Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

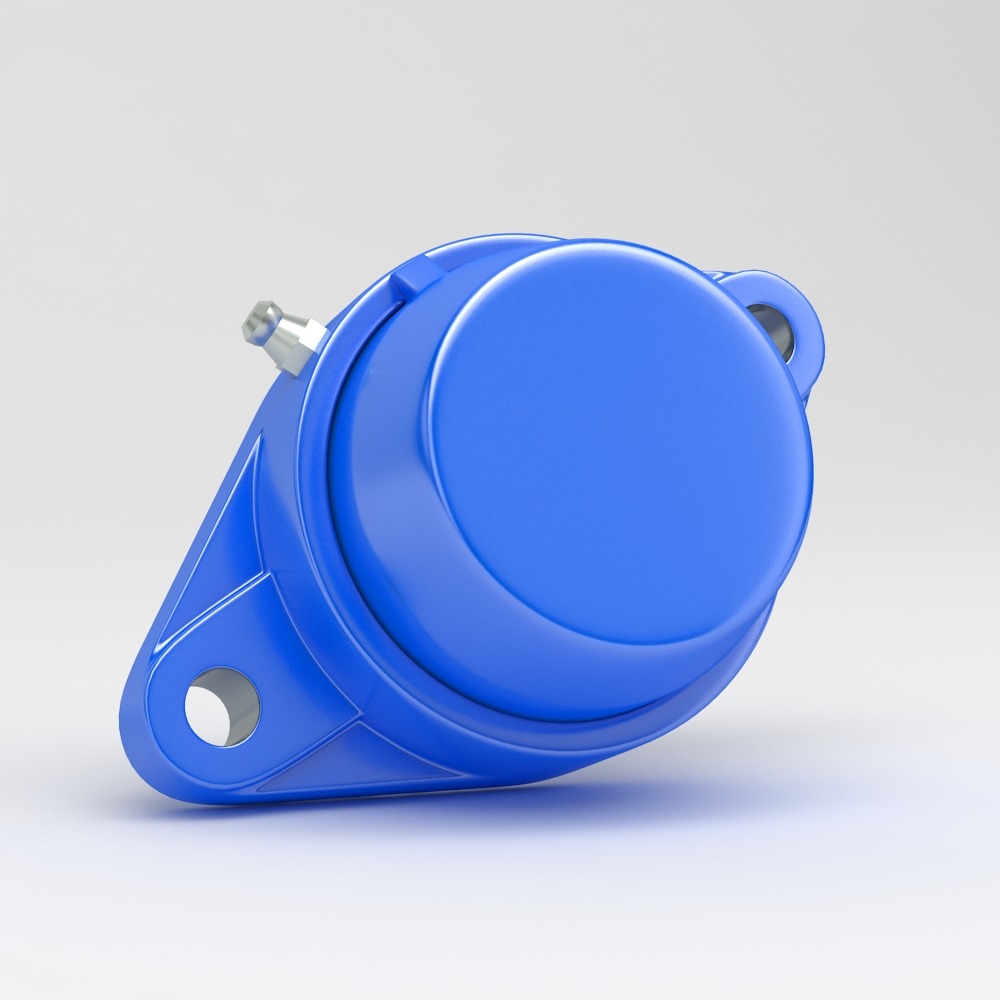

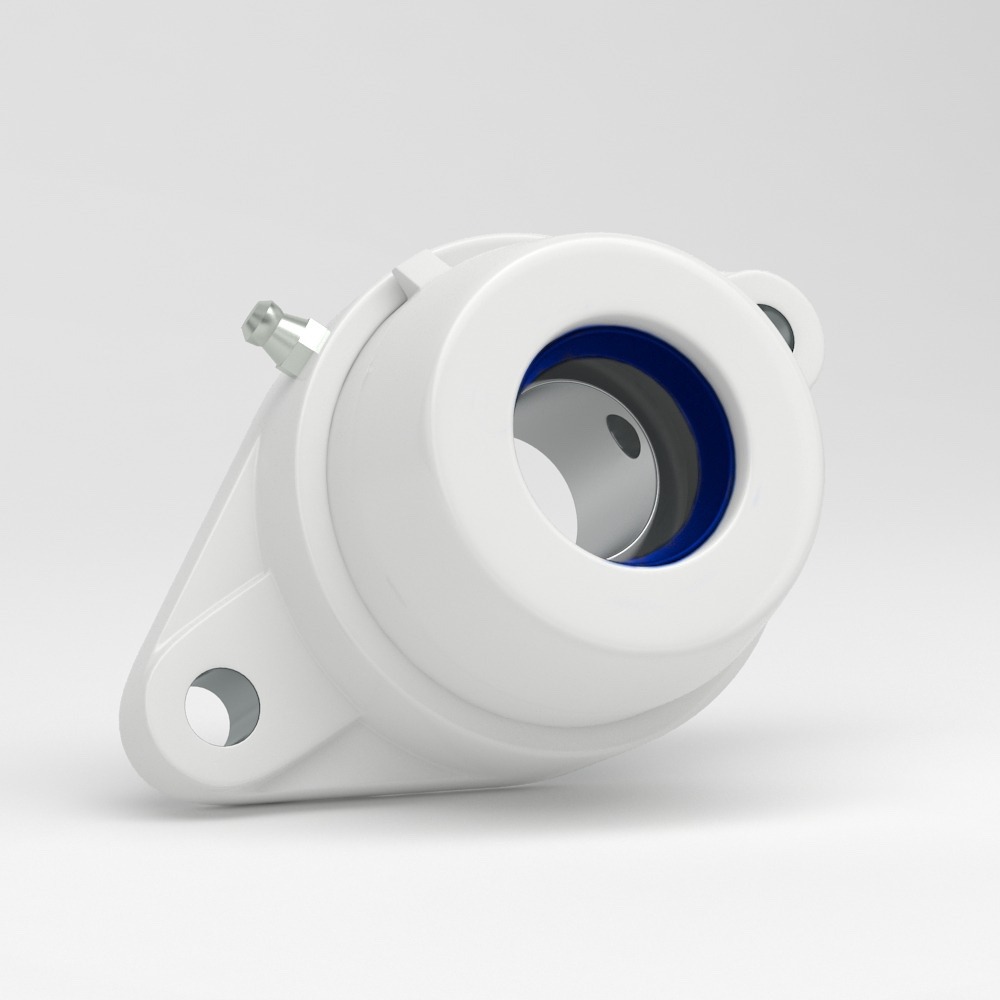

Thermo plastic bearing unit back seal

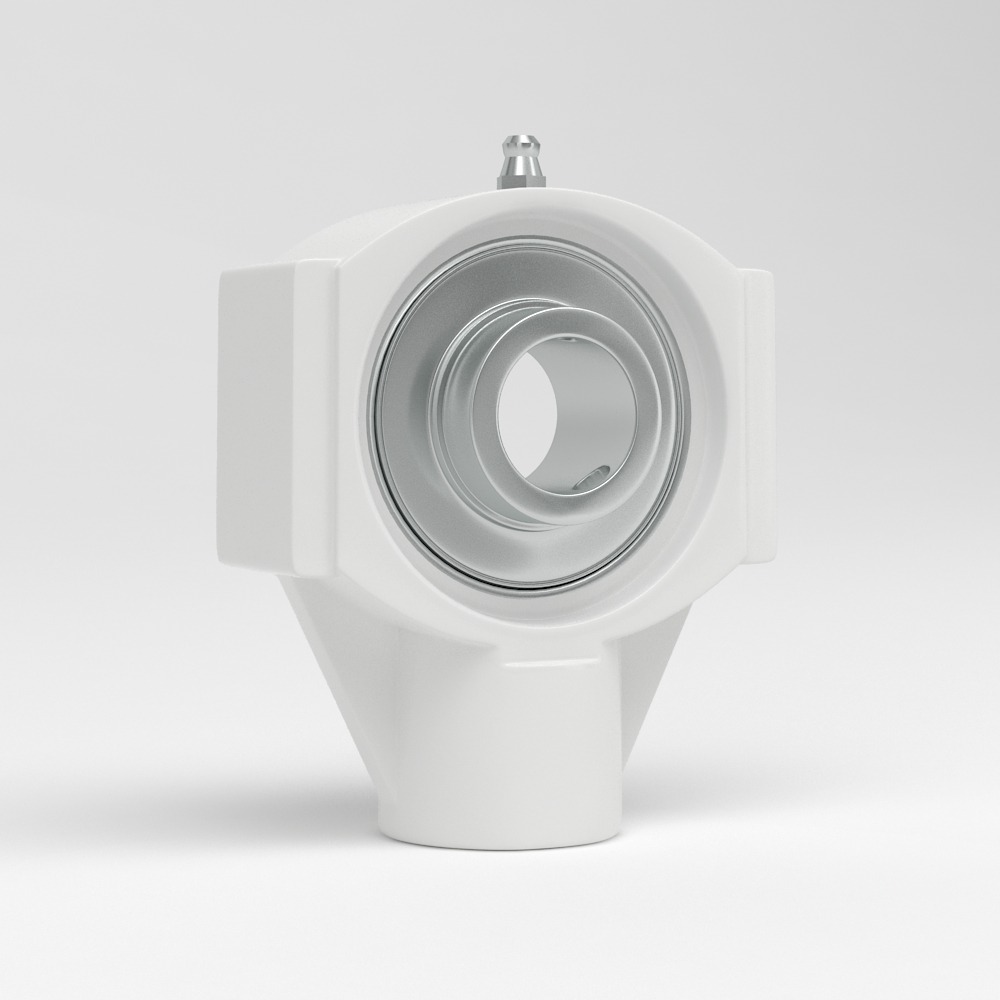

Optimized Sealing Solutions for Enhanced Protection

- Thermoplastic housings back seal in black or blue

- Back seal material: NBR Rubber

- Back seal TC (Double lip)

- Back seal with stainless steel spring

Available sizes

| Shaft Diameter | Catalog No. |

|---|---|

| Ø20 mm | BS 204 |

| Ø25 mm | BS 205 |

| Ø30 mm | BS 206 |

| Ø35 mm | BS 207 |

| Ø40 mm | BS 208 |

| Ø45 mm | BS 209 |

| Ø50 mm | BS 210 |

| Ø55 mm | BS 211 |

| Ø60 mm | BS 212 |

Optimized Sealing Solutions for Bearing Units in IP54 Composite Housing

In industrial applications, bearing units with IP54 composite housing play a crucial role in ensuring smooth and efficient operations. One of the key aspects of their performance is sealing technology, which protects against contaminants while maintaining optimal lubrication.

The Importance of Sealing in Bearing Units

Sealing systems in IP54-rated composite bearing housings are designed to provide protection against dust and splashing water, making them ideal for moderate environmental conditions. These seals prevent the ingress of dust, dirt, and moisture, extending the service life of bearings and reducing maintenance requirements.

Types of Seals for IP54 Composite Bearing Housings

- Contact Seals – Provide enhanced protection against contaminants while maintaining low friction.

- Labyrinth Seals – Use a non-contact design to create a tortuous path that prevents particle entry.

- Lip Seals – Made from high-performance elastomers, ensuring a tight seal while allowing smooth rotation.

Benefits of Optimized Sealing Solutions

- Extended Bearing Life – Reduces wear and tear by keeping contaminants out.

- Lower Maintenance Costs – Minimizes lubrication loss and the need for frequent servicing.

- Improved Performance – Ensures consistent operation in food processing, conveyor systems, and industrial machinery.

Choosing the right sealing system for IP54 composite bearing housings enhances durability and efficiency, making them a reliable choice for various industries.

Thermo plastic bearing unit back seal (BS)

Pillow block PPL ball bearing unit

Square 4 bolt flange FPL ball bearing unit

Oval 2 bolt flange FLPL ball bearing unit

Tapped base pillow block PAPL ball bearing unit

3 bolt one side flange FBPL ball bearing unit

Cartridge 4 Bolt Flange Unit FCPL

Blue Hanger HPPL ball bearing unit

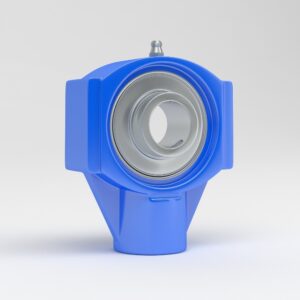

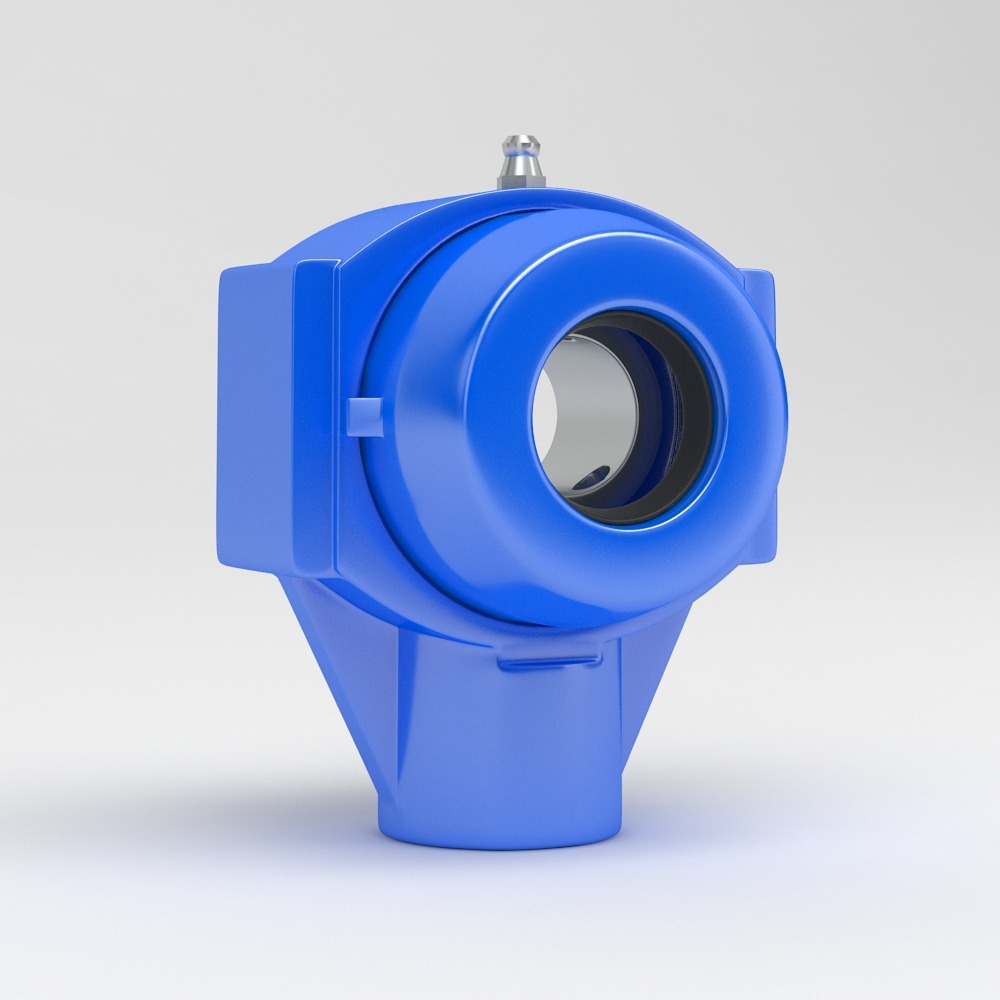

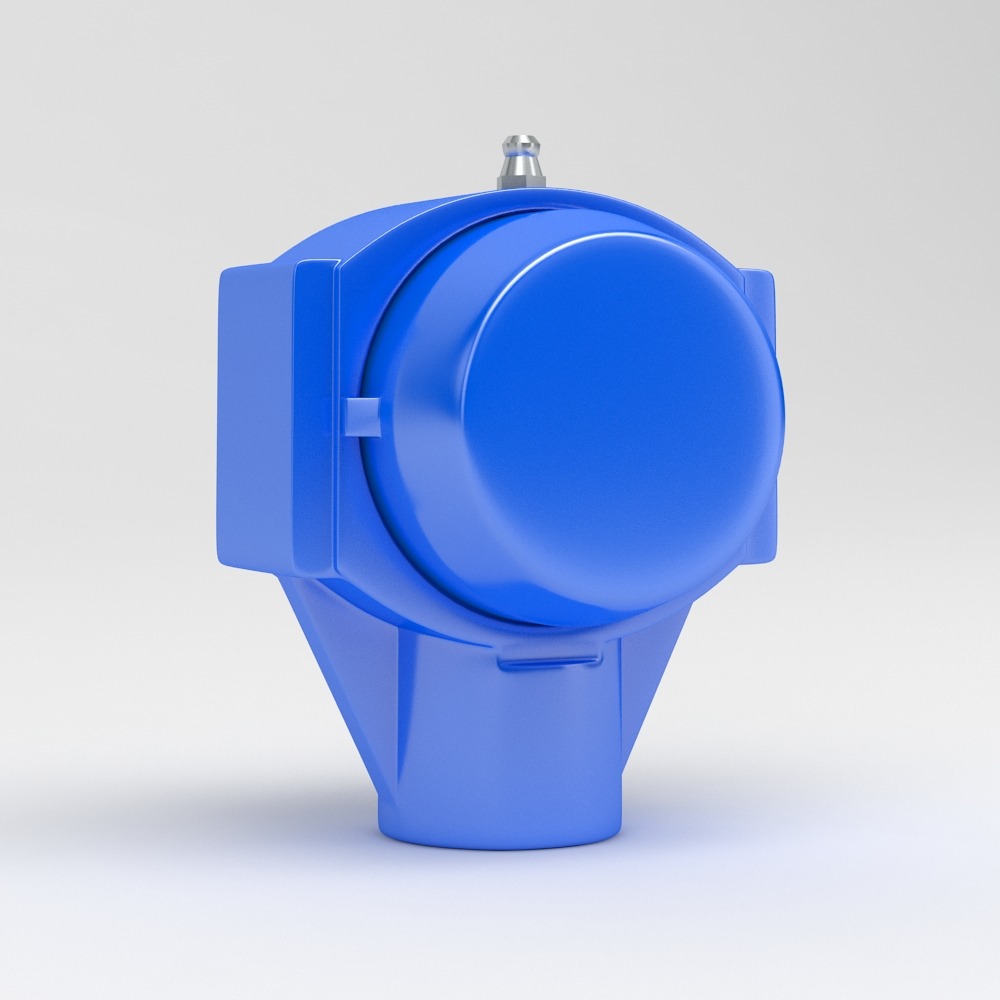

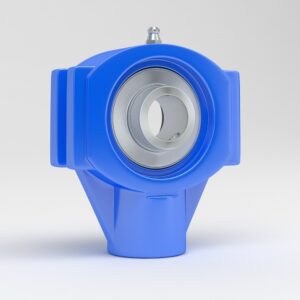

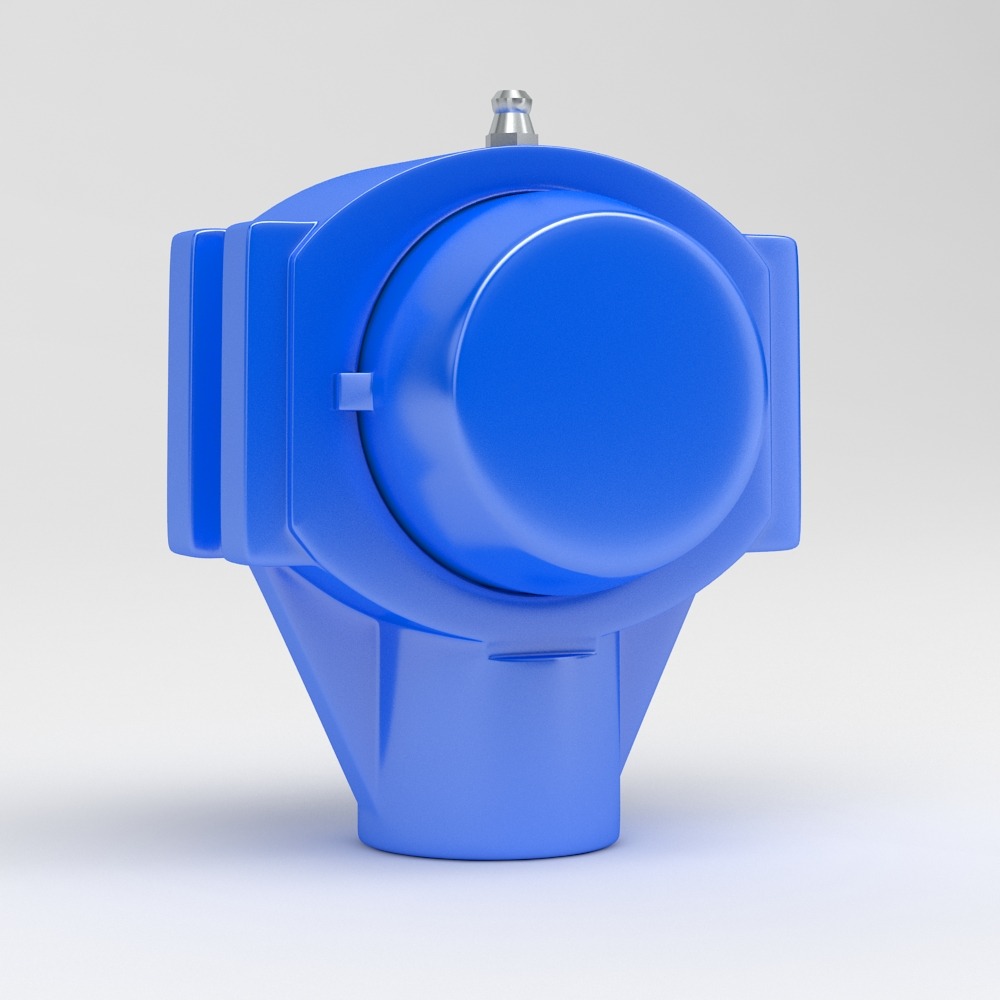

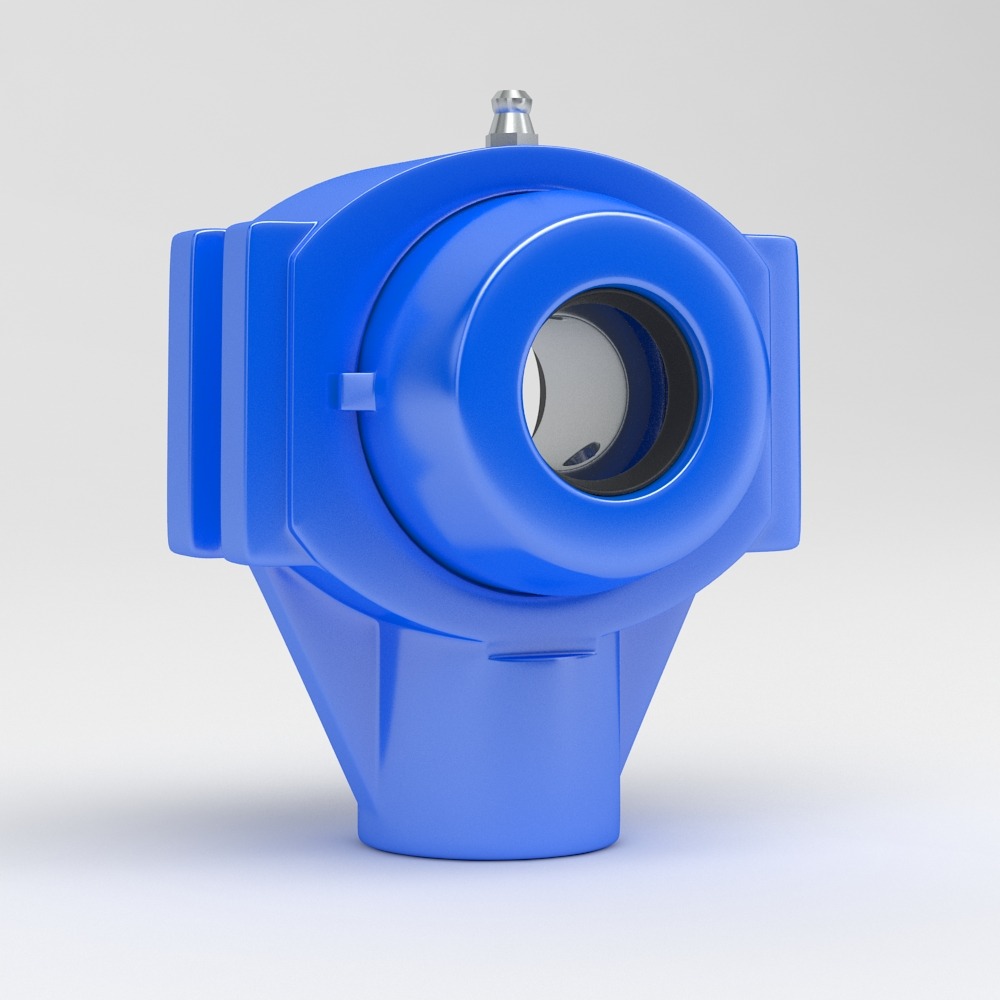

Blue Take-up TPL ball bearing unit

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Optimized Sealing Solutions for Enhanced Protection

- Thermoplastic housings back seal in black or blue

- Back seal material: NBR Rubber

- Back seal TC (Double lip)

- Back seal with stainless steel spring

Available sizes

| Shaft Diameter | Catalog No. |

|---|---|

| Ø20 mm | BS 204 |

| Ø25 mm | BS 205 |

| Ø30 mm | BS 206 |

| Ø35 mm | BS 207 |

| Ø40 mm | BS 208 |

| Ø45 mm | BS 209 |

| Ø50 mm | BS 210 |

| Ø55 mm | BS 211 |

| Ø60 mm | BS 212 |

Optimized Sealing Solutions for Bearing Units in IP54 Composite Housing

In industrial applications, bearing units with IP54 composite housing play a crucial role in ensuring smooth and efficient operations. One of the key aspects of their performance is sealing technology, which protects against contaminants while maintaining optimal lubrication.

The Importance of Sealing in Bearing Units

Sealing systems in IP54-rated composite bearing housings are designed to provide protection against dust and splashing water, making them ideal for moderate environmental conditions. These seals prevent the ingress of dust, dirt, and moisture, extending the service life of bearings and reducing maintenance requirements.

Types of Seals for IP54 Composite Bearing Housings

- Contact Seals – Provide enhanced protection against contaminants while maintaining low friction.

- Labyrinth Seals – Use a non-contact design to create a tortuous path that prevents particle entry.

- Lip Seals – Made from high-performance elastomers, ensuring a tight seal while allowing smooth rotation.

Benefits of Optimized Sealing Solutions

- Extended Bearing Life – Reduces wear and tear by keeping contaminants out.

- Lower Maintenance Costs – Minimizes lubrication loss and the need for frequent servicing.

- Improved Performance – Ensures consistent operation in food processing, conveyor systems, and industrial machinery.

Choosing the right sealing system for IP54 composite bearing housings enhances durability and efficiency, making them a reliable choice for various industries.

Thermo plastic bearing unit back seal (BS)

Pillow block PPL ball bearing unit

Square 4 bolt flange FPL ball bearing unit

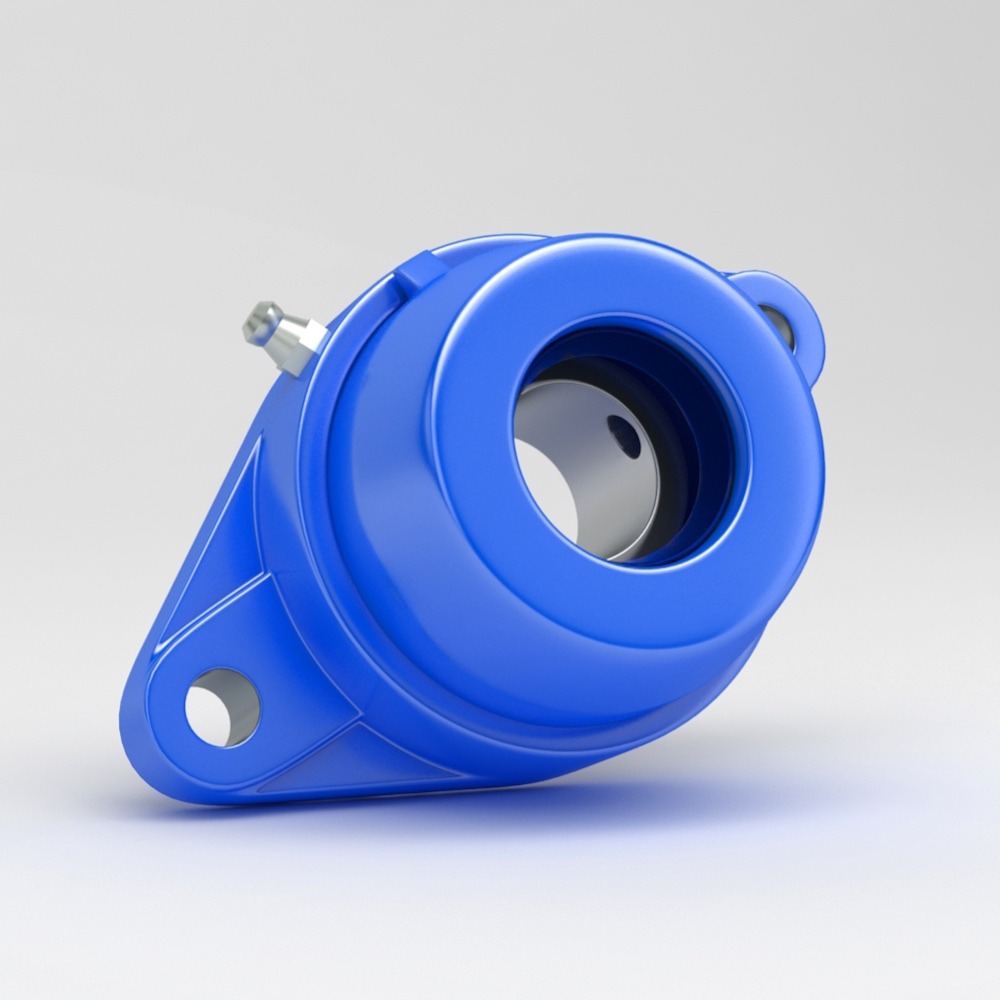

Oval 2 bolt flange FLPL ball bearing unit

Tapped base pillow block PAPL ball bearing unit

3 bolt one side flange FBPL ball bearing unit

Cartridge 4 Bolt Flange Unit FCPL

Blue Hanger HPPL ball bearing unit

Blue Take-up TPL ball bearing unit

Optimized Sealing Solutions for Enhanced Protection

- Thermoplastic housings back seal in black or blue

- Back seal material: NBR Rubber

- Back seal TC (Double lip)

- Back seal with stainless steel spring

Available sizes

| Shaft Diameter | Catalog No. |

|---|---|

| Ø20 mm | BS 204 |

| Ø25 mm | BS 205 |

| Ø30 mm | BS 206 |

| Ø35 mm | BS 207 |

| Ø40 mm | BS 208 |

| Ø45 mm | BS 209 |

| Ø50 mm | BS 210 |

| Ø55 mm | BS 211 |

| Ø60 mm | BS 212 |

Optimized Sealing Solutions for Bearing Units in IP54 Composite Housing

In industrial applications, bearing units with IP54 composite housing play a crucial role in ensuring smooth and efficient operations. One of the key aspects of their performance is sealing technology, which protects against contaminants while maintaining optimal lubrication.

The Importance of Sealing in Bearing Units

Sealing systems in IP54-rated composite bearing housings are designed to provide protection against dust and splashing water, making them ideal for moderate environmental conditions. These seals prevent the ingress of dust, dirt, and moisture, extending the service life of bearings and reducing maintenance requirements.

Types of Seals for IP54 Composite Bearing Housings

- Contact Seals – Provide enhanced protection against contaminants while maintaining low friction.

- Labyrinth Seals – Use a non-contact design to create a tortuous path that prevents particle entry.

- Lip Seals – Made from high-performance elastomers, ensuring a tight seal while allowing smooth rotation.

Benefits of Optimized Sealing Solutions

- Extended Bearing Life – Reduces wear and tear by keeping contaminants out.

- Lower Maintenance Costs – Minimizes lubrication loss and the need for frequent servicing.

- Improved Performance – Ensures consistent operation in food processing, conveyor systems, and industrial machinery.

Choosing the right sealing system for IP54 composite bearing housings enhances durability and efficiency, making them a reliable choice for various industries.

Thermo plastic bearing unit back seal (BS)

Pillow block PPL ball bearing unit

Square 4 bolt flange FPL ball bearing unit

Oval 2 bolt flange FLPL ball bearing unit

Tapped base pillow block PAPL ball bearing unit

3 bolt one side flange FBPL ball bearing unit

Cartridge 4 Bolt Flange Unit FCPL

Blue Hanger HPPL ball bearing unit

Blue Take-up TPL ball bearing unit

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.