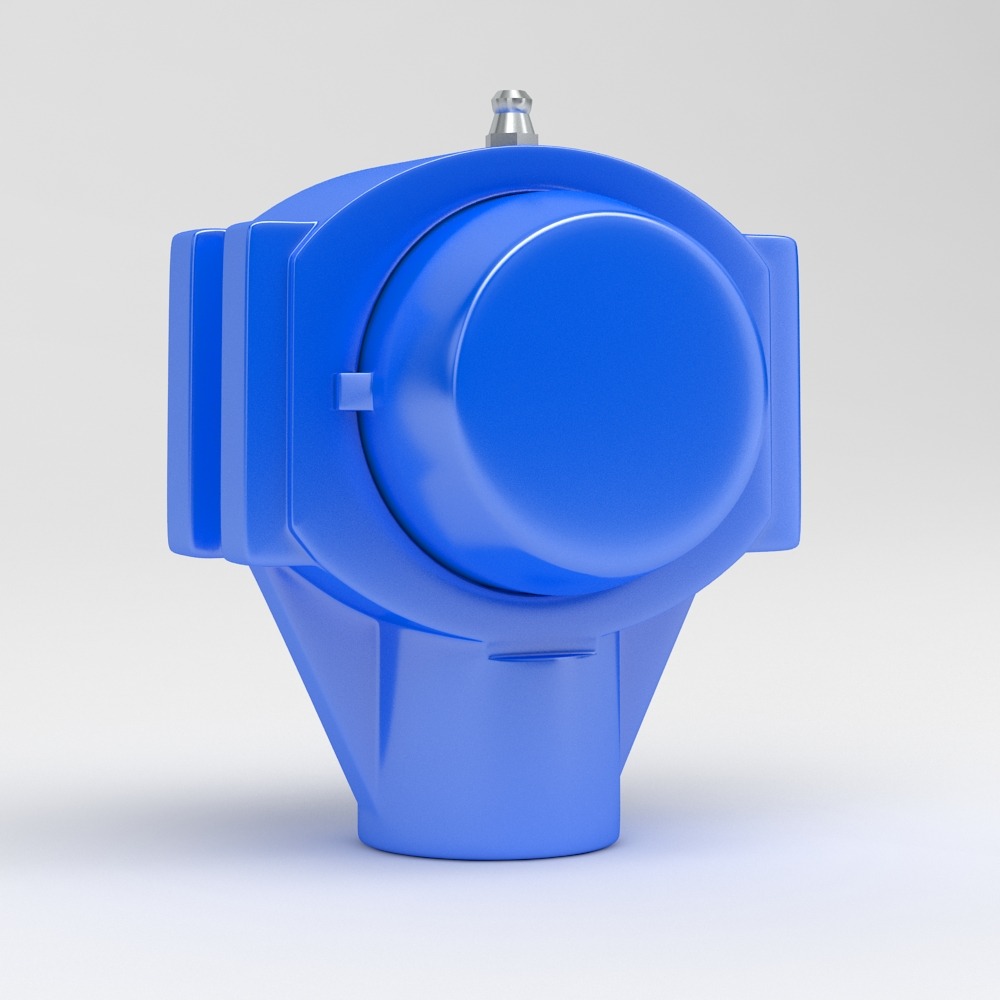

Enhancing Equipment Reliability with IP54 Housing Bearing Units

In the competitive landscape of the packaging industry, the emphasis on equipment reliability and continuous production is paramount. Companies are perpetually in the pursuit of innovative solutions to mitigate downtime, enhance operational efficiency, and boost productivity. One such groundbreaking solution is the integration of bearing units in IP54 housing, which is making significant strides. Indeed, this combination is not just a component; it is a cornerstone for building a reliable and efficient production environment.

High degree of protection

IP54 housing is renowned for its robust design, offering a high degree of protection against particles and water splashes. When we house bearing units in this protective enclosure, the result is an amalgamation of enhanced durability, reduced maintenance, and uninterrupted operations. We meticulously design the IP54-rated enclosures to prevent the ingress of dust particles, ensuring that the bearing units remain uncontaminated and function optimally.

Packaging industry

The packaging industry presents many challenges, including dust, debris, and moisture. In this context, IP54 housing emerges as a guardian. It shields the bearing units to ensure they operate at optimal performance. As a result, this reduces the frequency of maintenance and minimizes unscheduled downtimes. This implementation translates to enhanced reliability and ensures that packaging lines remain continuously operational.

Safeguarded bearings

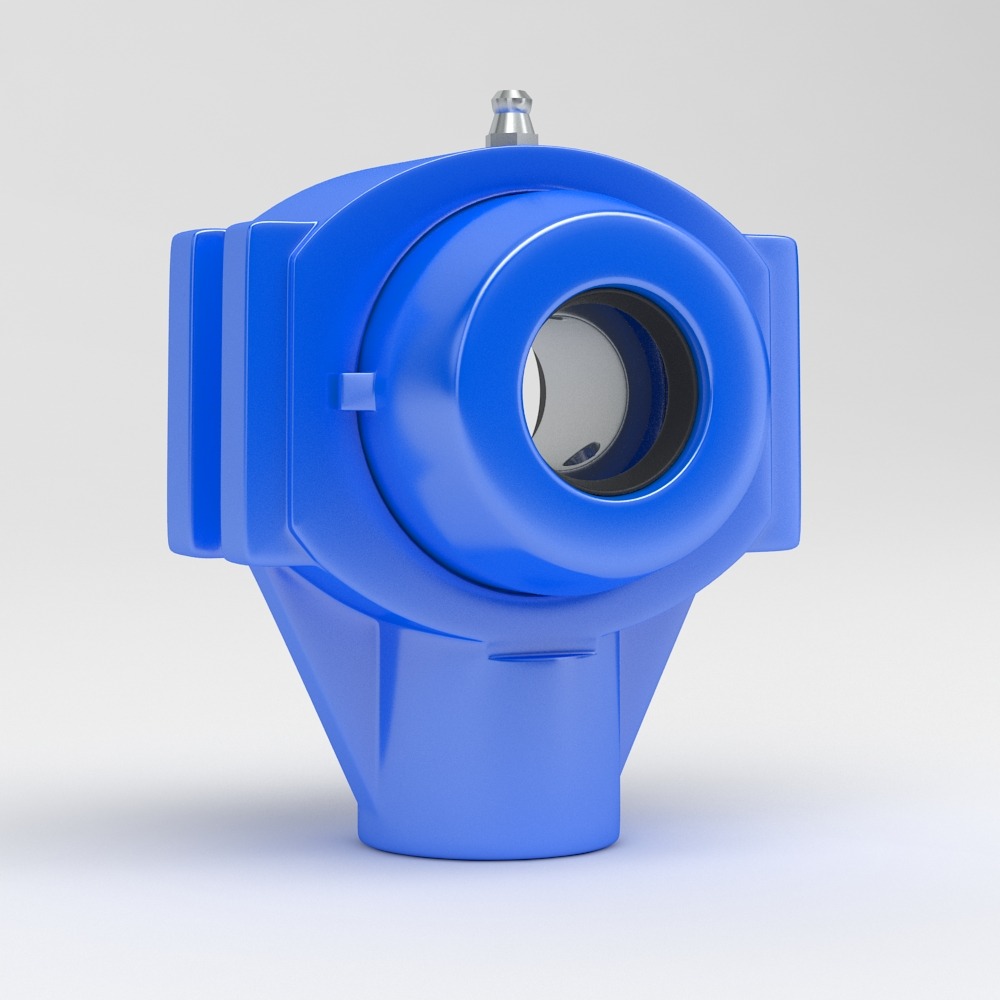

Moreover, bearing units encapsulated in IP54 housing are a testament to engineering excellence. They ensure that the bearings are not just protected but are also easily accessible for maintenance. This thoughtful design facilitates ease of maintenance, ensuring that operations are not heavily impacted during routine checks. It is a balanced approach, ensuring that while we safeguard the bearings, we do not ensconce them to a point where accessibility becomes a challenge.

Competitive advantage

The significance of this integration magnifies further when we view it through the lens of cost-efficiency. Reduced maintenance, coupled with enhanced reliability, translates to a lowered operational cost. For businesses in the packaging industry, this cost efficiency is not just a saving; it is a competitive advantage. It empowers companies to direct resources to other pivotal areas, driving innovation, and staying ahead in the competitive market.

Bearing units and IP54 housing

The marriage between bearing units and IP54 housing is a symbiotic relationship where durability meets efficiency. In an industry where every second of production counts, ensuring that equipment is not just operational but is functioning at peak performance is essential.

Bearing units in IP54 housing emerge as the unsung heroes, quietly yet significantly driving reliability and continuous production. Their role in ensuring that the wheels of the packaging industry keep turning, unencumbered by dust, debris, or moisture, is a testament to their indispensability. In the era where the demand for packaged goods is skyrocketing, relying on such innovative solutions is not just an option; it’s a necessity for any packaging entity eyeing global competitiveness and sustainability.

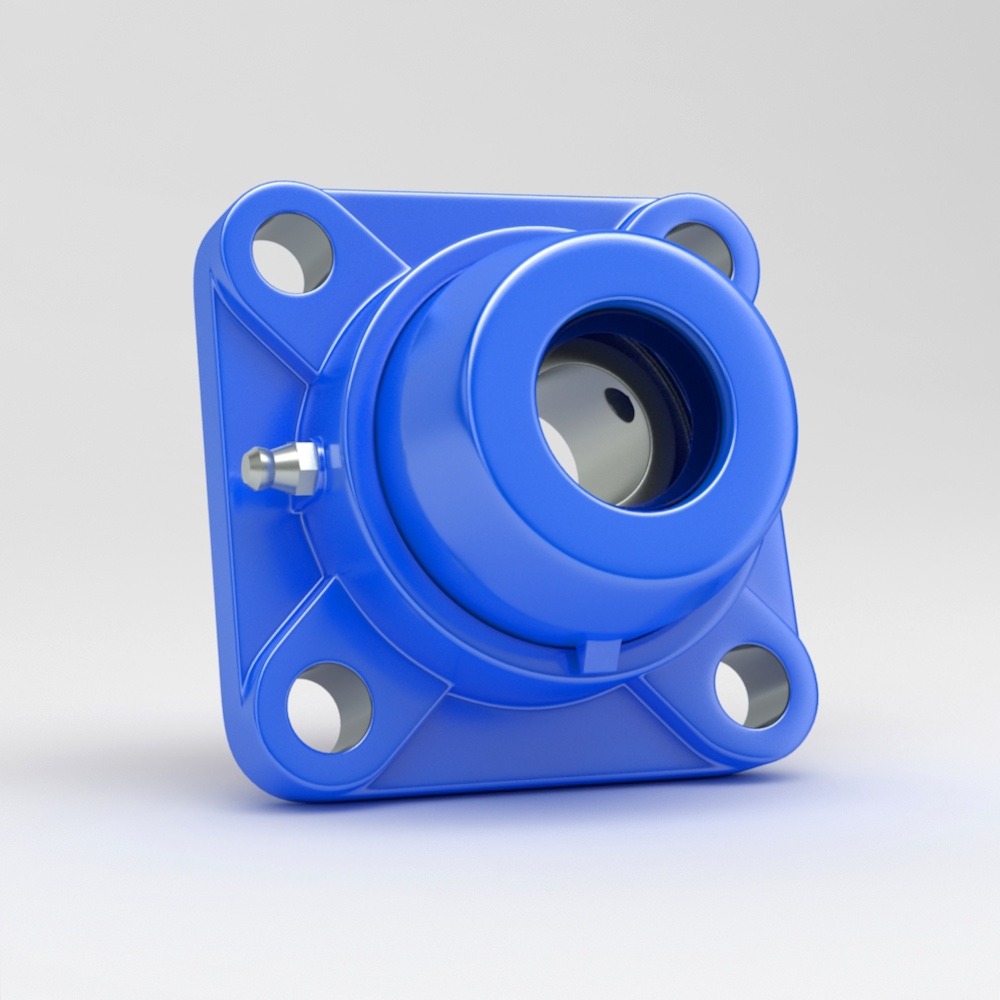

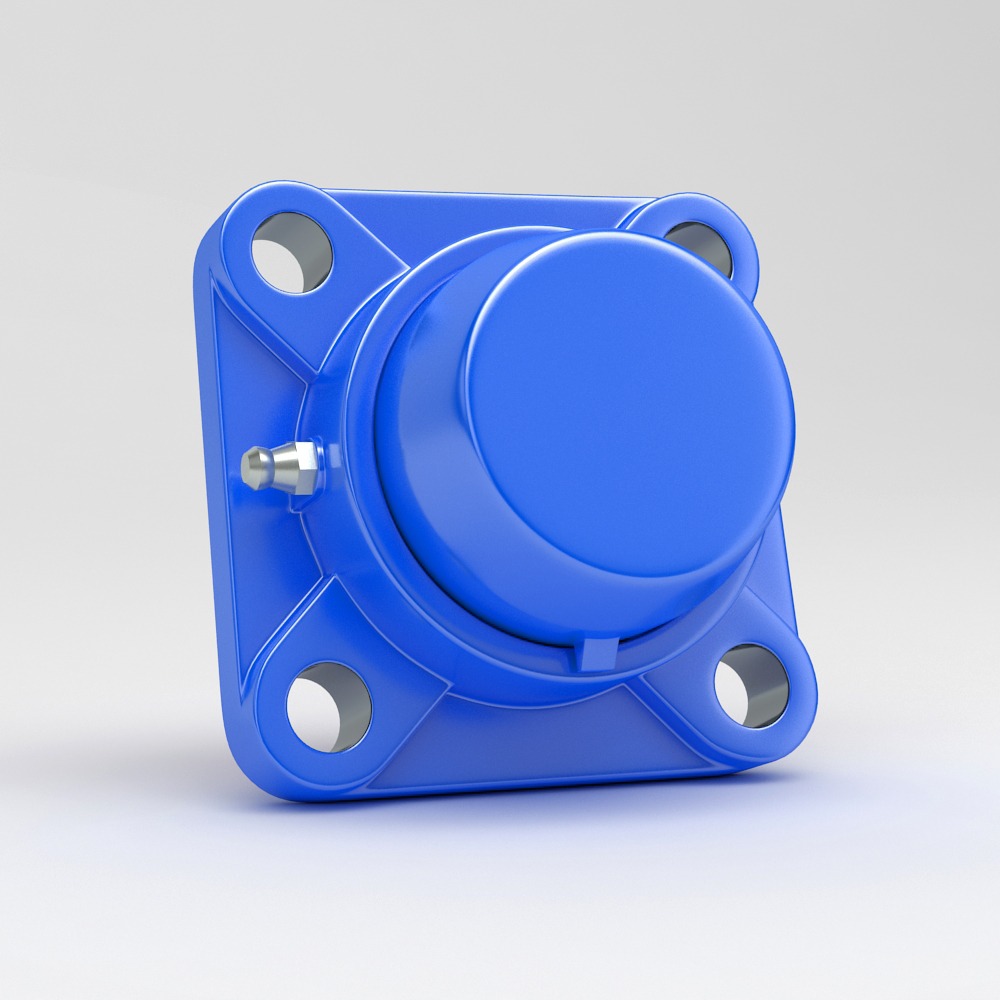

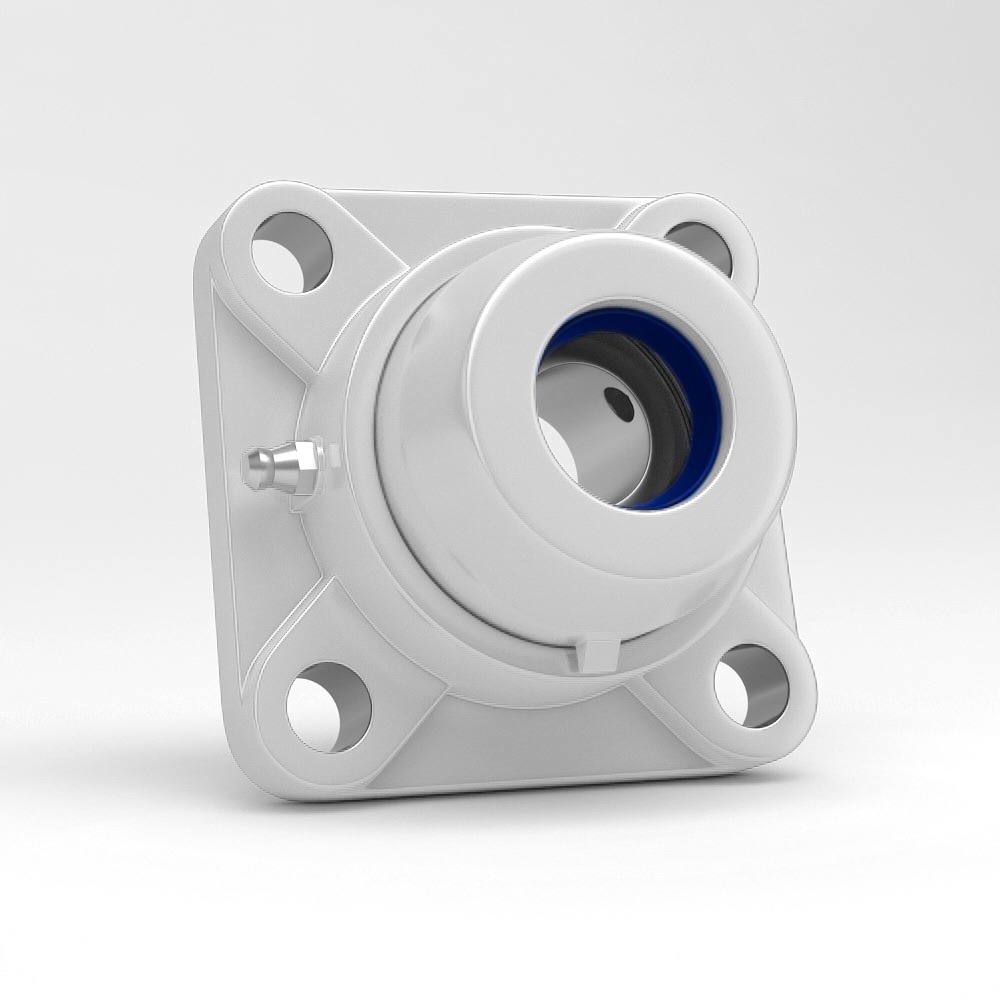

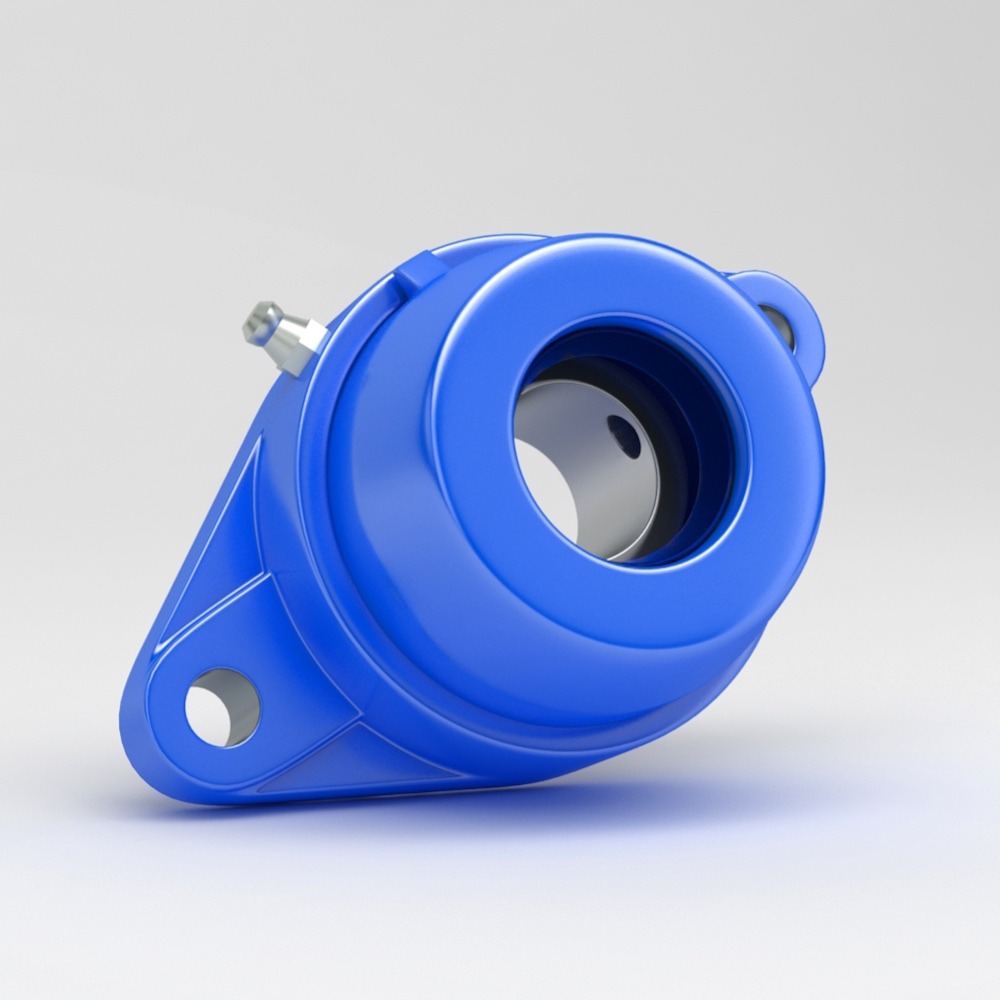

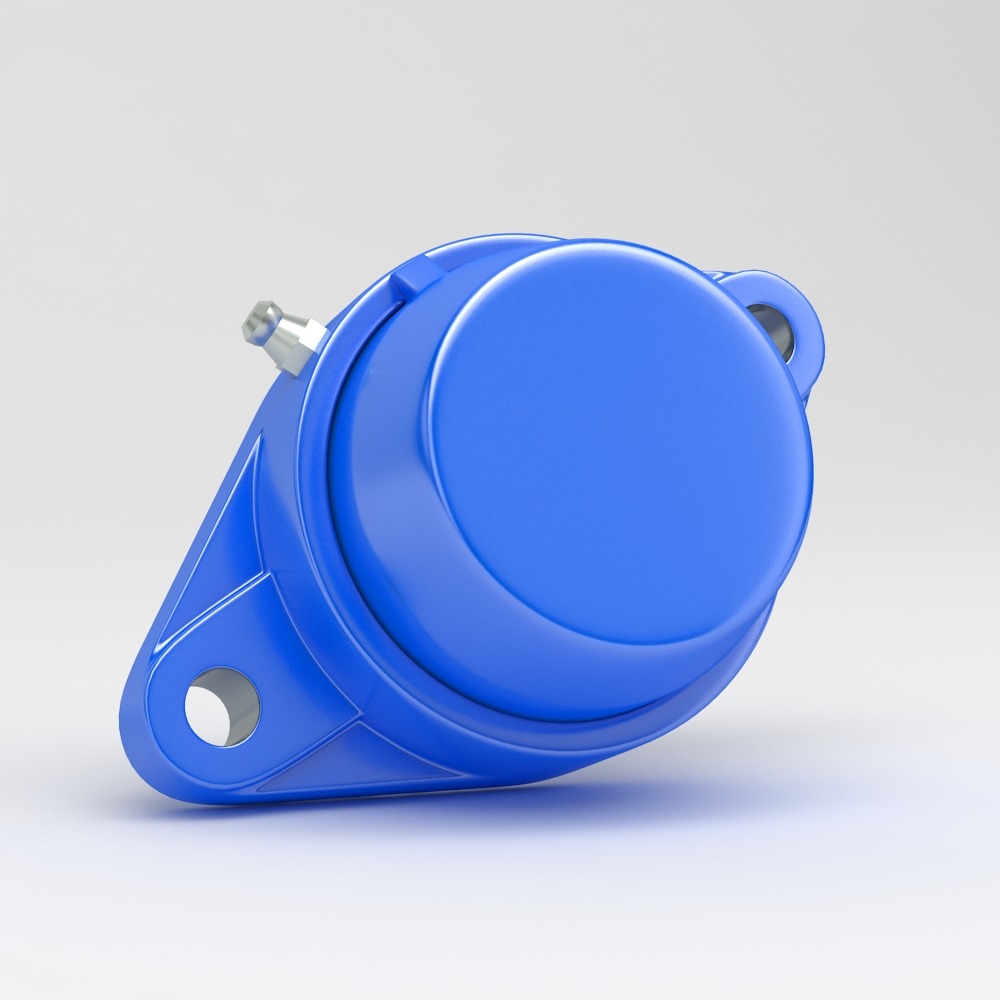

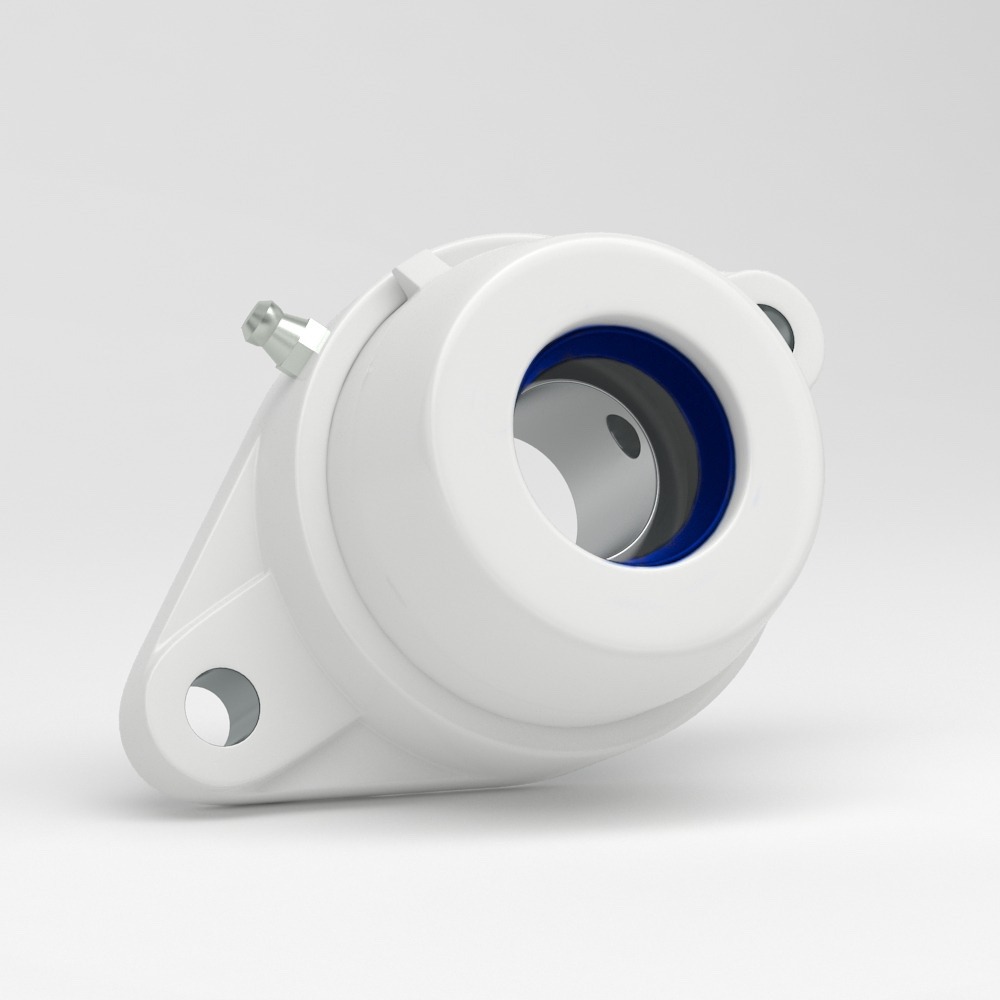

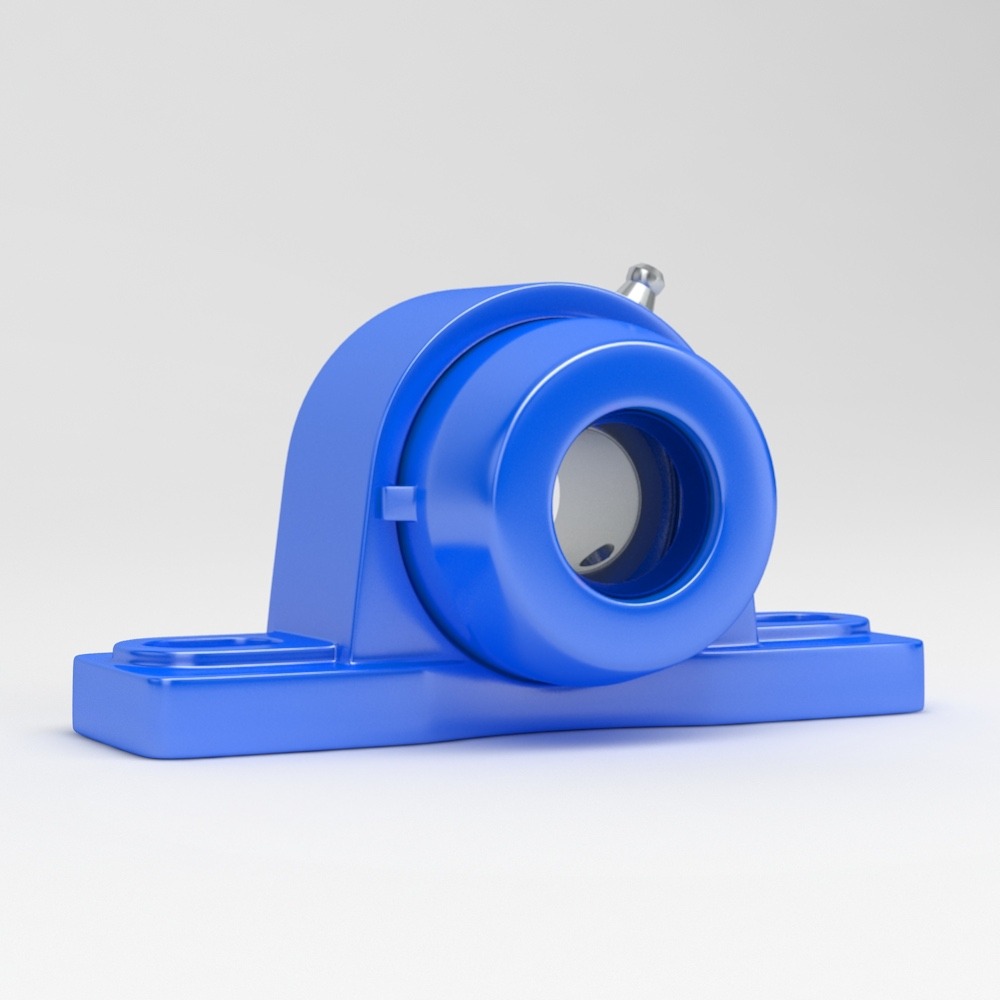

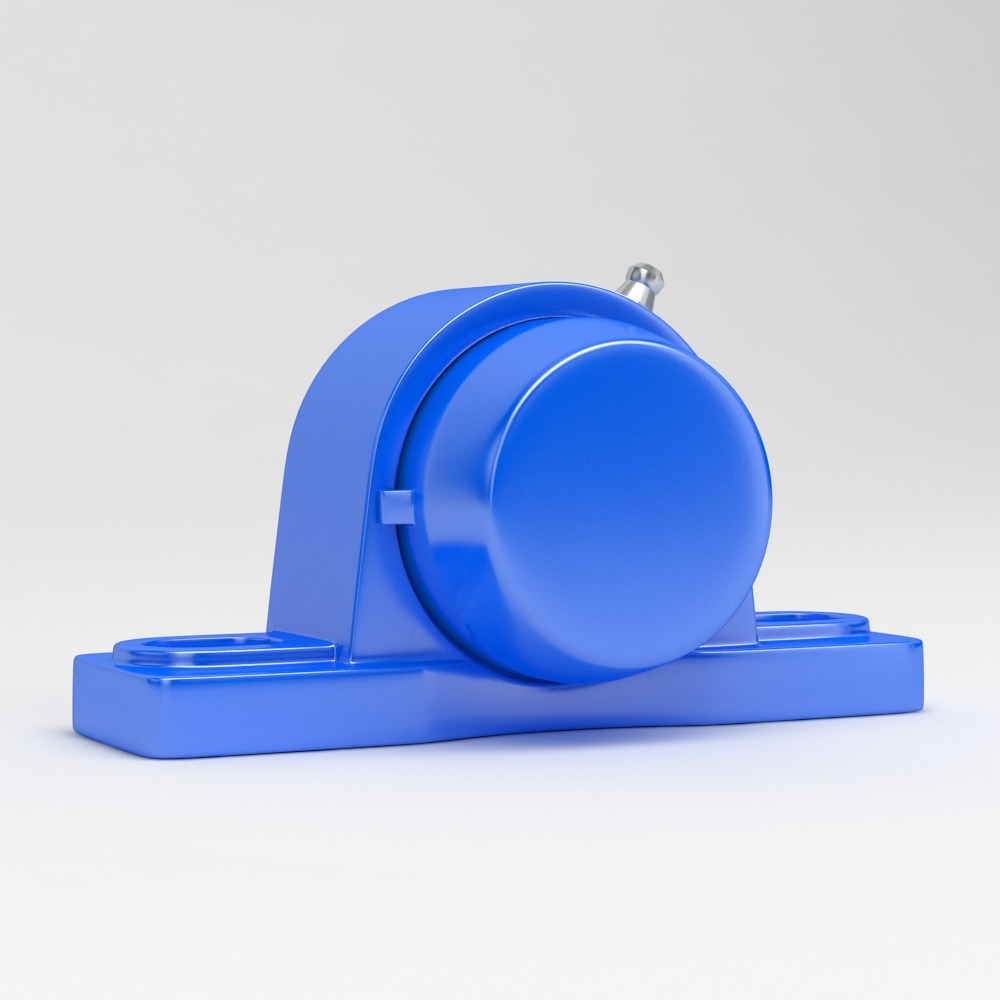

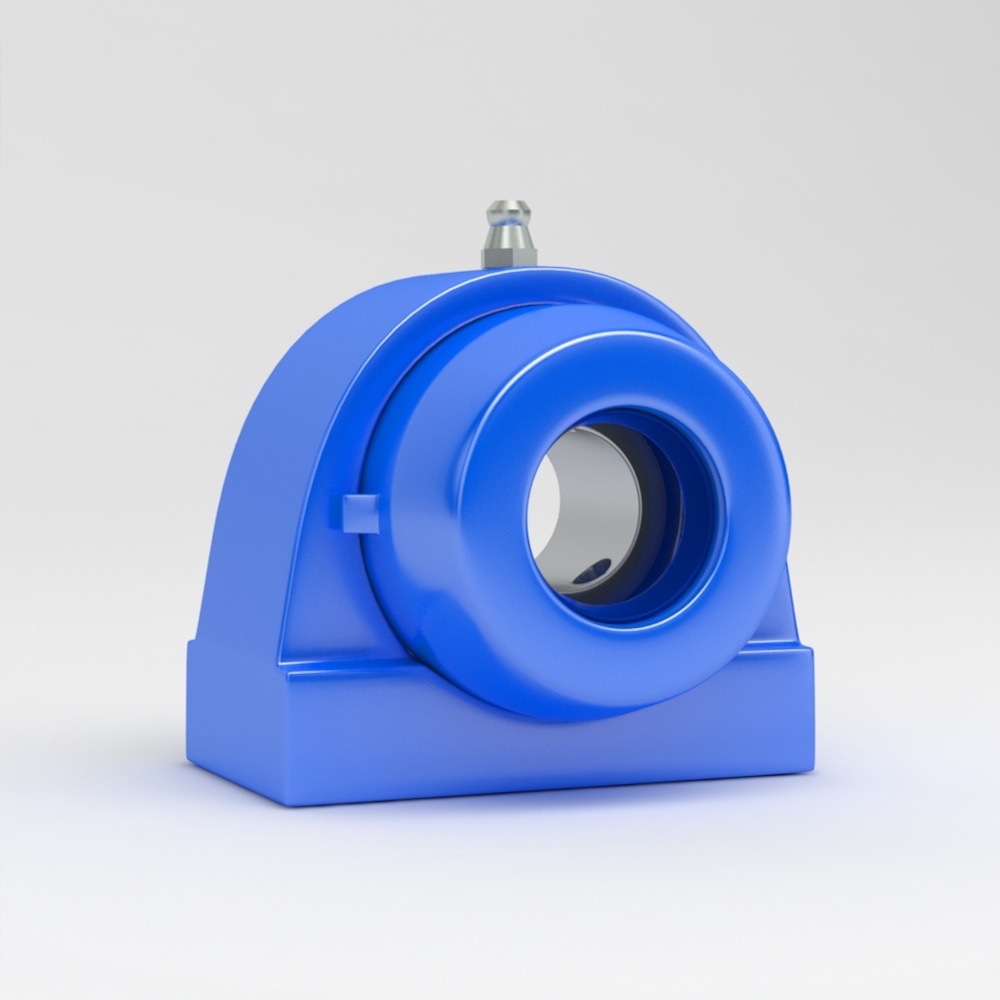

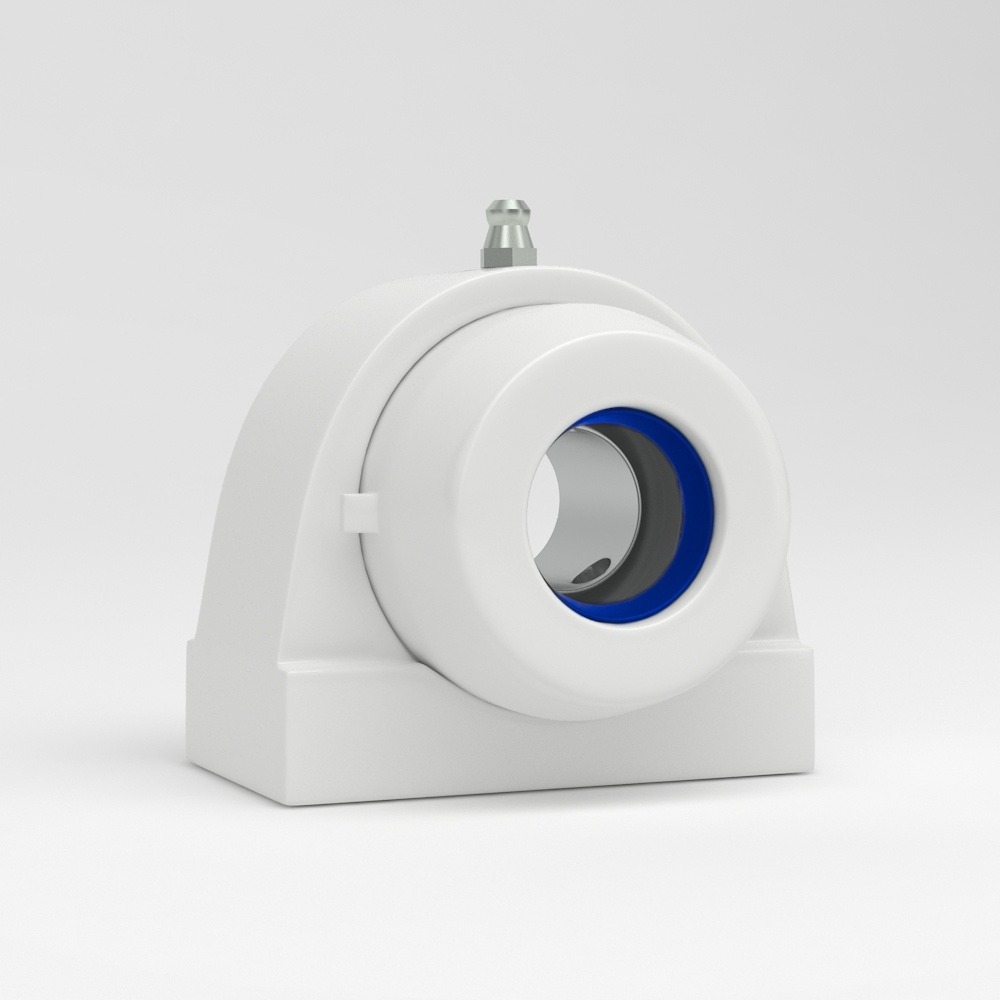

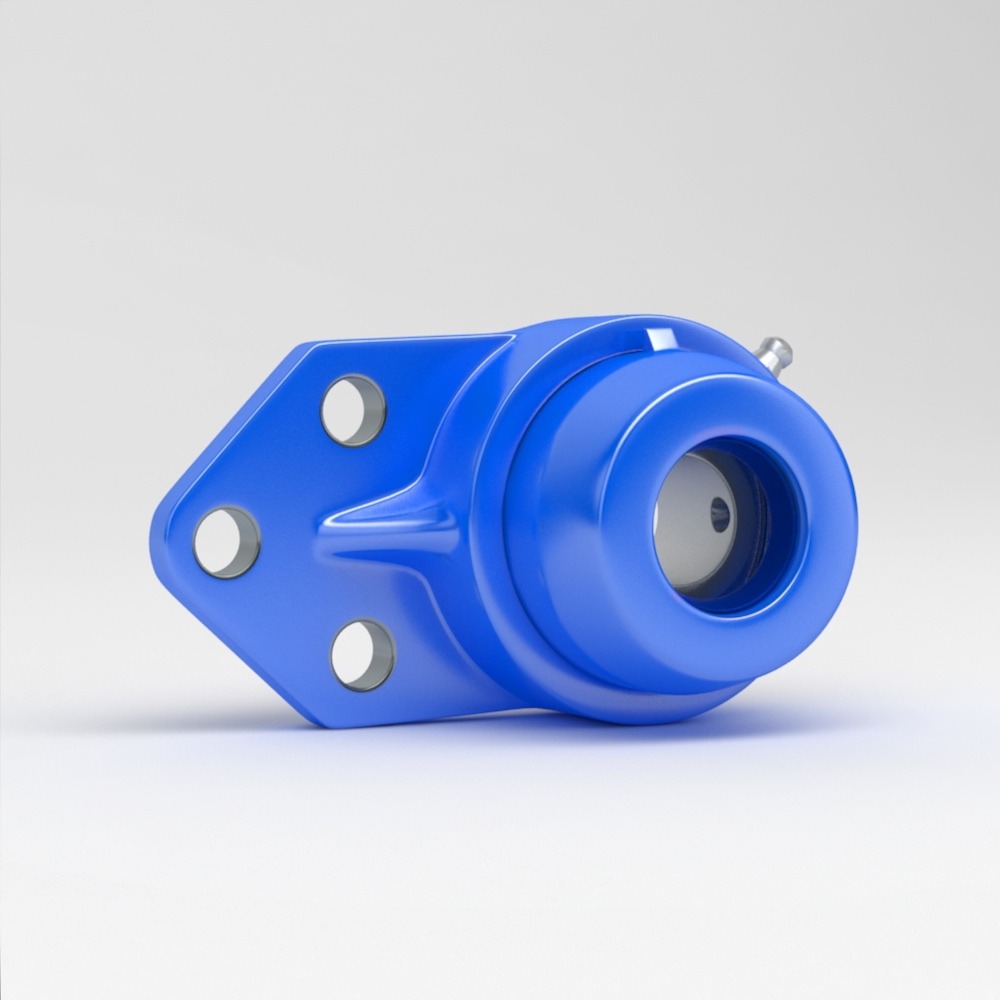

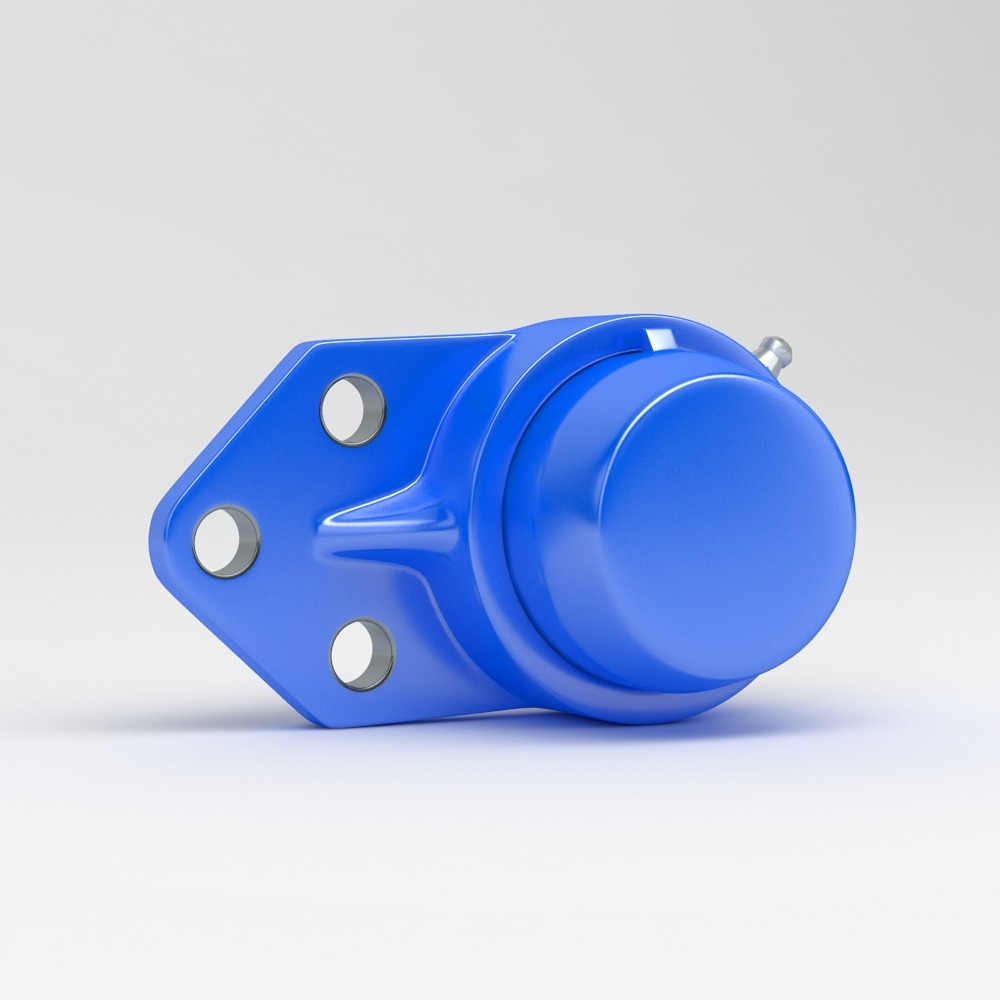

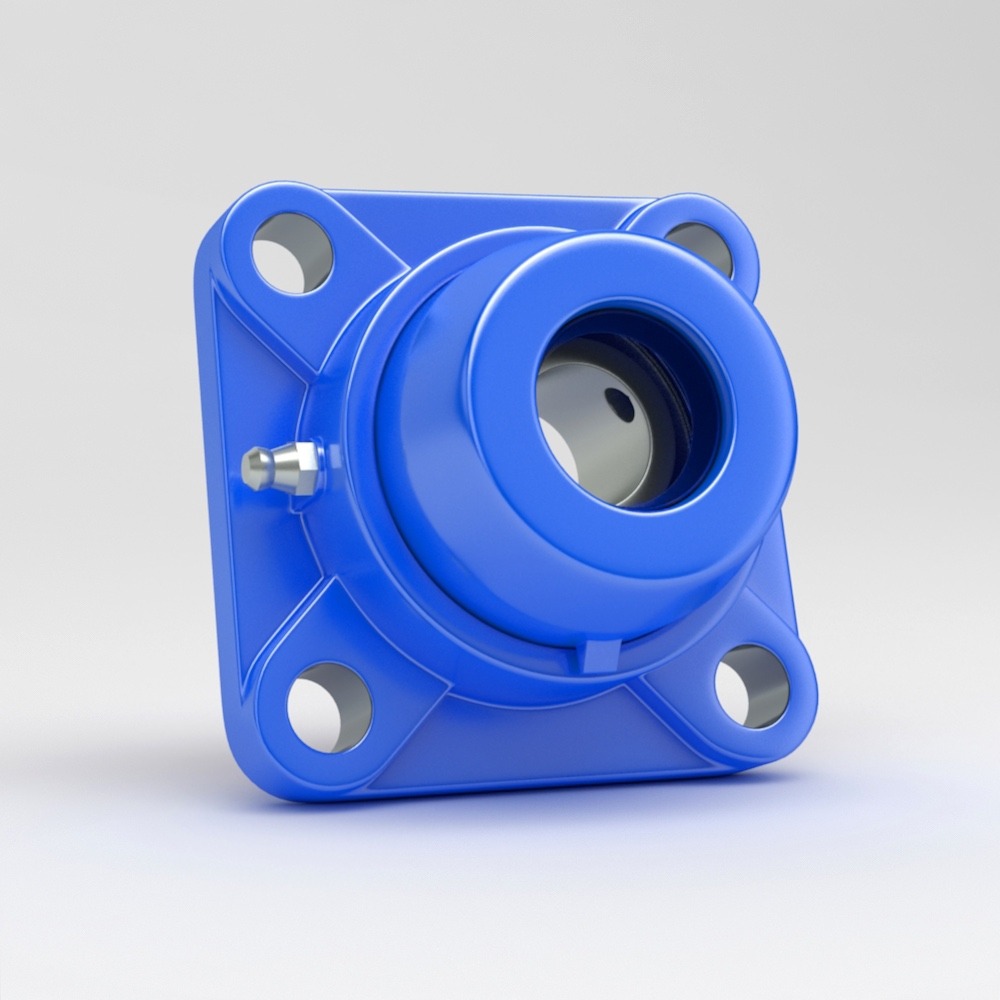

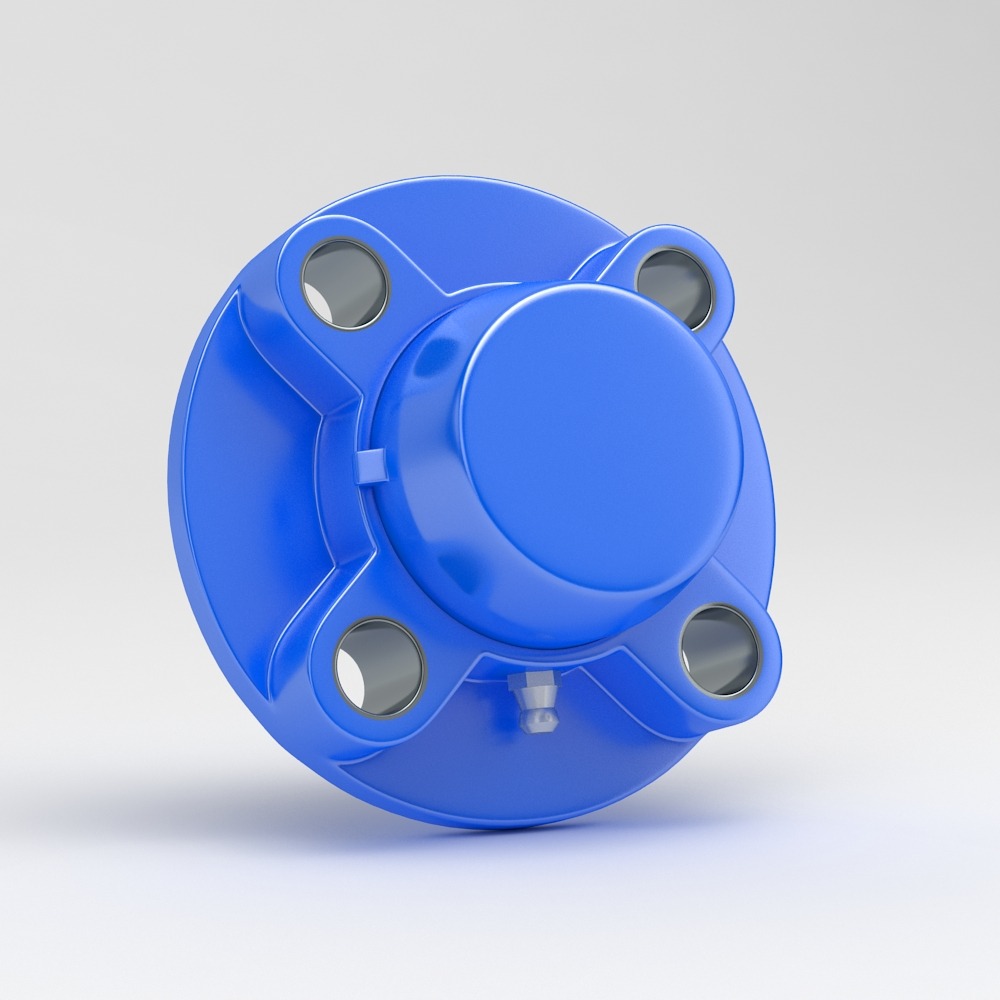

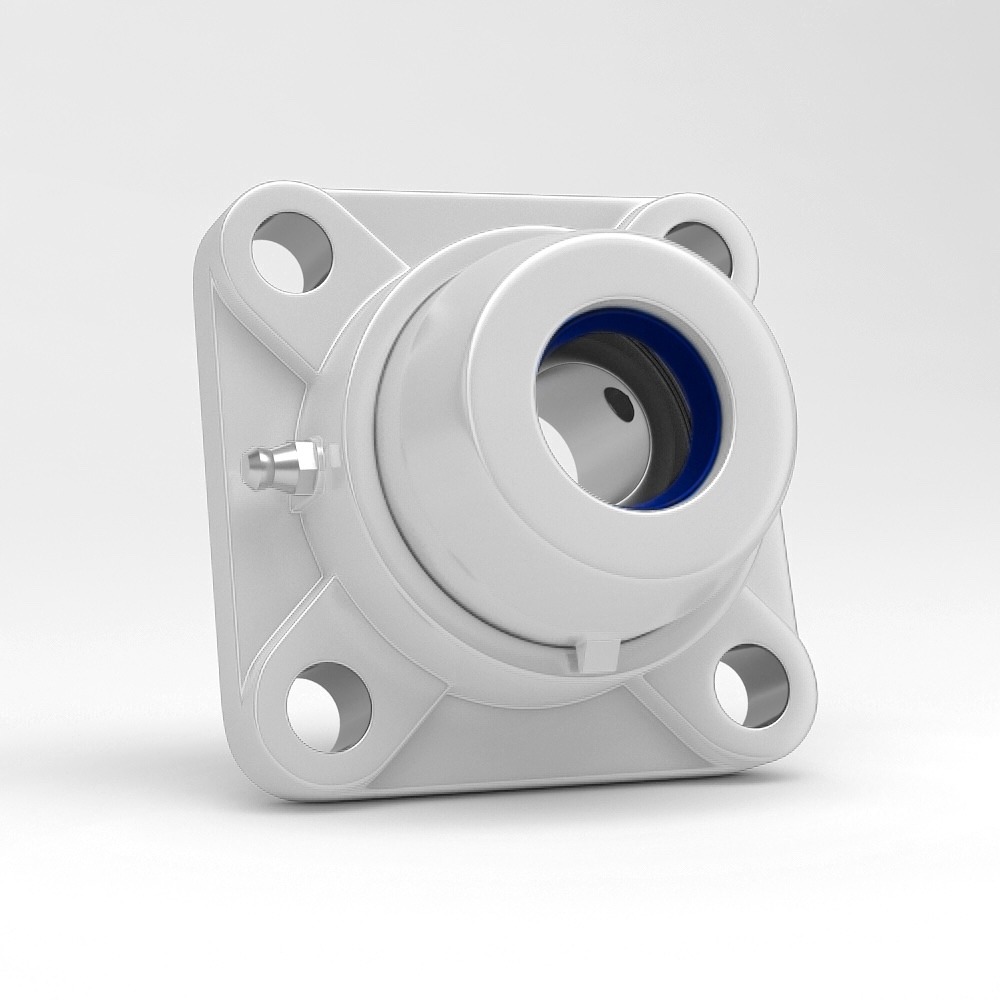

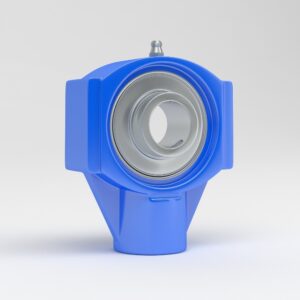

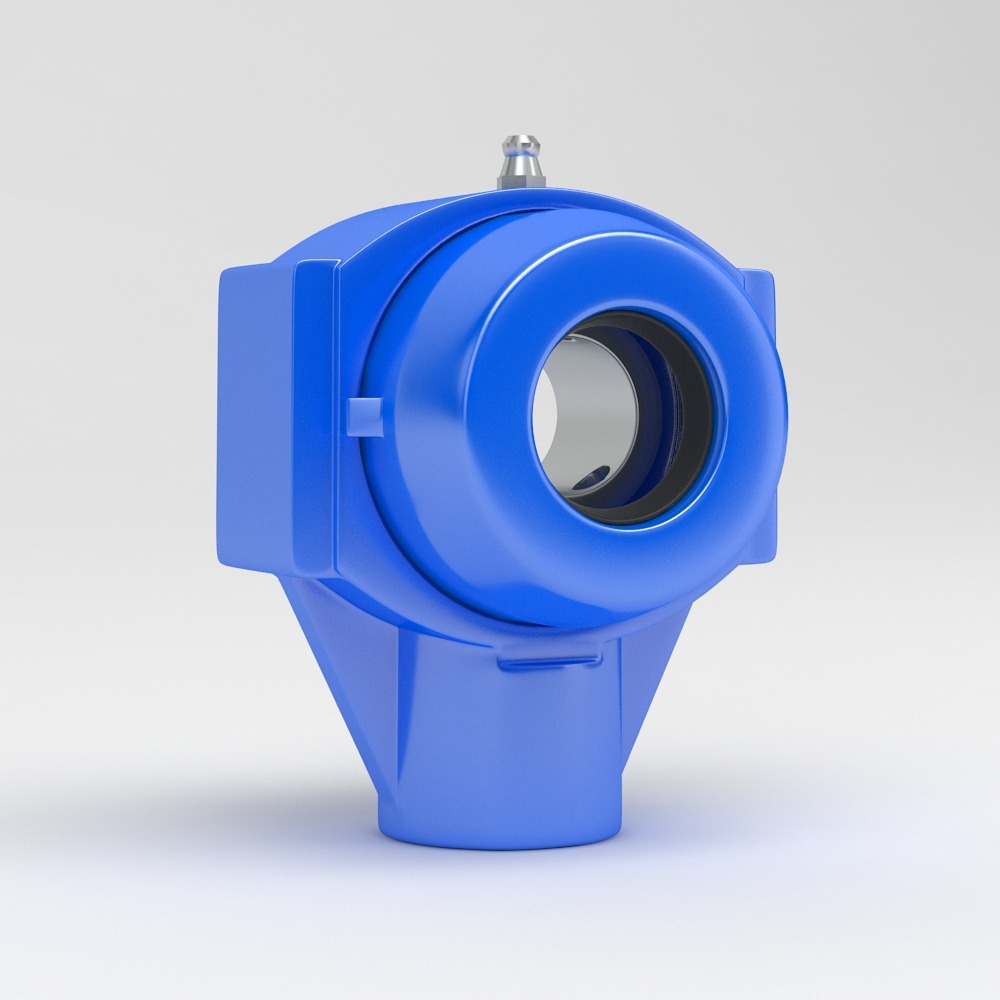

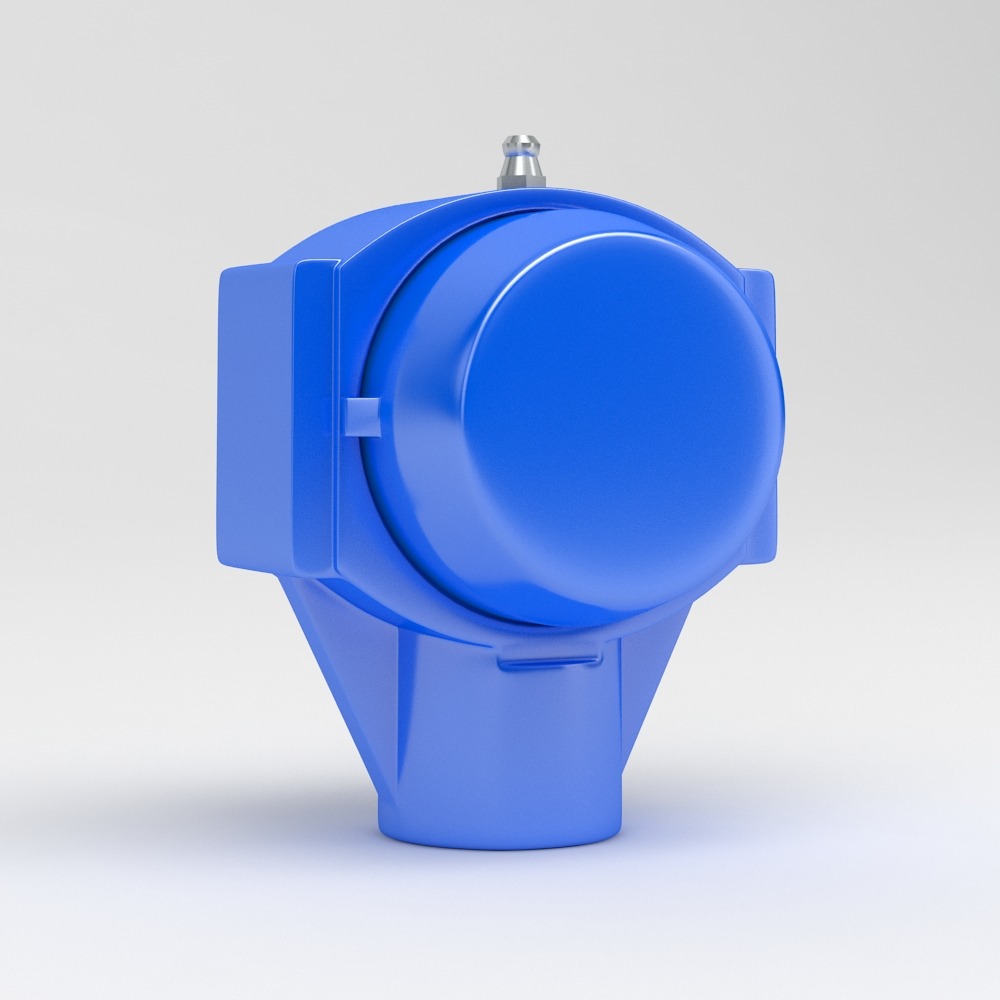

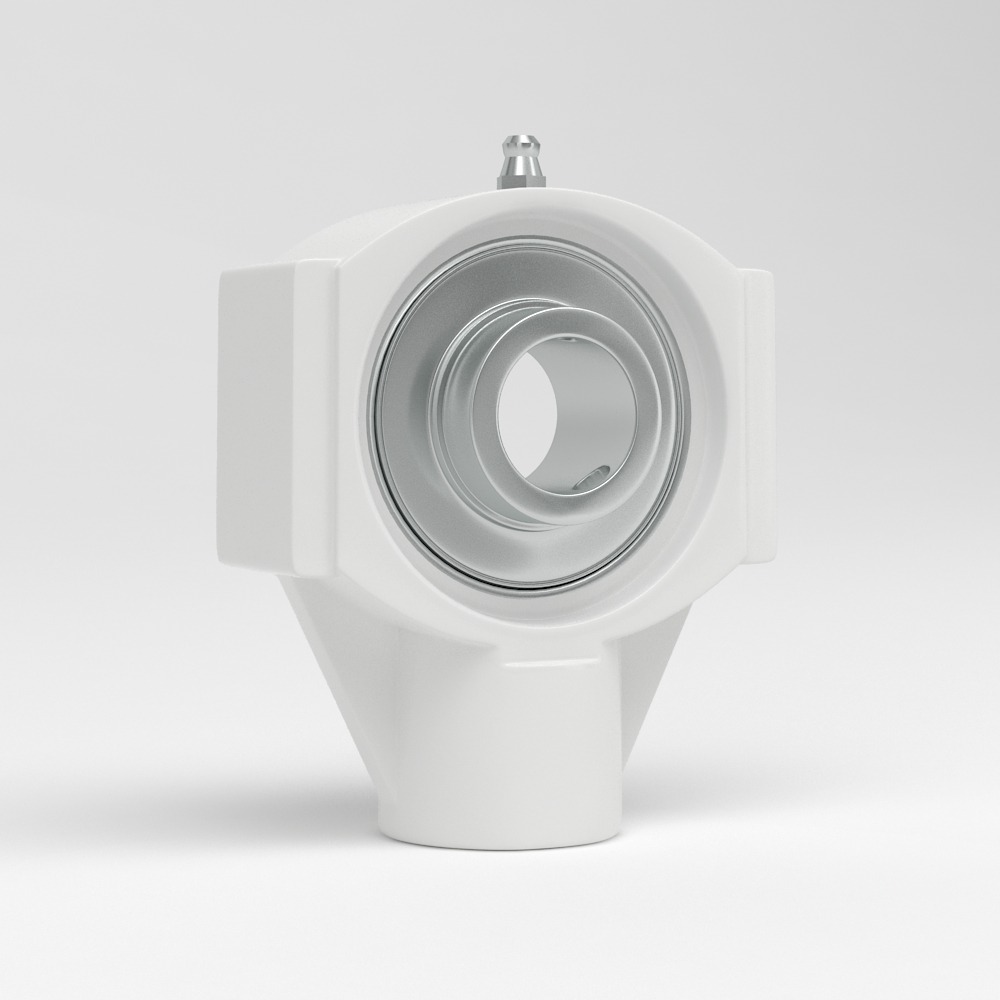

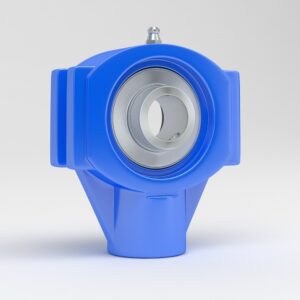

Easy-to-clean composite bearing units

NHK composite bearing units are designed for the food industry and other industries with continuously heavier demands on the material resistance and a design for easy-to-clean.

In order to reduce the risk of bacteria growth, this design is characterized by smooth surfaces and rounded corners.

Bearing Units IP54 in composite advantages

Composite housings in Blue, White and Black

Stainless bearing inserts AISI 440C or AISI420

Chrome steel bearings 100Cr6

Stainless grease nipple AISI 304 M6x1 mm

Operating temperature from -30°C to +100°C.

Cover material: Polypropylene

Oil seal material: NBR Rubber with stainless spring

The spherical bearing is self-aligning.

The bearing housing measurements are similar to market standards for easy replacement.

The bearing housing can be mounted in all angles

The stainless spherical insert bearings for an easy and precise assembly

The bearing inserts are lubricated with FM222 grease which meet requirements like DIN 51825, Halal, Kosher etc.

Possibility for private label.

Do you want to become a customer?

Do you have any questions about our products? You are always welcome to contact us for questions about performance and solutions for your machine or anything else. You can read more about how to contact us here. You can find us in Denmark, the UK, Germany and Hong Kong.

See our other hygienic components and machinery parts

Our product range includes Certified EHEDG standard components, such as Machine leveling feet with solid base plate, Industrial machine leveling feet in stainless steel, Adjustable feet with composite material base plate and Stainless industrial caster Noise reducing castor, alongside IP67 Waterproof bearing house units, Sealed Stainless Steel Bearing Units, Bearing units in IP54 composite housing, Mounted ball bearing house units and Mini Bearing Units in Stainless Steel as well as Hygienic machinery components in stainless steel and Conveyor components and side guides.

All crafted in hygienic stainless steel design for Food and beverage industry, Pharmaceutical manufacturing, Biotechnology industry, Cosmetics and personal care technology, Healthcare and medical device manufacturing, Dairy industry, Pet food processing industry, Meat and poultry processing industry, Seafood processing industry, Fruit and Vegetable processing industry, Snack food processing industry, Frozen food manufacturing industry, Cereal and grain processing industry, Baby food industry, Pastry and dough processing technology industry, Ice cream and frozen dessert industry, Coffee and chocolate processing technology, Sweets and snacks processing industry, Confectionery processing technology industry, production and packaging technology.