Spacer Nut in Stainless Steel

Reduce Downtime and Maintenance Costs

In industries where equipment performance is critical, choosing the right components can significantly impact efficiency and maintenance. Stainless steel spacer nuts are one such essential component designed to enhance operational reliability while reducing downtime and associated costs. Their durability and precision make them indispensable in various industries, from food processing to pharmaceuticals.

What Are Spacer Nuts?

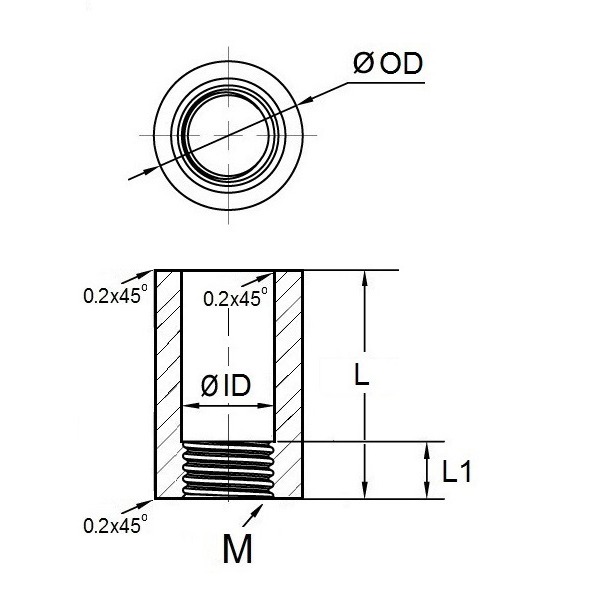

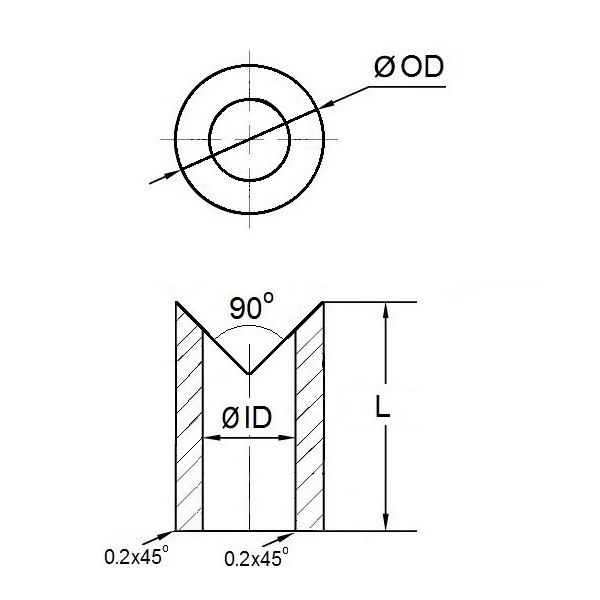

Spacer nuts are specialized fasteners used to maintain a precise distance between components, ensuring stability and alignment in machinery. Unlike traditional nuts, spacer nuts are designed to perform dual functions: fastening and spacing. When crafted from stainless steel, they gain additional advantages, such as corrosion resistance, strength, and hygiene.

Benefits of Stainless Steel Spacer Nuts

1. Corrosion Resistance

Stainless steel is renowned for its ability to withstand harsh environments, including exposure to moisture, chemicals, and extreme temperatures. This makes stainless steel spacer nuts ideal for industries like food processing and pharmaceuticals, where hygiene and durability are paramount.

2. Durability and Strength

The robust construction of stainless steel spacer nuts ensures they can withstand high loads and stresses, reducing the likelihood of mechanical failures. This durability leads to longer service life and lower replacement costs.

3. Hygienic Design

For industries that require strict adherence to hygiene standards, such as food and pharmaceutical production, stainless steel spacer nuts meet sanitary requirements. Their smooth surface resists bacterial buildup and is easy to clean, supporting compliance with EHEDG and 3-A standards.

4. Cost-Effective Maintenance

By maintaining the alignment and stability of machinery, stainless steel spacer nuts reduce wear and tear on equipment. This results in fewer breakdowns, minimizing downtime and repair costs.

5. Versatility Across Industries

Spacer nuts are compatible with a wide range of machinery and applications. Whether used in conveyors, pumps, or robotic systems, they provide consistent performance.

Key Applications of Stainless Steel Spacer Nuts

Food Processing Industry

In food production, maintaining hygiene is critical. Stainless steel spacer nuts are widely used in equipment such as conveyors and mixers, where precision spacing and hygiene are essential. Their corrosion-resistant properties ensure they can withstand regular cleaning and sanitization.

Pharmaceutical and Biotechnology Industries

Spacer nuts made from stainless steel meet the stringent standards required in pharmaceutical environments. Their ability to resist chemical exposure and maintain structural integrity ensures reliable performance in cleanrooms and laboratories.

Packaging Industry

Stainless steel spacer nuts are integral to high-speed packaging machinery, ensuring stability and alignment for smooth operation. Their durability reduces the need for frequent adjustments, maintaining productivity.

Automotive and Aerospace Sectors

In automotive and aerospace applications, precision and reliability are non-negotiable. Stainless steel spacer nuts provide the necessary stability and strength to keep components aligned in high-performance machinery.

Choosing the Right Stainless Steel Spacer Nut

When selecting spacer nuts for your operations, consider factors such as:

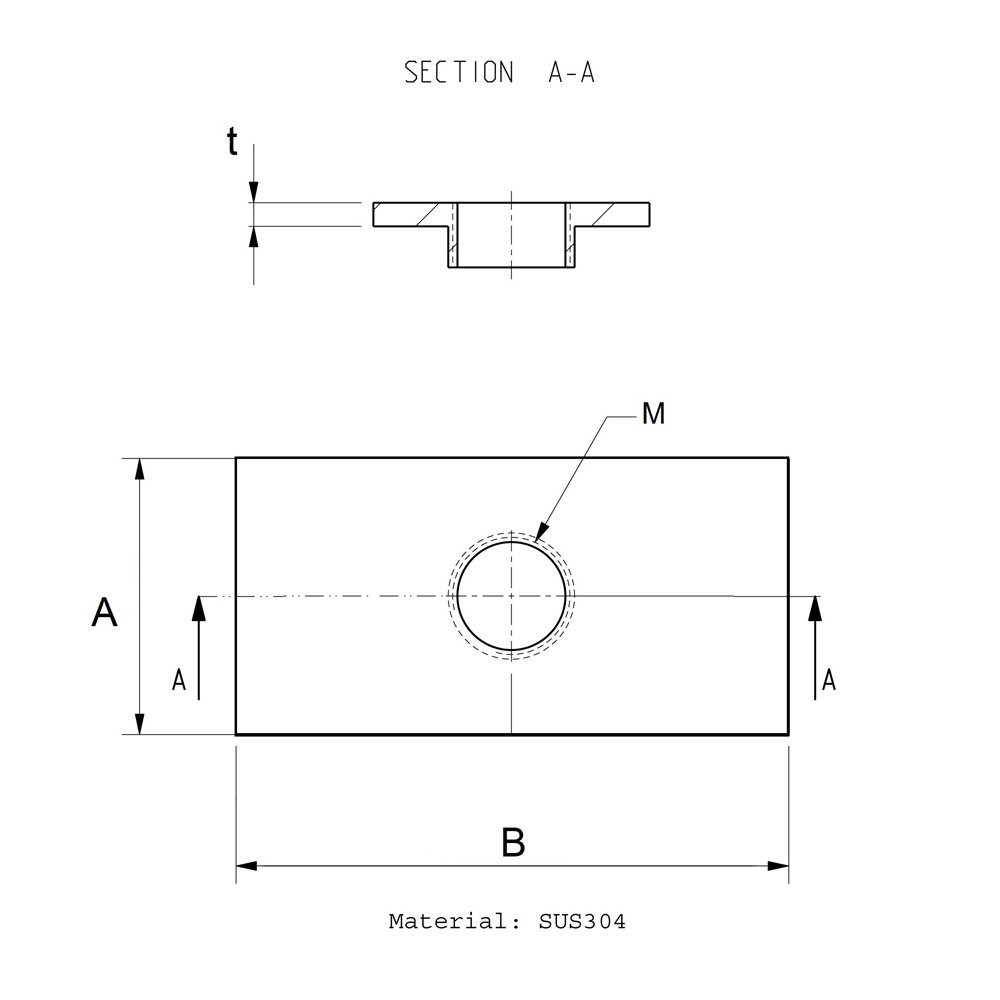

- Material Grade: Opt for stainless steel grades like 304 or 316 for superior corrosion resistance.

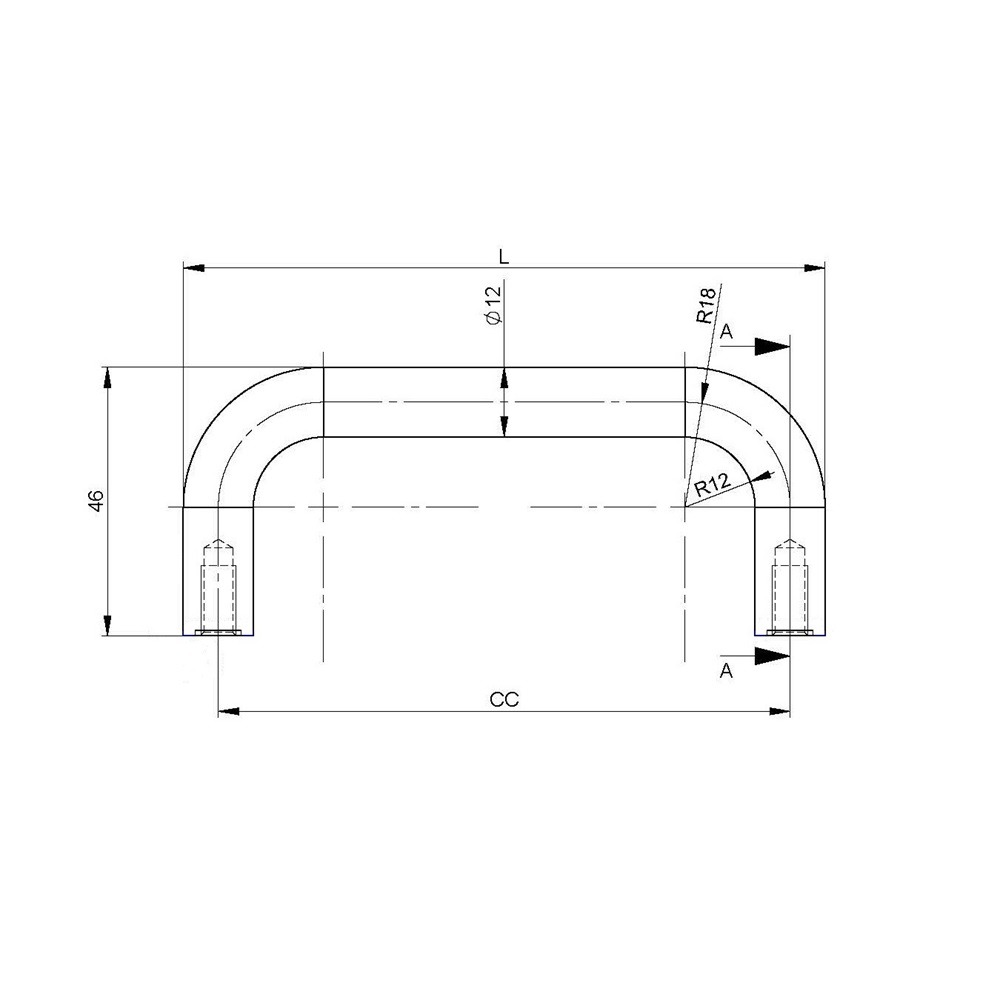

- Design Specifications: Ensure the dimensions and threading match your application requirements.

- Certifications: Look for spacer nuts that comply with industry standards such as ISO or EHEDG.

Stainless Steel Spacer Nuts: The Key to Reducing Downtime and Maintenance Costs

Investing in stainless steel spacer nuts is a strategic decision for industries aiming to minimize downtime and maintenance costs. Their corrosion resistance, durability, and hygienic design make them a valuable addition to various applications. By choosing high-quality spacer nuts, businesses can ensure operational efficiency, enhance productivity, and achieve long-term cost savings.

Upgrade your machinery today with stainless steel spacer nuts and experience the benefits of reduced maintenance, downtime, and enhanced reliability.