Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

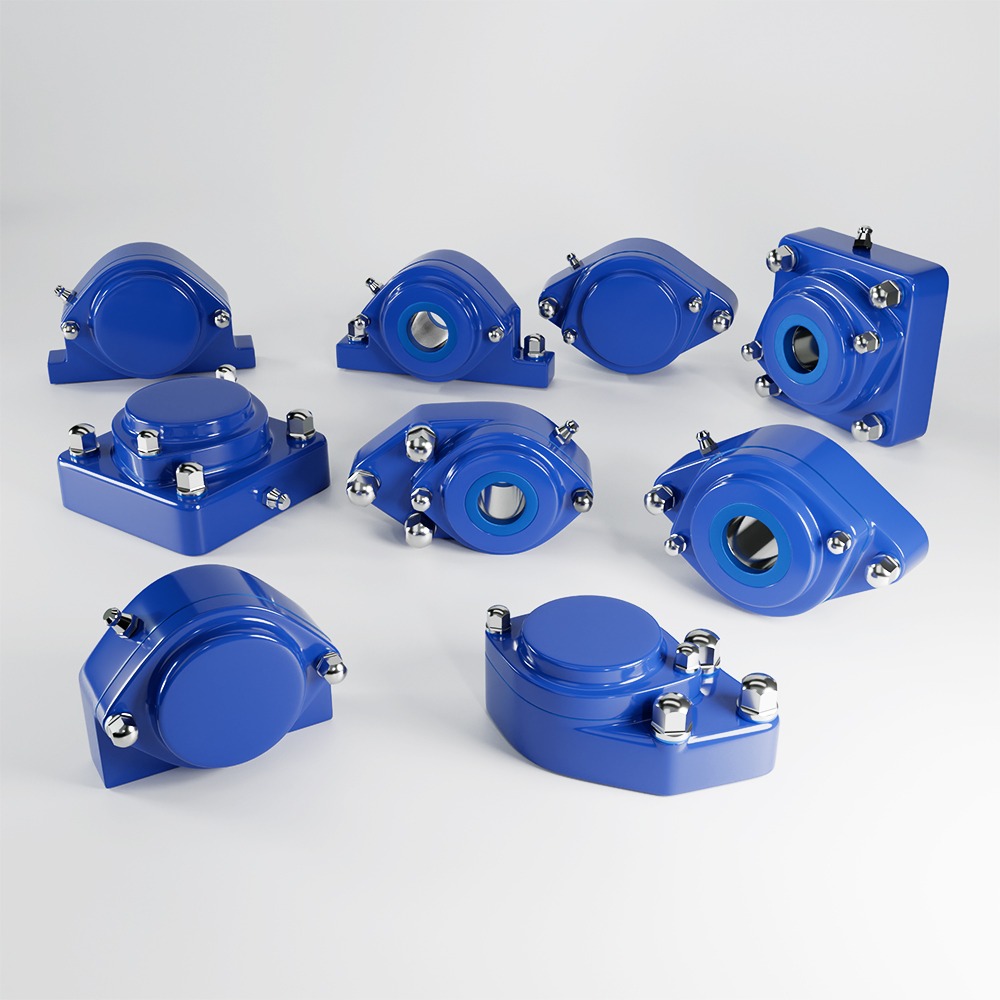

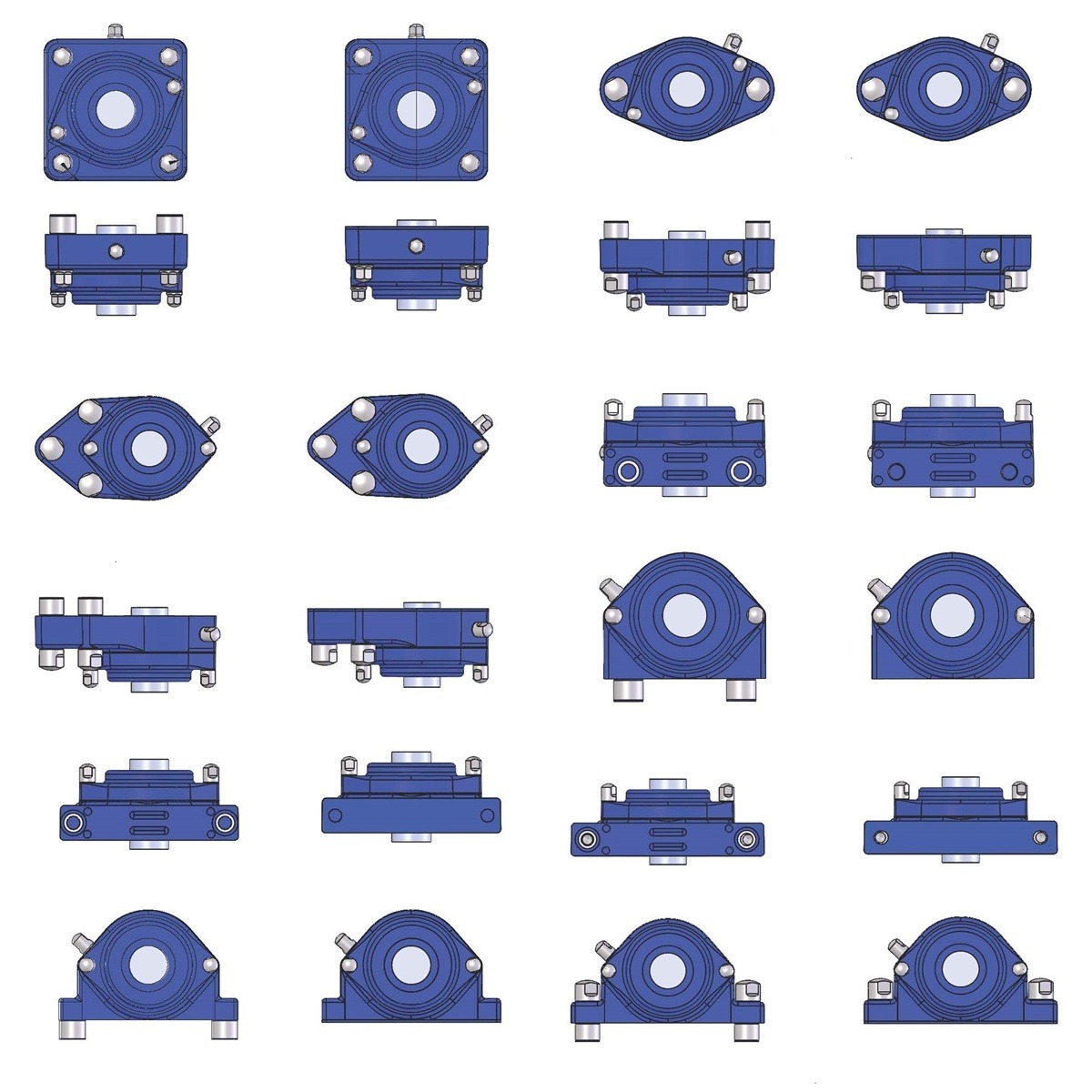

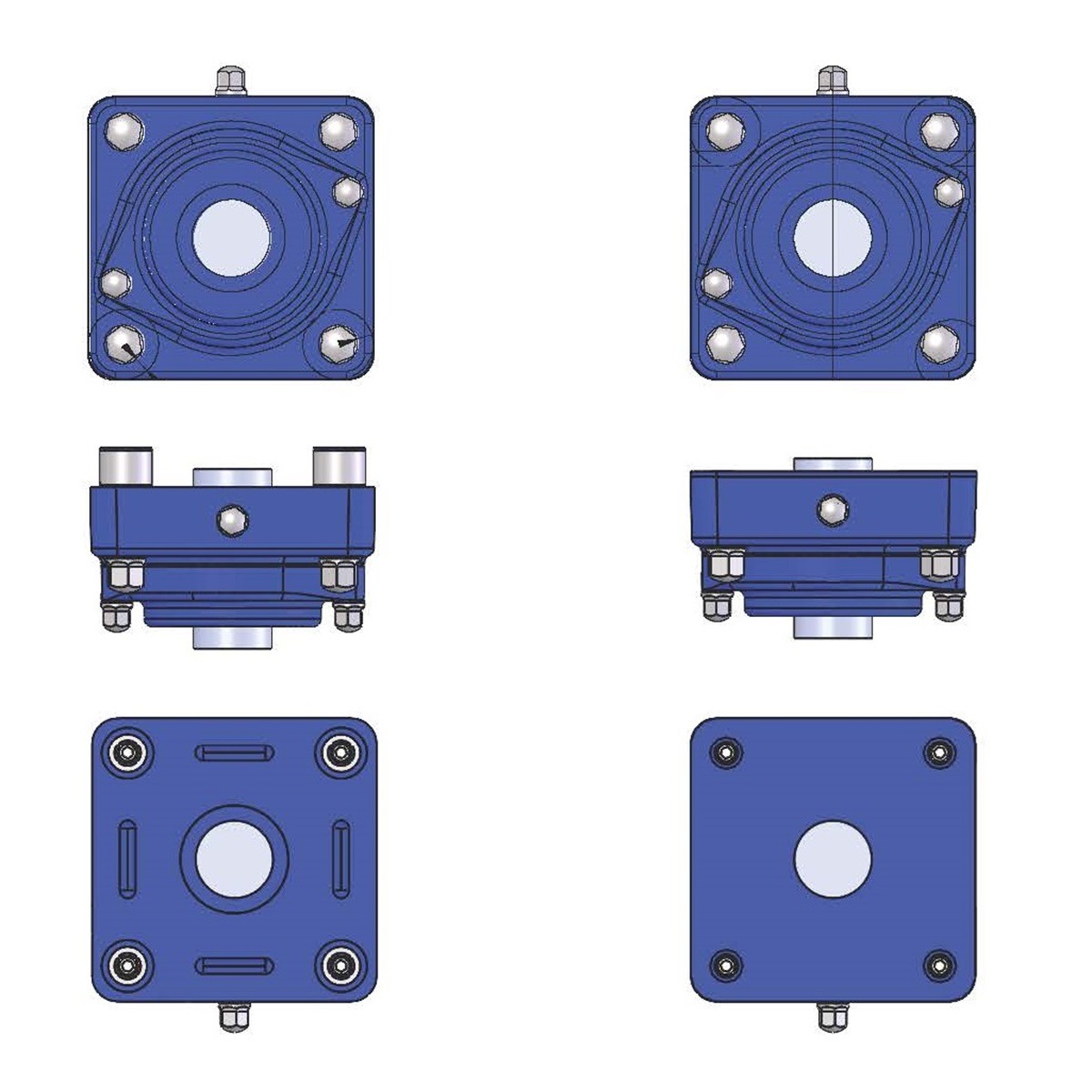

IP69K Certified Hygienic Bearing Units

Maximizing Safety and Efficiency in Essential Industries

EHEDG, 3A and IP69K Certified Hygienic Bearing Units

Check out our extensive range of waterproof bearings

In critical sectors such as food processing, pharmaceuticals, cosmetics, diary, butchery, and the chemical industry, the need for uncompromising hygiene and safety standards is paramount. EHEDG (European Hygienic Engineering & Design Group), 3A, and IP69K certified hygienic bearing units stand at the forefront of meeting these rigorous standards. This article explores the multifaceted benefits of integrating these certified bearing units into production lines, underscoring their pivotal role in elevating safety, compliance, and operational efficiency.

Adherence to Stringent Hygiene and Safety Standards

The certifications from EHEDG, 3A, and IP69K symbolize the highest level of commitment to hygiene and safety in manufacturing equipment. Bearing units that secure these certifications are designed meticulously to eliminate contamination risks. Their seamless surfaces and sophisticated sealing mechanisms significantly cut down the potential for microbial growth, ensuring products comply with strict safety and quality guidelines.

Exceptional Corrosion Resistance

For industries consistently exposed to severe processing conditions, the corrosion-resistant nature of these bearing units is invaluable. Made from materials like stainless steel and corrosion-resistant alloys, they offer robust resistance against various environmental challenges, including fluctuating temperatures and corrosive elements.

Streamlined Cleaning and Maintenance

These bearing units are engineered for ease of maintenance, a critical feature in high-demand industries. Their design facilitates quick disassembly and reassembly, streamlining the cleaning process, reducing downtime, and enhancing overall productivity.

Reduced Risk of Lubricant Contamination

With advanced sealing technologies, these bearing units effectively prevent lubricant leakage, crucial for maintaining product purity, especially in sectors like food processing and pharmaceuticals. This aspect of design ensures the safety and quality of the final product, mitigating contamination risks.

Regulatory Compliance Assurance

Using bearing units with these certifications ensures compliance with global standards in food safety and hygiene. This not only safeguards consumer health but also reinforces the integrity and trustworthiness of the brand in adhering to high safety standards.

Enhanced Efficiency and Reliability

Designed to withstand industry-specific challenges, these bearing units contribute to reduced maintenance needs and enhanced operational efficiency. This reliability is crucial for maintaining a competitive advantage in dynamic industrial environments.

Environmental and Economic Benefits

The features like reduced lubrication requirements contribute to lower environmental impact and operational costs. The longevity and efficiency of these units result in long-term cost savings, aligning with sustainable operational goals.

Conclusion

Incorporating EHEDG, 3A, and IP69K certified hygienic bearing units is a strategic decision for businesses in vital industries like food processing, pharmaceuticals, cosmetics, and chemicals. These units not only ensure top-notch safety and hygiene standards but also boost operational efficiency and sustainability. As these industries continue to evolve, the importance of using certified equipment to maintain safety, efficiency, and regulatory compliance becomes increasingly critical.

Questions and contact

If you have any questions about our products. You are always welcome to contact us for questions about performance and solutions for your machine or anything else. You can read more about how to contact us here. You can find us in Denmark, the UK, Germany and Hong Kong.

Checkout our range of hygienic machinery components here.

Check out all of our waterproof bearings

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Maximizing Safety and Efficiency in Essential Industries

EHEDG, 3A and IP69K Certified Hygienic Bearing Units

Check out our extensive range of waterproof bearings

In critical sectors such as food processing, pharmaceuticals, cosmetics, diary, butchery, and the chemical industry, the need for uncompromising hygiene and safety standards is paramount. EHEDG (European Hygienic Engineering & Design Group), 3A, and IP69K certified hygienic bearing units stand at the forefront of meeting these rigorous standards. This article explores the multifaceted benefits of integrating these certified bearing units into production lines, underscoring their pivotal role in elevating safety, compliance, and operational efficiency.

Adherence to Stringent Hygiene and Safety Standards

The certifications from EHEDG, 3A, and IP69K symbolize the highest level of commitment to hygiene and safety in manufacturing equipment. Bearing units that secure these certifications are designed meticulously to eliminate contamination risks. Their seamless surfaces and sophisticated sealing mechanisms significantly cut down the potential for microbial growth, ensuring products comply with strict safety and quality guidelines.

Exceptional Corrosion Resistance

For industries consistently exposed to severe processing conditions, the corrosion-resistant nature of these bearing units is invaluable. Made from materials like stainless steel and corrosion-resistant alloys, they offer robust resistance against various environmental challenges, including fluctuating temperatures and corrosive elements.

Streamlined Cleaning and Maintenance

These bearing units are engineered for ease of maintenance, a critical feature in high-demand industries. Their design facilitates quick disassembly and reassembly, streamlining the cleaning process, reducing downtime, and enhancing overall productivity.

Reduced Risk of Lubricant Contamination

With advanced sealing technologies, these bearing units effectively prevent lubricant leakage, crucial for maintaining product purity, especially in sectors like food processing and pharmaceuticals. This aspect of design ensures the safety and quality of the final product, mitigating contamination risks.

Regulatory Compliance Assurance

Using bearing units with these certifications ensures compliance with global standards in food safety and hygiene. This not only safeguards consumer health but also reinforces the integrity and trustworthiness of the brand in adhering to high safety standards.

Enhanced Efficiency and Reliability

Designed to withstand industry-specific challenges, these bearing units contribute to reduced maintenance needs and enhanced operational efficiency. This reliability is crucial for maintaining a competitive advantage in dynamic industrial environments.

Environmental and Economic Benefits

The features like reduced lubrication requirements contribute to lower environmental impact and operational costs. The longevity and efficiency of these units result in long-term cost savings, aligning with sustainable operational goals.

Conclusion

Incorporating EHEDG, 3A, and IP69K certified hygienic bearing units is a strategic decision for businesses in vital industries like food processing, pharmaceuticals, cosmetics, and chemicals. These units not only ensure top-notch safety and hygiene standards but also boost operational efficiency and sustainability. As these industries continue to evolve, the importance of using certified equipment to maintain safety, efficiency, and regulatory compliance becomes increasingly critical.

Questions and contact

If you have any questions about our products. You are always welcome to contact us for questions about performance and solutions for your machine or anything else. You can read more about how to contact us here. You can find us in Denmark, the UK, Germany and Hong Kong.

Checkout our range of hygienic machinery components here.

Check out all of our waterproof bearings

Maximizing Safety and Efficiency in Essential Industries

EHEDG, 3A and IP69K Certified Hygienic Bearing Units

Check out our extensive range of waterproof bearings

In critical sectors such as food processing, pharmaceuticals, cosmetics, diary, butchery, and the chemical industry, the need for uncompromising hygiene and safety standards is paramount. EHEDG (European Hygienic Engineering & Design Group), 3A, and IP69K certified hygienic bearing units stand at the forefront of meeting these rigorous standards. This article explores the multifaceted benefits of integrating these certified bearing units into production lines, underscoring their pivotal role in elevating safety, compliance, and operational efficiency.

Adherence to Stringent Hygiene and Safety Standards

The certifications from EHEDG, 3A, and IP69K symbolize the highest level of commitment to hygiene and safety in manufacturing equipment. Bearing units that secure these certifications are designed meticulously to eliminate contamination risks. Their seamless surfaces and sophisticated sealing mechanisms significantly cut down the potential for microbial growth, ensuring products comply with strict safety and quality guidelines.

Exceptional Corrosion Resistance

For industries consistently exposed to severe processing conditions, the corrosion-resistant nature of these bearing units is invaluable. Made from materials like stainless steel and corrosion-resistant alloys, they offer robust resistance against various environmental challenges, including fluctuating temperatures and corrosive elements.

Streamlined Cleaning and Maintenance

These bearing units are engineered for ease of maintenance, a critical feature in high-demand industries. Their design facilitates quick disassembly and reassembly, streamlining the cleaning process, reducing downtime, and enhancing overall productivity.

Reduced Risk of Lubricant Contamination

With advanced sealing technologies, these bearing units effectively prevent lubricant leakage, crucial for maintaining product purity, especially in sectors like food processing and pharmaceuticals. This aspect of design ensures the safety and quality of the final product, mitigating contamination risks.

Regulatory Compliance Assurance

Using bearing units with these certifications ensures compliance with global standards in food safety and hygiene. This not only safeguards consumer health but also reinforces the integrity and trustworthiness of the brand in adhering to high safety standards.

Enhanced Efficiency and Reliability

Designed to withstand industry-specific challenges, these bearing units contribute to reduced maintenance needs and enhanced operational efficiency. This reliability is crucial for maintaining a competitive advantage in dynamic industrial environments.

Environmental and Economic Benefits

The features like reduced lubrication requirements contribute to lower environmental impact and operational costs. The longevity and efficiency of these units result in long-term cost savings, aligning with sustainable operational goals.

Conclusion

Incorporating EHEDG, 3A, and IP69K certified hygienic bearing units is a strategic decision for businesses in vital industries like food processing, pharmaceuticals, cosmetics, and chemicals. These units not only ensure top-notch safety and hygiene standards but also boost operational efficiency and sustainability. As these industries continue to evolve, the importance of using certified equipment to maintain safety, efficiency, and regulatory compliance becomes increasingly critical.

Questions and contact

If you have any questions about our products. You are always welcome to contact us for questions about performance and solutions for your machine or anything else. You can read more about how to contact us here. You can find us in Denmark, the UK, Germany and Hong Kong.

Checkout our range of hygienic machinery components here.

Check out all of our waterproof bearings

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.