Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

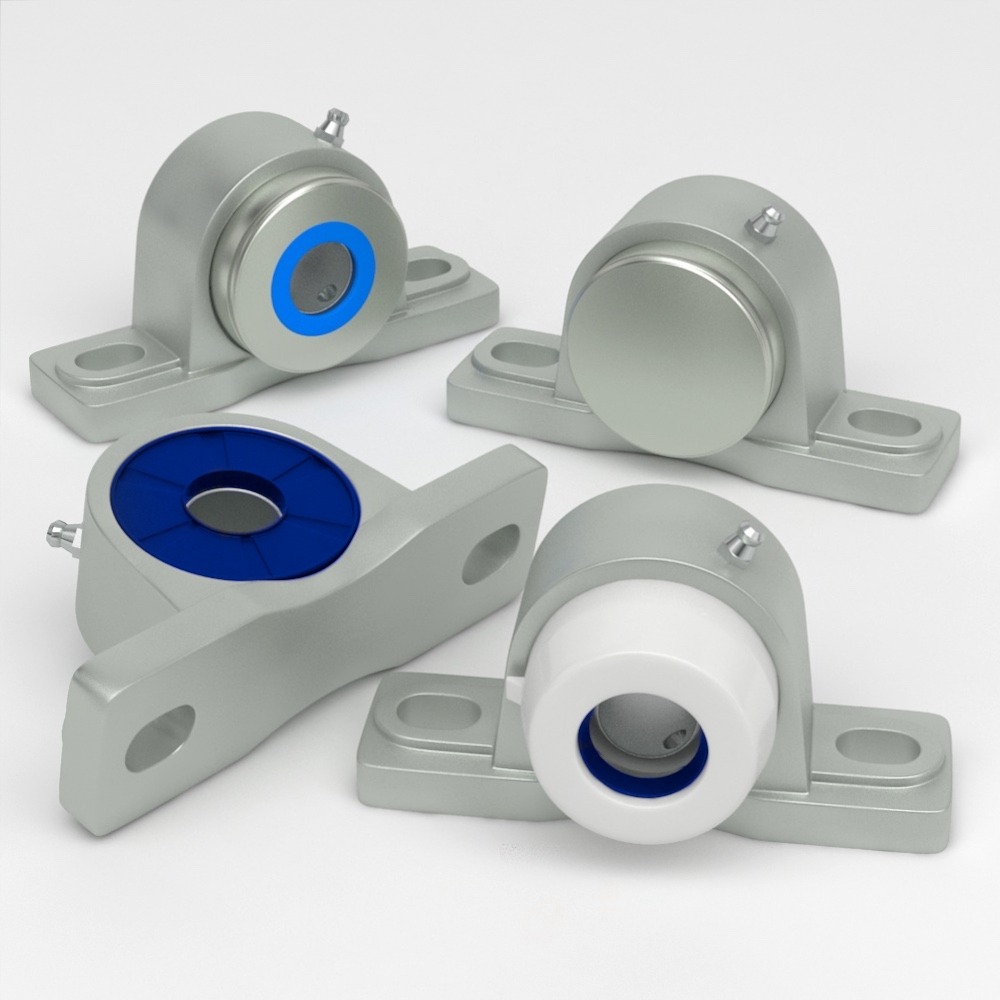

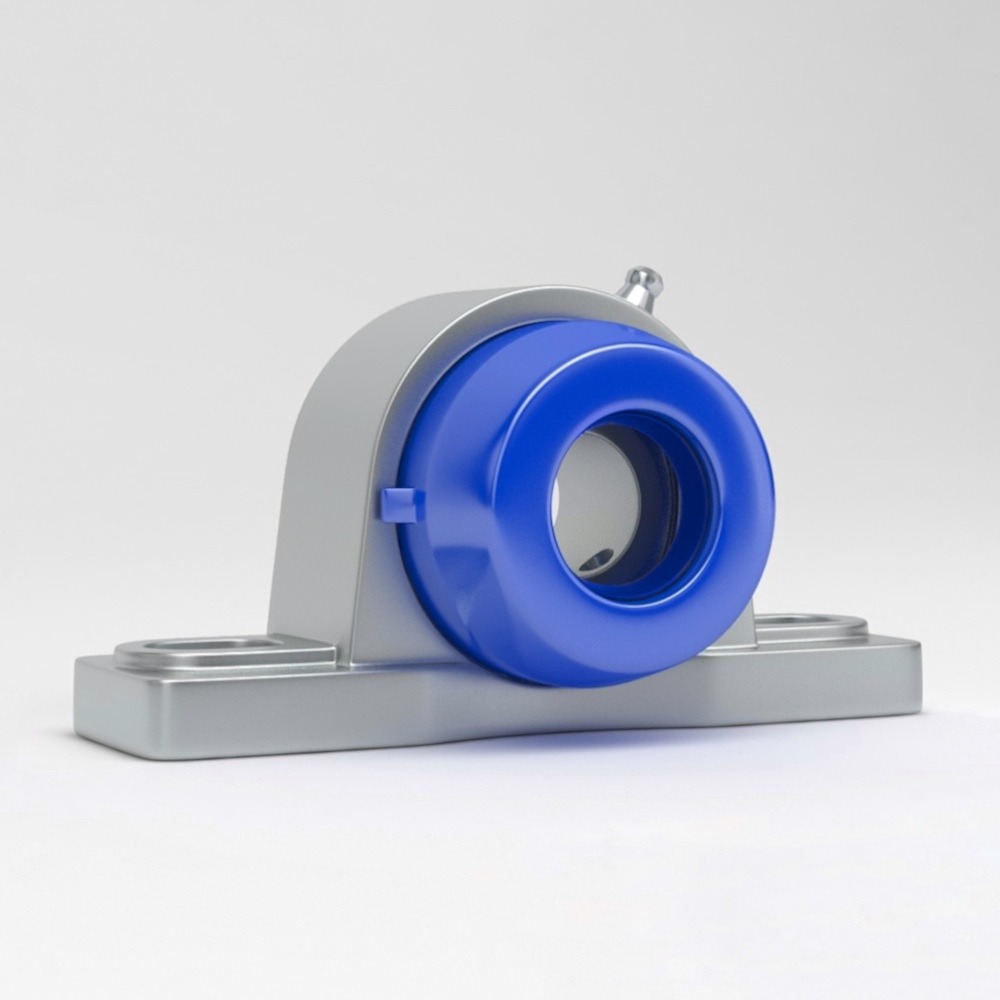

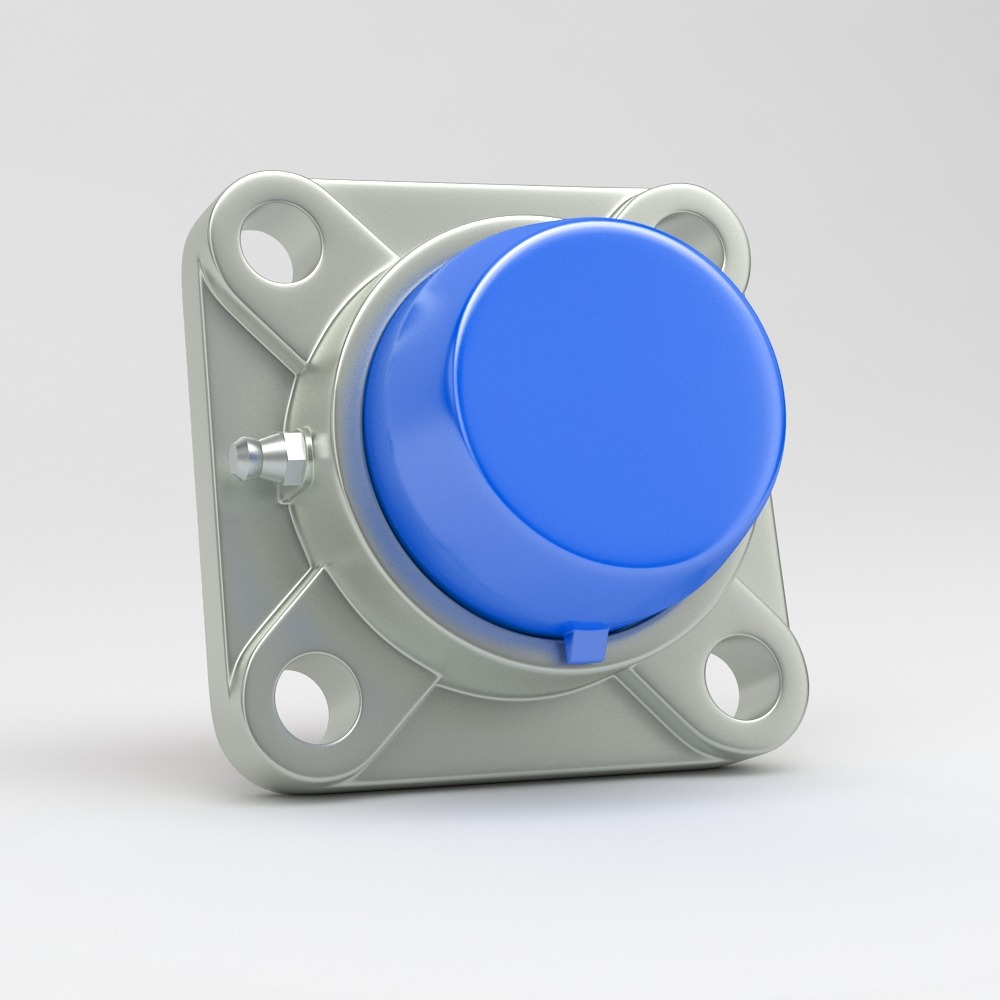

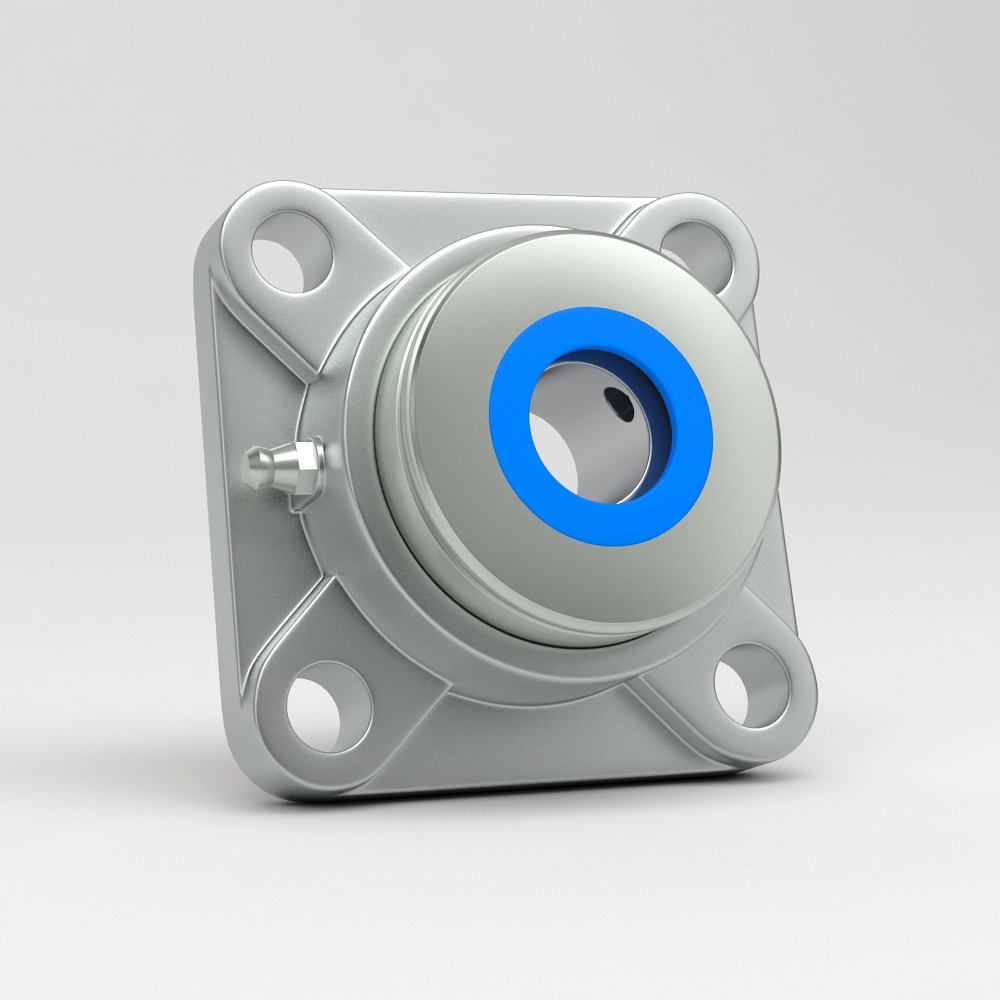

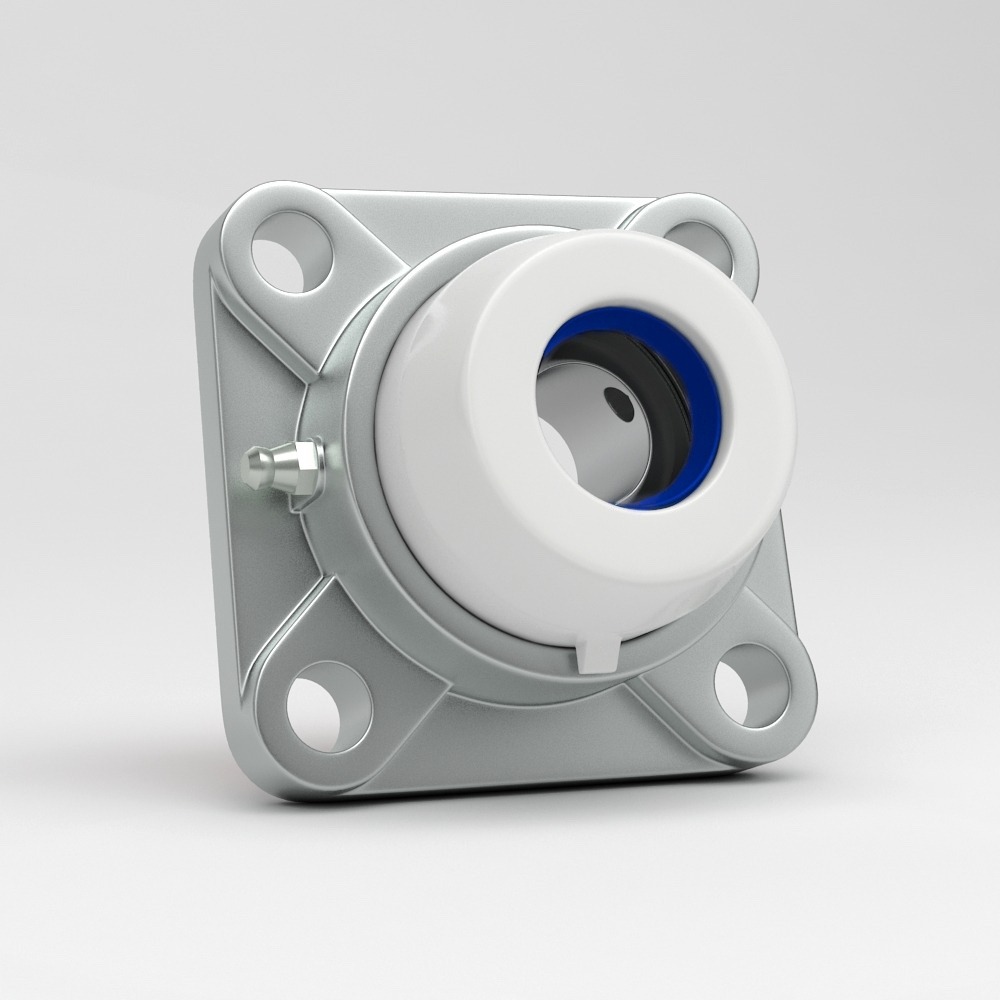

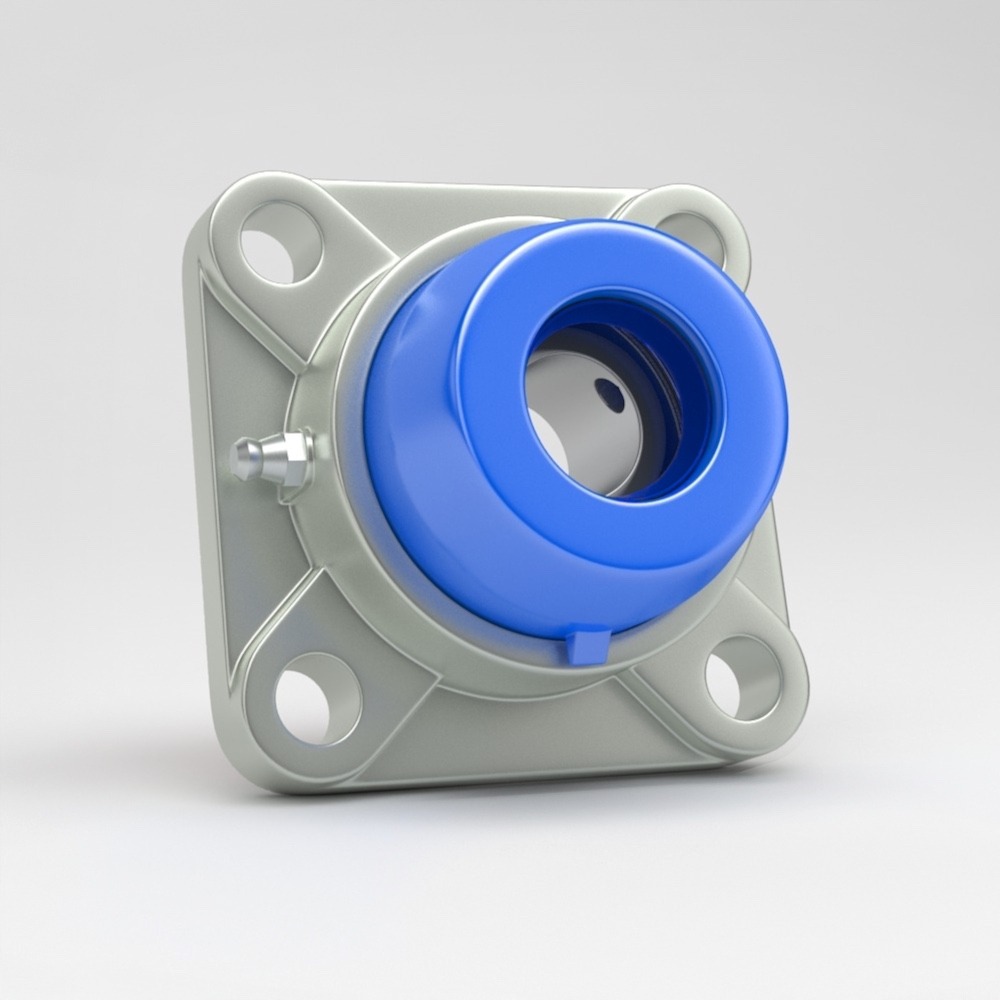

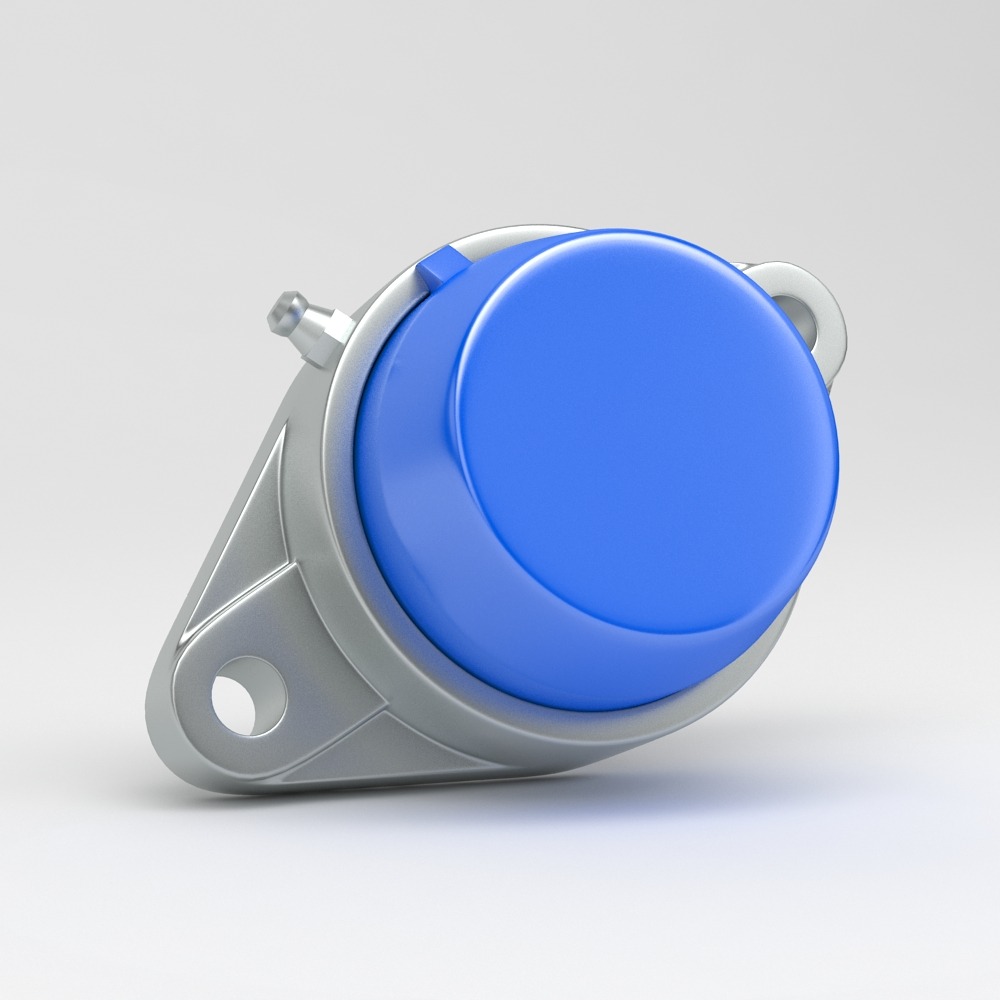

Pillow block Unit SP in stainless steel with cover

Pillow block Unit SP in stainless steel with cover.

The stainless steel pillow block bearing units type SP is suitable for the food industry and other demanding environments, due to the hygienic design and minimum of maintenance.

The stainless steel bearing units are characterized by high quality and finish for both the bearing and the bearing housing.

Pillow block Unit SP in stainless steel advantages.

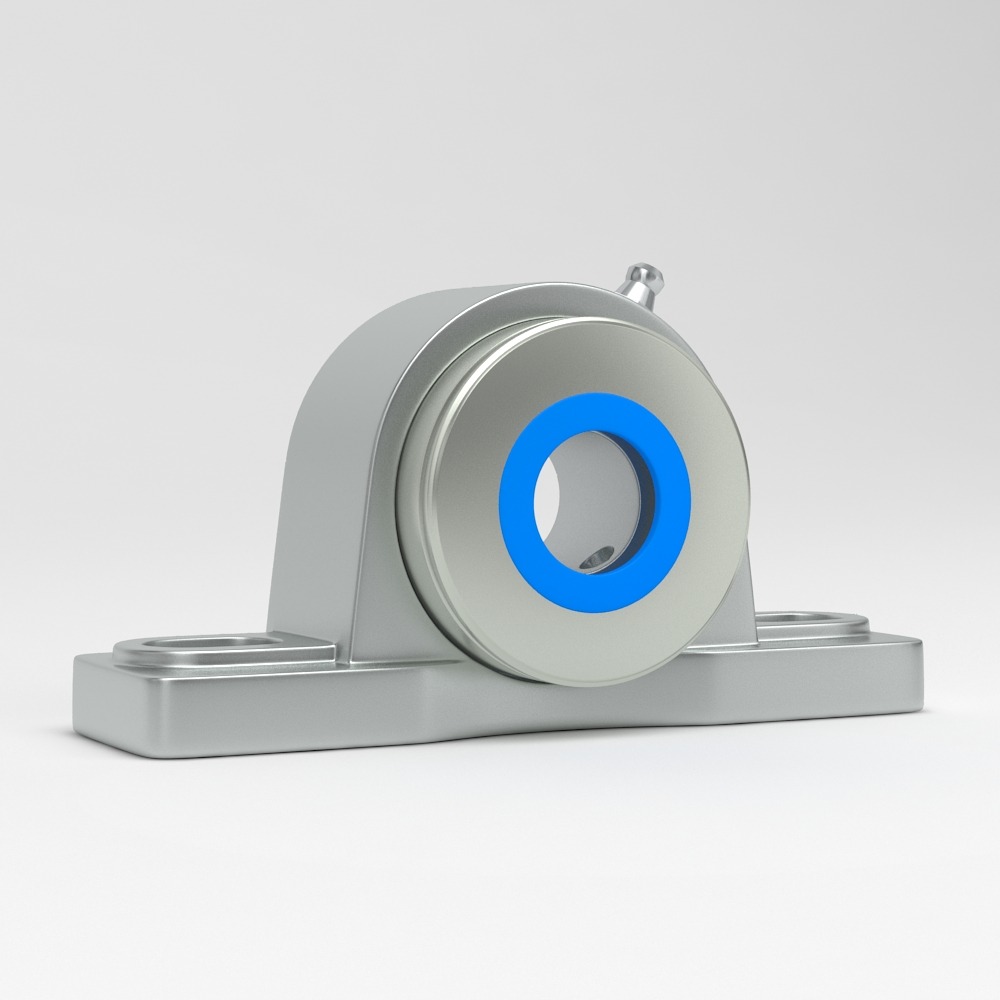

The bearing unit has adjustable pre-lubricated Aisi440C stainless steel ball bearing.

The bearing can be re-lubricated by stainless steel Aisi304 grease-nipple or a quick coupler.

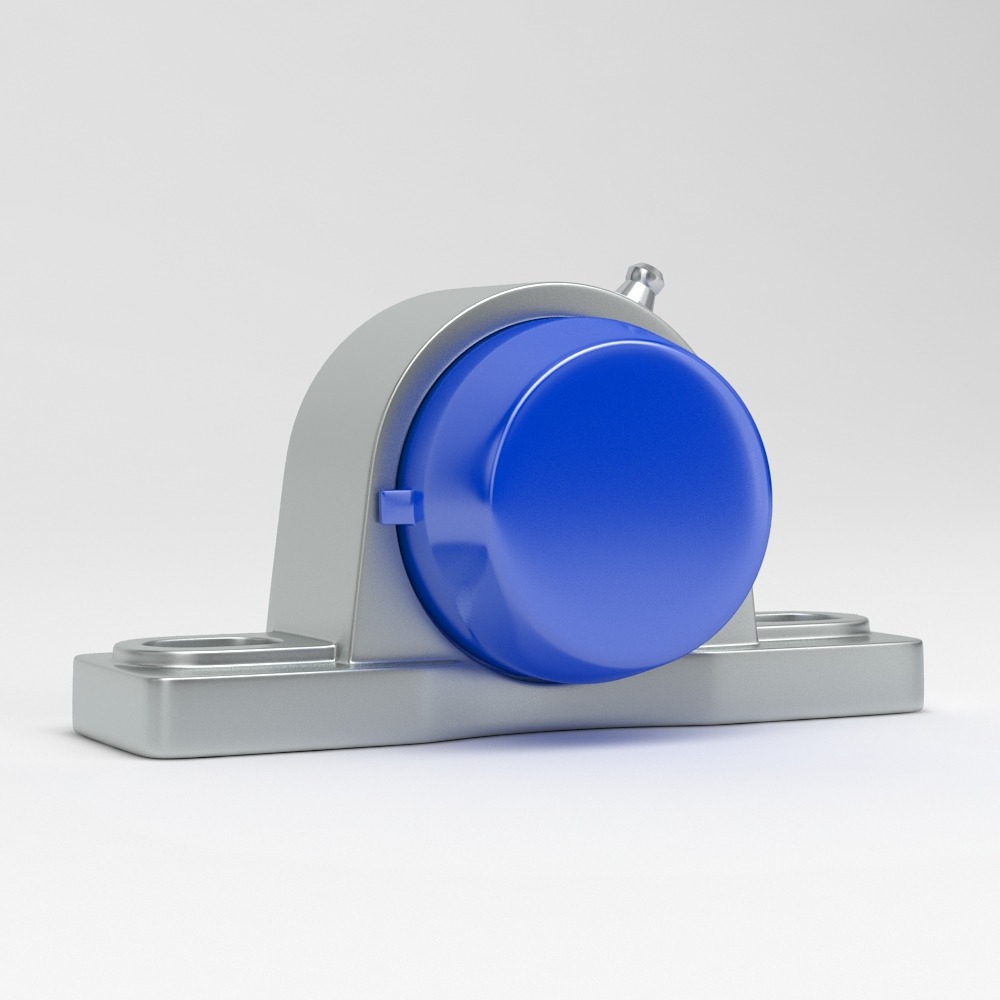

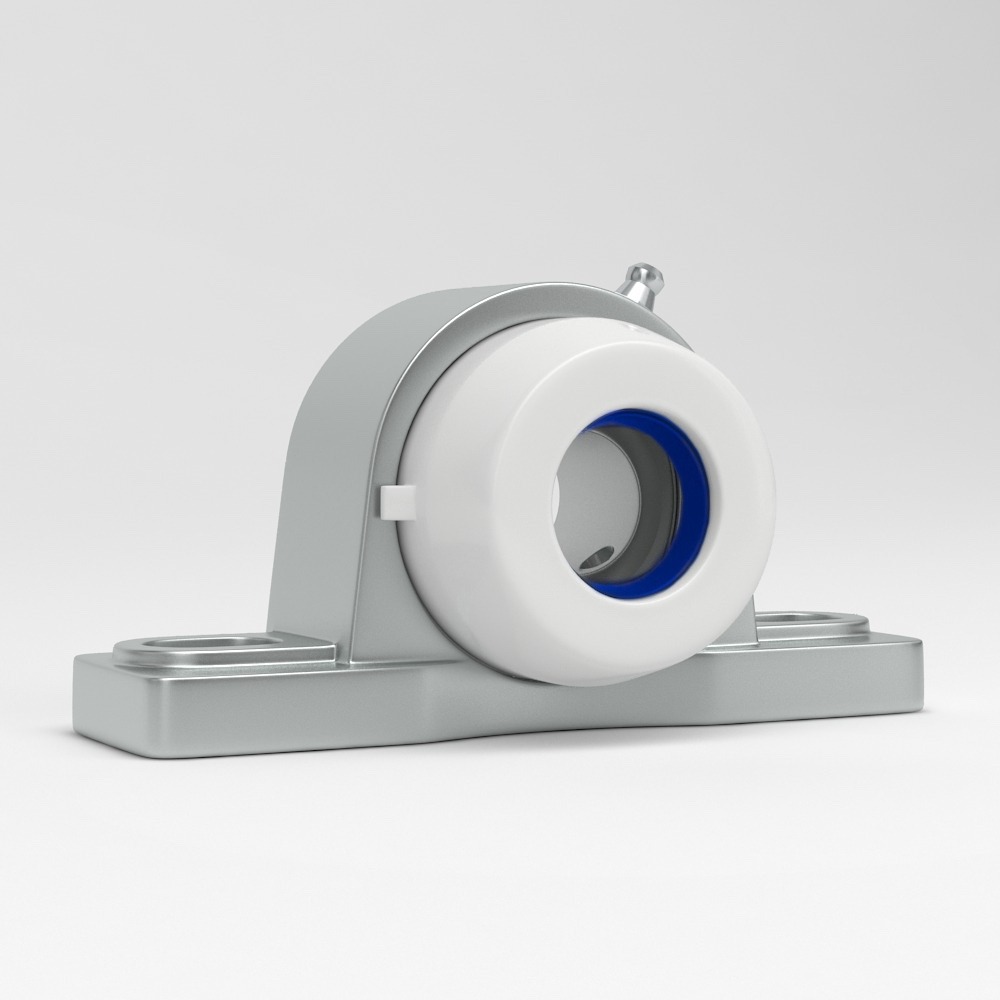

The bearing unit can be fitted with safety cap of polypropylene or Stainless steel AISI 304.

The bearing unit can be fitted with rotary shaft seal ring (TC) with extra dust-protection lip in NBR rubber and with Stainless steel spring.

Pillow block Unit SP in stainless steel features.

- Stainless steel housings AISI 304

- Stainless steel bearings AISI 440C (pre-lubricated)

- Stainless steel grease nipples AISI304 M6x1mm

- No surface coating are required

- Excellent life span

- Operating temperature from -30°C to +120°C.

- Cap material: Polypropylene or Stainless steel AISI 304

- Oil seal material: NBR Rubber with stainless spring

Pillow block Unit SP in stainless steel sizes available.

| Shaft Diameter | Catalog No. |

| Ø20 mm | SP 204 |

| Ø25 mm | SP 205 |

| Ø30 mm | SP 206 |

| Ø35 mm | SP 207 |

| Ø40 mm | SP 208 |

| Ø45 mm | SP 209 |

| Ø50 mm | SP 210 |

| Ø55 mm | SP 211 |

| Ø60 mm | SP 212 |

The SP2xx can be supplied with open cap or closed cap.

Open Cap, suffix “OC” is added to bearing numbers. ex.: SP204OC

Closed Cap, suffix “CC” is added to bearing numbers. ex.: SP204CC

Open Cap Aisi304, suffix “OCSS” is added to bearing numbers. ex.: SP204OCSS

Closed Cap Aisi304, suffix “CCSS” is added to bearing numbers. ex.: SP204CCSS

Sealed pillow block Unit SP in stainless steel with cover.

Stainless steel pillow block units with covers are essential components in various industrial applications, providing robust support for rotating shafts while ensuring protection against environmental factors. These units are designed to offer superior corrosion resistance, strength, and hygiene, making them ideal for demanding environments.

Key Features and Benefits

Exceptional Corrosion Resistance

Constructed from stainless steel alloys, these pillow block units exhibit outstanding resistance to rust and corrosion. This characteristic is particularly beneficial in industries exposed to moisture, chemicals, and other corrosive substances, as it extends the lifespan of the equipment and reduces maintenance requirements.

Enhanced Hygiene and Cleanliness

The non-porous surface of stainless steel prevents bacterial growth, making these units suitable for applications where hygiene is paramount. Industries such as food processing, pharmaceuticals, and healthcare benefit from the easy-to-clean nature of stainless steel pillow block units, ensuring compliance with strict sanitation standards.

High Load Capacity and Reliability

Stainless steel pillow block units are engineered to withstand heavy loads and high-speed operations. Their robust construction ensures reliable performance, even in challenging conditions, contributing to the overall efficiency and safety of industrial machinery.

Protective Covers for Extended Durability

The inclusion of protective covers shields the bearing from contaminants such as dust, debris, and moisture. This feature not only prolongs the service life of the bearing but also maintains optimal performance by preventing ingress of harmful particles.

Applications Across Industries

Due to their durability and hygienic properties, stainless steel pillow block units with covers are utilized across a wide range of industries:

Food and Beverage Processing: Ensuring sanitary conditions and compliance with health regulations.

Pharmaceutical Manufacturing: Maintaining sterile environments to prevent contamination.

Chemical Processing: Resisting corrosion from exposure to harsh chemicals.

Marine Applications: Withstanding the corrosive effects of saltwater environments.

Enhancing Performance and Durability

Stainless steel pillow block units with covers offer a combination of strength, corrosion resistance, and hygiene, making them indispensable in various industrial applications. Their ability to perform reliably under harsh conditions ensures that machinery operates efficiently, safely, and with minimal maintenance.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

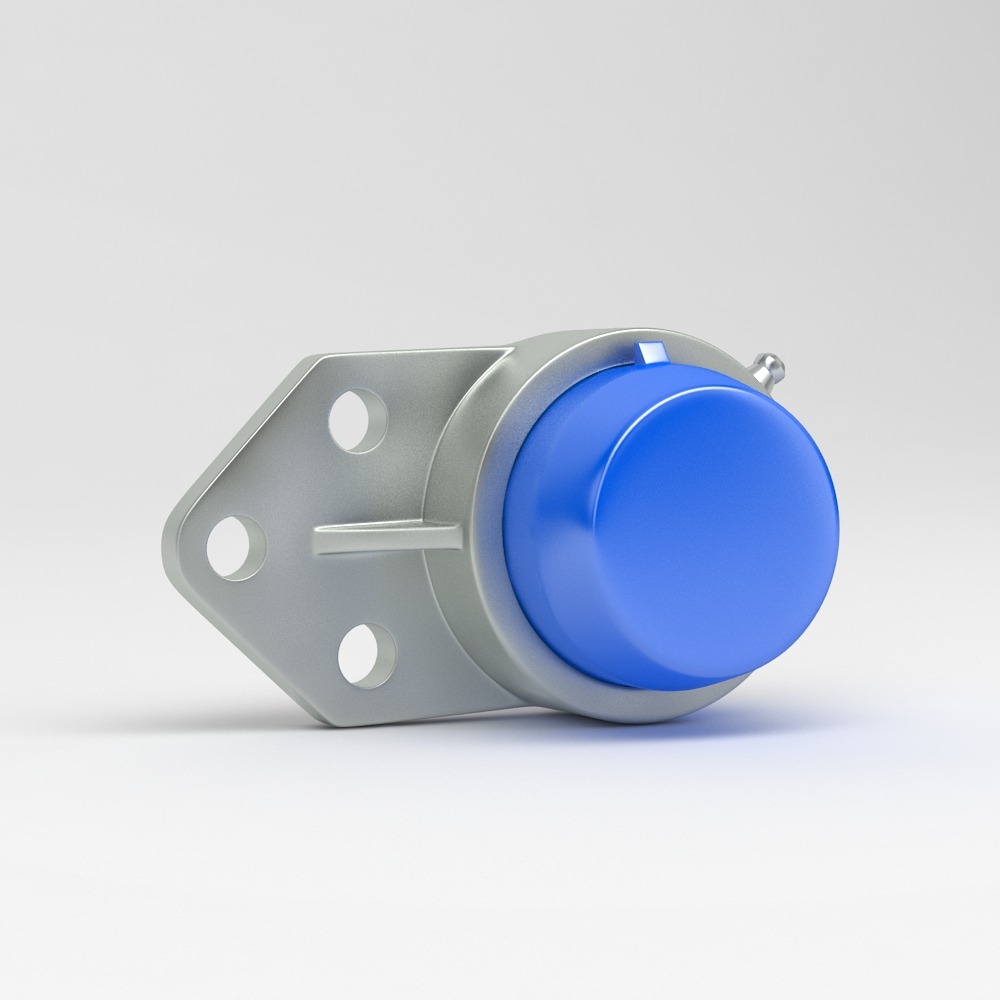

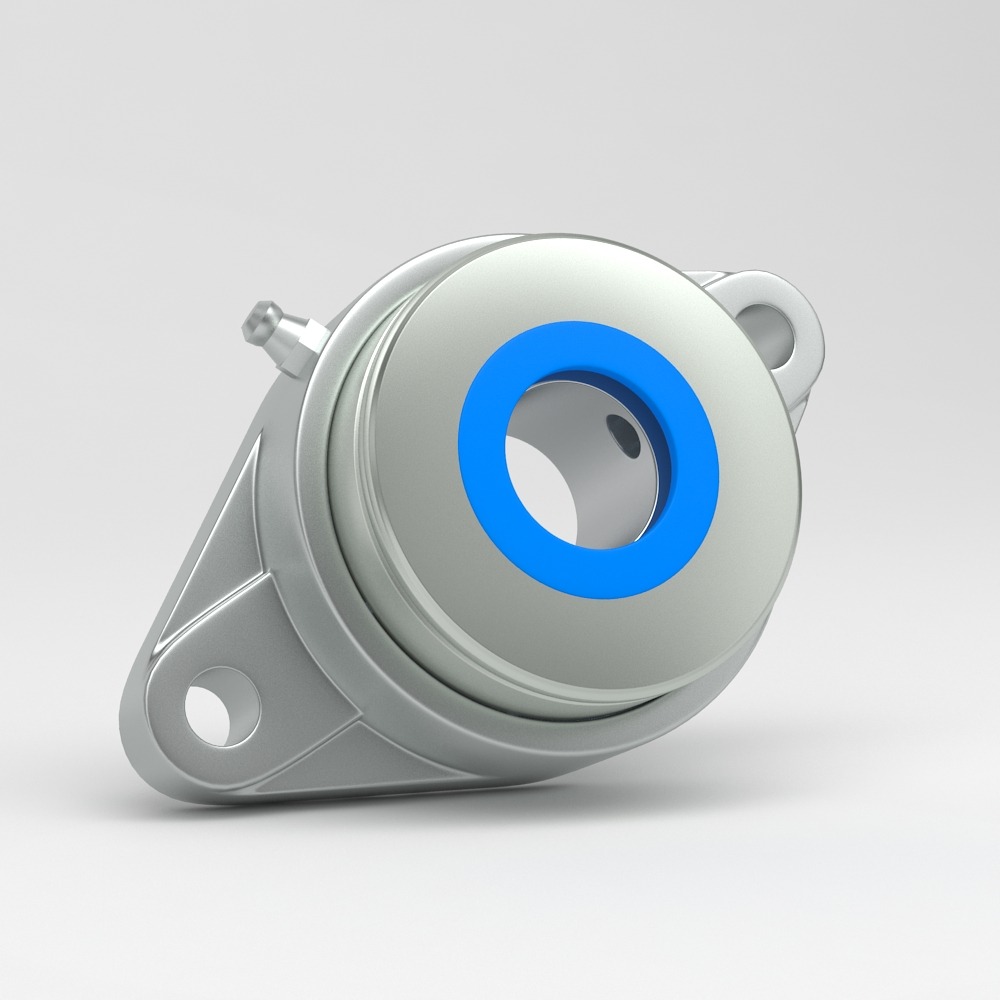

Pillow block Unit SP in stainless steel with cover.

The stainless steel pillow block bearing units type SP is suitable for the food industry and other demanding environments, due to the hygienic design and minimum of maintenance.

The stainless steel bearing units are characterized by high quality and finish for both the bearing and the bearing housing.

Pillow block Unit SP in stainless steel advantages.

The bearing unit has adjustable pre-lubricated Aisi440C stainless steel ball bearing.

The bearing can be re-lubricated by stainless steel Aisi304 grease-nipple or a quick coupler.

The bearing unit can be fitted with safety cap of polypropylene or Stainless steel AISI 304.

The bearing unit can be fitted with rotary shaft seal ring (TC) with extra dust-protection lip in NBR rubber and with Stainless steel spring.

Pillow block Unit SP in stainless steel features.

- Stainless steel housings AISI 304

- Stainless steel bearings AISI 440C (pre-lubricated)

- Stainless steel grease nipples AISI304 M6x1mm

- No surface coating are required

- Excellent life span

- Operating temperature from -30°C to +120°C.

- Cap material: Polypropylene or Stainless steel AISI 304

- Oil seal material: NBR Rubber with stainless spring

Pillow block Unit SP in stainless steel sizes available.

| Shaft Diameter | Catalog No. |

| Ø20 mm | SP 204 |

| Ø25 mm | SP 205 |

| Ø30 mm | SP 206 |

| Ø35 mm | SP 207 |

| Ø40 mm | SP 208 |

| Ø45 mm | SP 209 |

| Ø50 mm | SP 210 |

| Ø55 mm | SP 211 |

| Ø60 mm | SP 212 |

The SP2xx can be supplied with open cap or closed cap.

Open Cap, suffix “OC” is added to bearing numbers. ex.: SP204OC

Closed Cap, suffix “CC” is added to bearing numbers. ex.: SP204CC

Open Cap Aisi304, suffix “OCSS” is added to bearing numbers. ex.: SP204OCSS

Closed Cap Aisi304, suffix “CCSS” is added to bearing numbers. ex.: SP204CCSS

Sealed pillow block Unit SP in stainless steel with cover.

Stainless steel pillow block units with covers are essential components in various industrial applications, providing robust support for rotating shafts while ensuring protection against environmental factors. These units are designed to offer superior corrosion resistance, strength, and hygiene, making them ideal for demanding environments.

Key Features and Benefits

Exceptional Corrosion Resistance

Constructed from stainless steel alloys, these pillow block units exhibit outstanding resistance to rust and corrosion. This characteristic is particularly beneficial in industries exposed to moisture, chemicals, and other corrosive substances, as it extends the lifespan of the equipment and reduces maintenance requirements.

Enhanced Hygiene and Cleanliness

The non-porous surface of stainless steel prevents bacterial growth, making these units suitable for applications where hygiene is paramount. Industries such as food processing, pharmaceuticals, and healthcare benefit from the easy-to-clean nature of stainless steel pillow block units, ensuring compliance with strict sanitation standards.

High Load Capacity and Reliability

Stainless steel pillow block units are engineered to withstand heavy loads and high-speed operations. Their robust construction ensures reliable performance, even in challenging conditions, contributing to the overall efficiency and safety of industrial machinery.

Protective Covers for Extended Durability

The inclusion of protective covers shields the bearing from contaminants such as dust, debris, and moisture. This feature not only prolongs the service life of the bearing but also maintains optimal performance by preventing ingress of harmful particles.

Applications Across Industries

Due to their durability and hygienic properties, stainless steel pillow block units with covers are utilized across a wide range of industries:

Food and Beverage Processing: Ensuring sanitary conditions and compliance with health regulations.

Pharmaceutical Manufacturing: Maintaining sterile environments to prevent contamination.

Chemical Processing: Resisting corrosion from exposure to harsh chemicals.

Marine Applications: Withstanding the corrosive effects of saltwater environments.

Enhancing Performance and Durability

Stainless steel pillow block units with covers offer a combination of strength, corrosion resistance, and hygiene, making them indispensable in various industrial applications. Their ability to perform reliably under harsh conditions ensures that machinery operates efficiently, safely, and with minimal maintenance.

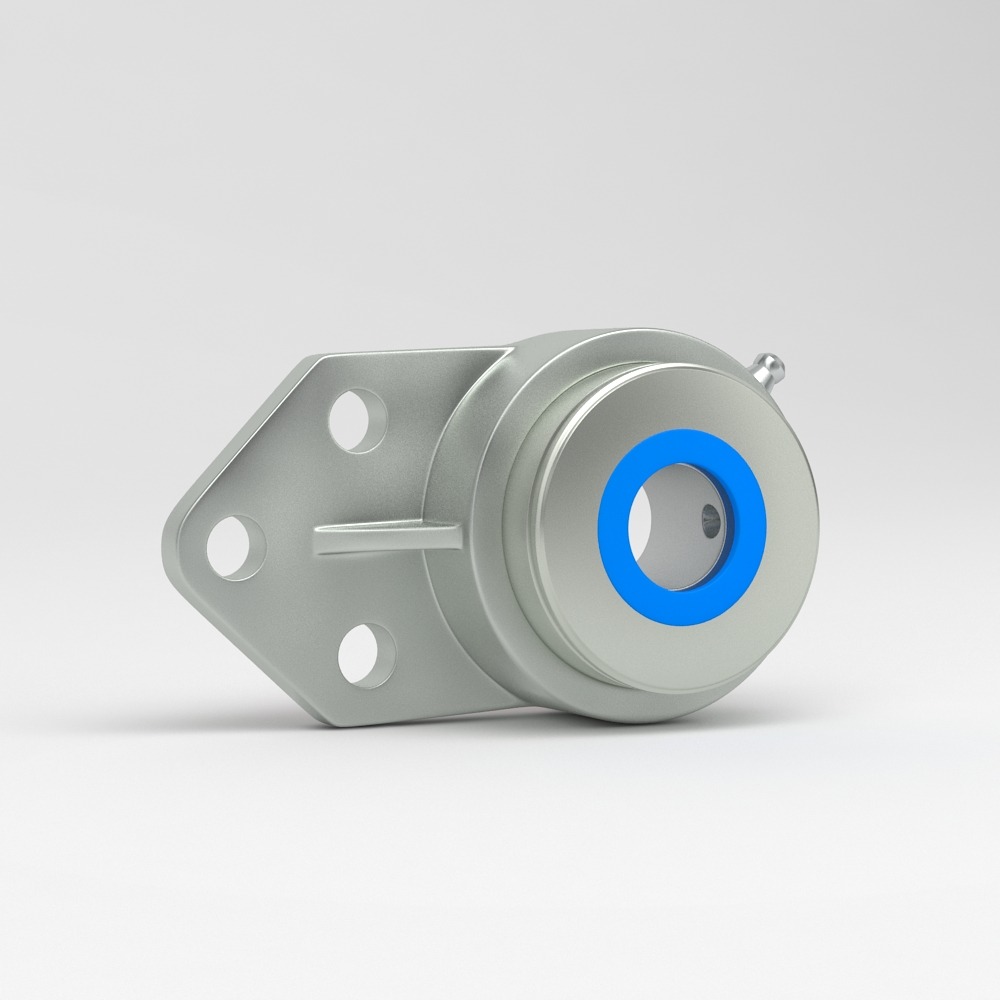

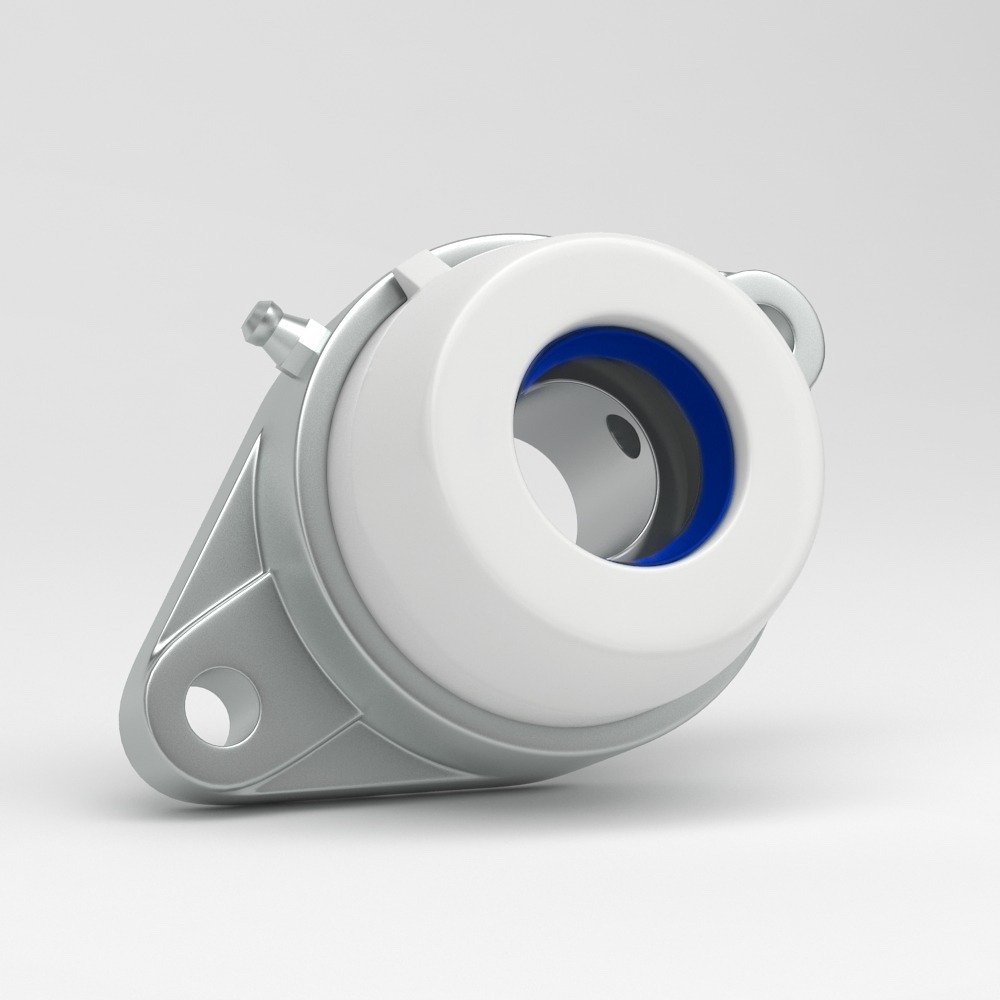

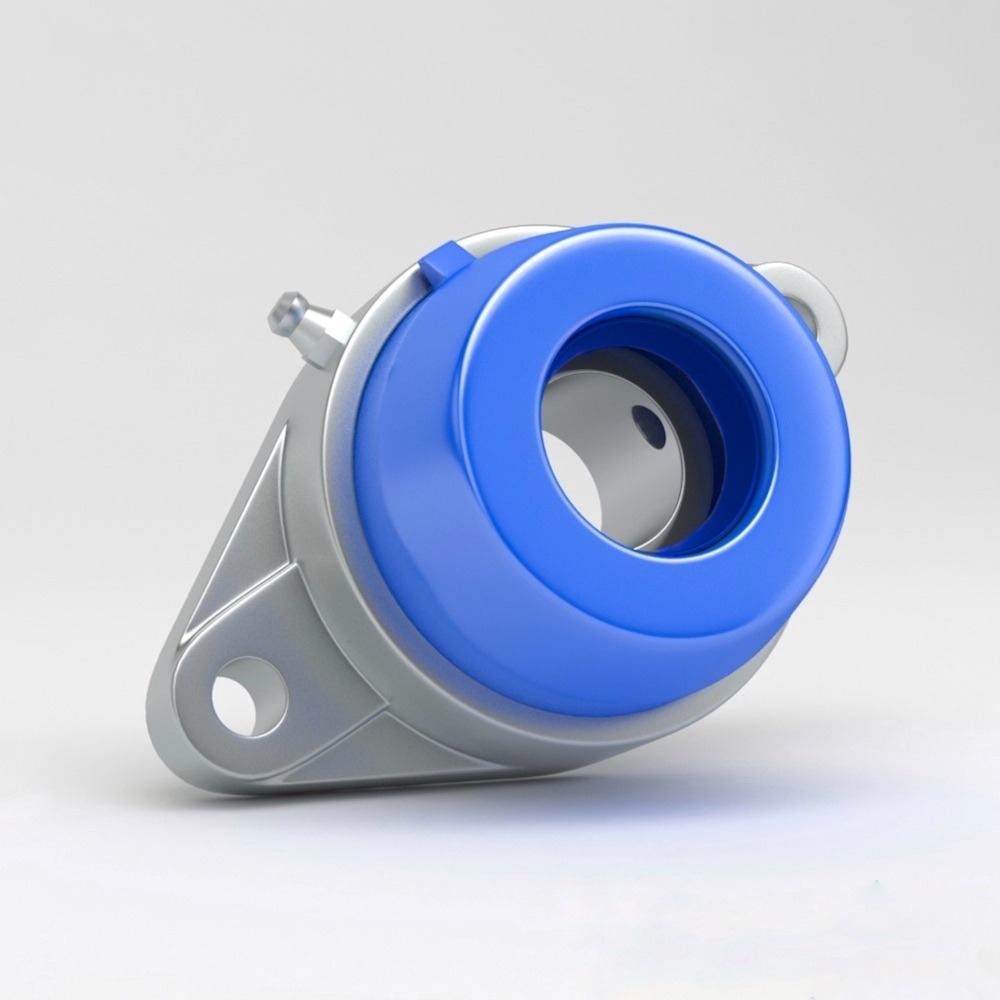

Pillow block Unit SP in stainless steel with cover.

The stainless steel pillow block bearing units type SP is suitable for the food industry and other demanding environments, due to the hygienic design and minimum of maintenance.

The stainless steel bearing units are characterized by high quality and finish for both the bearing and the bearing housing.

Pillow block Unit SP in stainless steel advantages.

The bearing unit has adjustable pre-lubricated Aisi440C stainless steel ball bearing.

The bearing can be re-lubricated by stainless steel Aisi304 grease-nipple or a quick coupler.

The bearing unit can be fitted with safety cap of polypropylene or Stainless steel AISI 304.

The bearing unit can be fitted with rotary shaft seal ring (TC) with extra dust-protection lip in NBR rubber and with Stainless steel spring.

Pillow block Unit SP in stainless steel features.

- Stainless steel housings AISI 304

- Stainless steel bearings AISI 440C (pre-lubricated)

- Stainless steel grease nipples AISI304 M6x1mm

- No surface coating are required

- Excellent life span

- Operating temperature from -30°C to +120°C.

- Cap material: Polypropylene or Stainless steel AISI 304

- Oil seal material: NBR Rubber with stainless spring

Pillow block Unit SP in stainless steel sizes available.

| Shaft Diameter | Catalog No. |

| Ø20 mm | SP 204 |

| Ø25 mm | SP 205 |

| Ø30 mm | SP 206 |

| Ø35 mm | SP 207 |

| Ø40 mm | SP 208 |

| Ø45 mm | SP 209 |

| Ø50 mm | SP 210 |

| Ø55 mm | SP 211 |

| Ø60 mm | SP 212 |

The SP2xx can be supplied with open cap or closed cap.

Open Cap, suffix “OC” is added to bearing numbers. ex.: SP204OC

Closed Cap, suffix “CC” is added to bearing numbers. ex.: SP204CC

Open Cap Aisi304, suffix “OCSS” is added to bearing numbers. ex.: SP204OCSS

Closed Cap Aisi304, suffix “CCSS” is added to bearing numbers. ex.: SP204CCSS

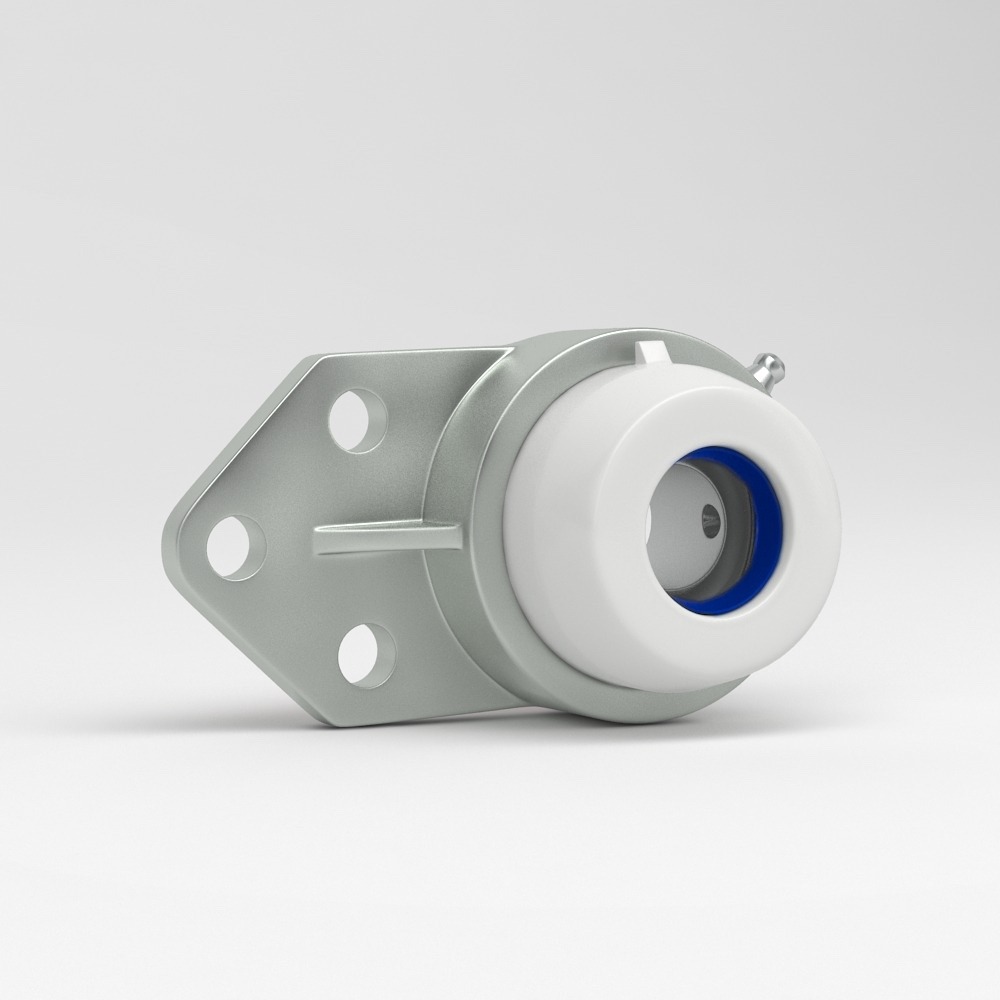

Sealed pillow block Unit SP in stainless steel with cover.

Stainless steel pillow block units with covers are essential components in various industrial applications, providing robust support for rotating shafts while ensuring protection against environmental factors. These units are designed to offer superior corrosion resistance, strength, and hygiene, making them ideal for demanding environments.

Key Features and Benefits

Exceptional Corrosion Resistance

Constructed from stainless steel alloys, these pillow block units exhibit outstanding resistance to rust and corrosion. This characteristic is particularly beneficial in industries exposed to moisture, chemicals, and other corrosive substances, as it extends the lifespan of the equipment and reduces maintenance requirements.

Enhanced Hygiene and Cleanliness

The non-porous surface of stainless steel prevents bacterial growth, making these units suitable for applications where hygiene is paramount. Industries such as food processing, pharmaceuticals, and healthcare benefit from the easy-to-clean nature of stainless steel pillow block units, ensuring compliance with strict sanitation standards.

High Load Capacity and Reliability

Stainless steel pillow block units are engineered to withstand heavy loads and high-speed operations. Their robust construction ensures reliable performance, even in challenging conditions, contributing to the overall efficiency and safety of industrial machinery.

Protective Covers for Extended Durability

The inclusion of protective covers shields the bearing from contaminants such as dust, debris, and moisture. This feature not only prolongs the service life of the bearing but also maintains optimal performance by preventing ingress of harmful particles.

Applications Across Industries

Due to their durability and hygienic properties, stainless steel pillow block units with covers are utilized across a wide range of industries:

Food and Beverage Processing: Ensuring sanitary conditions and compliance with health regulations.

Pharmaceutical Manufacturing: Maintaining sterile environments to prevent contamination.

Chemical Processing: Resisting corrosion from exposure to harsh chemicals.

Marine Applications: Withstanding the corrosive effects of saltwater environments.

Enhancing Performance and Durability

Stainless steel pillow block units with covers offer a combination of strength, corrosion resistance, and hygiene, making them indispensable in various industrial applications. Their ability to perform reliably under harsh conditions ensures that machinery operates efficiently, safely, and with minimal maintenance.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.