Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

PTFE and brass lined stainless rod ends

PTFE and brass lined stainless rod ends in food processing, cosmetic and pharmaceutical industry

PTFE (Polytetrafluoroethylene) and brass-lined stainless rod ends in the food processing, cosmetic, and pharmaceutical industries can be highly beneficial, given their unique properties and compliance with the stringent requirements of these sectors.

Ordering SCHS Stainless steel female PTFE composite lined rod end – Maintenance free

Left-hand thread, suffix “L” is added to bearing numbers. ex.: SCHS20SSL M20×1.5-6H

Right-hand thread, suffix “R” is added to bearing numbers. ex.: SCHS20SSR M20×1.5-6H

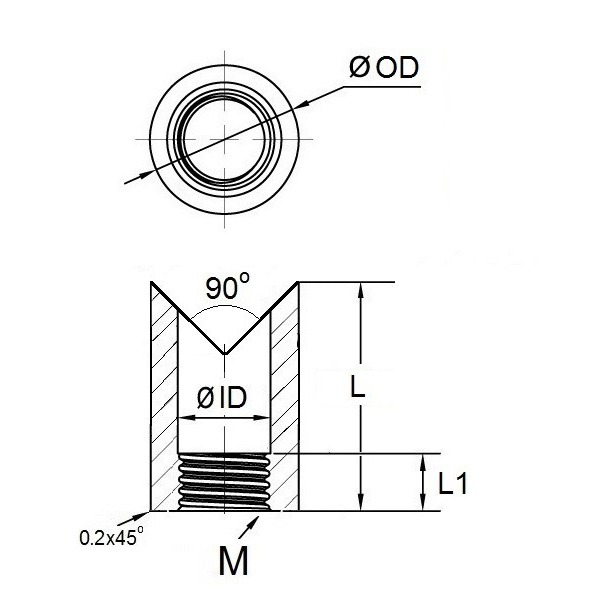

Ordering SCOS Stainless steel male PTFE composite lined rod end – Maintenance free

Left-hand thread, suffix “L” is added to bearing numbers. ex.: SCOS20SSL M20×1.5-6g

Right-hand thread, suffix “R” is added to bearing numbers. ex.: SCOS20SSR M20×1.5-6g

BALL

440C Stainless Steel

Heat Treated

Precision Ground

Polished surface

BODY

Aisi 304 Stainless Steel

Polished surface

Race: Aisi 304 Stainless Steel PTFE Composite lined

Ordering SPHS Stainless steel female brass lined rod end

Left-hand thread, suffix “L” is added to bearing numbers. ex.: SPHS20SSL M20×1.5-6H

Right-hand thread, suffix “R” is added to bearing numbers. ex.: SPHS20SSR M20×1.5-6H

Ordering SPOS Stainless steel male brass lined rod end

Left-hand thread, suffix “L” is added to bearing numbers. ex.: SPOS20SSL M20×1.5-6g

Right-hand thread, suffix “R” is added to bearing numbers. ex.: SPOS20SSR M20×1.5-6g

BALL

440C Stainless Steel

Heat Treated

Precision Ground

Polished surface

BODY

Aisi 304 Stainless Steel

Polished surface

Race: Aisi 304 Stainless Steel Brass Lined

Here’s an overview of why these materials are advantageous in these applications:

PTFE Properties:

- Non-Reactive and Inert: PTFE is chemically inert and does not react with most chemicals, making it safe for use in processing environments where it may come into contact with a variety of substances.

- Low Friction Coefficient: PTFE has a very low coefficient of friction, which reduces wear and extends the life of the rod ends.

- High Temperature Resistance: It can withstand high temperatures, which is beneficial in processes that involve heating or sterilization.

- Excellent Lubrication: PTFE’s natural lubricity can enhance the movement and lifespan of rod ends, especially in applications requiring regular movement or adjustments.

- FDA Compliance: PTFE is often compliant with FDA regulations for use in food processing, pharmaceuticals, and cosmetics, where non-toxic and non-contaminant materials are crucial.

Brass Properties:

- Corrosion Resistance: Brass is resistant to corrosion, important in environments where it may be exposed to moisture, cleaning agents, or other corrosive substances.

- Good Mechanical Properties: Brass offers a balance of strength and ductility, which can be beneficial in maintaining the integrity of the rod ends under various loads and usage conditions.

Stainless Steel Advantages:

- Durability and Strength: Stainless steel provides structural strength and durability to the rod ends.

- Hygienic and Easy to Clean: Like PTFE, stainless steel is easy to clean and sanitize, making it ideal for use in hygienic environments.

- Corrosion Resistance: Stainless steel’s resistance to corrosion is crucial in these industries, especially when exposed to various chemicals and cleaning agents.

Overall Benefits in Industry Applications:

- Food Processing: In food processing, these materials ensure that equipment does not contaminate food products, withstands regular cleaning and sanitization, and meets health and safety regulations.

- Cosmetic Industry: For cosmetics, the non-reactive and inert nature of these materials ensures that the products remain pure and uncontaminated during manufacturing.

- Pharmaceutical Industry: In pharmaceutical manufacturing, the high standards for cleanliness, non-reactivity, and contamination prevention are met by using PTFE, brass, and stainless steel components.

Maintenance and Longevity:

- These materials generally require less maintenance and have longer lifespans in harsh environments compared to other materials, making them cost-effective in the long run.

In conclusion, the combination of PTFE, brass, and stainless steel in rod ends offers a robust, hygienic, and durable solution suitable for the demanding conditions of the food processing, cosmetic, and pharmaceutical industries. Their unique properties help in maintaining the purity of products, ensuring machinery reliability, and complying with industry regulations.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

PTFE and brass lined stainless rod ends in food processing, cosmetic and pharmaceutical industry

PTFE (Polytetrafluoroethylene) and brass-lined stainless rod ends in the food processing, cosmetic, and pharmaceutical industries can be highly beneficial, given their unique properties and compliance with the stringent requirements of these sectors.

Ordering SCHS Stainless steel female PTFE composite lined rod end – Maintenance free

Left-hand thread, suffix “L” is added to bearing numbers. ex.: SCHS20SSL M20×1.5-6H

Right-hand thread, suffix “R” is added to bearing numbers. ex.: SCHS20SSR M20×1.5-6H

Ordering SCOS Stainless steel male PTFE composite lined rod end – Maintenance free

Left-hand thread, suffix “L” is added to bearing numbers. ex.: SCOS20SSL M20×1.5-6g

Right-hand thread, suffix “R” is added to bearing numbers. ex.: SCOS20SSR M20×1.5-6g

BALL

440C Stainless Steel

Heat Treated

Precision Ground

Polished surface

BODY

Aisi 304 Stainless Steel

Polished surface

Race: Aisi 304 Stainless Steel PTFE Composite lined

Ordering SPHS Stainless steel female brass lined rod end

Left-hand thread, suffix “L” is added to bearing numbers. ex.: SPHS20SSL M20×1.5-6H

Right-hand thread, suffix “R” is added to bearing numbers. ex.: SPHS20SSR M20×1.5-6H

Ordering SPOS Stainless steel male brass lined rod end

Left-hand thread, suffix “L” is added to bearing numbers. ex.: SPOS20SSL M20×1.5-6g

Right-hand thread, suffix “R” is added to bearing numbers. ex.: SPOS20SSR M20×1.5-6g

BALL

440C Stainless Steel

Heat Treated

Precision Ground

Polished surface

BODY

Aisi 304 Stainless Steel

Polished surface

Race: Aisi 304 Stainless Steel Brass Lined

Here’s an overview of why these materials are advantageous in these applications:

PTFE Properties:

- Non-Reactive and Inert: PTFE is chemically inert and does not react with most chemicals, making it safe for use in processing environments where it may come into contact with a variety of substances.

- Low Friction Coefficient: PTFE has a very low coefficient of friction, which reduces wear and extends the life of the rod ends.

- High Temperature Resistance: It can withstand high temperatures, which is beneficial in processes that involve heating or sterilization.

- Excellent Lubrication: PTFE’s natural lubricity can enhance the movement and lifespan of rod ends, especially in applications requiring regular movement or adjustments.

- FDA Compliance: PTFE is often compliant with FDA regulations for use in food processing, pharmaceuticals, and cosmetics, where non-toxic and non-contaminant materials are crucial.

Brass Properties:

- Corrosion Resistance: Brass is resistant to corrosion, important in environments where it may be exposed to moisture, cleaning agents, or other corrosive substances.

- Good Mechanical Properties: Brass offers a balance of strength and ductility, which can be beneficial in maintaining the integrity of the rod ends under various loads and usage conditions.

Stainless Steel Advantages:

- Durability and Strength: Stainless steel provides structural strength and durability to the rod ends.

- Hygienic and Easy to Clean: Like PTFE, stainless steel is easy to clean and sanitize, making it ideal for use in hygienic environments.

- Corrosion Resistance: Stainless steel’s resistance to corrosion is crucial in these industries, especially when exposed to various chemicals and cleaning agents.

Overall Benefits in Industry Applications:

- Food Processing: In food processing, these materials ensure that equipment does not contaminate food products, withstands regular cleaning and sanitization, and meets health and safety regulations.

- Cosmetic Industry: For cosmetics, the non-reactive and inert nature of these materials ensures that the products remain pure and uncontaminated during manufacturing.

- Pharmaceutical Industry: In pharmaceutical manufacturing, the high standards for cleanliness, non-reactivity, and contamination prevention are met by using PTFE, brass, and stainless steel components.

Maintenance and Longevity:

- These materials generally require less maintenance and have longer lifespans in harsh environments compared to other materials, making them cost-effective in the long run.

In conclusion, the combination of PTFE, brass, and stainless steel in rod ends offers a robust, hygienic, and durable solution suitable for the demanding conditions of the food processing, cosmetic, and pharmaceutical industries. Their unique properties help in maintaining the purity of products, ensuring machinery reliability, and complying with industry regulations.

PTFE and brass lined stainless rod ends in food processing, cosmetic and pharmaceutical industry

PTFE (Polytetrafluoroethylene) and brass-lined stainless rod ends in the food processing, cosmetic, and pharmaceutical industries can be highly beneficial, given their unique properties and compliance with the stringent requirements of these sectors.

Ordering SCHS Stainless steel female PTFE composite lined rod end – Maintenance free

Left-hand thread, suffix “L” is added to bearing numbers. ex.: SCHS20SSL M20×1.5-6H

Right-hand thread, suffix “R” is added to bearing numbers. ex.: SCHS20SSR M20×1.5-6H

Ordering SCOS Stainless steel male PTFE composite lined rod end – Maintenance free

Left-hand thread, suffix “L” is added to bearing numbers. ex.: SCOS20SSL M20×1.5-6g

Right-hand thread, suffix “R” is added to bearing numbers. ex.: SCOS20SSR M20×1.5-6g

BALL

440C Stainless Steel

Heat Treated

Precision Ground

Polished surface

BODY

Aisi 304 Stainless Steel

Polished surface

Race: Aisi 304 Stainless Steel PTFE Composite lined

Ordering SPHS Stainless steel female brass lined rod end

Left-hand thread, suffix “L” is added to bearing numbers. ex.: SPHS20SSL M20×1.5-6H

Right-hand thread, suffix “R” is added to bearing numbers. ex.: SPHS20SSR M20×1.5-6H

Ordering SPOS Stainless steel male brass lined rod end

Left-hand thread, suffix “L” is added to bearing numbers. ex.: SPOS20SSL M20×1.5-6g

Right-hand thread, suffix “R” is added to bearing numbers. ex.: SPOS20SSR M20×1.5-6g

BALL

440C Stainless Steel

Heat Treated

Precision Ground

Polished surface

BODY

Aisi 304 Stainless Steel

Polished surface

Race: Aisi 304 Stainless Steel Brass Lined

Here’s an overview of why these materials are advantageous in these applications:

PTFE Properties:

- Non-Reactive and Inert: PTFE is chemically inert and does not react with most chemicals, making it safe for use in processing environments where it may come into contact with a variety of substances.

- Low Friction Coefficient: PTFE has a very low coefficient of friction, which reduces wear and extends the life of the rod ends.

- High Temperature Resistance: It can withstand high temperatures, which is beneficial in processes that involve heating or sterilization.

- Excellent Lubrication: PTFE’s natural lubricity can enhance the movement and lifespan of rod ends, especially in applications requiring regular movement or adjustments.

- FDA Compliance: PTFE is often compliant with FDA regulations for use in food processing, pharmaceuticals, and cosmetics, where non-toxic and non-contaminant materials are crucial.

Brass Properties:

- Corrosion Resistance: Brass is resistant to corrosion, important in environments where it may be exposed to moisture, cleaning agents, or other corrosive substances.

- Good Mechanical Properties: Brass offers a balance of strength and ductility, which can be beneficial in maintaining the integrity of the rod ends under various loads and usage conditions.

Stainless Steel Advantages:

- Durability and Strength: Stainless steel provides structural strength and durability to the rod ends.

- Hygienic and Easy to Clean: Like PTFE, stainless steel is easy to clean and sanitize, making it ideal for use in hygienic environments.

- Corrosion Resistance: Stainless steel’s resistance to corrosion is crucial in these industries, especially when exposed to various chemicals and cleaning agents.

Overall Benefits in Industry Applications:

- Food Processing: In food processing, these materials ensure that equipment does not contaminate food products, withstands regular cleaning and sanitization, and meets health and safety regulations.

- Cosmetic Industry: For cosmetics, the non-reactive and inert nature of these materials ensures that the products remain pure and uncontaminated during manufacturing.

- Pharmaceutical Industry: In pharmaceutical manufacturing, the high standards for cleanliness, non-reactivity, and contamination prevention are met by using PTFE, brass, and stainless steel components.

Maintenance and Longevity:

- These materials generally require less maintenance and have longer lifespans in harsh environments compared to other materials, making them cost-effective in the long run.

In conclusion, the combination of PTFE, brass, and stainless steel in rod ends offers a robust, hygienic, and durable solution suitable for the demanding conditions of the food processing, cosmetic, and pharmaceutical industries. Their unique properties help in maintaining the purity of products, ensuring machinery reliability, and complying with industry regulations.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.