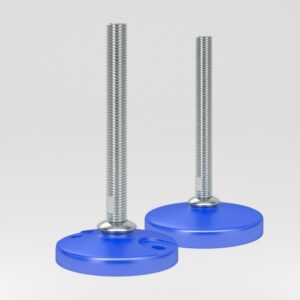

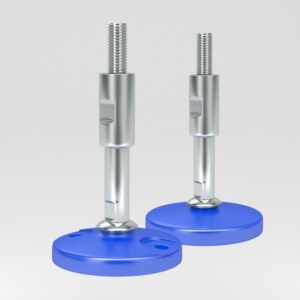

Key Features of Solid Base Machine Leveling Feet

1. High Load Capacity

One of the primary advantages of solid base machine leveling feet is their ability to handle substantial loads. The solid construction distributes weight more evenly, reducing the risk of deformation or failure, which is essential for machines in heavy industries such as manufacturing, food processing, and construction.

2. Vibration Reduction

Machinery vibrations can significantly affect performance and longevity. Solid base leveling feet are designed to absorb vibrations and prevent them from transferring to other components. This feature is particularly valuable in high-precision environments like CNC machining, where even slight vibrations can lead to inaccuracies in production.

3. Corrosion Resistance

Many solid base machine leveling feet are designed with a high level of corrosion resistance. This makes them suitable for environments that experience exposure to moisture, chemicals, or other corrosive substances, such as food processing plants, pharmaceutical manufacturing facilities, or outdoor industrial sites.

4. Easy Adjustability

Despite their sturdy construction, solid base leveling feet allow for easy height adjustment, ensuring that machines can be precisely leveled even on uneven surfaces. This flexibility enhances the efficiency of machine installation and ensures long-term operational stability.

5. Enhanced Durability

Solid base leveling feet are built to withstand the wear and tear of daily industrial use. Their robust design ensures they can handle both the static and dynamic stresses placed on machines, making them a long-lasting solution that reduces maintenance costs over time.

Applications of Solid Base Machine Leveling Feet

Solid base machine leveling feet are versatile components that can be found in a variety of industries. Below are some key applications where these leveling feet shine:

1. Manufacturing Plants

In manufacturing plants, particularly those with heavy-duty equipment like lathes, milling machines, and presses, solid base leveling feet provide the necessary support to keep machinery stable during operation. They help maintain precise alignment, which is crucial for maintaining product quality and minimizing defects.

2. Food Processing and Pharmaceutical Industries

Due to the hygienic requirements of these industries, machines often need to be supported by leveling feet that are easy to clean and resistant to corrosion. Solid base leveling feet, especially those made from stainless steel, meet these stringent standards, ensuring both stability and hygiene.

3. Construction Equipment

Heavy machinery used in construction, such as cranes, loaders, and concrete mixers, require a solid foundation to prevent accidents and ensure safety. Solid base leveling feet provide the strength and stability needed to support this equipment on uneven terrain, reducing the risk of tipping or shifting.

4. Precision Engineering

Industries that rely on precision engineering, such as aerospace, automotive, and electronics manufacturing, demand equipment that operates with extreme accuracy. Solid base leveling feet help eliminate any movement or vibration that could lead to production errors, ensuring optimal performance.

5. Packaging and Conveyor Systems

Conveyor systems are often subjected to continuous movement and heavy loads. Solid base machine leveling feet keep these systems balanced and secure, minimizing the chances of breakdowns or operational inefficiencies.

Advantages of Using Solid Base Machine Leveling Feet

1. Improved Machine Performance

By ensuring stability and eliminating vibrations, solid base leveling feet contribute to better machine performance, leading to higher production rates and improved product quality.

2. Extended Equipment Lifespan

Stabilizing heavy machinery reduces wear and tear on its components. As a result, machines supported by solid base leveling feet tend to have a longer operational lifespan, cutting down on costly repairs and replacements.

3. Enhanced Workplace Safety

Unstable machinery poses a significant risk to workers. Solid base leveling feet ensure that equipment remains firmly in place, reducing the risk of accidents or injuries caused by tipping or shifting machinery.

4. Versatile and Adjustable

Solid base leveling feet can be used in a wide variety of settings, from clean rooms to rugged outdoor environments. Their adjustability allows them to be adapted to different surfaces, ensuring stability in any setting.

5. Cost-Effective Solution

While solid base machine leveling feet may represent a higher upfront cost than lighter alternatives, their durability and low maintenance needs make them a cost-effective solution over the long term.

Choosing the Right Solid Base Machine Leveling Feet for Your Needs

When selecting solid base leveling feet, it’s important to consider factors such as load capacity, material composition, adjustability, and environmental conditions. Whether you need corrosion-resistant models for use in a wet environment or feet capable of handling extremely heavy machinery, there are options to suit your specific requirements.

Consulting with suppliers who specialize in industrial components can help you determine the best solid base leveling feet for your application. Ensuring compatibility with your machinery and operational environment will optimize performance and safety.

Building a Stable Future with Solid Base Machine Leveling Feet

Solid base machine leveling feet are a critical component in industrial settings where stability, precision, and durability are essential. Their ability to support heavy loads, reduce vibrations, and resist corrosion makes them a reliable choice across a variety of industries. By investing in high-quality solid base leveling feet, you can improve machine performance, enhance workplace safety, and reduce maintenance costs, ultimately leading to greater operational efficiency.