Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Sanitary side guide bracket in stainless steel

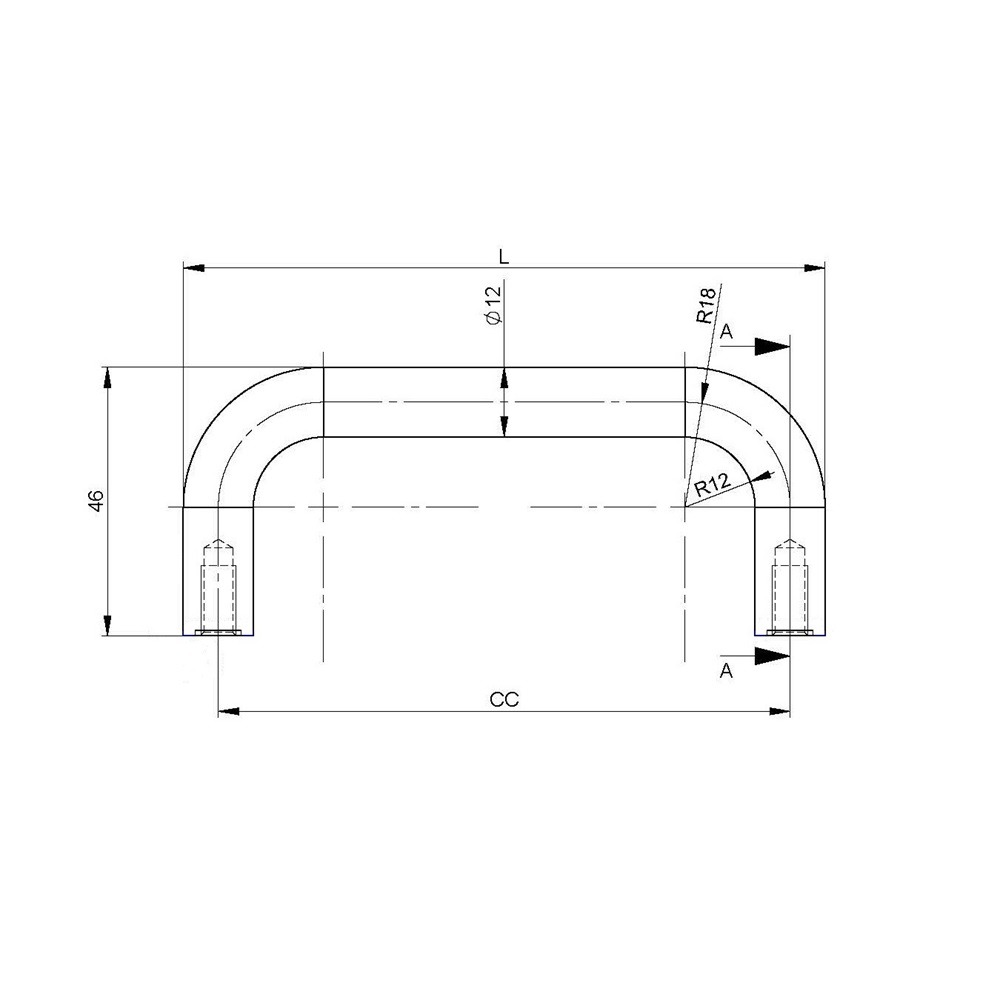

Side Guide Bracket in Stainless Steel AISI 304 (1.4301) for Sanitary Equipment

A side guide bracket in stainless steel AISI 304 (1.4301) is a small component with a big impact on hygiene, reliability, and line performance. The SG side guide bracket is designed for clean production environments where surfaces must be easy to wash down and resistant to corrosion. It supports precise guiding and stable positioning of side guides in demanding applications across food, pharma, packaging, dairy, and medical equipment.

SG Side Guide Bracket – Product Overview

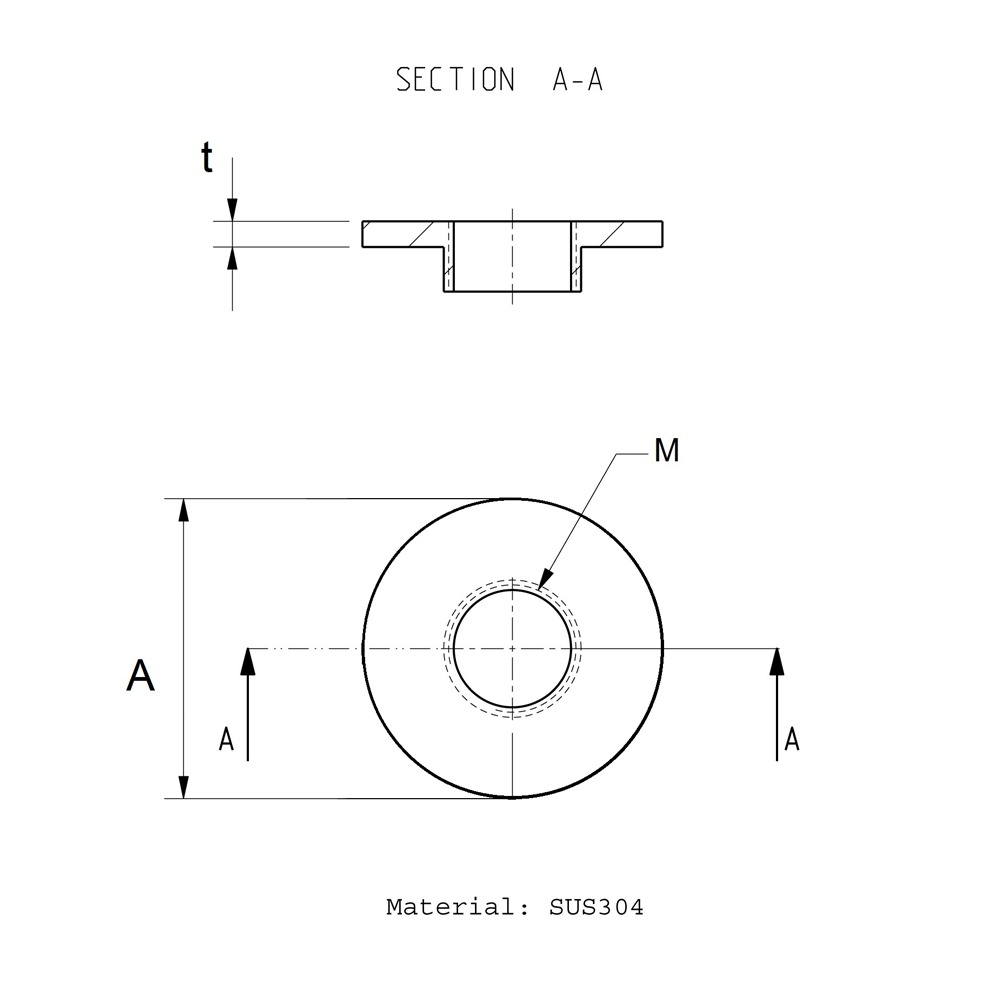

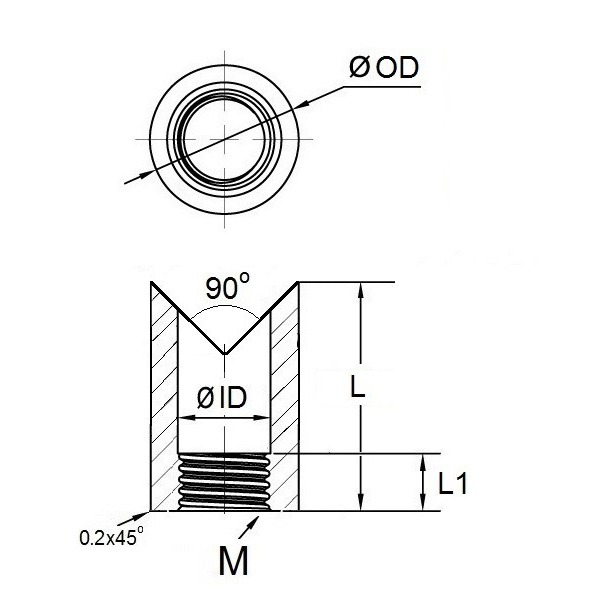

The SG side guide bracket is supplied as a complete assembly with:

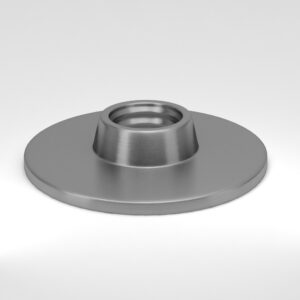

Star knob in polyamide (PA) with brass insert for fast, tool-free adjustment

Eyebolt and washer in stainless steel AISI 304 (1.4301) for strength and corrosion resistance

This combination delivers smooth handling for operators and dependable mounting performance in daily production.

Sanitary Side Guide Design for Easy Cleaning

All SG sanitary side guide brackets are engineered with a smooth surface design—without unnecessary ribs, flanges, recesses, or mounting holes. This reduces areas where product residue and bacteria can hide.

Benefits of this sanitary design include:

Faster and more effective cleaning

Lower risk of hidden contamination

Better support for hygiene audits and sanitation routines

Improved uptime through easier washdown procedures

Stainless Steel Side Guide Brackets for Harsh Environments

Modern production lines face heavier demands on material resistance, including frequent cleaning, water exposure, and chemical detergents. Stainless steel AISI 304 (1.4301) is widely used for sanitary machinery components because it offers strong corrosion resistance and durability for many industrial washdown environments.

The SG series is built for applications where easy-to-clean design and reliable operation are essential.

Available Types in the SG Sanitary Side Guide Series

The SG side guide bracket in stainless steel AISI 304 (1.4301) is available in these versions:

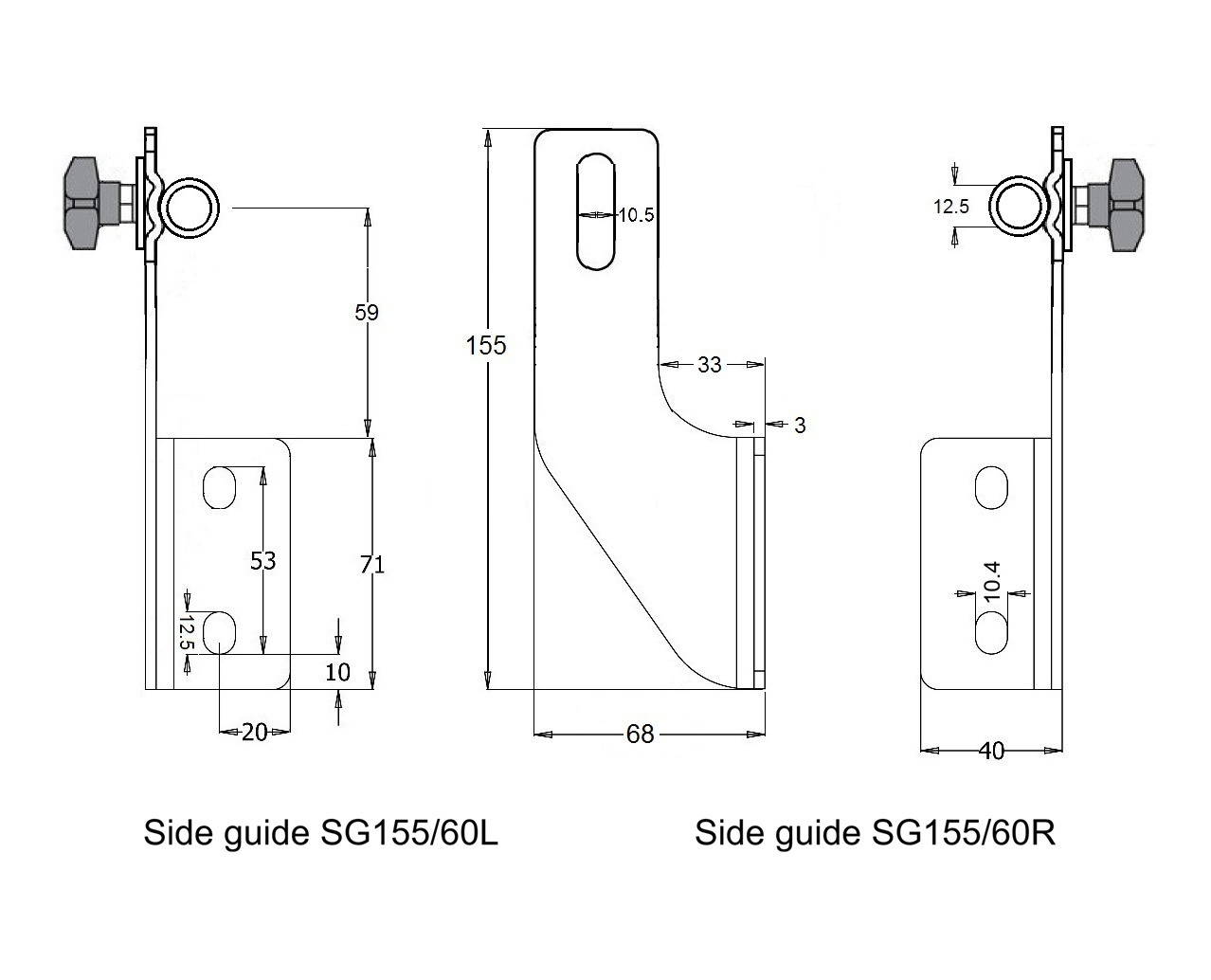

SG155-60

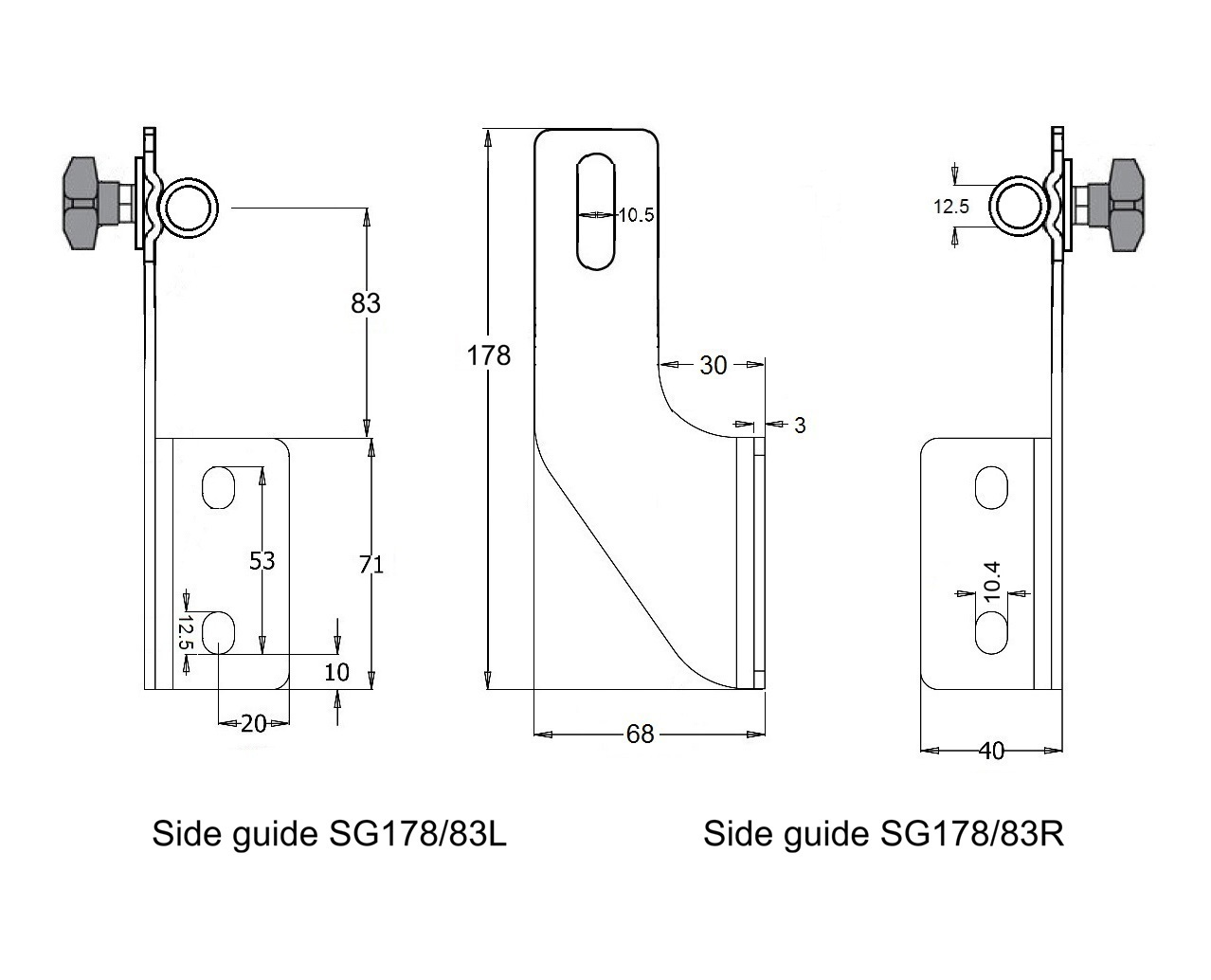

SG178-83

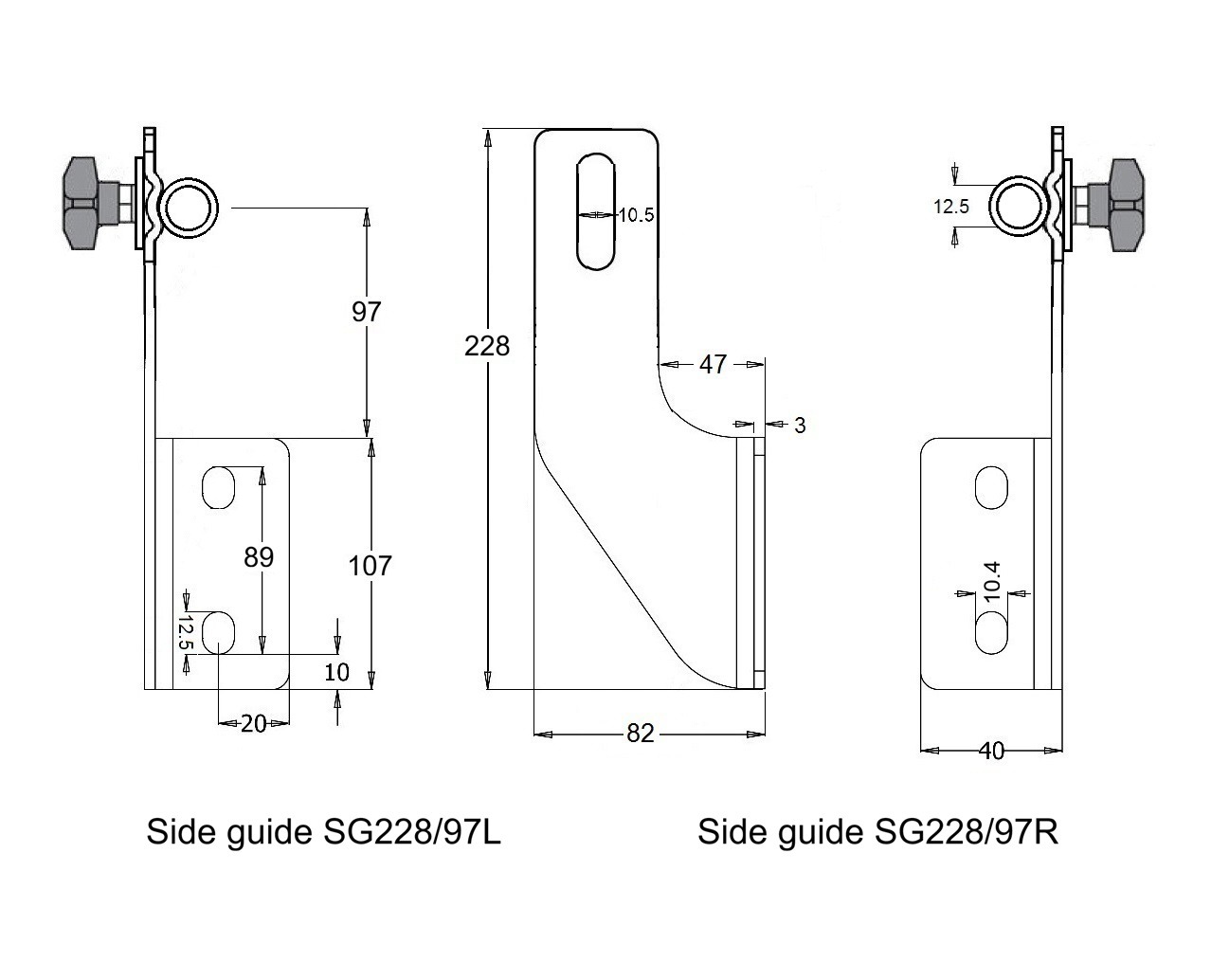

- SG228-97

Where Sanitary Side Guide Brackets Are Used

Medical Equipment

In medical environments, components must withstand frequent cleaning and exposure to disinfectants. A sanitary side guide bracket helps maintain a clean design while supporting stable guiding and repeatable positioning.

Food & Drug Processing Equipment

In food and pharmaceutical production, side guide brackets must support cleaning routines that prevent cross-contamination. Smooth, sanitary surfaces help reduce residue build-up and simplify sanitation.

Packaging Machinery

Packaging lines demand durable components that run reliably under continuous operation. Side guide brackets help keep product flow stable and support fast adjustments when switching formats.

3-A Design Meat & Poultry Processing Equipment

In meat and poultry applications, sanitary design principles emphasize smooth, easy-to-clean surfaces that minimize bacterial risk. A stainless steel side guide bracket supports sanitary equipment design and washdown performance.

Dairy Processing Machines

Dairy production requires frequent sanitation to remove residues and prevent microbial growth. Sanitary side guide brackets help reduce build-up areas and maintain clean production conditions.

Why Material Choice Matters

Choosing AISI 304 (1.4301) stainless steel for the bracket and stainless hardware improves resistance to corrosion and supports long service life in wet and regularly cleaned environments. The polyamide star knob with brass insert adds fast adjustment and strong thread performance—ideal for operators who need quick positioning without tools.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Side Guide Bracket in Stainless Steel AISI 304 (1.4301) for Sanitary Equipment

A side guide bracket in stainless steel AISI 304 (1.4301) is a small component with a big impact on hygiene, reliability, and line performance. The SG side guide bracket is designed for clean production environments where surfaces must be easy to wash down and resistant to corrosion. It supports precise guiding and stable positioning of side guides in demanding applications across food, pharma, packaging, dairy, and medical equipment.

SG Side Guide Bracket – Product Overview

The SG side guide bracket is supplied as a complete assembly with:

Star knob in polyamide (PA) with brass insert for fast, tool-free adjustment

Eyebolt and washer in stainless steel AISI 304 (1.4301) for strength and corrosion resistance

This combination delivers smooth handling for operators and dependable mounting performance in daily production.

Sanitary Side Guide Design for Easy Cleaning

All SG sanitary side guide brackets are engineered with a smooth surface design—without unnecessary ribs, flanges, recesses, or mounting holes. This reduces areas where product residue and bacteria can hide.

Benefits of this sanitary design include:

Faster and more effective cleaning

Lower risk of hidden contamination

Better support for hygiene audits and sanitation routines

Improved uptime through easier washdown procedures

Stainless Steel Side Guide Brackets for Harsh Environments

Modern production lines face heavier demands on material resistance, including frequent cleaning, water exposure, and chemical detergents. Stainless steel AISI 304 (1.4301) is widely used for sanitary machinery components because it offers strong corrosion resistance and durability for many industrial washdown environments.

The SG series is built for applications where easy-to-clean design and reliable operation are essential.

Available Types in the SG Sanitary Side Guide Series

The SG side guide bracket in stainless steel AISI 304 (1.4301) is available in these versions:

SG155-60

SG178-83

- SG228-97

Where Sanitary Side Guide Brackets Are Used

Medical Equipment

In medical environments, components must withstand frequent cleaning and exposure to disinfectants. A sanitary side guide bracket helps maintain a clean design while supporting stable guiding and repeatable positioning.

Food & Drug Processing Equipment

In food and pharmaceutical production, side guide brackets must support cleaning routines that prevent cross-contamination. Smooth, sanitary surfaces help reduce residue build-up and simplify sanitation.

Packaging Machinery

Packaging lines demand durable components that run reliably under continuous operation. Side guide brackets help keep product flow stable and support fast adjustments when switching formats.

3-A Design Meat & Poultry Processing Equipment

In meat and poultry applications, sanitary design principles emphasize smooth, easy-to-clean surfaces that minimize bacterial risk. A stainless steel side guide bracket supports sanitary equipment design and washdown performance.

Dairy Processing Machines

Dairy production requires frequent sanitation to remove residues and prevent microbial growth. Sanitary side guide brackets help reduce build-up areas and maintain clean production conditions.

Why Material Choice Matters

Choosing AISI 304 (1.4301) stainless steel for the bracket and stainless hardware improves resistance to corrosion and supports long service life in wet and regularly cleaned environments. The polyamide star knob with brass insert adds fast adjustment and strong thread performance—ideal for operators who need quick positioning without tools.

Side Guide Bracket in Stainless Steel AISI 304 (1.4301) for Sanitary Equipment

A side guide bracket in stainless steel AISI 304 (1.4301) is a small component with a big impact on hygiene, reliability, and line performance. The SG side guide bracket is designed for clean production environments where surfaces must be easy to wash down and resistant to corrosion. It supports precise guiding and stable positioning of side guides in demanding applications across food, pharma, packaging, dairy, and medical equipment.

SG Side Guide Bracket – Product Overview

The SG side guide bracket is supplied as a complete assembly with:

Star knob in polyamide (PA) with brass insert for fast, tool-free adjustment

Eyebolt and washer in stainless steel AISI 304 (1.4301) for strength and corrosion resistance

This combination delivers smooth handling for operators and dependable mounting performance in daily production.

Sanitary Side Guide Design for Easy Cleaning

All SG sanitary side guide brackets are engineered with a smooth surface design—without unnecessary ribs, flanges, recesses, or mounting holes. This reduces areas where product residue and bacteria can hide.

Benefits of this sanitary design include:

Faster and more effective cleaning

Lower risk of hidden contamination

Better support for hygiene audits and sanitation routines

Improved uptime through easier washdown procedures

Stainless Steel Side Guide Brackets for Harsh Environments

Modern production lines face heavier demands on material resistance, including frequent cleaning, water exposure, and chemical detergents. Stainless steel AISI 304 (1.4301) is widely used for sanitary machinery components because it offers strong corrosion resistance and durability for many industrial washdown environments.

The SG series is built for applications where easy-to-clean design and reliable operation are essential.

Available Types in the SG Sanitary Side Guide Series

The SG side guide bracket in stainless steel AISI 304 (1.4301) is available in these versions:

SG155-60

SG178-83

- SG228-97

Where Sanitary Side Guide Brackets Are Used

Medical Equipment

In medical environments, components must withstand frequent cleaning and exposure to disinfectants. A sanitary side guide bracket helps maintain a clean design while supporting stable guiding and repeatable positioning.

Food & Drug Processing Equipment

In food and pharmaceutical production, side guide brackets must support cleaning routines that prevent cross-contamination. Smooth, sanitary surfaces help reduce residue build-up and simplify sanitation.

Packaging Machinery

Packaging lines demand durable components that run reliably under continuous operation. Side guide brackets help keep product flow stable and support fast adjustments when switching formats.

3-A Design Meat & Poultry Processing Equipment

In meat and poultry applications, sanitary design principles emphasize smooth, easy-to-clean surfaces that minimize bacterial risk. A stainless steel side guide bracket supports sanitary equipment design and washdown performance.

Dairy Processing Machines

Dairy production requires frequent sanitation to remove residues and prevent microbial growth. Sanitary side guide brackets help reduce build-up areas and maintain clean production conditions.

Why Material Choice Matters

Choosing AISI 304 (1.4301) stainless steel for the bracket and stainless hardware improves resistance to corrosion and supports long service life in wet and regularly cleaned environments. The polyamide star knob with brass insert adds fast adjustment and strong thread performance—ideal for operators who need quick positioning without tools.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.