Why is 3-A Sanitary Standards Certification Important?

In the food, beverage, and pharmaceutical industries, maintaining the highest standards of hygiene and safety is paramount. One crucial certification that helps ensure these standards is the 3-A Sanitary Standards certification. This certification is essential for equipment and systems used in these industries, guaranteeing that they meet strict hygiene and safety criteria. In this article, we will delve into the importance of the 3-A Sanitary Standards certification, highlighting its significance through detailed explanations and real-world case studies. The 3-A Sanitary Standards, Inc. (3-A SSI) develops and maintains standards for hygienic equipment design in the food, beverage, and pharmaceutical industries. The certification process involves rigorous testing and evaluation to ensure that equipment meets these high standards. The primary goal is to promote food safety and public health by ensuring that equipment is designed and fabricated in a way that can be easily cleaned and sanitized. The 3-A Sanitary Standards certification plays a critical role in ensuring food safety. By adhering to these standards, manufacturers can minimize the risk of contamination and ensure that their products are safe for consumption. The certification process evaluates various aspects of equipment design, including materials, construction, and surface finish, to ensure they meet stringent hygienic requirements. Equipment that meets 3-A Sanitary Standards is not only hygienic but also reliable. The certification process ensures that the equipment is designed for easy cleaning and maintenance, reducing downtime and increasing operational efficiency. This reliability is crucial in industries where equipment failure can lead to significant financial losses and safety risks. In many regions, compliance with 3-A Sanitary Standards is mandatory for equipment used in the food, beverage, and pharmaceutical industries. Obtaining 3-A certification helps manufacturers comply with local and international regulations, avoiding legal issues and potential fines. It also demonstrates a commitment to quality and safety, which can enhance a company’s reputation and marketability. Consumers are increasingly concerned about the safety and quality of the products they consume. By obtaining 3-A Sanitary Standards certification, manufacturers can build trust with their customers, reassuring them that their products are produced using the highest hygienic standards. This trust can lead to increased customer loyalty and a stronger brand reputation. A dairy processing plant sought 3-A Sanitary Standards certification to ensure the safety and quality of its products. By upgrading its equipment to meet 3-A standards, the plant reduced the risk of contamination and improved its cleaning processes. As a result, the plant saw a significant decrease in product recalls and an increase in consumer confidence. A beverage manufacturer faced challenges with equipment reliability and frequent maintenance issues. After obtaining 3-A Sanitary Standards certification for its equipment, the company experienced fewer breakdowns and reduced maintenance costs. The improved equipment reliability also allowed the company to increase production and meet growing demand. A pharmaceutical company needed to comply with stringent regulatory requirements for its production equipment. By achieving 3-A Sanitary Standards certification, the company ensured compliance with industry regulations and enhanced the safety and efficacy of its products. This certification also helped the company expand into new markets with strict regulatory standards. A food processing facility aimed to improve its sanitation practices and reduce the risk of contamination. By implementing 3-A Sanitary Standards certified equipment, the facility achieved higher levels of cleanliness and hygiene. The certification also streamlined the cleaning process, saving time and resources while maintaining high safety standards. The 3-A Sanitary Standards certification is a vital component in ensuring the safety, reliability, and compliance of equipment used in the food, beverage, and pharmaceutical industries. By adhering to these standards, manufacturers can enhance their operational efficiency, build consumer trust, and meet regulatory requirements. The case studies presented here illustrate the tangible benefits of obtaining 3-A Sanitary Standards certification, highlighting its importance in maintaining the highest standards of hygiene and safety.

Why 3-A Sanitary Standards Certification Matters

Understanding 3-A Sanitary Standards Certification

Ensuring Food Safety

Enhancing Equipment Reliability

Compliance with Regulations

Building Consumer Trust

Case Studies

Case Study 1: Dairy Processing Plant

Case Study 2: Beverage Manufacturer

Case Study 3: Pharmaceutical Company

Case Study 4: Food Processing Facility

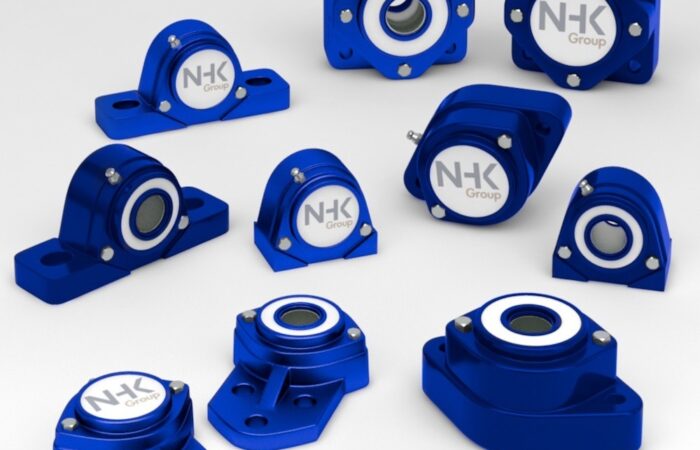

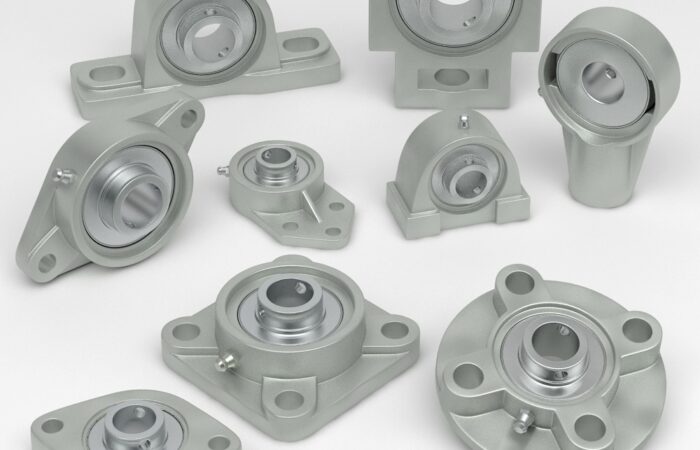

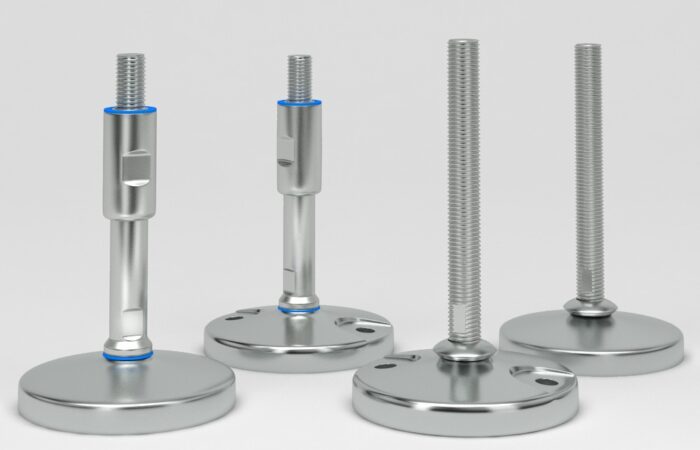

3A SSI Certified components | Order | NHK Machinery Parts

Contact

Articles