NHK Machinery Parts: Top-Quality EHEDG Certified Components

NHK Machinery Parts is a leading provider of high-quality components that meet stringent hygiene and safety standards. With a focus on EHEDG and sanitary standard certifications, NHK offers a range of products designed for maximum efficiency and reliability in various industrial applications. This article delves into the key offerings from NHK, highlighting their features and benefits.

EHEDG Certified and Sanitary Standard Components

NHK’s products are engineered to meet the highest hygiene standards, making them ideal for industries such as food processing, pharmaceuticals, and cosmetics. The EHEDG certification ensures that the components are designed for easy cleaning and minimal contamination risk. The sanitary standards further emphasize the commitment to hygiene and safety.

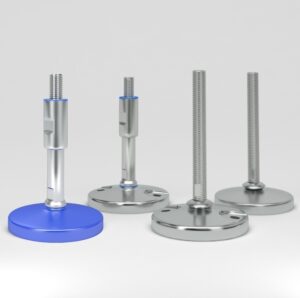

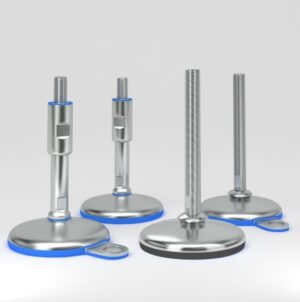

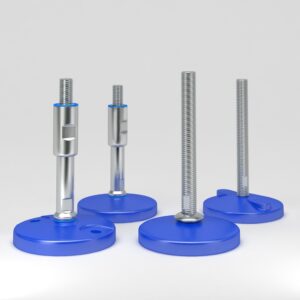

Stainless Steel and Composite Solid Base Feet

NHK offers solid base feet in both stainless steel and composite materials. These components provide stable support for machinery, ensuring optimal performance and longevity. The stainless steel options are particularly favored in environments where corrosion resistance is crucial.

Stainless Steel Machine Leveling Feet

Machine leveling feet from NHK are designed to provide precise adjustments, ensuring machinery remains level and stable. These feet are made from high-grade stainless steel, offering excellent durability and resistance to corrosion, making them perfect for harsh industrial environments.

Stainless Caster Noise Reducing Castor

NHK’s noise-reducing stainless casters are designed to minimize operational noise, improving the working environment. These casters are robust, capable of handling heavy loads, and ensure smooth, quiet movement of machinery and equipment.

IP67 Waterproof Bearing House Units

The IP67 waterproof bearing house units from NHK are engineered to withstand extreme conditions. These units prevent water and dust ingress, ensuring the longevity and reliability of the bearings, even in the most challenging environments.

Sealed Stainless Steel Bearing Units

NHK’s sealed stainless steel bearing units offer superior protection against contaminants. These units are perfect for applications where hygiene is paramount, as they prevent the ingress of dust, dirt, and moisture, ensuring smooth and efficient operation.

Bearing Units in IP54 Composite Housing

The IP54 composite housing bearing units are designed for environments where moderate protection against dust and water is required. These bearing units provide a cost-effective solution without compromising on performance and reliability.

Mounted Ball Bearing House Units

NHK’s mounted ball bearing house units are designed for easy installation and maintenance. These units provide robust support and ensure smooth operation, making them a popular choice in various industrial applications.

Mini Bearing Units in Stainless Steel

The mini bearing units in stainless steel from NHK are ideal for applications requiring compact yet robust components. These units offer excellent performance and durability, making them suitable for a wide range of machinery and equipment.

Hygienic Machinery Components in Stainless Steel

NHK’s range of hygienic machinery components is crafted from high-quality stainless steel, ensuring maximum hygiene and durability. These components are designed to meet the stringent requirements of industries where cleanliness is critical.

Conveyor Components and Machinery Parts

NHK provides a comprehensive range of conveyor components and machinery parts. These products are designed to enhance the efficiency and reliability of conveyor systems, ensuring smooth and trouble-free operation.

Drum and Gear Motor in Stainless Steel

The drum and gear motors from NHK are built for high performance and durability. Constructed from stainless steel, these motors are resistant to corrosion and ideal for use in demanding industrial environments.

Commitment to quality and innovation

NHK Machinery Parts stands out for its commitment to quality and innovation. With a wide range of EHEDG certified and sanitary standard components, NHK ensures that your machinery operates efficiently and reliably. Whether you need robust bearing units, precise leveling feet, or durable motors, NHK has the right solution for your needs.

Keywords

- NHK Machinery Parts

- EHEDG certified components

- Sanitary standard components

- Stainless steel machine leveling feet

- Noise reducing castor

- IP67 waterproof bearing house units

- Sealed stainless steel bearing units

- Mounted ball bearing house units

- Hygienic machinery components

- Conveyor components

- Drum and gear motor

Discover NHK Machinery Parts' range of EHEDG certified and sanitary standard components, including stainless steel machine leveling feet, noise-reducing castors, waterproof bearing house units, and more. Ensure your machinery operates efficiently and hygienically with NHK's top-quality products.