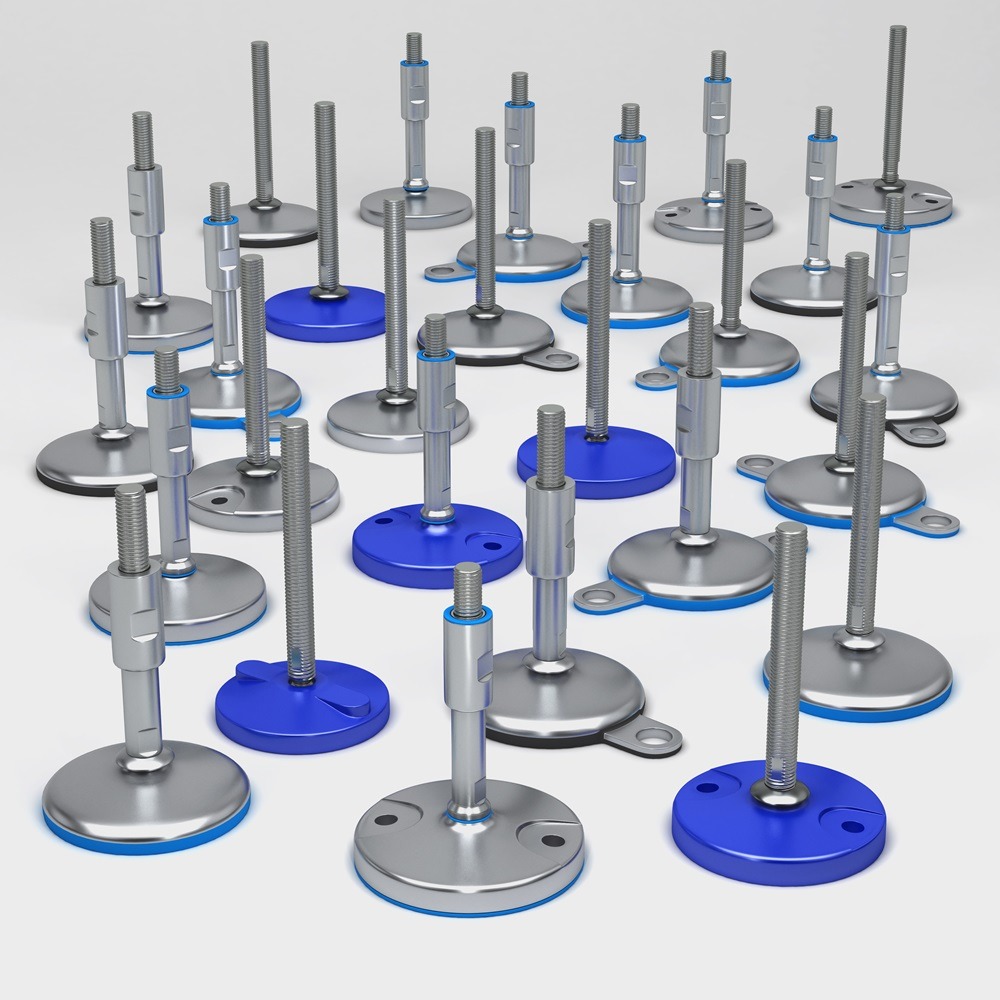

The Role of Stainless Steel Adjustable Feet in Key Industries

In industries with stringent hygiene and operational demands—such as food processing, packaging, pharmaceuticals, and biotechnology—choosing the right components is integral to operational efficiency and regulatory compliance. Among these components, stainless steel adjustable feet play a critical yet often overlooked role in stabilizing and supporting machinery. This article explores how these versatile, hygienic components enhance performance across sectors and how strategic planning with these components can lead to greater productivity, regulatory compliance, and operational longevity. Stainless steel adjustable feet are ideal for industries where hygiene, durability, and adjustability are paramount. Made from high-grade stainless steel, these feet resist corrosion and contamination, even in humid, chemical, or extreme environments. They allow machinery to remain level, stable, and secure, which reduces wear on equipment, lowers vibration, and ensures a consistent performance level. For industries that prioritize sanitary standards, such as pharmaceuticals and food production, adjustable feet certified with IP67 or IP69K ratings provide additional protection by being waterproof and dust-tight. In the packaging industry, efficiency is crucial, as high-speed production lines process thousands of items daily. Packaging equipment must be stable and adaptable to different product sizes and weights. Stainless steel adjustable feet enable the machines to maintain this stability on uneven surfaces and adjust quickly between product lines. Strategically investing in these components can increase uptime by reducing the risk of equipment shifts or vibrations, which can misalign packaging materials. This ensures consistent packaging quality and minimizes product damage, thereby reducing waste and increasing operational efficiency. In food processing, hygiene is a top priority. From meat and dairy to baby food, all food products must be processed in sterile environments to prevent contamination. Stainless steel adjustable feet, especially those certified for hygienic design, provide a reliable, easy-to-clean solution that meets stringent food safety standards such as EHEDG (European Hygienic Engineering & Design Group) and FDA guidelines. These feet help avoid microbial growth by minimizing surface irregularities and allowing for easy drainage of cleaning solutions. Strategic implementation of adjustable feet designed for hygiene ensures compliance with safety regulations, reducing the risk of costly recalls and maintaining consumer trust. The pet food and baby food sectors also benefit significantly from stainless steel adjustable feet. Pet and baby food processing facilities are held to rigorous hygiene and safety standards, as both pet and infant food must be free from contaminants to protect vulnerable consumers. Adjustable feet keep equipment secure and level, reducing the potential for mechanical failures or contamination from floor-level particles. With growing regulatory oversight on product safety, choosing stainless steel adjustable feet with IP67 waterproof ratings provides an extra layer of sanitation assurance. Such strategic planning not only meets safety requirements but also supports brand reputation by aligning with consumer expectations for high-quality, safe products. For pharmaceutical and medical applications, precision and cleanliness are vital. Equipment used in these sectors, such as tablet presses, mixing tanks, and capsule fillers, requires unwavering stability to maintain product consistency and meet regulatory standards. Stainless steel adjustable feet contribute to this stability while meeting ISO cleanroom standards by ensuring that no particles or dust are trapped in or around equipment bases. Furthermore, they can withstand rigorous cleaning cycles involving potent disinfectants, thus ensuring the equipment’s cleanliness over time. By incorporating these adjustable feet in strategic equipment planning, pharmaceutical manufacturers can lower maintenance costs, reduce downtime, and ensure consistent product quality. In cosmetics and biotechnology, where chemical stability and cleanliness are critical, stainless steel adjustable feet offer an ideal solution. Equipment in these industries often handles various compounds that can be corrosive or hazardous if spilled. Stainless steel adjustable feet are resistant to corrosion from chemicals, allowing for a safe, clean, and stable workspace. Additionally, in biotechnology, the importance of cleanroom environments and sterility cannot be overstated. Adjustable feet designed to withstand chemical cleaning agents while providing support for complex machinery, such as bioreactors and centrifuges, enable reliable operations that align with stringent regulatory standards. Implementing stainless steel adjustable feet in strategic planning yields numerous operational benefits: Selecting the ideal stainless steel adjustable feet requires consideration of several factors: By aligning these choices with your strategic goals, companies can leverage stainless steel adjustable feet to improve operational resilience and meet regulatory demands efficiently. Incorporating stainless steel adjustable feet as part of a strategic planning framework is a wise investment for industries ranging from food processing to biotechnology. These components provide unmatched stability, hygiene, and durability, ensuring equipment longevity and operational excellence. As these industries continue to evolve and face increased regulatory pressures, having reliable, adaptable, and compliant machinery components like stainless steel adjustable feet is essential for both daily operations and long-term success. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Bearing Housings and Direct Mount Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440 Grade Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Strategic Planning and Development: The Role of Stainless Steel Adjustable Feet in Key Industries

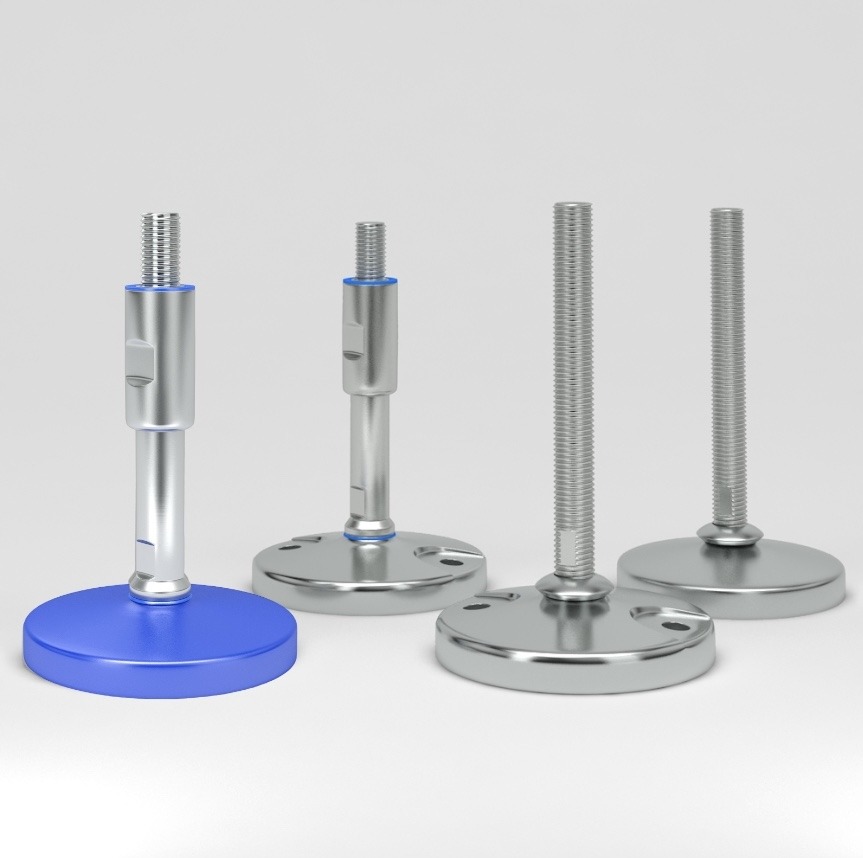

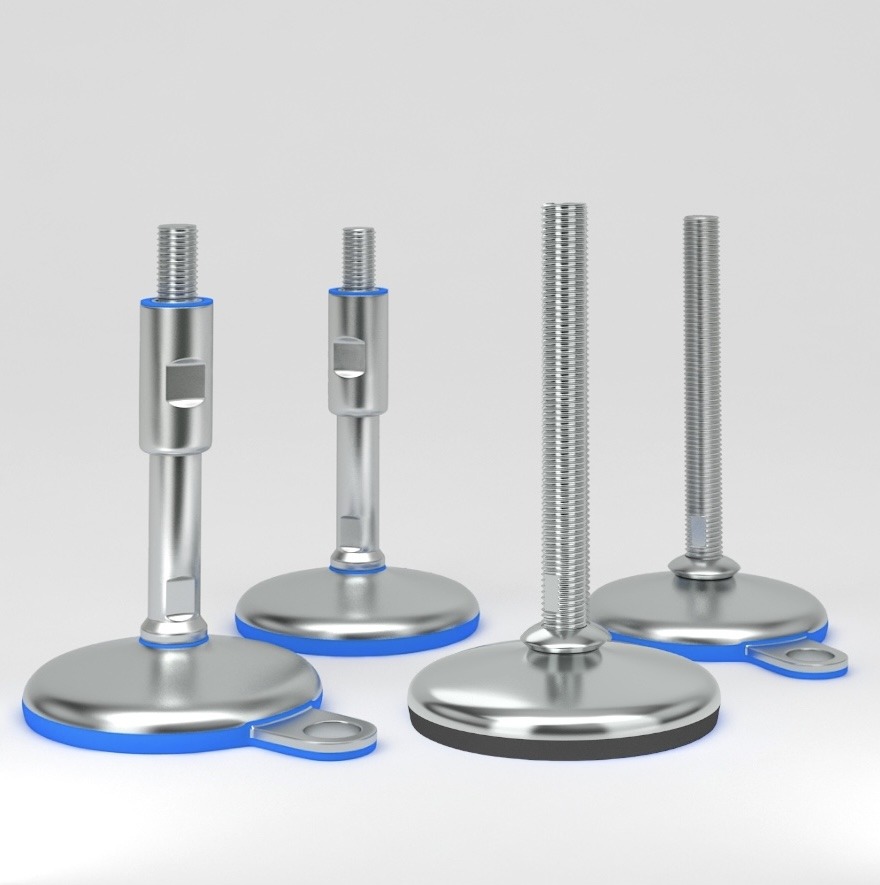

Why Stainless Steel Adjustable Feet?

The Strategic Advantage of Stainless Steel Adjustable Feet in Packaging

Enhancing Hygiene and Compliance in Food Processing

Stability and Sanitation in Pet and Baby Food Industries

Supporting the Pharmaceutical and Medical Sectors

Optimizing Cosmetic, Chemical, and Biotechnology Operations

Benefits of Strategic Planning with Stainless Steel Adjustable Feet

Choosing the Right Stainless Steel Adjustable Feet for Your Needs

The Role of Stainless Steel Adjustable Feet in Key Industries

Contact

Understanding Machinery Components & Protection Standards