Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Stainless threaded rods

Stainless threaded rods

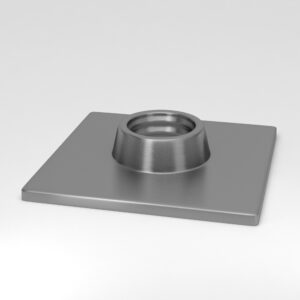

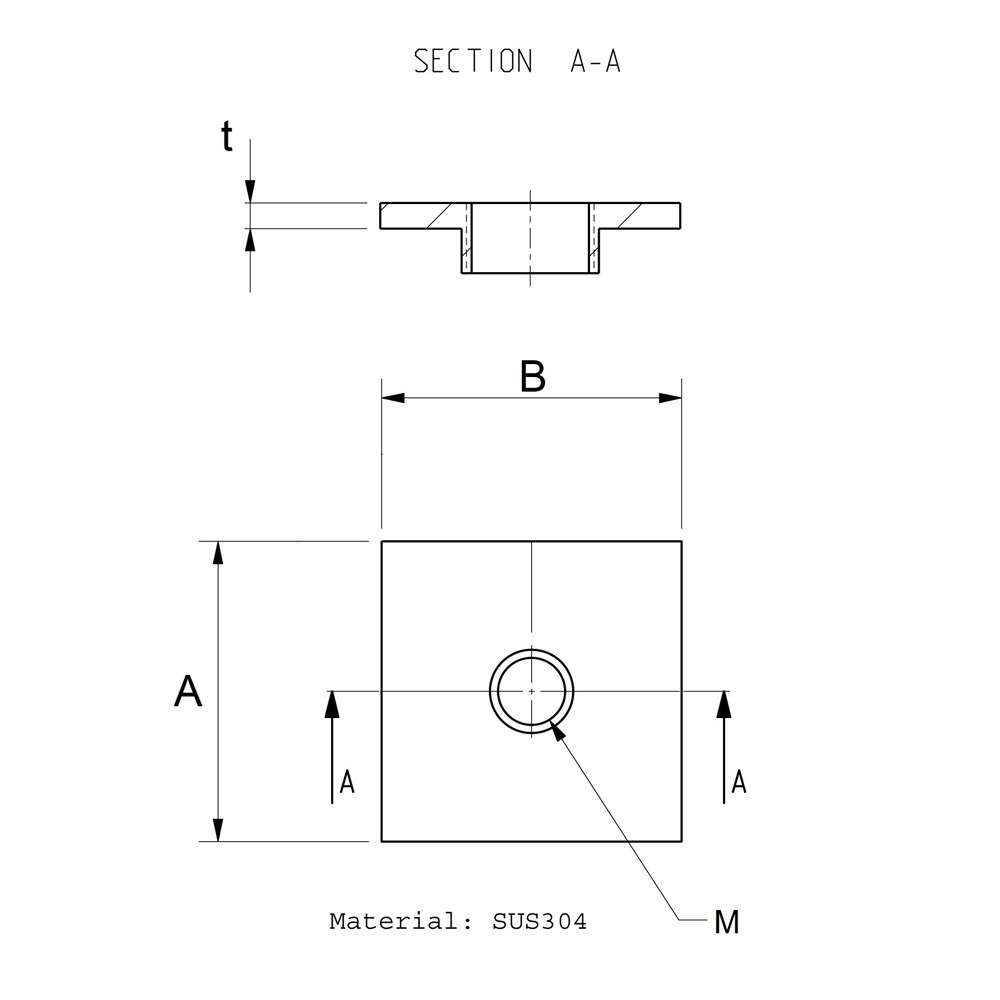

Using stainless steel threaded rods in the food processing, cosmetic, and pharmaceutical industries offers several significant benefits, mainly due to the material’s unique properties. These industries have stringent hygiene and cleanliness standards, and stainless steel is well-suited to meet these requirements.

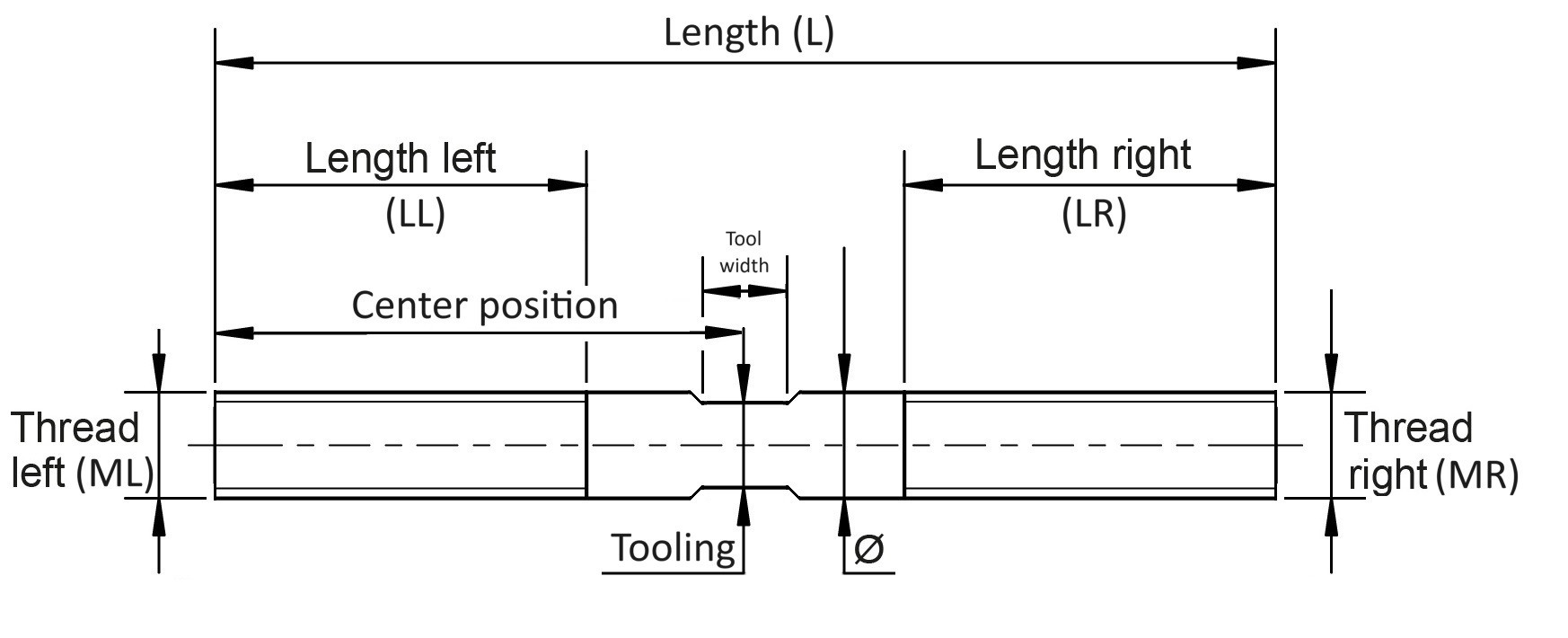

Ordering stainless threaded rods

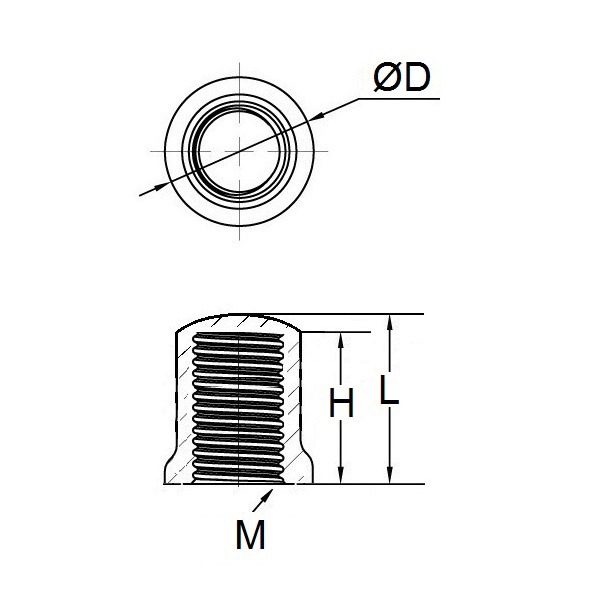

ML Threads left (Mxx)

MR Threads right (Myy)

L length (Lzzz)

Length left (LLpp)

Length right (LRqq)

MLxx-MRyy-Lzzz-LLpp-LRqq

All threaded rods are made to order

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Stainless threaded rods

Using stainless steel threaded rods in the food processing, cosmetic, and pharmaceutical industries offers several significant benefits, mainly due to the material’s unique properties. These industries have stringent hygiene and cleanliness standards, and stainless steel is well-suited to meet these requirements.

Ordering stainless threaded rods

ML Threads left (Mxx)

MR Threads right (Myy)

L length (Lzzz)

Length left (LLpp)

Length right (LRqq)

MLxx-MRyy-Lzzz-LLpp-LRqq

All threaded rods are made to order

Stainless threaded rods

Using stainless steel threaded rods in the food processing, cosmetic, and pharmaceutical industries offers several significant benefits, mainly due to the material’s unique properties. These industries have stringent hygiene and cleanliness standards, and stainless steel is well-suited to meet these requirements.

Ordering stainless threaded rods

ML Threads left (Mxx)

MR Threads right (Myy)

L length (Lzzz)

Length left (LLpp)

Length right (LRqq)

MLxx-MRyy-Lzzz-LLpp-LRqq

All threaded rods are made to order

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.