Understanding the Importance of Stainless Steel Machine Leveling Feet in Food Processing

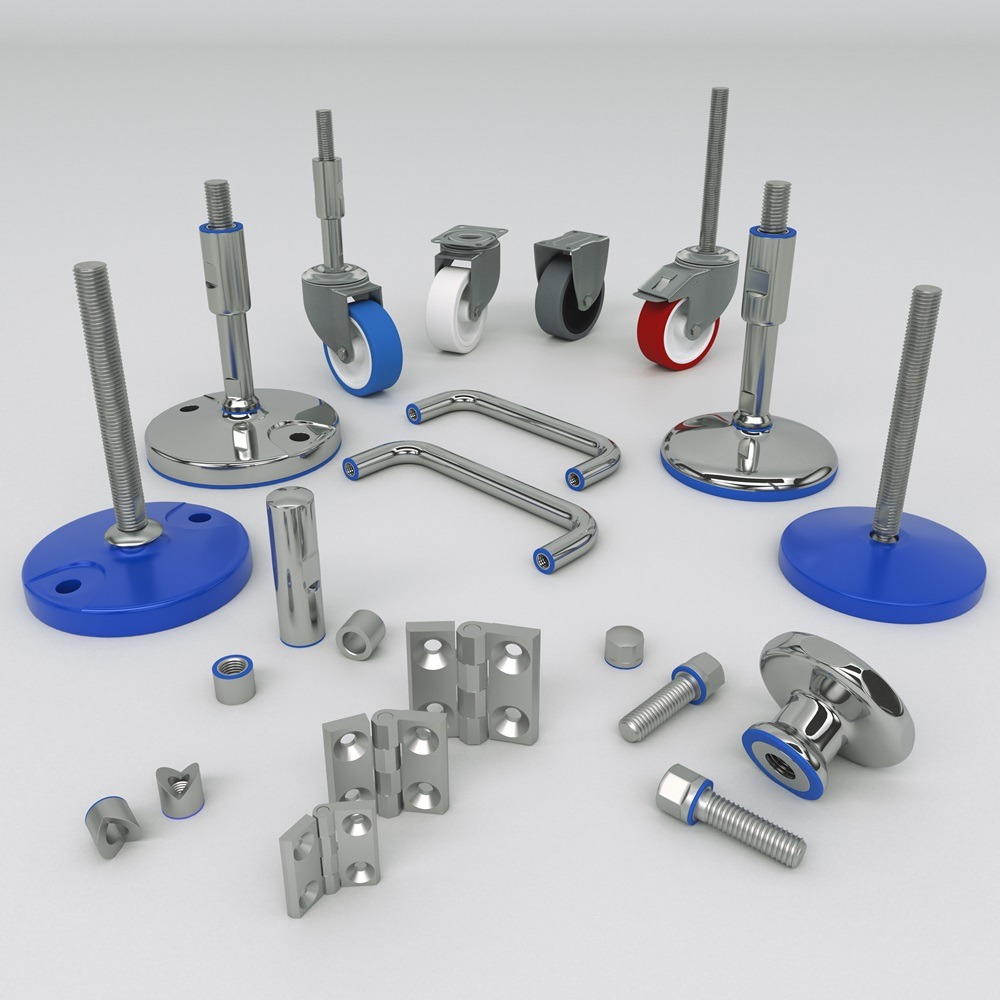

Certified stainless steel machine leveling feet ensure machines stay stable and aligned, critical for modular conveyors, food processing conveyors, parts conveyors, and other essential equipment in a production line. Designed to withstand demanding environments, leveling feet maintain a smooth operation of food packaging conveyors, parts separators, and packaging conveyors, ensuring alignment across modular conveyor systems. This attention to detail optimizes production flow and reduces downtime.

For strategic planning in machine construction, the adoption of certified stainless steel leveling feet supports key industry requirements such as food safety, cleanliness, and regulatory compliance. Stainless steel is resistant to corrosion and rust, making it the ideal choice for applications exposed to moisture, chemicals, and extreme temperature variations. By incorporating certified components into design and development plans, manufacturers are better prepared to meet industry standards, ensuring that their machines remain competitive and reliable over the long term.

Enhancing Flexibility and Scalability with Modular Conveyors and Leveling Feet

One of the foremost trends in food processing and packaging is the demand for flexible, scalable production lines. Modular conveyors, box filling systems, and parts separators need to adapt easily to different product types, batch sizes, and packaging configurations. Certified stainless steel leveling feet add a significant layer of adaptability by supporting easy machine adjustments and reconfiguration. For example, modular conveyors used in food packaging and processing often require height adjustments to accommodate different product lines. With stainless steel leveling feet, manufacturers can make these adjustments seamlessly, avoiding extensive downtime.

Certified leveling feet contribute to a future-proof design by allowing food processing conveyors and other machinery to be realigned or relocated with minimal disruption. This is particularly advantageous for facilities that frequently switch between various product types and packaging needs. By planning with scalability and flexibility in mind, manufacturers can reduce long-term costs and avoid unnecessary retrofitting.

Supporting Food Safety and Compliance with Hygienic Design

In the food industry, every component used in machine design must align with stringent hygienic standards. Certified stainless steel machine leveling feet are especially valuable for food processing conveyors, parts conveyors, and food packaging conveyors, where cleanliness is paramount. Stainless steel is not only durable but also easy to clean, reducing the risk of contamination and ensuring compliance with food safety regulations. This hygienic aspect is essential in facilities handling perishables, ready-to-eat foods, and other high-risk items.

Hygienic leveling feet are integral to parts separators, packaging conveyors, and box filling systems, as they prevent microbial buildup and allow thorough cleaning processes. Implementing components that adhere to these hygiene standards aligns with strategic planning goals, particularly when manufacturers aim to ensure regulatory compliance and enhance consumer safety. Choosing certified stainless steel components for these critical roles minimizes risks and adds value by aligning production practices with regulatory expectations.

Future-Proofing with Durability and Reduced Maintenance

Food processing environments can be harsh on machinery. Equipment such as parts conveyors, packaging conveyors, and modular conveyors faces frequent exposure to moisture, pressure, and temperature changes. Certified stainless steel machine leveling feet, known for their durability, play an essential role in sustaining this equipment’s longevity. Unlike traditional materials, stainless steel resists wear and tear, reducing the frequency of replacements and maintenance, which translates to lower operational costs.

Durable leveling feet offer strategic value for businesses focused on cost-effective and future-proof machine design. By reducing maintenance needs, stainless steel leveling feet help avoid costly downtime and enhance the overall efficiency of production lines. This stability is crucial for parts separators, box filling systems, and other high-traffic areas in food processing. With durable, reliable leveling components, companies can strategically extend the lifespan of machinery, making their investments more sustainable and predictable.

Strategic Planning for Streamlined Operations and Increased Efficiency

Incorporating certified stainless steel leveling feet into machine design contributes to streamlined operations. When paired with modular conveyors, food processing conveyors, and food packaging conveyors, leveling feet optimize workflow by ensuring machines are perfectly aligned and stable, reducing vibrations and unnecessary wear on parts. This alignment is especially vital for components such as parts separators and box filling systems, where precision is critical to maintaining an uninterrupted workflow.

With the strategic deployment of these leveling feet, manufacturers can achieve higher levels of productivity by eliminating potential operational issues stemming from misalignment or instability. In high-demand environments, such as those handling food packaging, continuous operation is crucial. Stainless steel leveling feet facilitate this by ensuring machines stay firmly in place, reducing the need for frequent adjustments and ultimately boosting the overall efficiency of production lines.

Aligning Machine Design with Evolving Industry Trends

The shift towards sustainable production practices is influencing equipment design across food processing, packaging, and manufacturing industries. Certified stainless steel machine leveling feet play a vital role in aligning machinery with these trends. Their long lifespan, coupled with low maintenance requirements, supports sustainable practices by minimizing waste and lowering resource consumption. For businesses seeking environmentally responsible solutions, these leveling feet are an excellent choice for machines like food processing conveyors, modular conveyors, and parts conveyors.

Furthermore, stainless steel’s recyclability aligns with broader industry goals of reducing carbon footprints and improving sustainability metrics. By incorporating recyclable components, companies can align their machine design and construction strategies with these sustainability goals, enhancing their brand reputation and appeal to eco-conscious consumers and stakeholders.

The Strategic Value of Certified Stainless Steel Leveling Feet in Future-Proof Machine Design

Certified stainless steel machine leveling feet are more than simple support components; they are strategic assets in the design and construction of future-proof, compliant, and efficient machines. From modular conveyors to food packaging conveyors and parts separators, these leveling feet contribute to enhanced flexibility, durability, and hygiene, addressing the unique demands of the food processing and packaging industry.

By prioritizing the use of certified stainless steel components, manufacturers position themselves for success in a competitive, regulation-heavy industry. The stability and adaptability offered by stainless steel leveling feet support long-term strategic goals, allowing businesses to maximize operational efficiency and compliance while reducing maintenance costs. As industry trends evolve towards flexibility, sustainability, and hygiene, these leveling feet provide an invaluable foundation for robust, future-ready machine design.