What Are Certified Hygienic Feet?

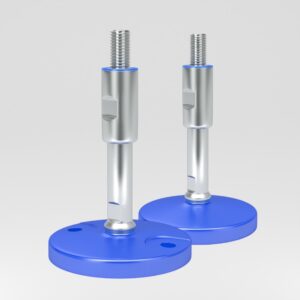

In today’s industrial landscape, where hygiene standards have become increasingly stringent, certified hygienic feet play a vital role in ensuring that machinery operates safely and in compliance with health regulations. Hygienic feet are specialized leveling components designed for use in industries such as food and beverage, pharmaceuticals, and cleanrooms, where maintaining a clean and contamination-free environment is critical.

These components are manufactured from materials and designs that prevent the accumulation of dirt, bacteria, and other contaminants, making them an essential part of sanitary environments. In this article, we’ll explore the key features of certified hygienic feet, their certifications, and their applications across various industries.

What Makes Hygienic Feet “Certified”?

The term certified hygienic feet refers to leveling feet that meet specific regulatory standards and certifications. These certifications often include globally recognized standards from organizations like EHEDG (European Hygienic Engineering and Design Group) and 3-A Sanitary Standards in the United States.

These certifications guarantee that the feet are designed and manufactured to reduce the risk of contamination, often adhering to:

- Smooth surfaces that prevent bacteria from hiding in cracks or crevices

- Non-porous materials such as stainless steel that are easy to clean and resistant to corrosion

- Sealed structures that eliminate areas where dirt and germs can accumulate

- Sloped surfaces to ensure effective drainage of liquids

Additionally, many certified hygienic feet are designed to meet FDA and GMP (Good Manufacturing Practice) standards, further assuring that they are safe for use in industries with high hygiene demands.

Importance of Certifications in Hygienic Feet

For industries where contamination is a significant concern, choosing leveling feet that are certified is non-negotiable. Certifications serve as a mark of reliability and adherence to strict hygiene and safety guidelines. When you see an EHEDG or 3-A certification, you can be confident that the product has passed rigorous testing for:

- Ease of cleaning

- Resistance to chemicals used in cleaning agents

- Durability in hygienic environments

Certifications ensure that the hygienic feet will not contribute to contamination during their service life, safeguarding product integrity and consumer health.

Key Benefits of Certified Hygienic Feet

1. Enhanced Cleanability

Certified hygienic feet are typically designed with smooth, rounded edges and minimal surface area, making them easy to clean. This ensures that dirt, bacteria, and debris do not accumulate, reducing the risk of contamination. Their surfaces are also resistant to harsh cleaning chemicals, allowing for regular cleaning without degrading the material.

2. Durability and Resistance to Corrosion

Industries with high hygiene standards often require frequent cleaning with aggressive chemicals. Hygienic feet are made from materials like AISI 304 or 316 stainless steel, which offer excellent resistance to corrosion, prolonging their lifespan even in harsh cleaning environments.

3. Non-Porous Materials

Non-porous materials, such as stainless steel, prevent the absorption of moisture or liquids that could harbor bacteria. This feature is especially important in food processing plants, where moisture and food particles can create the perfect environment for bacterial growth.

4. Compliance with Hygiene Regulations

Certified hygienic feet ensure compliance with national and international hygiene regulations. By using certified components, companies can meet the demands of HACCP (Hazard Analysis and Critical Control Points) programs and avoid penalties during audits or inspections.

5. Improved Safety

In addition to hygiene, certified feet contribute to the overall safety of machinery and equipment. Their durable construction and resistance to environmental wear and tear reduce the risk of machinery destabilization, which could lead to accidents.

Applications of Certified Hygienic Feet

1. Food and Beverage Industry

In the food and beverage industry, maintaining a contamination-free environment is paramount. Certified hygienic feet are commonly used in equipment such as mixers, conveyors, and packaging machines. Their smooth, non-porous surfaces prevent food particles and liquids from becoming trapped, ensuring compliance with food safety standards.

2. Pharmaceuticals

In pharmaceutical manufacturing, contamination risks can compromise the quality of drugs and lead to costly recalls. Certified hygienic feet are used in equipment that handles everything from production to packaging, reducing the risk of contamination at every step.

3. Cleanrooms and Laboratories

Cleanrooms, often used in biotech and electronics manufacturing, require highly controlled environments. Certified hygienic feet are ideal for cleanroom furniture and equipment because they can be easily sanitized, ensuring that no contaminants are introduced into the sterile environment.

4. Cosmetics Industry

In the cosmetics industry, hygiene is critical during production. Certified hygienic feet are used in mixing, filling, and packaging machines to maintain the cleanliness of the environment and ensure product safety.

Choosing the Right Certified Hygienic Feet for Your Operation

When selecting certified hygienic feet for your operation, it’s important to consider the specific needs of your industry. Here are a few factors to keep in mind:

- Material: Stainless steel (AISI 304 or 316) is often the best choice due to its corrosion resistance and durability.

- Design: Look for feet with a smooth surface and no crevices to minimize contamination risks.

- Certifications: Ensure the feet are certified by recognized organizations like EHEDG or 3-A Sanitary Standards.

- Load capacity: Choose feet that can support the weight of your machinery without compromising hygiene.

Investing in Certified Hygienic Feet

Certified hygienic feet are a critical investment for industries that prioritize hygiene and safety. They provide durability, resistance to contamination, and compliance with strict hygiene standards, ensuring smooth operations and helping companies avoid the risks of contamination. Whether you’re operating in the food, pharmaceutical, or cosmetic industry, the importance of certified hygienic feet cannot be overstated.

By incorporating certified hygienic feet into your operations, you enhance your ability to maintain a clean and safe environment, which is key to meeting industry standards and ensuring the safety of your products.

Questions and contact

Do you have any questions about our products? You are always welcome to contact us for questions about performance and solutions for your machine or anything else. You can read more about how to contact us here. You can find us in Denmark, the UK, Germany and Hong Kong.