Embracing Hygienic Certified Components: A Strategic Imperative

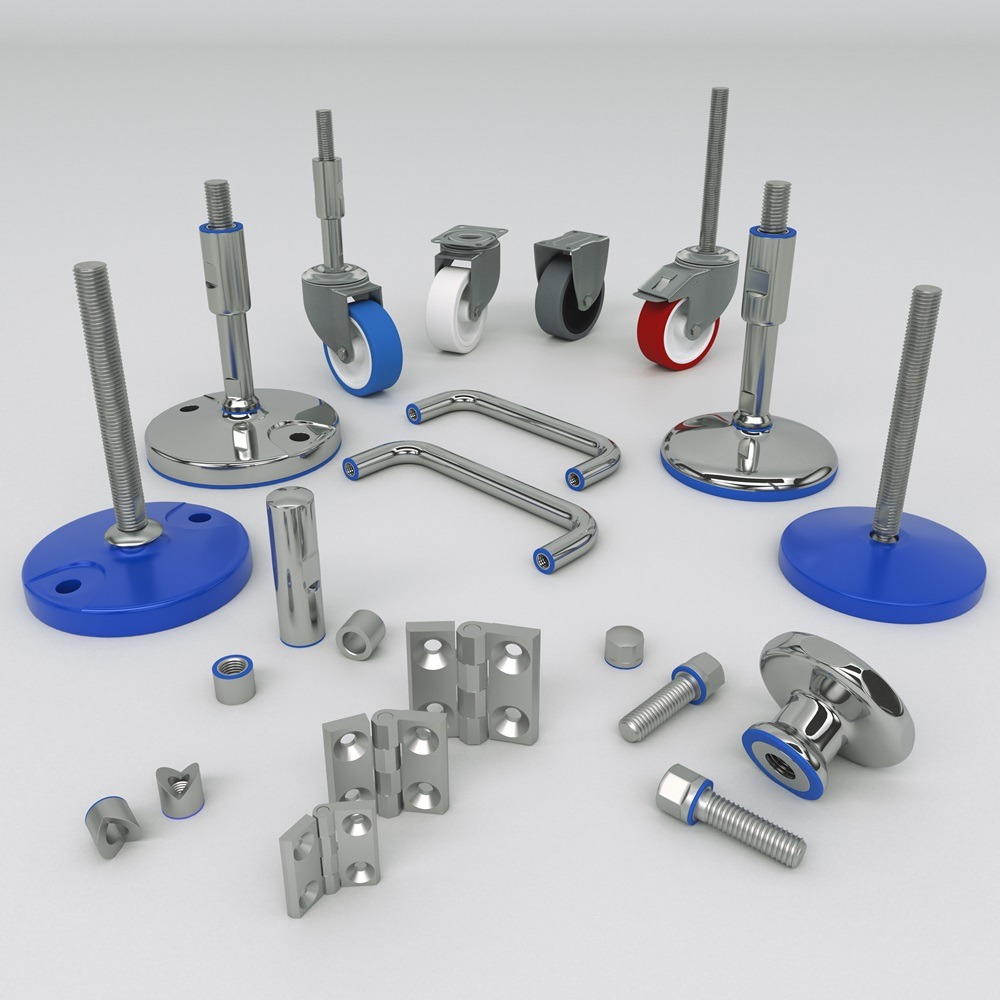

For machine manufacturers, designing processing equipment that uses hygienic certified components is no longer optional but a requirement to meet industry standards. The use of these components ensures a contamination-free environment crucial for products that are highly sensitive to cleanliness, such as baby carrots, baby leaf, and spinach. Certified parts enhance equipment reliability, allowing for efficient processes in leafy vegetable washing, drying, and carrot peeling, to name a few.

By prioritizing hygiene and sanitation in the design phase, manufacturers future-proof their machines for industries with rigorous cleanliness standards, such as vegetable processing and salad washing. For example, employing hygienic components in carrot cutting lines and leafy vegetable drying machinery minimizes microbial contamination, a critical factor in delivering quality products to consumers. Certified components not only provide a high degree of cleanliness but also increase the lifespan of the machines, making them resilient against wear and tear from constant washing and peeling processes.

Future-Proof Development in Vegetable Processing Lines

Future-proof development involves designing vegetable processing lines that are adaptable, easy to maintain, and scalable. The inclusion of hygienic certified parts offers the added benefit of being compatible with various automation technologies, which are essential for processing equipment intended for large kitchens and catering companies. These facilities handle a significant volume of vegetables, and machines designed with hygienic certified parts simplify the extensive cleaning procedures required in high-capacity environments.

Consider a vegetable processing line for potato peeling, carrot processing, and leafy vegetable washing. By utilizing certified components, these machines can handle both the delicate needs of baby leaf and spinach as well as the robust requirements for potato peeling without risking contamination or cross-contamination. This level of versatility allows manufacturers to cater to specific needs, such as those of baby carrot specialists, while also addressing general requirements in vegetable processing.

Ensuring Safety and Compliance with In-House Laboratory & Test Facilities

The development of machinery with hygienic certified parts often relies on rigorous testing and validation processes, which are essential for maintaining high safety standards. For companies specializing in vegetable processing equipment, having in-house laboratory and test facilities is critical to ensuring that machines meet hygiene standards. These facilities enable manufacturers to test components, such as those used in leafy vegetable washing and onion peeling, under conditions that replicate real-world environments.

The ability to conduct extensive product testing in-house ensures that each machine is compliant with industry regulations and equipped to handle specific challenges. For instance, leafy vegetables are notoriously difficult to clean due to their delicate texture and tendency to retain water. Testing allows manufacturers to create washing and drying systems that maintain the quality and freshness of these products while minimizing water retention. This capability reinforces their standing as baby leaf and spinach specialists, ensuring that leafy vegetable washing equipment operates at optimal performance levels without compromising hygiene.

Leveraging Extensive Product & Process Know-How

Strategic planning in machine design for vegetable processing relies heavily on extensive product and process know-how. Manufacturers who specialize in carrot processing, salad washing, and potato peeling understand the unique requirements of each product. Machines for large kitchens and catering operations demand flexibility and reliability across various functions, from carrot cutting lines to potato peeling systems. Manufacturers with deep knowledge of vegetable processing can design adaptable machines that meet the requirements of multiple applications.

For example, designing a machine for carrot peeling involves more than just removing the outer layer. To meet industry demands, equipment must be able to handle high throughput without damaging the product, especially when dealing with baby carrots. Similarly, creating machines for leafy vegetable washing and drying requires expertise in managing delicate products that can bruise or tear easily. Manufacturers with specialized knowledge ensure that their machines provide gentle yet effective cleaning and drying, thus preserving the quality of the vegetables.

Advantages for Machines in Large Kitchens and Catering Operations

Large kitchens and catering operations, which often handle significant volumes of vegetables daily, require processing equipment that combines efficiency, hygiene, and adaptability. Machines designed with hygienic certified components are better suited for these environments due to their easy-to-clean surfaces and high resistance to bacterial growth. In addition, these machines streamline processes for potato peeling, carrot peeling, and leafy vegetable drying, which are essential in preparing large quantities of vegetables quickly and safely.

For these high-demand operations, certified parts reduce downtime for cleaning and maintenance. Equipment like onion peeling and leafy vegetable washing machines can function continuously while meeting strict sanitation standards. The ability to operate without frequent cleaning interruptions is invaluable in large kitchen settings where time is a crucial factor. Additionally, machines equipped with hygienic components require less manual intervention, ensuring a higher degree of consistency and hygiene in the final product.

Sustainable and Future-Proof Equipment for Diverse Applications

Hygienic certified components play a pivotal role in enhancing the sustainability of vegetable processing equipment. These parts are often designed for durability, which minimizes the need for frequent replacements and reduces waste. For vegetable processing equipment used in carrot peeling, potato peeling, and salad washing, this durability translates to a longer lifespan and a more environmentally friendly production process.

Future-proofing also involves ensuring that machines can easily adapt to new industry standards and technological advancements. Hygienic certified components make it easier for manufacturers to upgrade machines for various applications, including onion peeling and leafy vegetable washing, without requiring significant redesigns. For example, as demands shift towards more automated processes, machines with modular designs and certified components can be upgraded to incorporate sensors and IoT features, which enhance process control and monitoring.

Building a Competitive Edge with Hygienic Certified Components

In an industry where hygiene, efficiency, and adaptability are paramount, vegetable processing equipment designed with hygienic certified components provides manufacturers with a competitive edge. Machines for large kitchens and catering, such as those used in potato peeling, carrot processing, and leafy vegetable drying, benefit immensely from the enhanced cleanliness and ease of maintenance that certified parts offer. With a focus on future-proof development, in-house laboratory testing, and extensive process know-how, manufacturers can produce equipment that not only meets today’s stringent hygiene requirements but also adapts to tomorrow’s demands.

By investing in machines with hygienic components, manufacturers can better serve the food processing industry, especially those specializing in delicate produce like baby leaf, spinach, and carrots. This approach ensures that vegetable processing equipment remains efficient, safe, and compliant, fostering an environment of continuous innovation and excellence.