Standard Parts in Hygienic Design

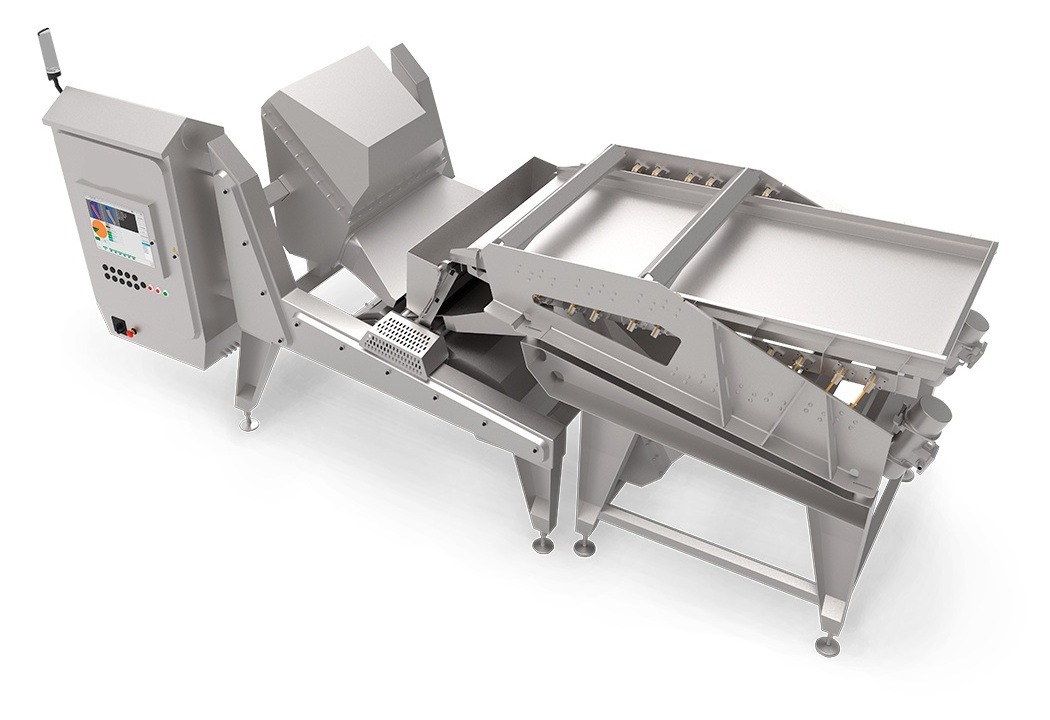

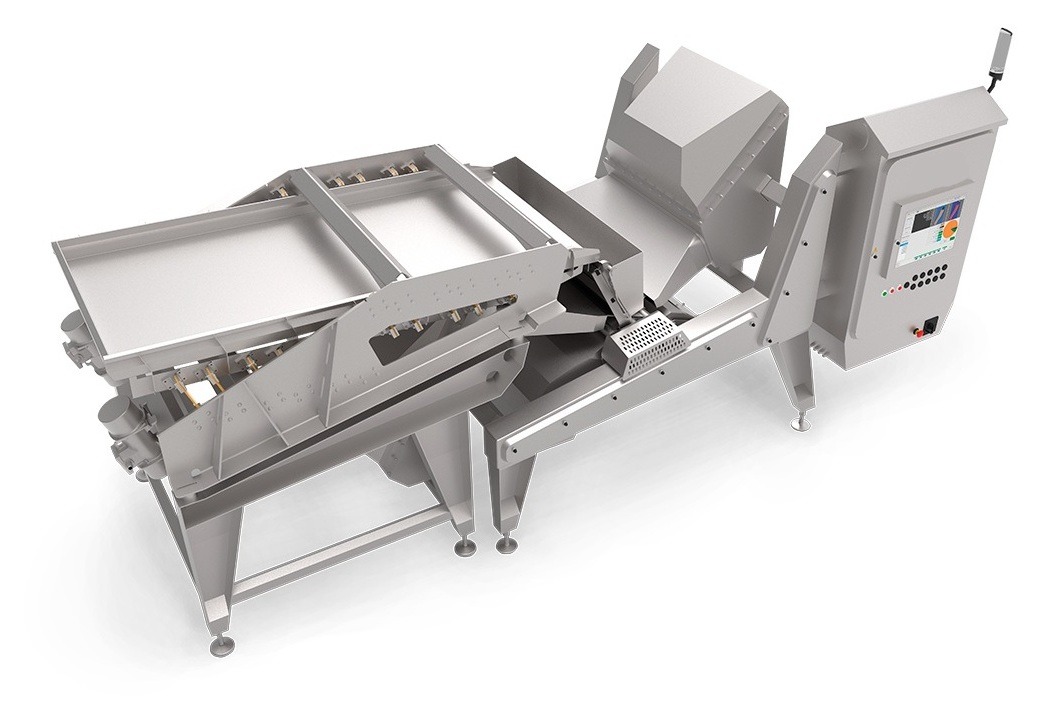

In industries where hygiene is paramount—such as food processing, pharmaceuticals, and biotechnology—ensuring cleanliness and contamination control is a top priority. One of the fundamental aspects of maintaining hygiene is the implementation of standard parts in hygienic design. These components, including knobs, handles, fasteners, and leveling feet, are specifically engineered to meet stringent hygiene standards while also enhancing operational efficiency. This article explores the significance of hygienic standard parts, their role in ensuring cleanliness, and how they contribute to regulatory compliance and resource efficiency. In industries such as food processing, pharmaceuticals, and biotechnology, maintaining stringent hygiene standards is paramount. A critical aspect of this is the implementation of standard parts in hygienic design, which ensures that equipment is not only efficient but also minimizes the risk of contamination. Hygienic design refers to the engineering and configuration of equipment and facilities to meet specific cleanliness standards. This design approach aims to prevent contamination by ensuring that all equipment surfaces are cleanable to a microbiological level. Key principles of hygienic design include: Implementing these principles reduces contamination risks and enhances overall equipment efficiency. Standard parts, such as knobs, handles, leveling feet, and screws, play a vital role in the hygienic design of equipment. These components must adhere to the same stringent hygiene standards as the primary equipment to prevent them from becoming contamination points. Manufacturers like Elesa offer a comprehensive range of standard machine parts designed for hygienic applications, including adjustable handles, knobs, screws, and nuts. Adhering to established standards is crucial in implementing hygienic design. Key organizations and standards include: Utilizing components that meet these standards ensures compliance with regulatory requirements and promotes best practices in hygienic design. Incorporating standard parts designed with hygienic principles is essential for industries where cleanliness and contamination control are critical. By selecting components that adhere to established hygienic design standards, manufacturers can enhance product safety, comply with regulations, and achieve operational efficiencies. Investing in hygienic standard parts is not merely a regulatory obligation but a commitment to quality and consumer safety, ultimately contributing to a company’s success and reputation in the market. Hygienic design refers to the engineering and construction of equipment in a way that minimizes contamination risks and ensures that all surfaces can be cleaned to a microbiological level. This concept is essential in food, pharmaceutical, and chemical industries, where even minor contamination can lead to serious health risks and regulatory penalties. Standard parts play a crucial role in ensuring that hygienic processes remain contamination-free. Traditional components often contain threaded sections, sharp edges, and unsealed joints, all of which create contamination risks. By contrast, hygienic standard parts are specifically designed to eliminate these vulnerabilities. In industries where machinery must be adjusted or operated manually, knobs and handles must be easy to clean and resistant to bacterial growth. Hygienic versions are designed with: Adjustable leveling feet provide stability for machinery while also allowing for easy cleaning underneath equipment. Hygienic models are: Even small fasteners can create hygiene risks if they trap particles or are difficult to clean. Hygienic fasteners: In food and pharmaceutical facilities, equipment doors must be securely closed while also being easy to clean. Hygienic hinges and latches: Hygienic standard parts reduce cleaning time by up to 30% compared to conventional components. Their smooth, sealed surfaces ensure that contaminants do not accumulate, making them easy to sanitize using industry-standard cleaning procedures such as CIP (Clean-in-Place) and SIP (Sterilization-in-Place). Using certified hygienic components minimizes the risk of bacterial contamination, thereby enhancing food safety and reducing the likelihood of recalls due to hygiene breaches. By optimizing cleanability, hygienic parts help businesses: Industries must meet strict hygiene regulations, and using certified standard parts simplifies compliance with organizations such as: When selecting hygienic components, businesses should consider the following factors: ✔ Material Composition – Stainless steel (AISI 304/316) or high-performance plastics like POM (Polyoxymethylene). Leading manufacturers offer certified hygienic standard parts for various industries, ensuring compliance with the latest sanitary requirements. Hygienic standard parts are an essential yet often overlooked element in ensuring cleanliness, safety, and compliance in critical industries. From leveling feet to fasteners, every component must be designed with hygiene in mind to minimize contamination risks and improve operational efficiency. By investing in high-quality, certified hygienic standard parts, businesses can enhance product safety, reduce cleaning costs, and comply with stringent regulatory standards. As the demand for food safety and pharmaceutical-grade cleanliness increases, adopting these components is not just an option—it is a necessity. Are your equipment components truly hygienic? Make the switch to certified hygienic standard parts today for a cleaner, safer, and more efficient operation. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Bearing Housings and Flange Mounted Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440 Grade Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.A Key to Clean and Safe Operations

Enhancing Hygiene and Efficiency

The Essential Role of Standard Parts in Hygienic Design

Understanding Hygienic Design

The Role of Standard Parts in Hygienic Design

Benefits of Using Hygienic Standard Parts

Examples of Hygienic Standard Parts

Industry Standards and Certifications

Understanding Hygienic Design

Key Principles of Hygienic Design

Standard parts used in hygienic environments must be made from materials resistant to corrosion, chemicals, and bacterial growth. Stainless steel (AISI 304 and AISI 316) is the most commonly used material due to its durability, non-reactivity, and ease of cleaning.

Hygienic components must have a surface roughness (Ra) of ≤0.8 µm, ensuring bacteria and dirt cannot accumulate in microscopic crevices. Polished and seamless surfaces further improve cleanability.

Parts must be designed to prevent liquid accumulation, which can harbor bacteria. A minimum 3% slope in components like leveling feet ensures self-draining properties.

Equipment and standard parts should allow tool-free disassembly or have minimal dead zones where contaminants could accumulate.

Components should adhere to standards like:Importance of Standard Parts in Hygienic Design

1. Hygienic Knobs and Handles

2. Hygienic Leveling Feet

3. Hygienic Fasteners (Bolts, Nuts, Screws)

4. Hygienic Hinges and Latches

Benefits of Using Hygienic Standard Parts

1. Improved Cleanability and Hygiene Compliance

2. Enhanced Food and Product Safety

3. Cost and Resource Efficiency

4. Regulatory Compliance

Choosing the Right Hygienic Standard Parts

✔ Certifications – Ensure the component is EHEDG-certified or Sanitary approved.

✔ Application-Specific Needs – Choose parts designed for high-pressure washdowns, corrosive environments, or extreme temperatures if required.

✔ Manufacturer Reputation – Select suppliers with a proven track record in hygienic design.Ensuring Cleanliness, Compliance and Efficiency

Contact

Understanding Machinery Components & Protection Standards