3-A Certification for Sanitary Food Equipment

The roots of hygienic equipment design standards trace back to the 1920s when the first standards for dairy industry equipment emerged. These standards, known as “3-A standards,” were the result of collaboration among three key interest groups: regulatory sanitarians, equipment fabricators, and processors. Together, they worked to enhance equipment design and sanitation practices.

Reliable and Competitive 3-A Certification

3-A SSI plays a crucial role in maintaining and advancing hygienic equipment design standards. It manages an extensive inventory of design criteria for equipment and processing systems, oversees the 3-A Symbol Authorization program, and offers other voluntary certificates to affirm the integrity of hygienic processing equipment and systems.

3-A certification is important for several reasons:

- High Standards of Hygiene: 3-A certification ensures that equipment and components meet rigorous sanitary standards established by industry experts. This helps to maintain high levels of hygiene in food processing, beverage production, and pharmaceutical manufacturing.

- Regulatory Compliance: Many regulatory agencies, including the U.S. Food and Drug Administration (FDA), recognize 3-A certification as a benchmark for hygienic design. Compliance with 3-A standards helps manufacturers meet regulatory requirements and ensure the safety and quality of their products.

- Consumer Confidence: Consumers are increasingly concerned about food safety and hygiene. Products bearing the 3-A symbol provide reassurance that they have been manufactured using equipment that meets stringent sanitary standards, enhancing consumer confidence in the safety and quality of the products they purchase.

- Reduced Risk of Contamination: 3-A certified equipment is designed with features that minimize the risk of contamination, such as smooth surfaces, sanitary welds, and easy-to-clean designs. This helps to prevent microbial growth, allergen cross-contamination, and other food safety hazards.

- Prevention of Product Recalls: By using 3-A certified equipment, manufacturers can reduce the risk of product recalls due to contamination issues. This protects their brand reputation, minimizes financial losses, and helps to maintain customer trust.

- Operational Efficiency: 3-A certified equipment is designed for easy cleaning, maintenance, and sanitation, which improves operational efficiency and reduces downtime in food processing facilities.

- Global Recognition: While 3-A certification is primarily recognized in North America, it is also respected internationally as a symbol of quality and compliance with hygienic design standards. This facilitates trade and market access for manufacturers operating in global supply chains.

Overall, 3-A certification plays a crucial role in ensuring food safety, regulatory compliance, and consumer confidence in the food and beverage industry. It helps manufacturers meet industry standards, mitigate risks, and maintain the highest levels of hygiene throughout the production process.

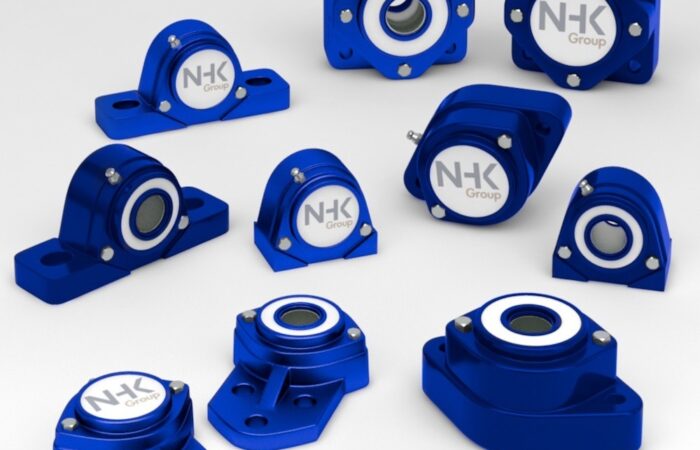

IP67 Waterproof bearing units with spherical inserts | NHK Machinery Parts

Waterproof IP67 bearing house | Order | NHK Machinery Parts

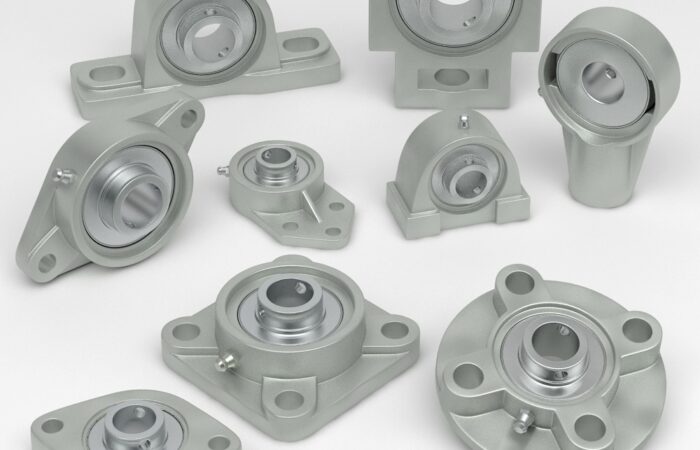

Certified hygienic components | Order | NHK Machinery Parts