Strategic Development with Industrial Casters and Leveling Feet

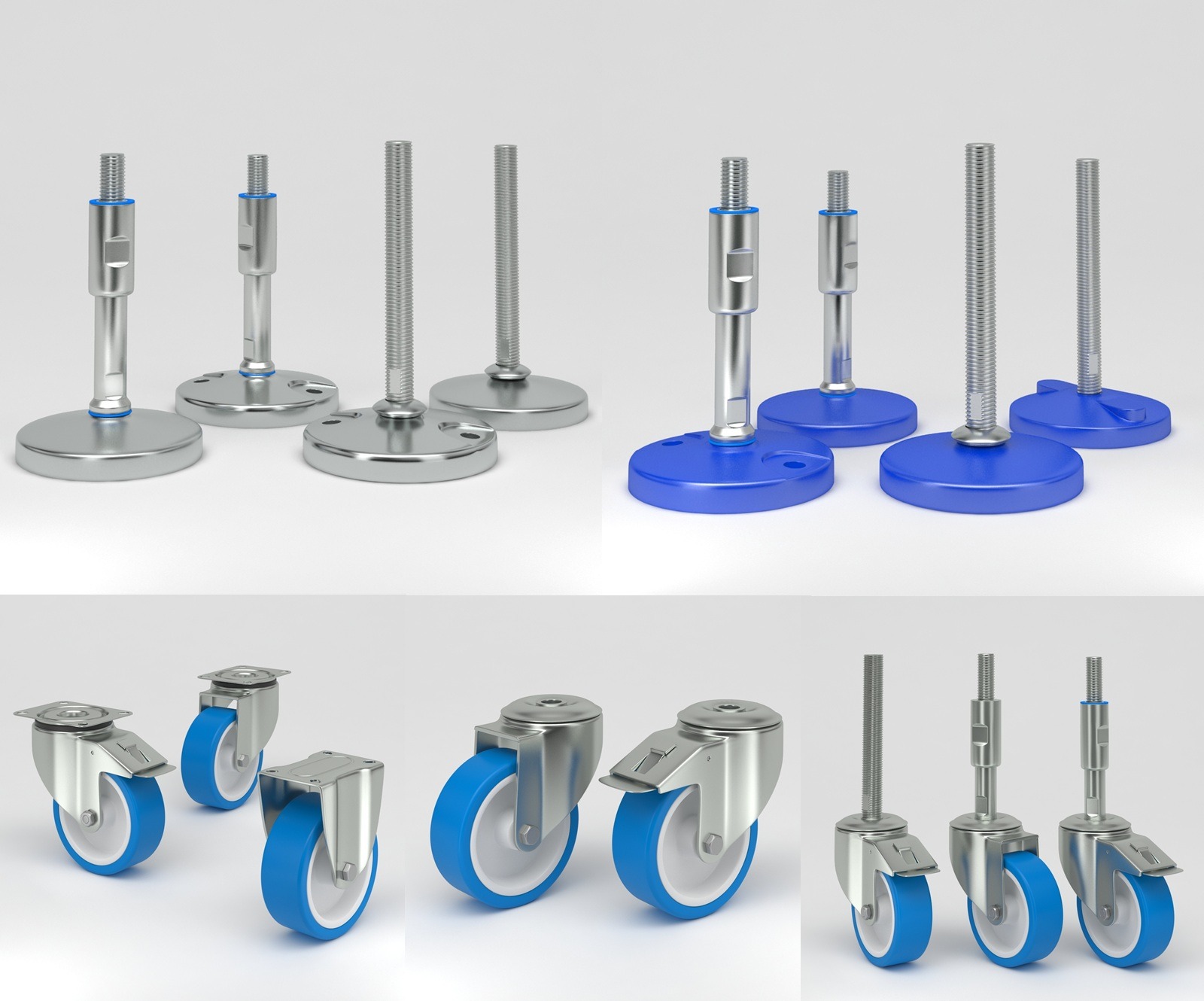

In industries such as packaging, food processing, medical, chemical, healthcare, biotechnology, and sanitation, maintaining stringent hygiene standards is paramount. The integration of industrial casters and leveling feet with hygienic design into strategic planning and development can significantly enhance operational efficiency, safety, and compliance. Hygienic design focuses on creating equipment and components that are easy to clean, minimizing the risk of contamination. In sectors where cleanliness is critical, such as food processing and pharmaceuticals, equipment must be designed to prevent the accumulation of dirt and bacteria. Components like industrial casters and leveling feet play a crucial role in this design philosophy. Industrial casters facilitate the mobility of equipment, allowing for flexible production layouts and easy cleaning access. When designed with hygiene in mind, these casters feature smooth, non-porous surfaces that resist corrosion and are easy to sanitize. For instance, NHK Group offers stainless steel casters ideal for extreme conditions and immense pressure, featuring hygienic designs suitable for industries with stringent cleanliness requirements. Leveling feet provide stability to machinery on uneven surfaces, ensuring optimal operation. In hygienic applications, these components are designed to prevent the buildup of contaminants. Certified hygienic leveling feet, like those from NHK Group, feature self-draining surfaces and sealed movable parts, eliminating exposed threads where bacteria can accumulate. These designs not only enhance cleanliness but also reduce cleaning time and resource consumption. Incorporating industrial casters and leveling feet with hygienic design into strategic planning enhances operational efficiency and safety across various industries. By selecting components that prioritize hygiene, businesses can improve cleanliness, reduce maintenance costs, and ensure compliance with stringent industry standards. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Bearing Housings and Flange Mounted Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440 Stainless Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Strategic Planning and Development with Industrial Casters and Leveling Feet

The Importance of Hygienic Design

Industrial Casters in Hygienic Design

Leveling Feet in Hygienic Design

Strategic Integration in Various Industries

Benefits of Hygienic Components

Optimizing Strategic Hygienic Development in Critical Sanitary Industries

Contact

Understanding Machinery Components & Protection Standards