Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Spacer in stainless steel

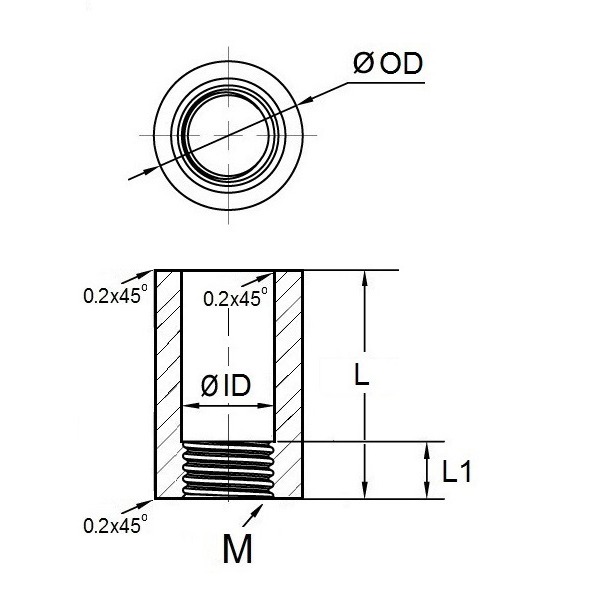

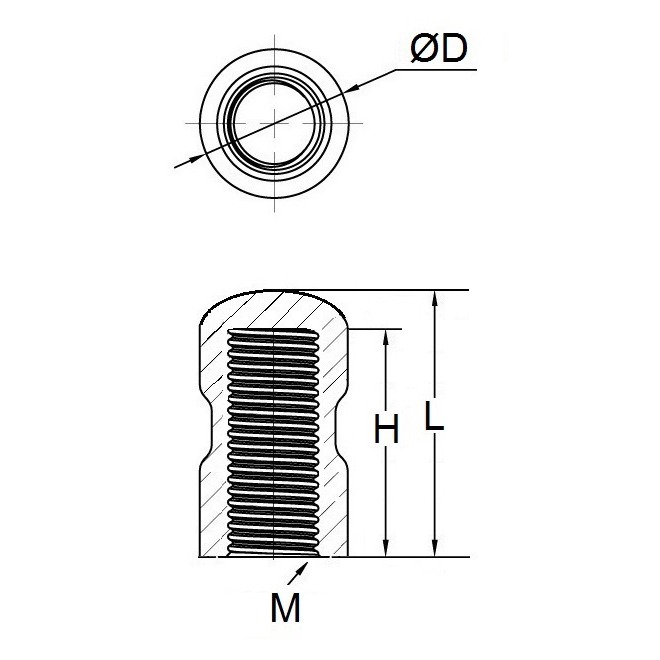

Spacer nut in stainless steel (Aisi 1.4301)

Threaded stainless steel spacer nut (Aisi 1.4301)

Spacer nut M8-16-9 – ID=8.2 – OD=16.0 – L=9 – L1=6

Spacer nut M8-16-18 – ID=8.2 – OD=16.0 – L=18 – L1=12

Spacer nut M10-18-9 – ID=10.2 – OD=18.0 – L=9 – L1=6

Spacer nut M10-18-18 – ID=10.2 – OD=18.0 – L=18 – L1=12

Spacer nut M12-22-9 – ID=12.2 – OD=22.0 – L=9 – L1=6

Spacer nut M12-22-18 – ID=12.2 – OD=22.0 – L=18 – L1=12

Spacer nut M16-26-9 – ID=16.2 – OD=26.0 – L=9 – L1=6

Spacer nut M16-26-18 – ID=16.2 – OD=26.0 – L=18 – L1=12

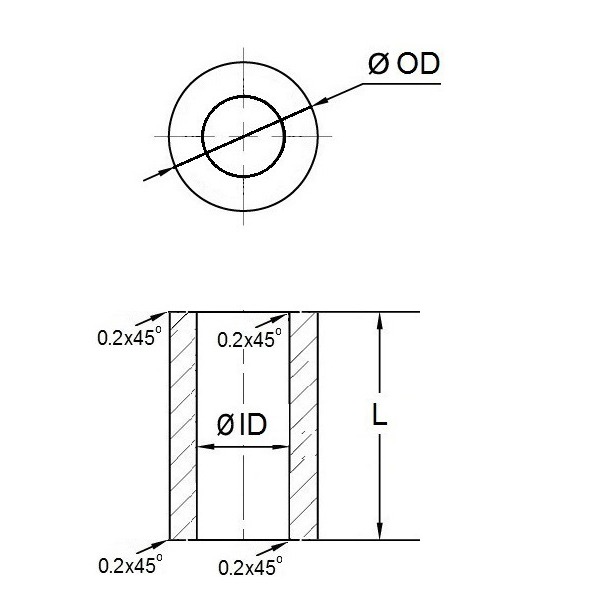

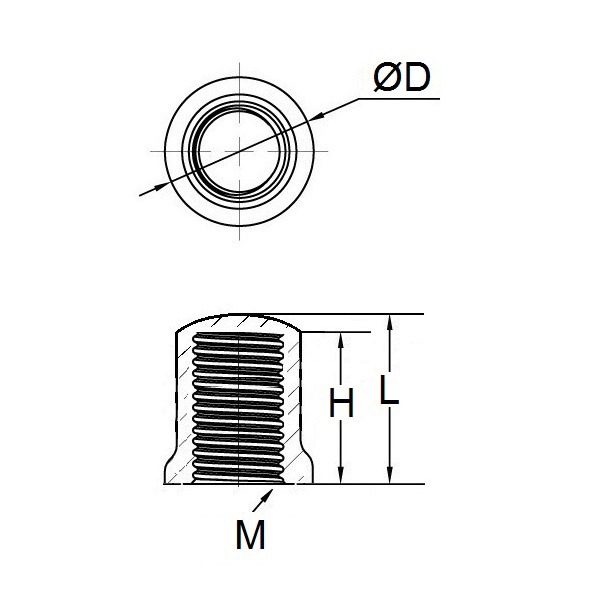

Spacer in stainless steel (Aisi 1.4301)

Spacer 8-16-9 – ID=8.2 – OD=16.0 – L=9

Spacer 8-16-18 – ID=8.2 – OD=16.0 – L=18

Spacer 10-18-9 – ID=10.2 – OD=18.0 – L=9

Spacer 10-18-18 – ID=10.2 – OD=18.0 – L=18

Spacer 12-22-9 – ID=12.2 – OD=22.0 – L=9

Spacer 12-22-18 – ID=12.2 – OD=22.0 – L=18

Spacer 16-26-9 – ID=16.2 – OD=26.0 – L=9

Spacer 16-26-18 – ID=16.2 – OD=26.0 – L=18

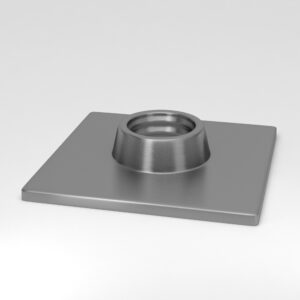

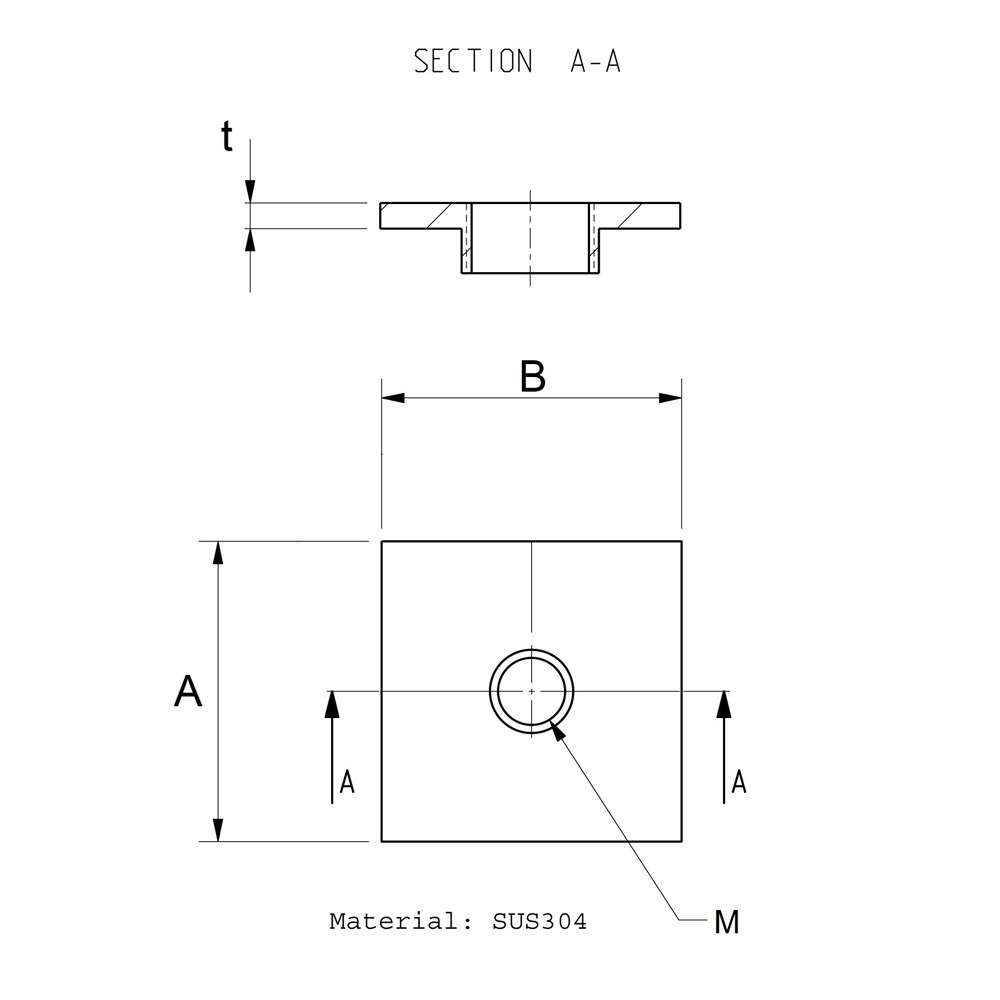

Stainless steel spacer for threading (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Spacer for threads 6.8-16-15 – ID=6.8 – OD=16.0 – L=9

Spacer for threads 6.8-16-25 – ID=6.8 – OD=16.0 – L=18

Spacer for threads 8.5-18-15 – ID=8.5 – OD=18.0 – L=9

Spacer for threads 8.5-18-25 – ID=8.5 – OD=18.0 – L=18

Spacer for threads 10.2-22-15 – ID=10.2 – OD=22.0 – L=9

Spacer for threads 10.2-22-25 – ID=10.2 – OD=22.0 – L=18

Spacer for threads 14.0-26-15 – ID=14.0 – OD=26.0 – L=9

Spacer for threads 14.0-26-25 – ID=14.0 – OD=26.0 – L=18

Machinery components in hygienic design

For other size, please contact us.

Stainless Steel Spacer: Easy-to-Clean Application for Optimal Hygiene

Why Stainless Steel Spacers Are Essential

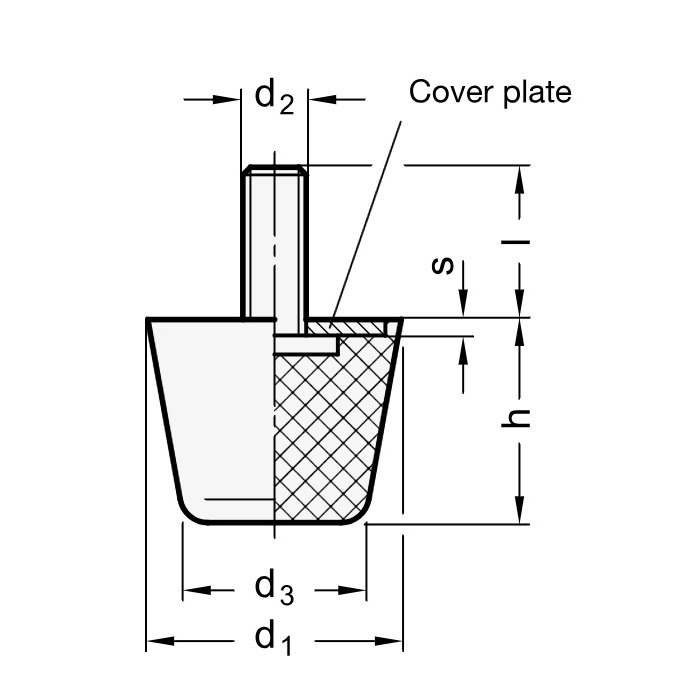

In industries like food processing, pharmaceuticals, and biotechnology, maintaining cleanliness is paramount. Stainless steel spacers offer a robust, hygienic, and easy-to-clean solution, ensuring that machinery and equipment meet stringent sanitary standards. These components not only enhance operational efficiency but also contribute to the longevity of equipment in demanding environments.

Understanding Stainless Steel Spacers

Stainless steel spacers are small but critical components used to maintain precise spacing between machinery parts. Made from high-grade stainless steel, they offer exceptional resistance to corrosion, temperature variations, and wear.

Their smooth, non-porous surface prevents the accumulation of dirt, bacteria, or debris, making them an ideal choice for applications in clean environments. Moreover, their easy-to-clean design simplifies maintenance routines, reducing downtime and operational costs.

Key Benefits of Stainless Steel Spacers

1. Hygienic Design

Stainless steel spacers are engineered with hygiene in mind. Their seamless construction eliminates crevices where contaminants could hide, ensuring compliance with industry standards such as EHEDG and 3-A.

2. Durability

The strength and corrosion resistance of stainless steel make these spacers ideal for use in environments exposed to moisture, chemicals, and high temperatures.

3. Easy Maintenance

With a polished finish, stainless steel spacers are easy to clean and sterilize, helping to maintain a safe and hygienic workspace.

4. Versatility

These spacers are compatible with various machinery types and are widely used across industries like food and beverage, pharmaceuticals, and medical devices.

Applications in Key Industries

Food and Beverage Processing

Stainless steel spacers are integral in equipment like conveyors, mixers, and filling machines, ensuring the machinery remains contamination-free during operation.

Pharmaceutical and Biotechnology

In sterile environments, these spacers help maintain the cleanliness of lab and production equipment, reducing the risk of cross-contamination.

Packaging Industry

Used in sealing, filling, and labeling machines, stainless steel spacers enhance the reliability and cleanliness of packaging processes.

Choosing the Right Stainless Steel Spacer

When selecting stainless steel spacers, consider factors like:

- Material Grade: Look for 304 or 316 stainless steel for superior corrosion resistance.

- Compliance: Ensure the spacers meet industry standards like EHEDG or FDA.

- Customization: Opt for designs tailored to your machinery and operational needs.

Enhancing Efficiency with Easy-to-Clean Spacers

Regular maintenance is simplified with stainless steel spacers, which can withstand rigorous cleaning procedures such as high-pressure washing and exposure to harsh chemicals. Their robust design minimizes wear and tear, ensuring consistent performance.

By incorporating these spacers, businesses can achieve:

- Improved sanitation

- Reduced equipment downtime

- Compliance with regulatory standards

Stainless Steel Spacers: The Ultimate Easy-to-Clean Solution

Stainless steel spacers are an indispensable component in industries requiring stringent hygiene and durability. Their easy-to-clean design, coupled with excellent resistance to harsh environments, makes them a valuable addition to any operation.

Investing in high-quality stainless steel spacers not only ensures equipment reliability but also enhances overall productivity and safety. Upgrade your machinery today to experience the long-term benefits of these exceptional components.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Spacer nut in stainless steel (Aisi 1.4301)

Threaded stainless steel spacer nut (Aisi 1.4301)

Spacer nut M8-16-9 – ID=8.2 – OD=16.0 – L=9 – L1=6

Spacer nut M8-16-18 – ID=8.2 – OD=16.0 – L=18 – L1=12

Spacer nut M10-18-9 – ID=10.2 – OD=18.0 – L=9 – L1=6

Spacer nut M10-18-18 – ID=10.2 – OD=18.0 – L=18 – L1=12

Spacer nut M12-22-9 – ID=12.2 – OD=22.0 – L=9 – L1=6

Spacer nut M12-22-18 – ID=12.2 – OD=22.0 – L=18 – L1=12

Spacer nut M16-26-9 – ID=16.2 – OD=26.0 – L=9 – L1=6

Spacer nut M16-26-18 – ID=16.2 – OD=26.0 – L=18 – L1=12

Spacer in stainless steel (Aisi 1.4301)

Spacer 8-16-9 – ID=8.2 – OD=16.0 – L=9

Spacer 8-16-18 – ID=8.2 – OD=16.0 – L=18

Spacer 10-18-9 – ID=10.2 – OD=18.0 – L=9

Spacer 10-18-18 – ID=10.2 – OD=18.0 – L=18

Spacer 12-22-9 – ID=12.2 – OD=22.0 – L=9

Spacer 12-22-18 – ID=12.2 – OD=22.0 – L=18

Spacer 16-26-9 – ID=16.2 – OD=26.0 – L=9

Spacer 16-26-18 – ID=16.2 – OD=26.0 – L=18

Stainless steel spacer for threading (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Spacer for threads 6.8-16-15 – ID=6.8 – OD=16.0 – L=9

Spacer for threads 6.8-16-25 – ID=6.8 – OD=16.0 – L=18

Spacer for threads 8.5-18-15 – ID=8.5 – OD=18.0 – L=9

Spacer for threads 8.5-18-25 – ID=8.5 – OD=18.0 – L=18

Spacer for threads 10.2-22-15 – ID=10.2 – OD=22.0 – L=9

Spacer for threads 10.2-22-25 – ID=10.2 – OD=22.0 – L=18

Spacer for threads 14.0-26-15 – ID=14.0 – OD=26.0 – L=9

Spacer for threads 14.0-26-25 – ID=14.0 – OD=26.0 – L=18

Machinery components in hygienic design

For other size, please contact us.

Stainless Steel Spacer: Easy-to-Clean Application for Optimal Hygiene

Why Stainless Steel Spacers Are Essential

In industries like food processing, pharmaceuticals, and biotechnology, maintaining cleanliness is paramount. Stainless steel spacers offer a robust, hygienic, and easy-to-clean solution, ensuring that machinery and equipment meet stringent sanitary standards. These components not only enhance operational efficiency but also contribute to the longevity of equipment in demanding environments.

Understanding Stainless Steel Spacers

Stainless steel spacers are small but critical components used to maintain precise spacing between machinery parts. Made from high-grade stainless steel, they offer exceptional resistance to corrosion, temperature variations, and wear.

Their smooth, non-porous surface prevents the accumulation of dirt, bacteria, or debris, making them an ideal choice for applications in clean environments. Moreover, their easy-to-clean design simplifies maintenance routines, reducing downtime and operational costs.

Key Benefits of Stainless Steel Spacers

1. Hygienic Design

Stainless steel spacers are engineered with hygiene in mind. Their seamless construction eliminates crevices where contaminants could hide, ensuring compliance with industry standards such as EHEDG and 3-A.

2. Durability

The strength and corrosion resistance of stainless steel make these spacers ideal for use in environments exposed to moisture, chemicals, and high temperatures.

3. Easy Maintenance

With a polished finish, stainless steel spacers are easy to clean and sterilize, helping to maintain a safe and hygienic workspace.

4. Versatility

These spacers are compatible with various machinery types and are widely used across industries like food and beverage, pharmaceuticals, and medical devices.

Applications in Key Industries

Food and Beverage Processing

Stainless steel spacers are integral in equipment like conveyors, mixers, and filling machines, ensuring the machinery remains contamination-free during operation.

Pharmaceutical and Biotechnology

In sterile environments, these spacers help maintain the cleanliness of lab and production equipment, reducing the risk of cross-contamination.

Packaging Industry

Used in sealing, filling, and labeling machines, stainless steel spacers enhance the reliability and cleanliness of packaging processes.

Choosing the Right Stainless Steel Spacer

When selecting stainless steel spacers, consider factors like:

- Material Grade: Look for 304 or 316 stainless steel for superior corrosion resistance.

- Compliance: Ensure the spacers meet industry standards like EHEDG or FDA.

- Customization: Opt for designs tailored to your machinery and operational needs.

Enhancing Efficiency with Easy-to-Clean Spacers

Regular maintenance is simplified with stainless steel spacers, which can withstand rigorous cleaning procedures such as high-pressure washing and exposure to harsh chemicals. Their robust design minimizes wear and tear, ensuring consistent performance.

By incorporating these spacers, businesses can achieve:

- Improved sanitation

- Reduced equipment downtime

- Compliance with regulatory standards

Stainless Steel Spacers: The Ultimate Easy-to-Clean Solution

Stainless steel spacers are an indispensable component in industries requiring stringent hygiene and durability. Their easy-to-clean design, coupled with excellent resistance to harsh environments, makes them a valuable addition to any operation.

Investing in high-quality stainless steel spacers not only ensures equipment reliability but also enhances overall productivity and safety. Upgrade your machinery today to experience the long-term benefits of these exceptional components.

Spacer nut in stainless steel (Aisi 1.4301)

Threaded stainless steel spacer nut (Aisi 1.4301)

Spacer nut M8-16-9 – ID=8.2 – OD=16.0 – L=9 – L1=6

Spacer nut M8-16-18 – ID=8.2 – OD=16.0 – L=18 – L1=12

Spacer nut M10-18-9 – ID=10.2 – OD=18.0 – L=9 – L1=6

Spacer nut M10-18-18 – ID=10.2 – OD=18.0 – L=18 – L1=12

Spacer nut M12-22-9 – ID=12.2 – OD=22.0 – L=9 – L1=6

Spacer nut M12-22-18 – ID=12.2 – OD=22.0 – L=18 – L1=12

Spacer nut M16-26-9 – ID=16.2 – OD=26.0 – L=9 – L1=6

Spacer nut M16-26-18 – ID=16.2 – OD=26.0 – L=18 – L1=12

Spacer in stainless steel (Aisi 1.4301)

Spacer 8-16-9 – ID=8.2 – OD=16.0 – L=9

Spacer 8-16-18 – ID=8.2 – OD=16.0 – L=18

Spacer 10-18-9 – ID=10.2 – OD=18.0 – L=9

Spacer 10-18-18 – ID=10.2 – OD=18.0 – L=18

Spacer 12-22-9 – ID=12.2 – OD=22.0 – L=9

Spacer 12-22-18 – ID=12.2 – OD=22.0 – L=18

Spacer 16-26-9 – ID=16.2 – OD=26.0 – L=9

Spacer 16-26-18 – ID=16.2 – OD=26.0 – L=18

Stainless steel spacer for threading (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Spacer for threads 6.8-16-15 – ID=6.8 – OD=16.0 – L=9

Spacer for threads 6.8-16-25 – ID=6.8 – OD=16.0 – L=18

Spacer for threads 8.5-18-15 – ID=8.5 – OD=18.0 – L=9

Spacer for threads 8.5-18-25 – ID=8.5 – OD=18.0 – L=18

Spacer for threads 10.2-22-15 – ID=10.2 – OD=22.0 – L=9

Spacer for threads 10.2-22-25 – ID=10.2 – OD=22.0 – L=18

Spacer for threads 14.0-26-15 – ID=14.0 – OD=26.0 – L=9

Spacer for threads 14.0-26-25 – ID=14.0 – OD=26.0 – L=18

Machinery components in hygienic design

For other size, please contact us.

Stainless Steel Spacer: Easy-to-Clean Application for Optimal Hygiene

Why Stainless Steel Spacers Are Essential

In industries like food processing, pharmaceuticals, and biotechnology, maintaining cleanliness is paramount. Stainless steel spacers offer a robust, hygienic, and easy-to-clean solution, ensuring that machinery and equipment meet stringent sanitary standards. These components not only enhance operational efficiency but also contribute to the longevity of equipment in demanding environments.

Understanding Stainless Steel Spacers

Stainless steel spacers are small but critical components used to maintain precise spacing between machinery parts. Made from high-grade stainless steel, they offer exceptional resistance to corrosion, temperature variations, and wear.

Their smooth, non-porous surface prevents the accumulation of dirt, bacteria, or debris, making them an ideal choice for applications in clean environments. Moreover, their easy-to-clean design simplifies maintenance routines, reducing downtime and operational costs.

Key Benefits of Stainless Steel Spacers

1. Hygienic Design

Stainless steel spacers are engineered with hygiene in mind. Their seamless construction eliminates crevices where contaminants could hide, ensuring compliance with industry standards such as EHEDG and 3-A.

2. Durability

The strength and corrosion resistance of stainless steel make these spacers ideal for use in environments exposed to moisture, chemicals, and high temperatures.

3. Easy Maintenance

With a polished finish, stainless steel spacers are easy to clean and sterilize, helping to maintain a safe and hygienic workspace.

4. Versatility

These spacers are compatible with various machinery types and are widely used across industries like food and beverage, pharmaceuticals, and medical devices.

Applications in Key Industries

Food and Beverage Processing

Stainless steel spacers are integral in equipment like conveyors, mixers, and filling machines, ensuring the machinery remains contamination-free during operation.

Pharmaceutical and Biotechnology

In sterile environments, these spacers help maintain the cleanliness of lab and production equipment, reducing the risk of cross-contamination.

Packaging Industry

Used in sealing, filling, and labeling machines, stainless steel spacers enhance the reliability and cleanliness of packaging processes.

Choosing the Right Stainless Steel Spacer

When selecting stainless steel spacers, consider factors like:

- Material Grade: Look for 304 or 316 stainless steel for superior corrosion resistance.

- Compliance: Ensure the spacers meet industry standards like EHEDG or FDA.

- Customization: Opt for designs tailored to your machinery and operational needs.

Enhancing Efficiency with Easy-to-Clean Spacers

Regular maintenance is simplified with stainless steel spacers, which can withstand rigorous cleaning procedures such as high-pressure washing and exposure to harsh chemicals. Their robust design minimizes wear and tear, ensuring consistent performance.

By incorporating these spacers, businesses can achieve:

- Improved sanitation

- Reduced equipment downtime

- Compliance with regulatory standards

Stainless Steel Spacers: The Ultimate Easy-to-Clean Solution

Stainless steel spacers are an indispensable component in industries requiring stringent hygiene and durability. Their easy-to-clean design, coupled with excellent resistance to harsh environments, makes them a valuable addition to any operation.

Investing in high-quality stainless steel spacers not only ensures equipment reliability but also enhances overall productivity and safety. Upgrade your machinery today to experience the long-term benefits of these exceptional components.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.