Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

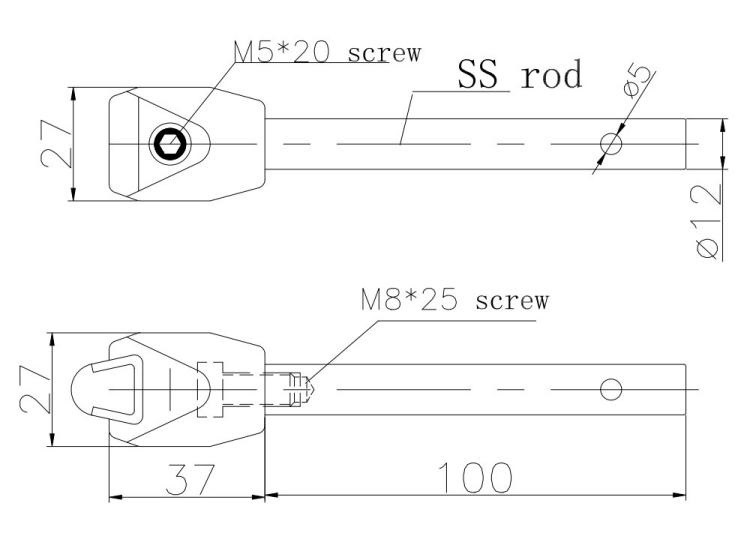

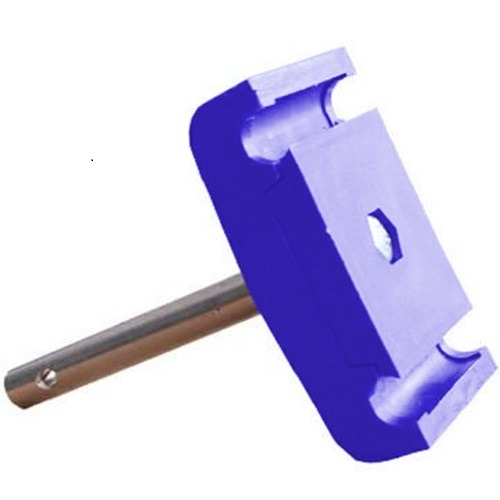

Single clamps for conical side guide rails with stainless steel rod

Single clamps for conical side guide rails with stainless steel rod

Clamp in polyamide with stainless steel A2-70 screw

Rod in stainless steel AISI 304 (Aisi 1.4301)

Single clamps for conical side guide rails types

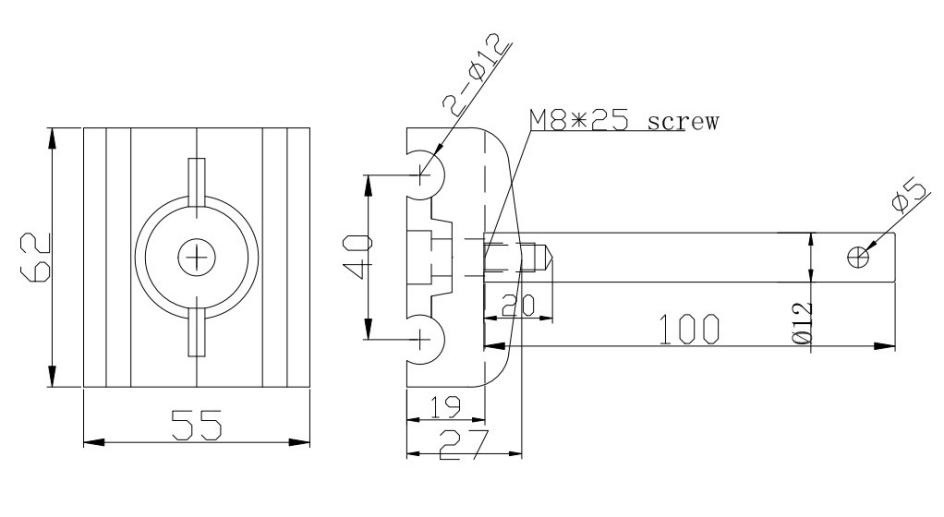

SCC 12-L100

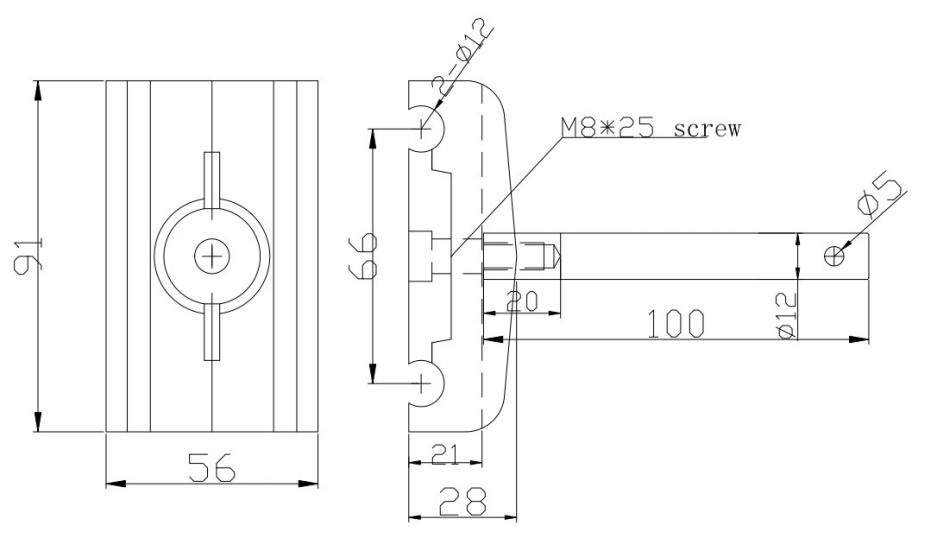

SCC 12-L150

SCC 12-L200

SCC 12-L250

Crucial components across various industries

Single clamps for conical side guide rails equipped with a stainless steel rod are crucial components in the assembly and adjustment of guide rail systems across various industries. Here’s a look at their characteristics and uses:

Features of Single Clamps for conical Side Guide Rails

- Material: These clamps are typically made of stainless steel, which offers excellent corrosion resistance, durability, and is suitable for sanitary environments necessary in industries such as food processing, pharmaceuticals, and medical equipment.

- Design: Unlike double clamps, single clamps consist of a single piece that clamps onto the rail, often with a simpler, more compact design. This makes them easier to install and adjust in tighter spaces or where less force is required.

- Compatibility: Designed to fit specific diameters of conical side guide rails, ensuring a snug and secure fit. It’s important to choose the correct size to prevent movement or slippage of the rail.

- Adjustability: Single clamps generally allow for quick adjustments, making it easy to reposition the guide rails during setup or maintenance without completely disassembling the system.

- Ease of Installation: These clamps are straightforward to install, typically requiring minimal tools. This simplicity is advantageous in systems that require frequent modifications or adjustments.

Conveyor Systems

In smaller or less complex conveyor setups, single clamps offer a lightweight and flexible option for mounting guide rails. These are particularly useful in packaging, manufacturing, and material handling industries.

Light Machinery

For machinery where large forces are not exerted on the guide rails, single clamps provide sufficient stability and are easier to handle and adjust compared to heavier-duty double clamps.

Food and Beverage Production

The hygienic properties of stainless steel make single clamps ideal for food and beverage production lines, where preventing contamination is critical. They are easy to clean and resist the harsh cleaning chemicals often used in these environments.

Pharmaceutical Manufacturing

Like in food processing, the cleanability and corrosion resistance of stainless steel single clamps meet the stringent cleanliness standards required in pharmaceutical manufacturing.

Small Equipment and Devices

In smaller devices or equipment where space is limited, single clamps are advantageous due to their compact size and ease of installation.

Space efficiency and ease of maintenance

Overall, single clamps for conical side guide rails with a stainless steel rod are versatile and useful in various settings, particularly where simplicity, space efficiency, and ease of maintenance are valued. Their design and material make them an excellent choice for many industrial applications, particularly where cleanliness and resistance to corrosion are priorities.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

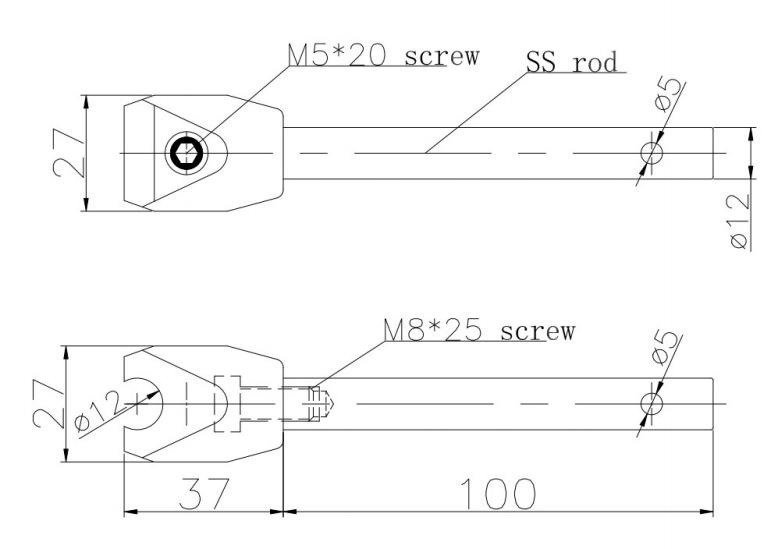

Single clamps for conical side guide rails with stainless steel rod

Clamp in polyamide with stainless steel A2-70 screw

Rod in stainless steel AISI 304 (Aisi 1.4301)

Single clamps for conical side guide rails types

SCC 12-L100

SCC 12-L150

SCC 12-L200

SCC 12-L250

Crucial components across various industries

Single clamps for conical side guide rails equipped with a stainless steel rod are crucial components in the assembly and adjustment of guide rail systems across various industries. Here’s a look at their characteristics and uses:

Features of Single Clamps for conical Side Guide Rails

- Material: These clamps are typically made of stainless steel, which offers excellent corrosion resistance, durability, and is suitable for sanitary environments necessary in industries such as food processing, pharmaceuticals, and medical equipment.

- Design: Unlike double clamps, single clamps consist of a single piece that clamps onto the rail, often with a simpler, more compact design. This makes them easier to install and adjust in tighter spaces or where less force is required.

- Compatibility: Designed to fit specific diameters of conical side guide rails, ensuring a snug and secure fit. It’s important to choose the correct size to prevent movement or slippage of the rail.

- Adjustability: Single clamps generally allow for quick adjustments, making it easy to reposition the guide rails during setup or maintenance without completely disassembling the system.

- Ease of Installation: These clamps are straightforward to install, typically requiring minimal tools. This simplicity is advantageous in systems that require frequent modifications or adjustments.

Conveyor Systems

In smaller or less complex conveyor setups, single clamps offer a lightweight and flexible option for mounting guide rails. These are particularly useful in packaging, manufacturing, and material handling industries.

Light Machinery

For machinery where large forces are not exerted on the guide rails, single clamps provide sufficient stability and are easier to handle and adjust compared to heavier-duty double clamps.

Food and Beverage Production

The hygienic properties of stainless steel make single clamps ideal for food and beverage production lines, where preventing contamination is critical. They are easy to clean and resist the harsh cleaning chemicals often used in these environments.

Pharmaceutical Manufacturing

Like in food processing, the cleanability and corrosion resistance of stainless steel single clamps meet the stringent cleanliness standards required in pharmaceutical manufacturing.

Small Equipment and Devices

In smaller devices or equipment where space is limited, single clamps are advantageous due to their compact size and ease of installation.

Space efficiency and ease of maintenance

Overall, single clamps for conical side guide rails with a stainless steel rod are versatile and useful in various settings, particularly where simplicity, space efficiency, and ease of maintenance are valued. Their design and material make them an excellent choice for many industrial applications, particularly where cleanliness and resistance to corrosion are priorities.

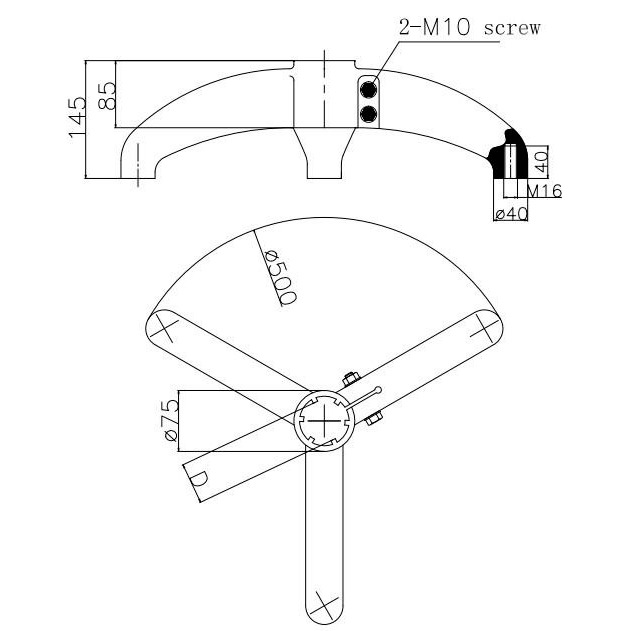

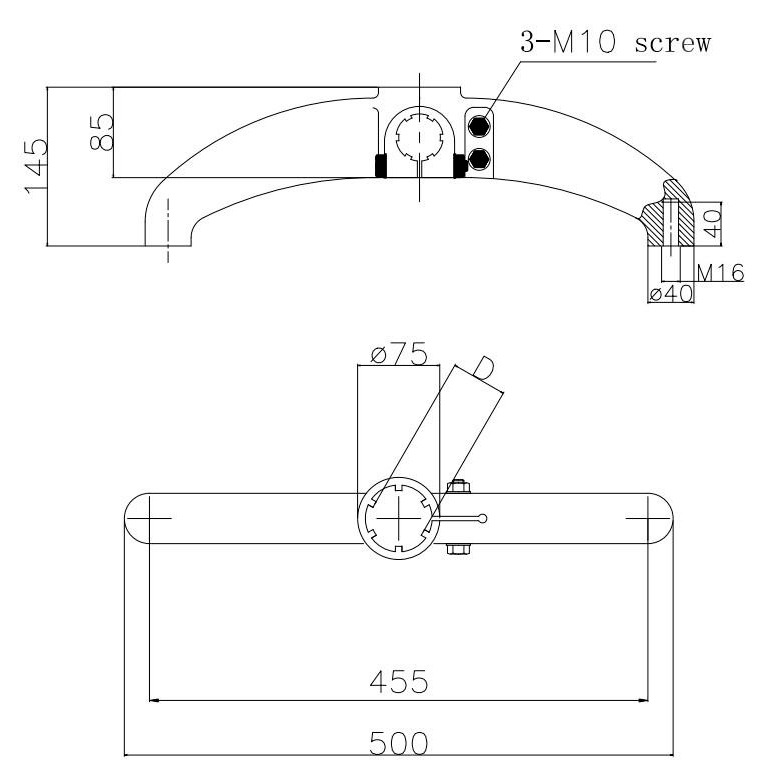

Single clamps for conical side guide rails with stainless steel rod

Clamp in polyamide with stainless steel A2-70 screw

Rod in stainless steel AISI 304 (Aisi 1.4301)

Single clamps for conical side guide rails types

SCC 12-L100

SCC 12-L150

SCC 12-L200

SCC 12-L250

Crucial components across various industries

Single clamps for conical side guide rails equipped with a stainless steel rod are crucial components in the assembly and adjustment of guide rail systems across various industries. Here’s a look at their characteristics and uses:

Features of Single Clamps for conical Side Guide Rails

- Material: These clamps are typically made of stainless steel, which offers excellent corrosion resistance, durability, and is suitable for sanitary environments necessary in industries such as food processing, pharmaceuticals, and medical equipment.

- Design: Unlike double clamps, single clamps consist of a single piece that clamps onto the rail, often with a simpler, more compact design. This makes them easier to install and adjust in tighter spaces or where less force is required.

- Compatibility: Designed to fit specific diameters of conical side guide rails, ensuring a snug and secure fit. It’s important to choose the correct size to prevent movement or slippage of the rail.

- Adjustability: Single clamps generally allow for quick adjustments, making it easy to reposition the guide rails during setup or maintenance without completely disassembling the system.

- Ease of Installation: These clamps are straightforward to install, typically requiring minimal tools. This simplicity is advantageous in systems that require frequent modifications or adjustments.

Conveyor Systems

In smaller or less complex conveyor setups, single clamps offer a lightweight and flexible option for mounting guide rails. These are particularly useful in packaging, manufacturing, and material handling industries.

Light Machinery

For machinery where large forces are not exerted on the guide rails, single clamps provide sufficient stability and are easier to handle and adjust compared to heavier-duty double clamps.

Food and Beverage Production

The hygienic properties of stainless steel make single clamps ideal for food and beverage production lines, where preventing contamination is critical. They are easy to clean and resist the harsh cleaning chemicals often used in these environments.

Pharmaceutical Manufacturing

Like in food processing, the cleanability and corrosion resistance of stainless steel single clamps meet the stringent cleanliness standards required in pharmaceutical manufacturing.

Small Equipment and Devices

In smaller devices or equipment where space is limited, single clamps are advantageous due to their compact size and ease of installation.

Space efficiency and ease of maintenance

Overall, single clamps for conical side guide rails with a stainless steel rod are versatile and useful in various settings, particularly where simplicity, space efficiency, and ease of maintenance are valued. Their design and material make them an excellent choice for many industrial applications, particularly where cleanliness and resistance to corrosion are priorities.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.