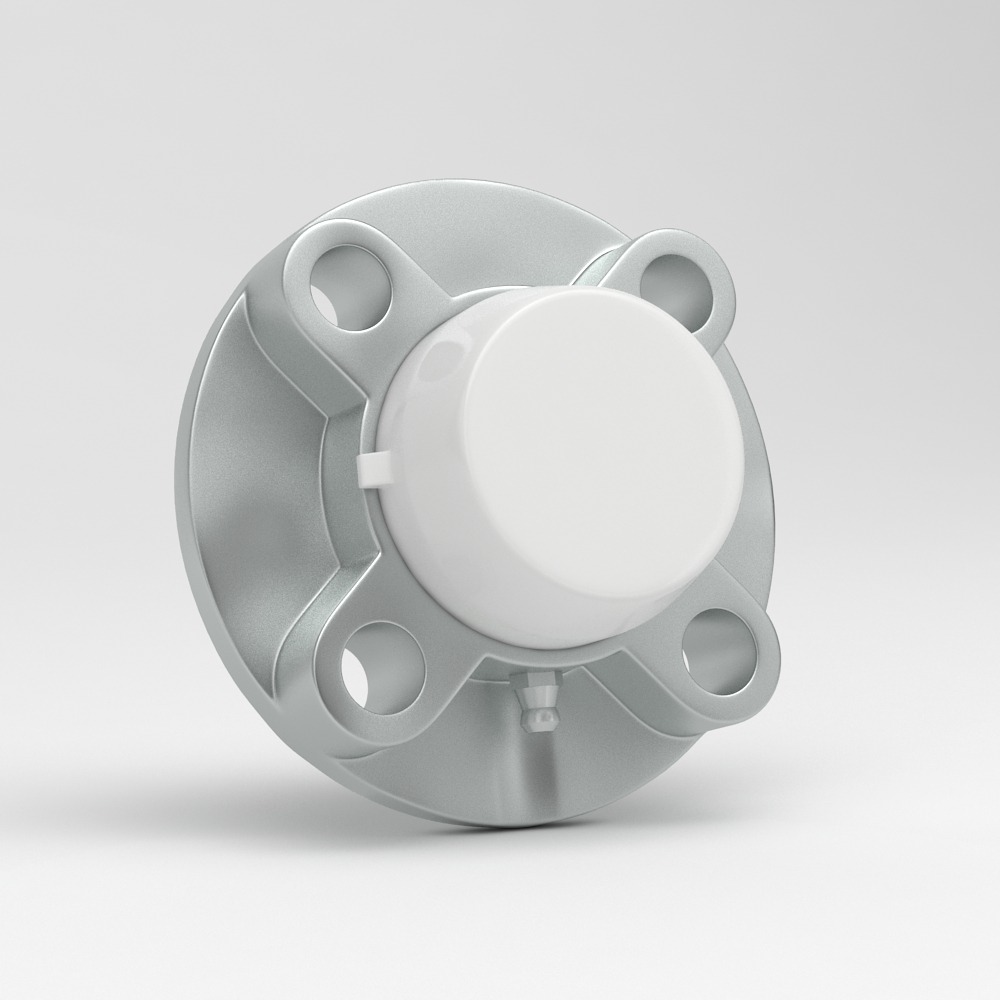

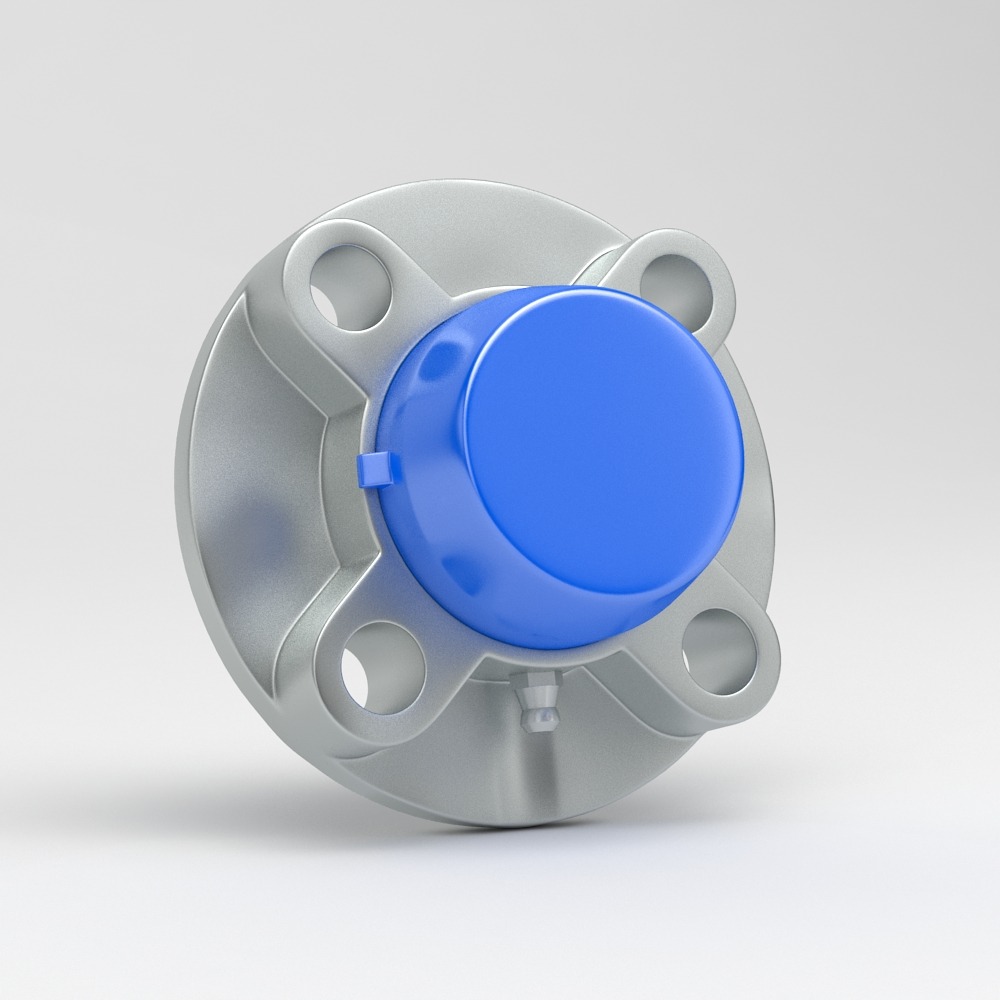

Advantages of Sealed Design

The sealed design of these bearing units offers protection against the ingress of contaminants. This is particularly important in environments where exposure to particulate matter, fluids, and other contaminants is common. The seal helps maintain the integrity of the bearing, extending its service life and ensuring consistent performance.

In summary, Sealed Stainless Bearing Units with stainless steel 304 housings and 440C bearing units, complemented by FDA-certified lifetime lubrication, represent a significant technological advancement in the manufacturing equipment used in hygiene-critical industries. Their robust design, material choice, and maintenance-free lubrication system make them a valuable component for ensuring operational efficiency, safety, and compliance with industry standards.