Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

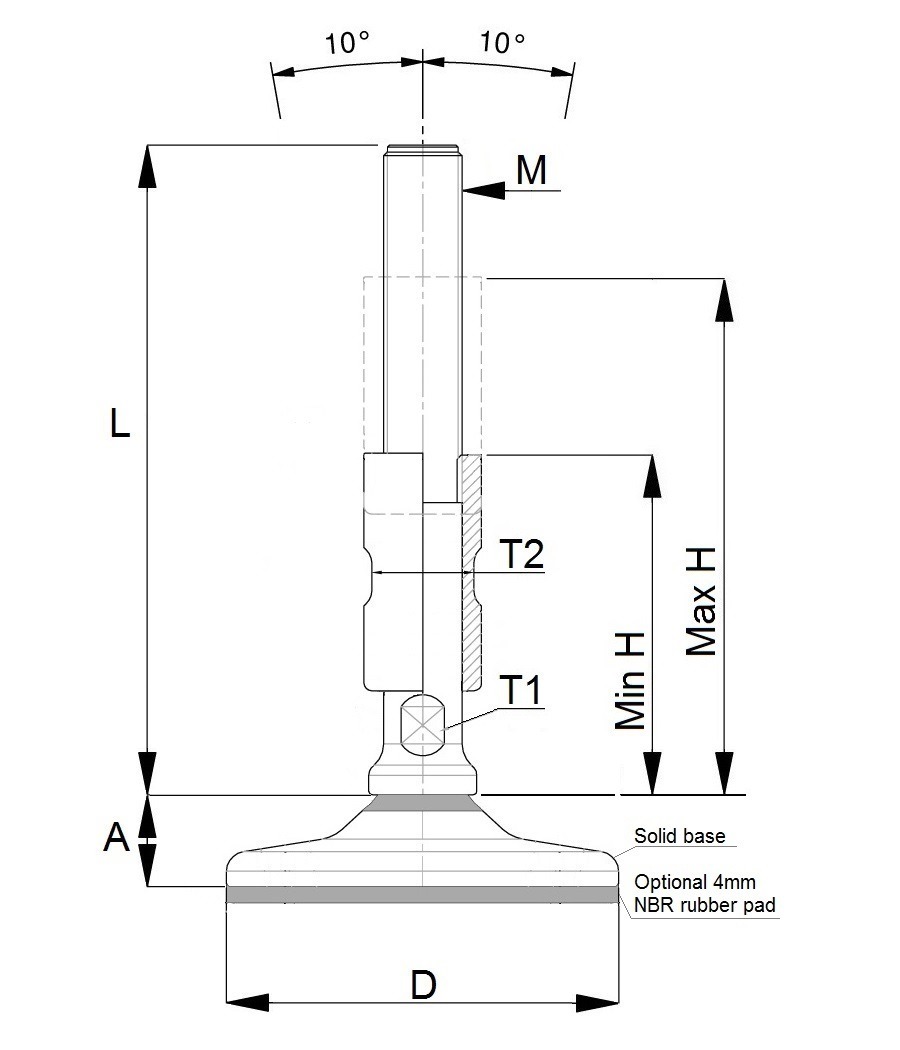

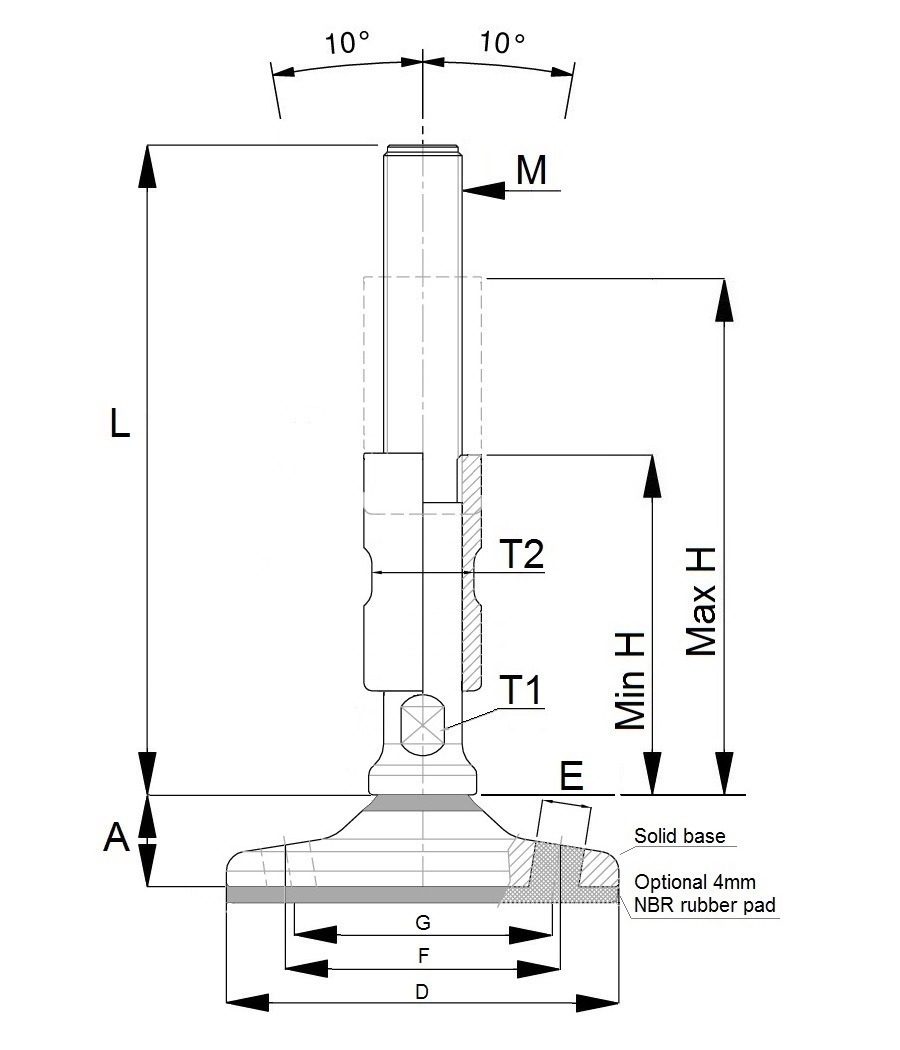

Seismic levelling feet Heavy duty hinged joint machinery feet

Seismic stainless machine leveling feet

Seismic leveling feet are specialized supports designed for machinery, equipment, and structures to protect them from seismic activities, such as earthquakes. These feet can also level the equipment, ensuring it operates correctly even if installed on uneven surfaces. Here’s how they typically work and why they’re important:

Vibration Isolation and Damping:

Seismic leveling feet often incorporate materials and designs that absorb and dissipate vibrations. This reduces the transmission of seismic forces to the equipment, minimizing the risk of damage.

Level Adjustment:

They can be adjusted in height, allowing for precise leveling of the machinery or equipment. This is crucial for machines that require precise alignment to operate efficiently and accurately.

Structural Protection:

By isolating equipment from ground movements, these feet help in protecting the structural integrity of both the machinery and the facility. This is especially important in regions prone to earthquakes.

Compliance and Safety:

In many cases, installing seismic leveling feet is part of compliance with local building codes and standards, especially in earthquake-prone areas. This not only ensures the safety of the equipment but also protects the people working around it.

Design Varieties:

Seismic leveling feet come in various designs, including spring-loaded, elastomeric, and sliding types, each offering different levels of isolation and load-bearing capacities to suit various applications.

Application span:

Their application spans across numerous industries, including manufacturing, healthcare (for sensitive medical equipment), and telecommunications, where the protection of equipment from seismic activities is paramount.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

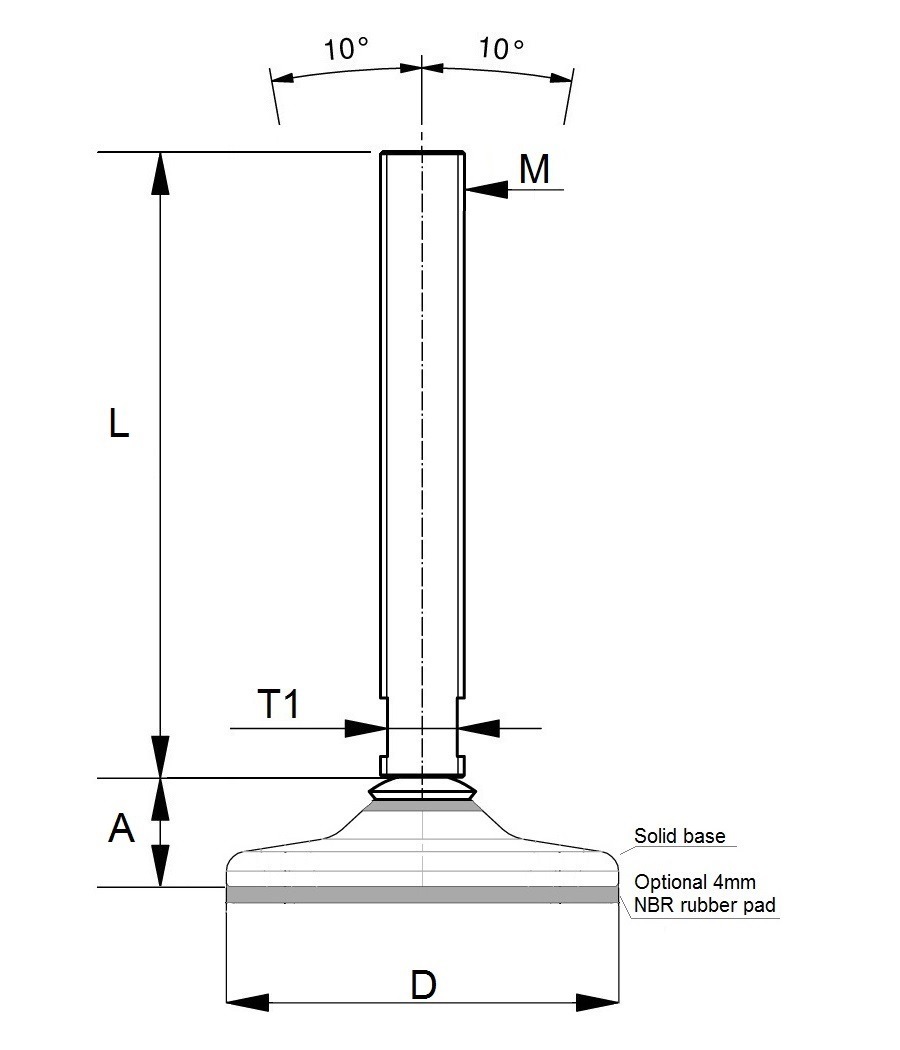

Seismic stainless machine leveling feet

Seismic leveling feet are specialized supports designed for machinery, equipment, and structures to protect them from seismic activities, such as earthquakes. These feet can also level the equipment, ensuring it operates correctly even if installed on uneven surfaces. Here’s how they typically work and why they’re important:

Vibration Isolation and Damping:

Seismic leveling feet often incorporate materials and designs that absorb and dissipate vibrations. This reduces the transmission of seismic forces to the equipment, minimizing the risk of damage.

Level Adjustment:

They can be adjusted in height, allowing for precise leveling of the machinery or equipment. This is crucial for machines that require precise alignment to operate efficiently and accurately.

Structural Protection:

By isolating equipment from ground movements, these feet help in protecting the structural integrity of both the machinery and the facility. This is especially important in regions prone to earthquakes.

Compliance and Safety:

In many cases, installing seismic leveling feet is part of compliance with local building codes and standards, especially in earthquake-prone areas. This not only ensures the safety of the equipment but also protects the people working around it.

Design Varieties:

Seismic leveling feet come in various designs, including spring-loaded, elastomeric, and sliding types, each offering different levels of isolation and load-bearing capacities to suit various applications.

Application span:

Their application spans across numerous industries, including manufacturing, healthcare (for sensitive medical equipment), and telecommunications, where the protection of equipment from seismic activities is paramount.

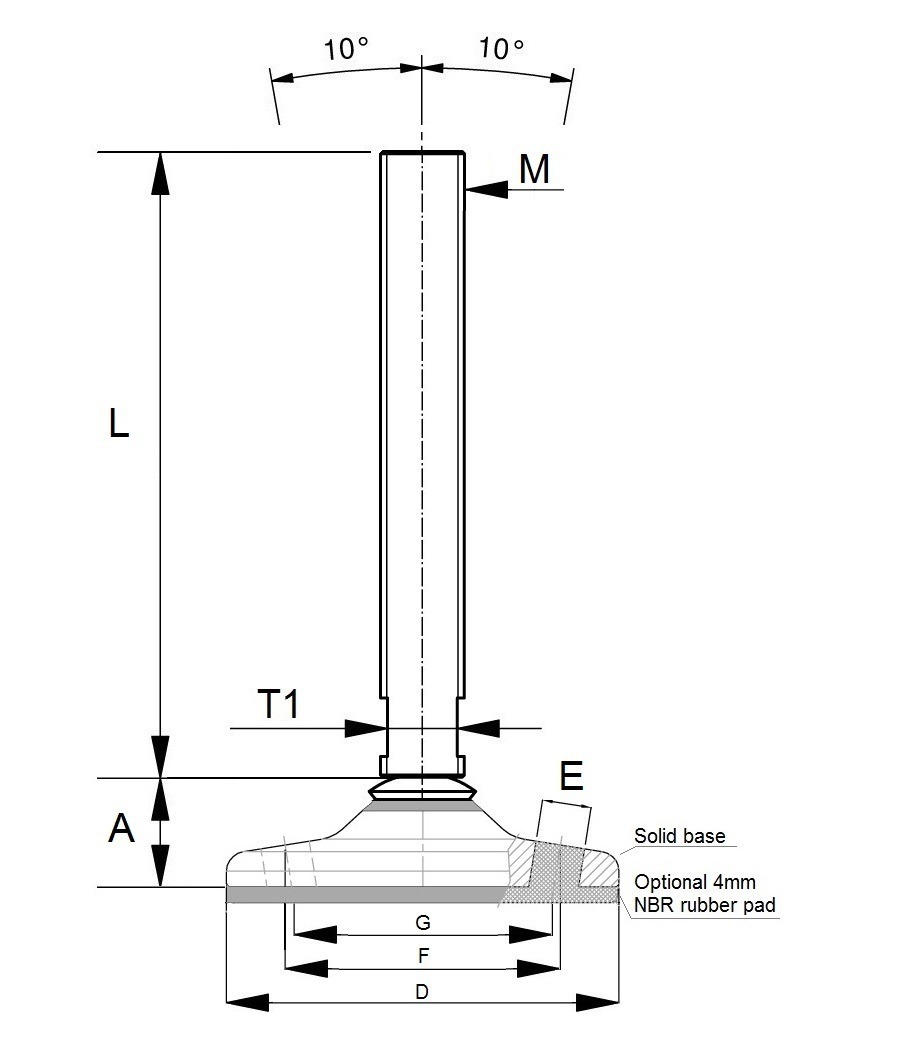

Seismic stainless machine leveling feet

Seismic leveling feet are specialized supports designed for machinery, equipment, and structures to protect them from seismic activities, such as earthquakes. These feet can also level the equipment, ensuring it operates correctly even if installed on uneven surfaces. Here’s how they typically work and why they’re important:

Vibration Isolation and Damping:

Seismic leveling feet often incorporate materials and designs that absorb and dissipate vibrations. This reduces the transmission of seismic forces to the equipment, minimizing the risk of damage.

Level Adjustment:

They can be adjusted in height, allowing for precise leveling of the machinery or equipment. This is crucial for machines that require precise alignment to operate efficiently and accurately.

Structural Protection:

By isolating equipment from ground movements, these feet help in protecting the structural integrity of both the machinery and the facility. This is especially important in regions prone to earthquakes.

Compliance and Safety:

In many cases, installing seismic leveling feet is part of compliance with local building codes and standards, especially in earthquake-prone areas. This not only ensures the safety of the equipment but also protects the people working around it.

Design Varieties:

Seismic leveling feet come in various designs, including spring-loaded, elastomeric, and sliding types, each offering different levels of isolation and load-bearing capacities to suit various applications.

Application span:

Their application spans across numerous industries, including manufacturing, healthcare (for sensitive medical equipment), and telecommunications, where the protection of equipment from seismic activities is paramount.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.