Stainless Steel 420 vs. 440 Bearing Units: A Comprehensive Comparison

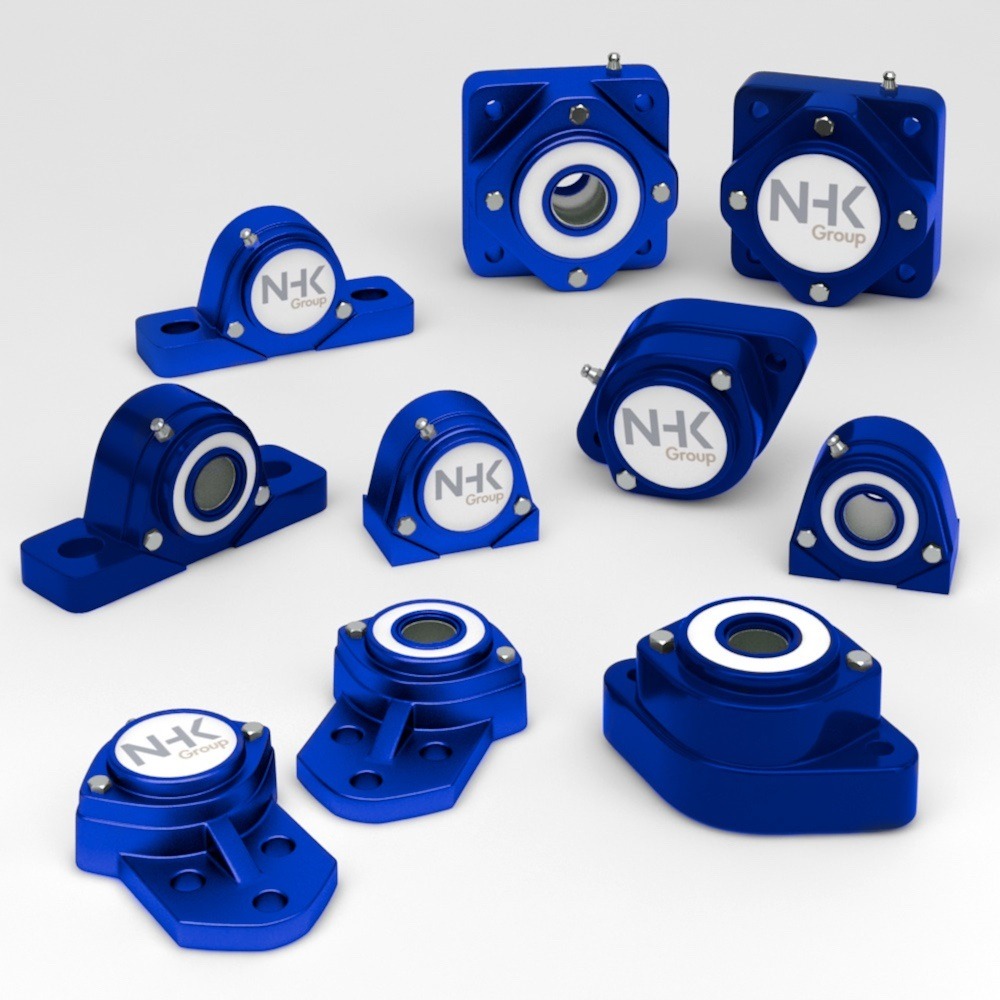

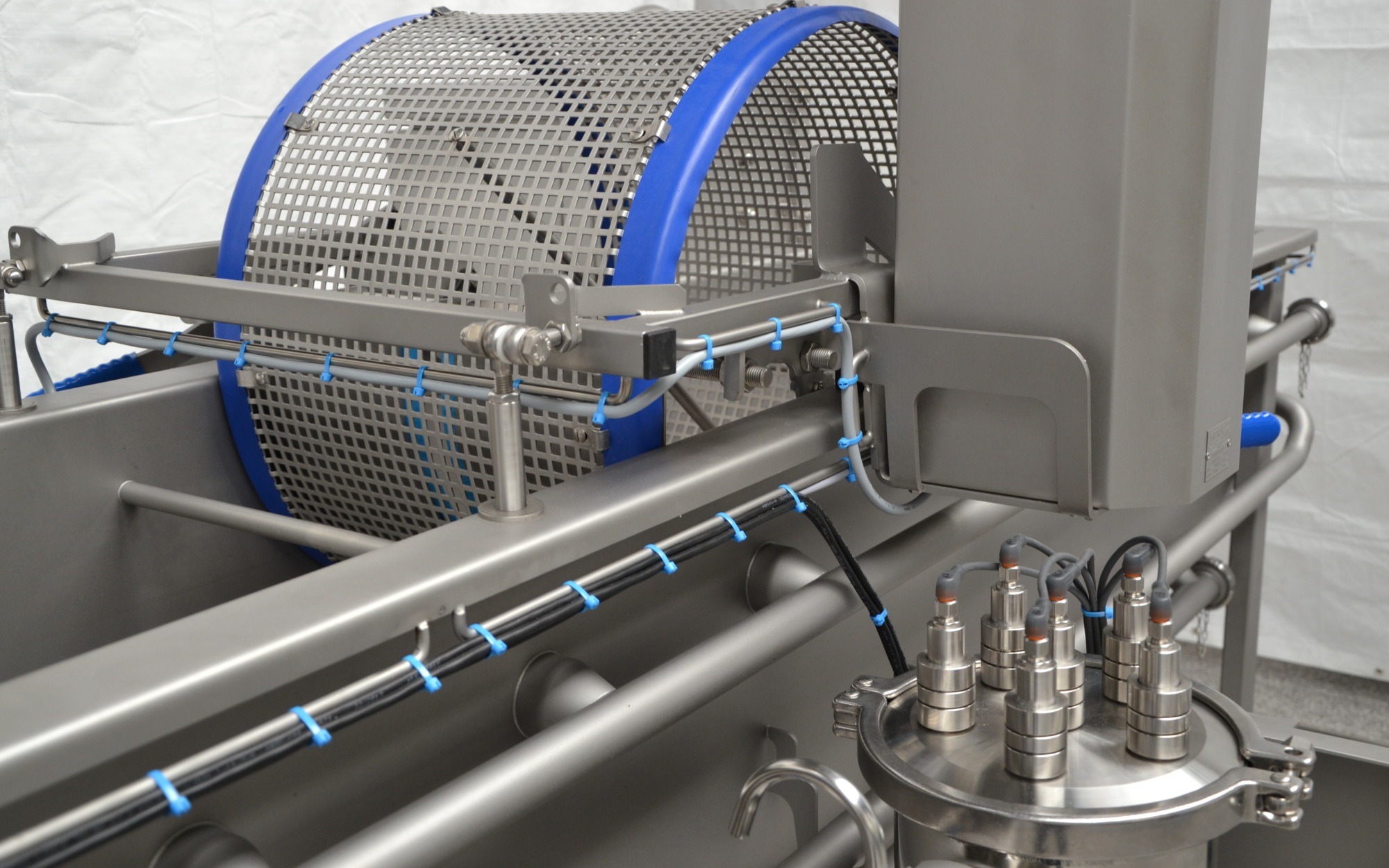

When selecting stainless steel bearing units for industrial applications, the choice between 420 and 440 stainless steel plays a crucial role in determining performance, longevity, and resistance to wear and corrosion. Both materials offer unique benefits, making them suitable for different environments, including food processing, pharmaceutical production, and heavy-duty machinery. This guide will provide a detailed comparison between Stainless Steel 420 and 440 bearing units, examining their properties, applications, advantages, and limitations to help you make an informed decision. Stainless Steel 420 is a martensitic stainless steel with a high carbon content that enhances hardness and wear resistance. It is widely used in applications where moderate corrosion resistance and high strength are required. Stainless Steel 440, particularly 440C, is another martensitic stainless steel with higher carbon content, making it harder and more wear-resistant than 420 stainless steel. It is often used in extreme wear applications. ✔ You need a more cost-effective solution. ✔ You need high wear resistance for heavy loads. Both Stainless Steel 420 and 440 bearing units serve important roles in industrial applications. The decision between these two materials comes down to balancing performance, cost, and environmental conditions. By understanding the key differences and selecting the right material, you can improve machine efficiency, reduce maintenance costs, and enhance long-term reliability. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Blocks and Flanged Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. Stainless Steel 440 and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Performance and Durability

Understanding Stainless Steel 420 and 440

What is Stainless Steel 420?

Key properties of 420 stainless steel:

What is Stainless Steel 440?

Key properties of 440 stainless steel:

Comparing Stainless Steel 420 vs. 440 in Bearing Units

Property Stainless Steel 420 Stainless Steel 440 Hardness (HRC) 48-50 58-60 Corrosion Resistance Moderate High Wear Resistance Moderate Excellent Strength Good Higher than 420 Magnetic Yes Yes Machinability Easier to machine Difficult to machine Cost Lower Higher Corrosion Resistance Comparison

Wear Resistance and Hardness

Machinability and Workability

Cost and Availability

Applications of Stainless Steel 420 vs. 440 Bearing Units

Best Applications for 420 Stainless Steel Bearing Units

Best Applications for 440 Stainless Steel Bearing Units

Which Stainless Steel Bearing Unit Should You Choose?

Choose 420 Stainless Steel If:

✔ The application involves moderate corrosion conditions.

✔ You require easier machinability.

✔ You need a balance between strength and affordability.Choose 440 Stainless Steel If:

✔ The environment involves higher humidity and mild chemicals.

✔ You require superior hardness and durability.

✔ You are using bearings in high-speed applications.Balancing Performance and Cost

Contact

Understanding Machinery Components & Protection Standards