Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

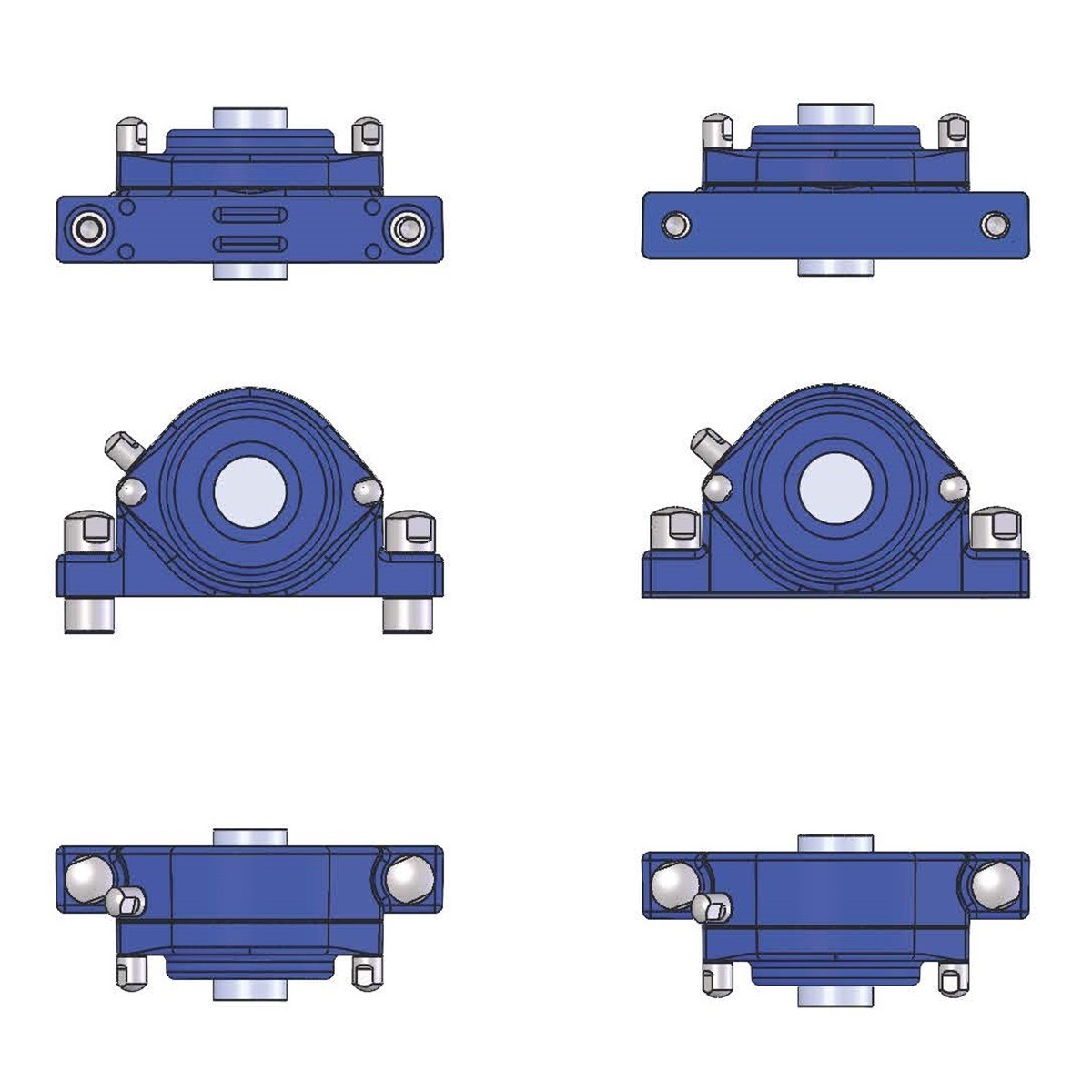

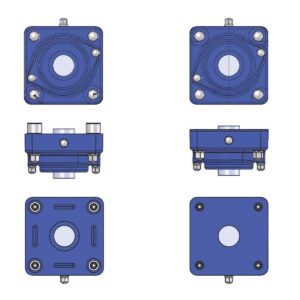

EHEDG IP69K Pillow Block Bearing Units

Trusted Solutions for Extreme Environments

Industries such as food processing, pharmaceuticals, and chemical manufacturing operate in environments where cleanliness, durability, and reliability are non-negotiable. For these demanding conditions, EHEDG-certified IP69K pillow block bearing units stand out as the epitome of engineering excellence. Designed for extreme conditions, these bearing units combine hygienic design, durability, and compliance with stringent industry standards.

In this article, we’ll explore the experience, expertise, authoritativeness and trustworthiness that these components bring to critical applications in harsh and extreme environments.

Experience: Decades of Innovation in Hygienic Engineering

EHEDG IP69K pillow block bearing units stem from years of specialized experience in engineering components for hygienic environments. This level of experience ensures:

- Proven Performance: These units have been rigorously tested in high-pressure washdowns, extreme temperatures, and corrosive environments, ensuring they stand the test of time.

- Hygienic Design Expertise: Developed with expertise in European Hygienic Engineering and Design Group (EHEDG) principles, the pillow block bearings eliminate crevices where contaminants might accumulate.

- Adaptability Across Sectors: With decades of experience in food, beverage, pharmaceutical, and chemical industries, manufacturers ensure these units meet diverse application requirements.

By incorporating input from industry leaders and end-users, these bearing units continue to deliver proven reliability under challenging conditions.

Expertise: Superior Engineering for Harsh Environments

The expertise behind EHEDG IP69K pillow block bearing units lies in their meticulous design and material selection. Every component of these units is tailored to withstand extreme operational demands.

Key Features Demonstrating Expertise:

- IP69K Certification:

The IP69K rating ensures the units can endure high-pressure, high-temperature washdowns frequently used in industries with strict hygiene protocols. This makes them ideal for environments requiring frequent cleaning and sanitization. - Stainless Steel Construction:

Crafted from 304 or 316-grade stainless steel, these bearings are resistant to rust, corrosion, and chemical exposure, ensuring long-lasting performance. - Hygienic Sealing Technology:

Advanced seals prevent ingress of water, dust, and contaminants, even in extreme conditions. This is essential for industries like food processing, where contamination risks must be minimized. - Self-Lubrication Options:

These units often come with self-lubricating features or food-grade lubricants, reducing maintenance requirements and ensuring compliance with hygiene standards.

Authoritativeness: Industry-Recognized Standards and Certifications

EHEDG-certified pillow block bearing units bring an undeniable level of authority to hygienic and harsh-environment applications. Their design is guided by stringent standards, including:

- EHEDG Guidelines:

These bearings adhere to the principles of hygienic design as defined by EHEDG, ensuring they minimize the risk of microbial contamination. - Compliance with Global Standards:

They meet industry-specific certifications such as FDA, NSF, and 3-A Sanitary Standards, providing universal applicability. - Proven Track Record:

Many global manufacturers rely on these bearing units for critical operations, from dairy and beverage processing to pharmaceutical production. Their consistent performance in demanding industries further cements their authority.

Trustworthiness: Reliability Backed by Rigorous Testing

Trustworthiness is a cornerstone of EHEDG IP69K pillow block bearing units. From design to delivery, these components undergo rigorous processes to ensure unparalleled reliability.

Reasons They’re Trusted by Industry Leaders:

- Rigorous Testing Protocols:

These bearing units are subjected to high-pressure cleaning simulations, corrosion resistance tests, and durability evaluations under extreme temperatures. - Material Traceability:

All materials used in manufacturing are fully traceable, ensuring compliance with safety and quality standards. - Reduced Downtime:

By delivering consistent performance in harsh environments, these units reduce unplanned downtime and operational disruptions, making them a dependable choice for critical applications. - Ease of Maintenance:

Hygienic designs and self-lubricating options make these bearings easy to clean and maintain, reducing the risk of contamination and improving equipment reliability.

Applications of EHEDG IP69K Pillow Block Bearing Units

The versatility of these bearing units makes them suitable for a wide range of applications, including:

- Food and Beverage Processing:

Ideal for conveyor systems, filling machines, and packaging equipment where frequent washdowns are required. - Pharmaceutical Manufacturing:

Ensures clean and contamination-free operations in equipment like mixers, dryers, and granulators. - Chemical Processing:

Withstand exposure to corrosive chemicals and extreme temperatures, ensuring reliable performance in harsh environments. - Dairy Production:

Perfect for use in pasteurizers, separators, and filling lines where hygiene is paramount.

Why Choose EHEDG IP69K Pillow Block Bearing Units?

EHEDG IP69K pillow block bearing units deliver unmatched performance and reliability for extreme conditions. Here’s why they’re the go-to choice for many industries:

- Uncompromising Hygiene: Designed for easy cleaning and sanitation, they reduce contamination risks.

- Long-Term Durability: Withstand harsh environments and extend equipment lifespan.

- Reduced Maintenance Costs: Lower maintenance needs and minimal downtime lead to cost savings.

- Global Trust: Backed by leading certifications and a proven track record in the most demanding industries.

Building the Future with EHEDG IP69K Pillow Block Bearing Units

EHEDG IP69K pillow block bearing units are more than just components—they are strategic investments in operational efficiency, hygiene, and reliability. With experience, expertise, authoritativeness, and trustworthiness at their core, these bearings enable industries to operate seamlessly, even under the harshest conditions.

By choosing these advanced solutions, businesses not only meet today’s stringent standards but also future-proof their operations in the ever-evolving industrial landscape. Invest in EHEDG IP69K pillow block bearing units to ensure your systems are built for success.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Trusted Solutions for Extreme Environments

Industries such as food processing, pharmaceuticals, and chemical manufacturing operate in environments where cleanliness, durability, and reliability are non-negotiable. For these demanding conditions, EHEDG-certified IP69K pillow block bearing units stand out as the epitome of engineering excellence. Designed for extreme conditions, these bearing units combine hygienic design, durability, and compliance with stringent industry standards.

In this article, we’ll explore the experience, expertise, authoritativeness and trustworthiness that these components bring to critical applications in harsh and extreme environments.

Experience: Decades of Innovation in Hygienic Engineering

EHEDG IP69K pillow block bearing units stem from years of specialized experience in engineering components for hygienic environments. This level of experience ensures:

- Proven Performance: These units have been rigorously tested in high-pressure washdowns, extreme temperatures, and corrosive environments, ensuring they stand the test of time.

- Hygienic Design Expertise: Developed with expertise in European Hygienic Engineering and Design Group (EHEDG) principles, the pillow block bearings eliminate crevices where contaminants might accumulate.

- Adaptability Across Sectors: With decades of experience in food, beverage, pharmaceutical, and chemical industries, manufacturers ensure these units meet diverse application requirements.

By incorporating input from industry leaders and end-users, these bearing units continue to deliver proven reliability under challenging conditions.

Expertise: Superior Engineering for Harsh Environments

The expertise behind EHEDG IP69K pillow block bearing units lies in their meticulous design and material selection. Every component of these units is tailored to withstand extreme operational demands.

Key Features Demonstrating Expertise:

- IP69K Certification:

The IP69K rating ensures the units can endure high-pressure, high-temperature washdowns frequently used in industries with strict hygiene protocols. This makes them ideal for environments requiring frequent cleaning and sanitization. - Stainless Steel Construction:

Crafted from 304 or 316-grade stainless steel, these bearings are resistant to rust, corrosion, and chemical exposure, ensuring long-lasting performance. - Hygienic Sealing Technology:

Advanced seals prevent ingress of water, dust, and contaminants, even in extreme conditions. This is essential for industries like food processing, where contamination risks must be minimized. - Self-Lubrication Options:

These units often come with self-lubricating features or food-grade lubricants, reducing maintenance requirements and ensuring compliance with hygiene standards.

Authoritativeness: Industry-Recognized Standards and Certifications

EHEDG-certified pillow block bearing units bring an undeniable level of authority to hygienic and harsh-environment applications. Their design is guided by stringent standards, including:

- EHEDG Guidelines:

These bearings adhere to the principles of hygienic design as defined by EHEDG, ensuring they minimize the risk of microbial contamination. - Compliance with Global Standards:

They meet industry-specific certifications such as FDA, NSF, and 3-A Sanitary Standards, providing universal applicability. - Proven Track Record:

Many global manufacturers rely on these bearing units for critical operations, from dairy and beverage processing to pharmaceutical production. Their consistent performance in demanding industries further cements their authority.

Trustworthiness: Reliability Backed by Rigorous Testing

Trustworthiness is a cornerstone of EHEDG IP69K pillow block bearing units. From design to delivery, these components undergo rigorous processes to ensure unparalleled reliability.

Reasons They’re Trusted by Industry Leaders:

- Rigorous Testing Protocols:

These bearing units are subjected to high-pressure cleaning simulations, corrosion resistance tests, and durability evaluations under extreme temperatures. - Material Traceability:

All materials used in manufacturing are fully traceable, ensuring compliance with safety and quality standards. - Reduced Downtime:

By delivering consistent performance in harsh environments, these units reduce unplanned downtime and operational disruptions, making them a dependable choice for critical applications. - Ease of Maintenance:

Hygienic designs and self-lubricating options make these bearings easy to clean and maintain, reducing the risk of contamination and improving equipment reliability.

Applications of EHEDG IP69K Pillow Block Bearing Units

The versatility of these bearing units makes them suitable for a wide range of applications, including:

- Food and Beverage Processing:

Ideal for conveyor systems, filling machines, and packaging equipment where frequent washdowns are required. - Pharmaceutical Manufacturing:

Ensures clean and contamination-free operations in equipment like mixers, dryers, and granulators. - Chemical Processing:

Withstand exposure to corrosive chemicals and extreme temperatures, ensuring reliable performance in harsh environments. - Dairy Production:

Perfect for use in pasteurizers, separators, and filling lines where hygiene is paramount.

Why Choose EHEDG IP69K Pillow Block Bearing Units?

EHEDG IP69K pillow block bearing units deliver unmatched performance and reliability for extreme conditions. Here’s why they’re the go-to choice for many industries:

- Uncompromising Hygiene: Designed for easy cleaning and sanitation, they reduce contamination risks.

- Long-Term Durability: Withstand harsh environments and extend equipment lifespan.

- Reduced Maintenance Costs: Lower maintenance needs and minimal downtime lead to cost savings.

- Global Trust: Backed by leading certifications and a proven track record in the most demanding industries.

Building the Future with EHEDG IP69K Pillow Block Bearing Units

EHEDG IP69K pillow block bearing units are more than just components—they are strategic investments in operational efficiency, hygiene, and reliability. With experience, expertise, authoritativeness, and trustworthiness at their core, these bearings enable industries to operate seamlessly, even under the harshest conditions.

By choosing these advanced solutions, businesses not only meet today’s stringent standards but also future-proof their operations in the ever-evolving industrial landscape. Invest in EHEDG IP69K pillow block bearing units to ensure your systems are built for success.

Trusted Solutions for Extreme Environments

Industries such as food processing, pharmaceuticals, and chemical manufacturing operate in environments where cleanliness, durability, and reliability are non-negotiable. For these demanding conditions, EHEDG-certified IP69K pillow block bearing units stand out as the epitome of engineering excellence. Designed for extreme conditions, these bearing units combine hygienic design, durability, and compliance with stringent industry standards.

In this article, we’ll explore the experience, expertise, authoritativeness and trustworthiness that these components bring to critical applications in harsh and extreme environments.

Experience: Decades of Innovation in Hygienic Engineering

EHEDG IP69K pillow block bearing units stem from years of specialized experience in engineering components for hygienic environments. This level of experience ensures:

- Proven Performance: These units have been rigorously tested in high-pressure washdowns, extreme temperatures, and corrosive environments, ensuring they stand the test of time.

- Hygienic Design Expertise: Developed with expertise in European Hygienic Engineering and Design Group (EHEDG) principles, the pillow block bearings eliminate crevices where contaminants might accumulate.

- Adaptability Across Sectors: With decades of experience in food, beverage, pharmaceutical, and chemical industries, manufacturers ensure these units meet diverse application requirements.

By incorporating input from industry leaders and end-users, these bearing units continue to deliver proven reliability under challenging conditions.

Expertise: Superior Engineering for Harsh Environments

The expertise behind EHEDG IP69K pillow block bearing units lies in their meticulous design and material selection. Every component of these units is tailored to withstand extreme operational demands.

Key Features Demonstrating Expertise:

- IP69K Certification:

The IP69K rating ensures the units can endure high-pressure, high-temperature washdowns frequently used in industries with strict hygiene protocols. This makes them ideal for environments requiring frequent cleaning and sanitization. - Stainless Steel Construction:

Crafted from 304 or 316-grade stainless steel, these bearings are resistant to rust, corrosion, and chemical exposure, ensuring long-lasting performance. - Hygienic Sealing Technology:

Advanced seals prevent ingress of water, dust, and contaminants, even in extreme conditions. This is essential for industries like food processing, where contamination risks must be minimized. - Self-Lubrication Options:

These units often come with self-lubricating features or food-grade lubricants, reducing maintenance requirements and ensuring compliance with hygiene standards.

Authoritativeness: Industry-Recognized Standards and Certifications

EHEDG-certified pillow block bearing units bring an undeniable level of authority to hygienic and harsh-environment applications. Their design is guided by stringent standards, including:

- EHEDG Guidelines:

These bearings adhere to the principles of hygienic design as defined by EHEDG, ensuring they minimize the risk of microbial contamination. - Compliance with Global Standards:

They meet industry-specific certifications such as FDA, NSF, and 3-A Sanitary Standards, providing universal applicability. - Proven Track Record:

Many global manufacturers rely on these bearing units for critical operations, from dairy and beverage processing to pharmaceutical production. Their consistent performance in demanding industries further cements their authority.

Trustworthiness: Reliability Backed by Rigorous Testing

Trustworthiness is a cornerstone of EHEDG IP69K pillow block bearing units. From design to delivery, these components undergo rigorous processes to ensure unparalleled reliability.

Reasons They’re Trusted by Industry Leaders:

- Rigorous Testing Protocols:

These bearing units are subjected to high-pressure cleaning simulations, corrosion resistance tests, and durability evaluations under extreme temperatures. - Material Traceability:

All materials used in manufacturing are fully traceable, ensuring compliance with safety and quality standards. - Reduced Downtime:

By delivering consistent performance in harsh environments, these units reduce unplanned downtime and operational disruptions, making them a dependable choice for critical applications. - Ease of Maintenance:

Hygienic designs and self-lubricating options make these bearings easy to clean and maintain, reducing the risk of contamination and improving equipment reliability.

Applications of EHEDG IP69K Pillow Block Bearing Units

The versatility of these bearing units makes them suitable for a wide range of applications, including:

- Food and Beverage Processing:

Ideal for conveyor systems, filling machines, and packaging equipment where frequent washdowns are required. - Pharmaceutical Manufacturing:

Ensures clean and contamination-free operations in equipment like mixers, dryers, and granulators. - Chemical Processing:

Withstand exposure to corrosive chemicals and extreme temperatures, ensuring reliable performance in harsh environments. - Dairy Production:

Perfect for use in pasteurizers, separators, and filling lines where hygiene is paramount.

Why Choose EHEDG IP69K Pillow Block Bearing Units?

EHEDG IP69K pillow block bearing units deliver unmatched performance and reliability for extreme conditions. Here’s why they’re the go-to choice for many industries:

- Uncompromising Hygiene: Designed for easy cleaning and sanitation, they reduce contamination risks.

- Long-Term Durability: Withstand harsh environments and extend equipment lifespan.

- Reduced Maintenance Costs: Lower maintenance needs and minimal downtime lead to cost savings.

- Global Trust: Backed by leading certifications and a proven track record in the most demanding industries.

Building the Future with EHEDG IP69K Pillow Block Bearing Units

EHEDG IP69K pillow block bearing units are more than just components—they are strategic investments in operational efficiency, hygiene, and reliability. With experience, expertise, authoritativeness, and trustworthiness at their core, these bearings enable industries to operate seamlessly, even under the harshest conditions.

By choosing these advanced solutions, businesses not only meet today’s stringent standards but also future-proof their operations in the ever-evolving industrial landscape. Invest in EHEDG IP69K pillow block bearing units to ensure your systems are built for success.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.