Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Key for IP67 hygienic lock in stainless steel

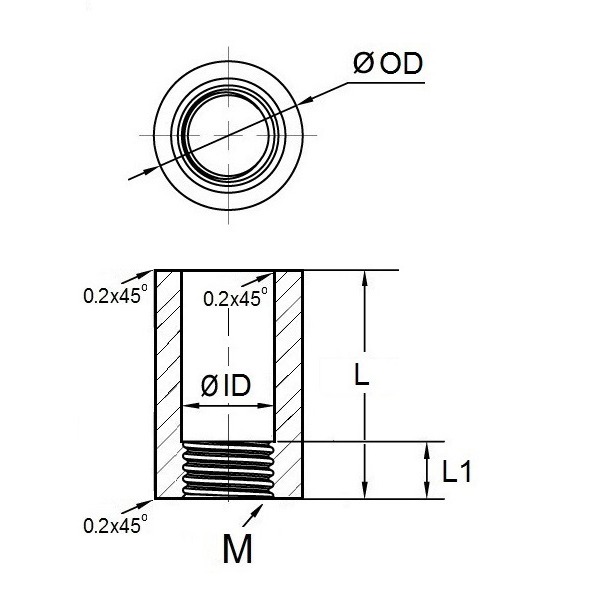

Key for Sealed IP67 Hygienic Locks for Enclosures in Strict Hygiene Environments

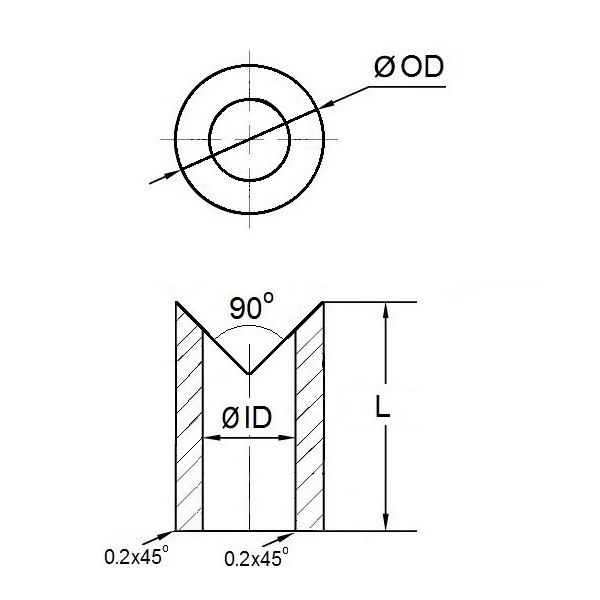

Key for 12.8mm top IP67 Hygienic Locks

Key for triangle top IP67 Hygienic Locks

Introduction to Hygienic Locks for Enclosures

In industries with stringent hygiene requirements, such as food processing, pharmaceuticals, and biotechnology, equipment components must meet the highest standards for cleanliness and safety. Hygienic locks for enclosures, particularly those rated IP67, play a critical role in maintaining sanitary environments. These locks are specially designed to resist water, dust, and contamination, making them ideal for harsh industrial settings.

What Are IP67 Hygienic Locks?

IP67 hygienic locks are sealing mechanisms designed to secure enclosures while meeting stringent hygiene and environmental standards. The IP67 rating signifies that these locks are:

- Dust-tight: Preventing the ingress of dust and fine particles.

- Waterproof: Resistant to water immersion up to 1 meter for 30 minutes.

This makes them indispensable in environments where equipment cleaning involves high-pressure washdowns or exposure to moisture.

Key Features of IP67 Hygienic Locks

1. Seamless Design for Easy Cleaning

Hygienic locks often feature a seamless, rounded design to prevent the accumulation of dirt, bacteria, and other contaminants. These smooth surfaces allow for effortless cleaning during routine sanitation processes.

2. Corrosion-Resistant Materials

Constructed from high-grade stainless steel, IP67 locks are resistant to corrosion caused by cleaning chemicals, salty environments, or industrial processes. This enhances their durability and ensures a long service life.

3. Secure Sealing Mechanisms

The locks are equipped with advanced sealing technologies that provide an airtight closure for enclosures. This minimizes the risk of contamination and protects sensitive equipment from environmental damage.

4. Compliance with Industry Standards

IP67 hygienic locks are often compliant with international standards such as:

- EHEDG (European Hygienic Engineering & Design Group) for hygienic design.

- FDA (Food and Drug Administration) for food-grade materials.

- ISO 14159 for safety in machinery.

5. Ease of Installation and Operation

These locks are designed for quick installation and ergonomic operation, reducing downtime and enhancing productivity in industrial settings.

Benefits of Using IP67 Hygienic Locks

Enhanced Hygiene and Safety

By preventing contamination and ensuring equipment integrity, these locks support strict hygiene protocols in industries like food and pharmaceutical processing.

Longevity and Reliability

The use of durable materials and robust sealing mechanisms ensures that these locks can withstand repeated cleaning cycles and harsh environments.

Cost Efficiency

Investing in IP67 hygienic locks minimizes maintenance and replacement costs, delivering long-term value to businesses.

Industry-Specific Versatility

From food processing to biotechnology, these locks are versatile enough to meet the unique demands of various sectors.

Applications of IP67 Hygienic Locks

Food Processing

In food production, equipment cleanliness is paramount to avoid cross-contamination. Hygienic locks ensure that enclosures remain sealed during high-pressure cleaning, safeguarding food quality.

Pharmaceutical Manufacturing

Pharmaceutical environments demand absolute sterility. IP67 locks provide secure containment for equipment, preventing contamination during production processes.

Biotechnology and Healthcare

In laboratories and healthcare facilities, these locks are used to maintain the integrity of sensitive equipment and protect against environmental contaminants.

Beverage Industry

From bottling lines to fermentation tanks, the beverage industry relies on IP67 locks to ensure equipment remains sealed and uncontaminated during operation and cleaning.

Choosing the Right IP67 Hygienic Lock

When selecting hygienic locks for your enclosures, consider the following factors:

- Material Quality: Stainless steel or other FDA-compliant materials.

- Sealing Performance: Ensure the IP67 rating for water and dust resistance.

- Compatibility: Match the lock design to your specific enclosure and industry requirements.

- Certification: Look for compliance with relevant hygiene and safety standards.

Maintenance and Best Practices

To maximize the performance and lifespan of IP67 hygienic locks:

- Regular Cleaning: Use approved cleaning agents to maintain the lock’s hygienic integrity.

- Routine Inspections: Check for signs of wear, corrosion, or damage.

- Proper Installation: Ensure the locks are securely fitted and operational.

Optimal choice for equipment that must comply with strict hygiene requirements.

Sealed IP67 hygienic locks are critical components in maintaining strict hygiene standards across industries such as food processing, pharmaceuticals, and biotechnology. Their innovative design, durable materials, and compliance with global standards make them an invaluable investment for any organization focused on cleanliness and safety.

By choosing the right locks and following proper maintenance practices, businesses can enhance operational efficiency, protect equipment, and uphold the highest hygiene standards.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Key for Sealed IP67 Hygienic Locks for Enclosures in Strict Hygiene Environments

Key for 12.8mm top IP67 Hygienic Locks

Key for triangle top IP67 Hygienic Locks

Introduction to Hygienic Locks for Enclosures

In industries with stringent hygiene requirements, such as food processing, pharmaceuticals, and biotechnology, equipment components must meet the highest standards for cleanliness and safety. Hygienic locks for enclosures, particularly those rated IP67, play a critical role in maintaining sanitary environments. These locks are specially designed to resist water, dust, and contamination, making them ideal for harsh industrial settings.

What Are IP67 Hygienic Locks?

IP67 hygienic locks are sealing mechanisms designed to secure enclosures while meeting stringent hygiene and environmental standards. The IP67 rating signifies that these locks are:

- Dust-tight: Preventing the ingress of dust and fine particles.

- Waterproof: Resistant to water immersion up to 1 meter for 30 minutes.

This makes them indispensable in environments where equipment cleaning involves high-pressure washdowns or exposure to moisture.

Key Features of IP67 Hygienic Locks

1. Seamless Design for Easy Cleaning

Hygienic locks often feature a seamless, rounded design to prevent the accumulation of dirt, bacteria, and other contaminants. These smooth surfaces allow for effortless cleaning during routine sanitation processes.

2. Corrosion-Resistant Materials

Constructed from high-grade stainless steel, IP67 locks are resistant to corrosion caused by cleaning chemicals, salty environments, or industrial processes. This enhances their durability and ensures a long service life.

3. Secure Sealing Mechanisms

The locks are equipped with advanced sealing technologies that provide an airtight closure for enclosures. This minimizes the risk of contamination and protects sensitive equipment from environmental damage.

4. Compliance with Industry Standards

IP67 hygienic locks are often compliant with international standards such as:

- EHEDG (European Hygienic Engineering & Design Group) for hygienic design.

- FDA (Food and Drug Administration) for food-grade materials.

- ISO 14159 for safety in machinery.

5. Ease of Installation and Operation

These locks are designed for quick installation and ergonomic operation, reducing downtime and enhancing productivity in industrial settings.

Benefits of Using IP67 Hygienic Locks

Enhanced Hygiene and Safety

By preventing contamination and ensuring equipment integrity, these locks support strict hygiene protocols in industries like food and pharmaceutical processing.

Longevity and Reliability

The use of durable materials and robust sealing mechanisms ensures that these locks can withstand repeated cleaning cycles and harsh environments.

Cost Efficiency

Investing in IP67 hygienic locks minimizes maintenance and replacement costs, delivering long-term value to businesses.

Industry-Specific Versatility

From food processing to biotechnology, these locks are versatile enough to meet the unique demands of various sectors.

Applications of IP67 Hygienic Locks

Food Processing

In food production, equipment cleanliness is paramount to avoid cross-contamination. Hygienic locks ensure that enclosures remain sealed during high-pressure cleaning, safeguarding food quality.

Pharmaceutical Manufacturing

Pharmaceutical environments demand absolute sterility. IP67 locks provide secure containment for equipment, preventing contamination during production processes.

Biotechnology and Healthcare

In laboratories and healthcare facilities, these locks are used to maintain the integrity of sensitive equipment and protect against environmental contaminants.

Beverage Industry

From bottling lines to fermentation tanks, the beverage industry relies on IP67 locks to ensure equipment remains sealed and uncontaminated during operation and cleaning.

Choosing the Right IP67 Hygienic Lock

When selecting hygienic locks for your enclosures, consider the following factors:

- Material Quality: Stainless steel or other FDA-compliant materials.

- Sealing Performance: Ensure the IP67 rating for water and dust resistance.

- Compatibility: Match the lock design to your specific enclosure and industry requirements.

- Certification: Look for compliance with relevant hygiene and safety standards.

Maintenance and Best Practices

To maximize the performance and lifespan of IP67 hygienic locks:

- Regular Cleaning: Use approved cleaning agents to maintain the lock’s hygienic integrity.

- Routine Inspections: Check for signs of wear, corrosion, or damage.

- Proper Installation: Ensure the locks are securely fitted and operational.

Optimal choice for equipment that must comply with strict hygiene requirements.

Sealed IP67 hygienic locks are critical components in maintaining strict hygiene standards across industries such as food processing, pharmaceuticals, and biotechnology. Their innovative design, durable materials, and compliance with global standards make them an invaluable investment for any organization focused on cleanliness and safety.

By choosing the right locks and following proper maintenance practices, businesses can enhance operational efficiency, protect equipment, and uphold the highest hygiene standards.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Key for Sealed IP67 Hygienic Locks for Enclosures in Strict Hygiene Environments

Key for 12.8mm top IP67 Hygienic Locks

Key for triangle top IP67 Hygienic Locks

Introduction to Hygienic Locks for Enclosures

In industries with stringent hygiene requirements, such as food processing, pharmaceuticals, and biotechnology, equipment components must meet the highest standards for cleanliness and safety. Hygienic locks for enclosures, particularly those rated IP67, play a critical role in maintaining sanitary environments. These locks are specially designed to resist water, dust, and contamination, making them ideal for harsh industrial settings.

What Are IP67 Hygienic Locks?

IP67 hygienic locks are sealing mechanisms designed to secure enclosures while meeting stringent hygiene and environmental standards. The IP67 rating signifies that these locks are:

- Dust-tight: Preventing the ingress of dust and fine particles.

- Waterproof: Resistant to water immersion up to 1 meter for 30 minutes.

This makes them indispensable in environments where equipment cleaning involves high-pressure washdowns or exposure to moisture.

Key Features of IP67 Hygienic Locks

1. Seamless Design for Easy Cleaning

Hygienic locks often feature a seamless, rounded design to prevent the accumulation of dirt, bacteria, and other contaminants. These smooth surfaces allow for effortless cleaning during routine sanitation processes.

2. Corrosion-Resistant Materials

Constructed from high-grade stainless steel, IP67 locks are resistant to corrosion caused by cleaning chemicals, salty environments, or industrial processes. This enhances their durability and ensures a long service life.

3. Secure Sealing Mechanisms

The locks are equipped with advanced sealing technologies that provide an airtight closure for enclosures. This minimizes the risk of contamination and protects sensitive equipment from environmental damage.

4. Compliance with Industry Standards

IP67 hygienic locks are often compliant with international standards such as:

- EHEDG (European Hygienic Engineering & Design Group) for hygienic design.

- FDA (Food and Drug Administration) for food-grade materials.

- ISO 14159 for safety in machinery.

5. Ease of Installation and Operation

These locks are designed for quick installation and ergonomic operation, reducing downtime and enhancing productivity in industrial settings.

Benefits of Using IP67 Hygienic Locks

Enhanced Hygiene and Safety

By preventing contamination and ensuring equipment integrity, these locks support strict hygiene protocols in industries like food and pharmaceutical processing.

Longevity and Reliability

The use of durable materials and robust sealing mechanisms ensures that these locks can withstand repeated cleaning cycles and harsh environments.

Cost Efficiency

Investing in IP67 hygienic locks minimizes maintenance and replacement costs, delivering long-term value to businesses.

Industry-Specific Versatility

From food processing to biotechnology, these locks are versatile enough to meet the unique demands of various sectors.

Applications of IP67 Hygienic Locks

Food Processing

In food production, equipment cleanliness is paramount to avoid cross-contamination. Hygienic locks ensure that enclosures remain sealed during high-pressure cleaning, safeguarding food quality.

Pharmaceutical Manufacturing

Pharmaceutical environments demand absolute sterility. IP67 locks provide secure containment for equipment, preventing contamination during production processes.

Biotechnology and Healthcare

In laboratories and healthcare facilities, these locks are used to maintain the integrity of sensitive equipment and protect against environmental contaminants.

Beverage Industry

From bottling lines to fermentation tanks, the beverage industry relies on IP67 locks to ensure equipment remains sealed and uncontaminated during operation and cleaning.

Choosing the Right IP67 Hygienic Lock

When selecting hygienic locks for your enclosures, consider the following factors:

- Material Quality: Stainless steel or other FDA-compliant materials.

- Sealing Performance: Ensure the IP67 rating for water and dust resistance.

- Compatibility: Match the lock design to your specific enclosure and industry requirements.

- Certification: Look for compliance with relevant hygiene and safety standards.

Maintenance and Best Practices

To maximize the performance and lifespan of IP67 hygienic locks:

- Regular Cleaning: Use approved cleaning agents to maintain the lock’s hygienic integrity.

- Routine Inspections: Check for signs of wear, corrosion, or damage.

- Proper Installation: Ensure the locks are securely fitted and operational.

Optimal choice for equipment that must comply with strict hygiene requirements.

Sealed IP67 hygienic locks are critical components in maintaining strict hygiene standards across industries such as food processing, pharmaceuticals, and biotechnology. Their innovative design, durable materials, and compliance with global standards make them an invaluable investment for any organization focused on cleanliness and safety.

By choosing the right locks and following proper maintenance practices, businesses can enhance operational efficiency, protect equipment, and uphold the highest hygiene standards.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.