Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

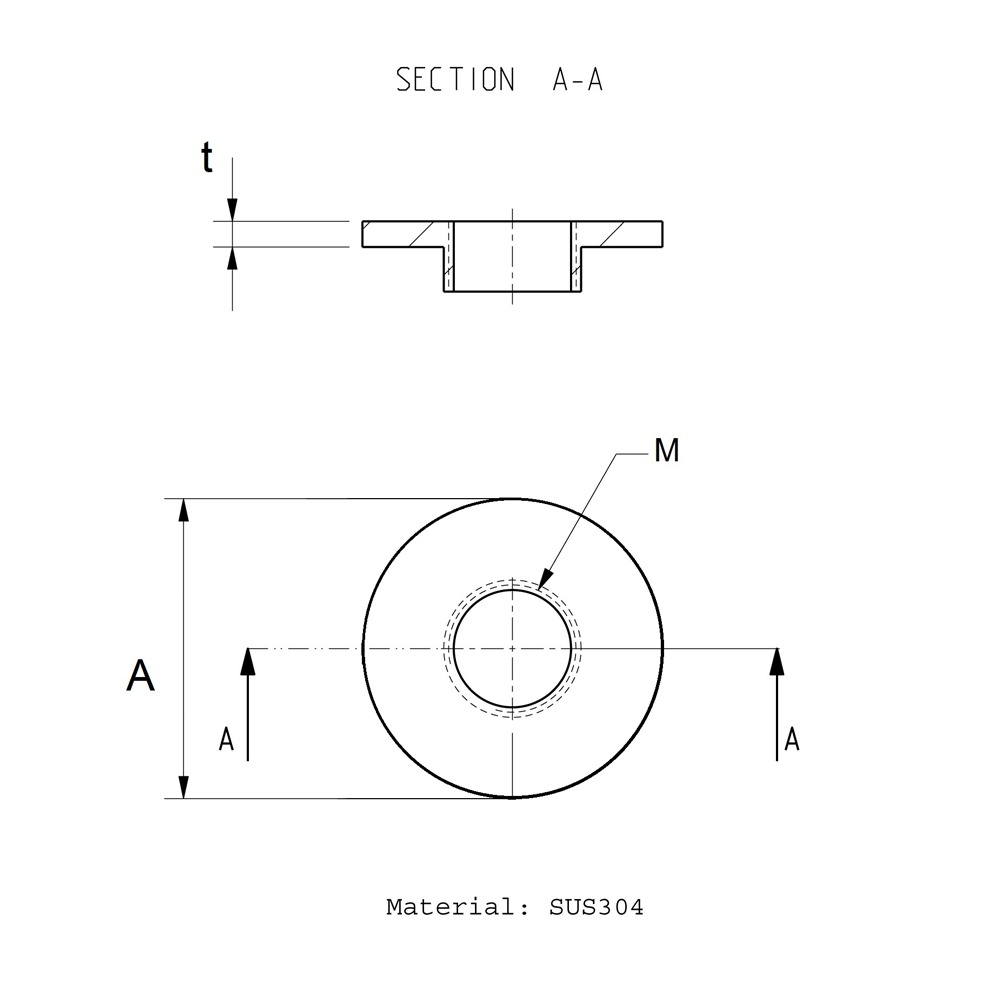

Hygienic side guide bracket in stainless steel

Hygienic side guide bracket in stainless steel 304 (Aisi 1.4301)

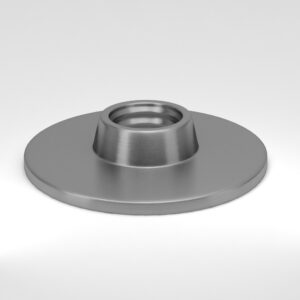

HSG side guide bracket with nut, eyebolt and washer in stainless steel AISI 304 (Aisi 1.4301).

Side guide in hygienic stainless steel design

All the hygienic side guide HSG are designed with a smooth surface without any unnecessary ribs, flanges, recesses or mounting holes, minimizing the risk of hidden sources of contamination. The smooth surface makes the cleaning easier and minimizes the risk of hidden contamination.

Stainless steel side guide brackets

Our side guide series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: Medical equipment, Food & drug processing equipment, Packaging machinery, 3A design-meat & poultry processing equipment, Dairy processing machines.

Hygienic side guide bracket in stainless steel available types

HSG side guide bracket with nut, eyebolt and washer in stainless steel AISI 304 (Aisi 1.4301).

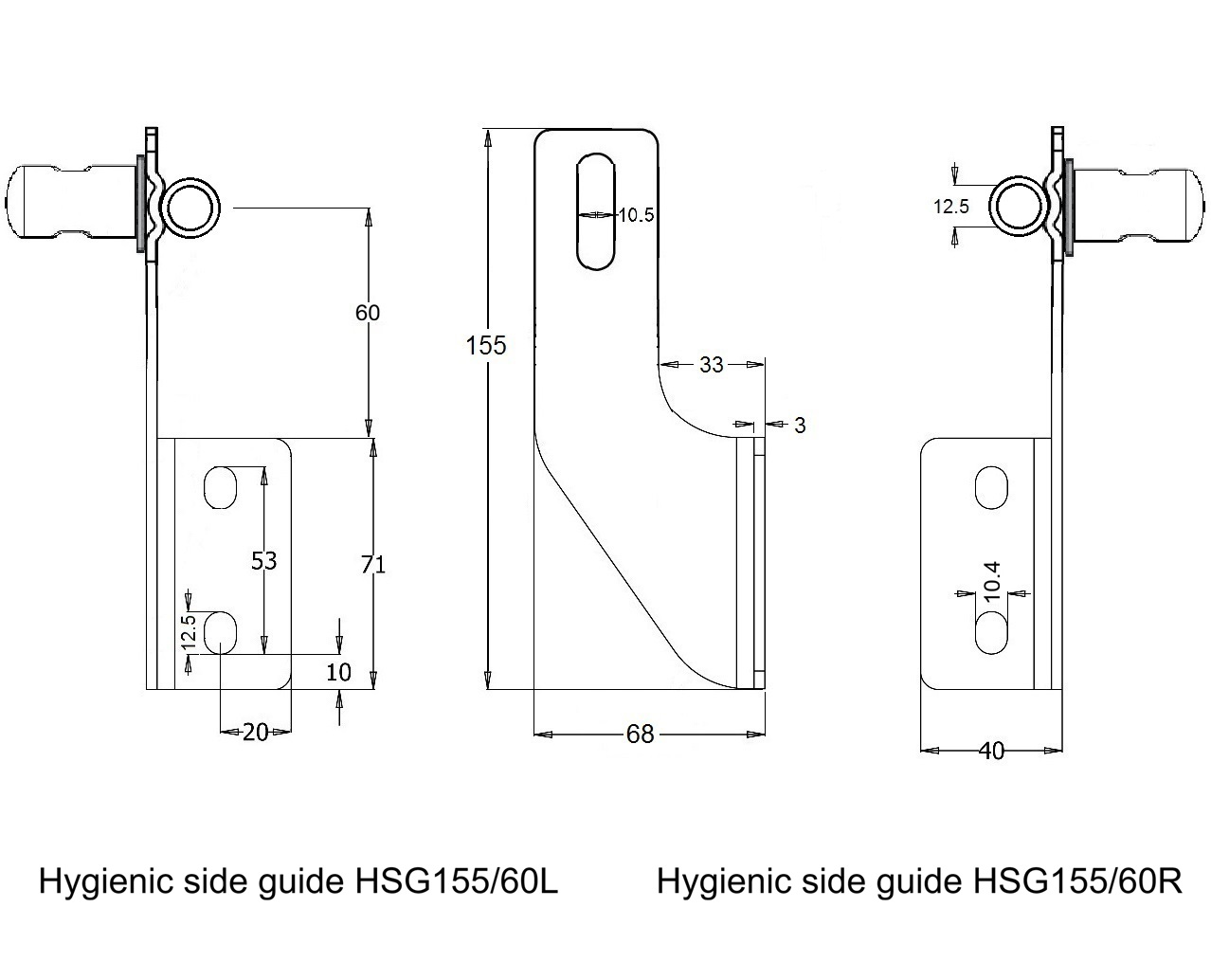

HSG155-60

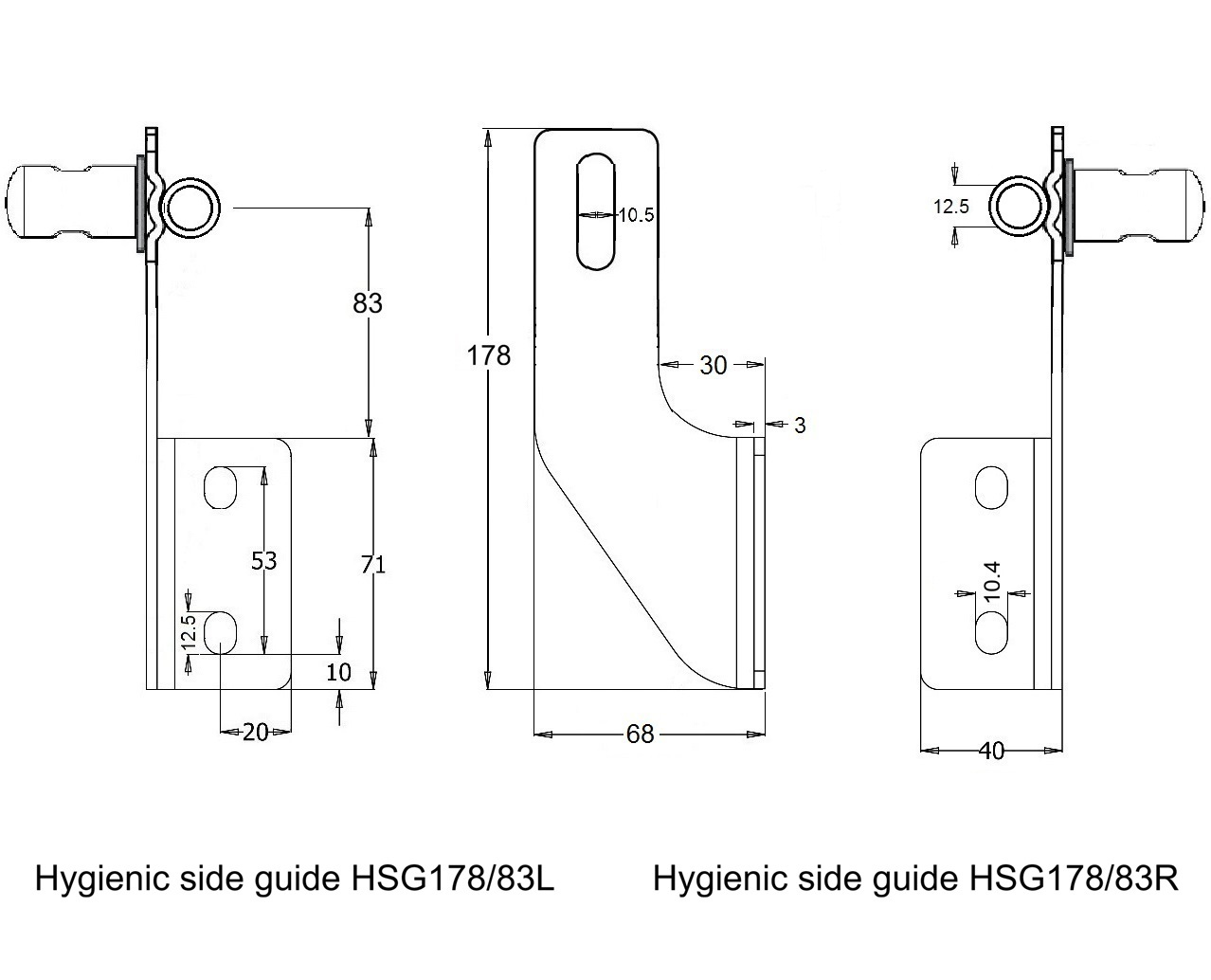

HSG178-83

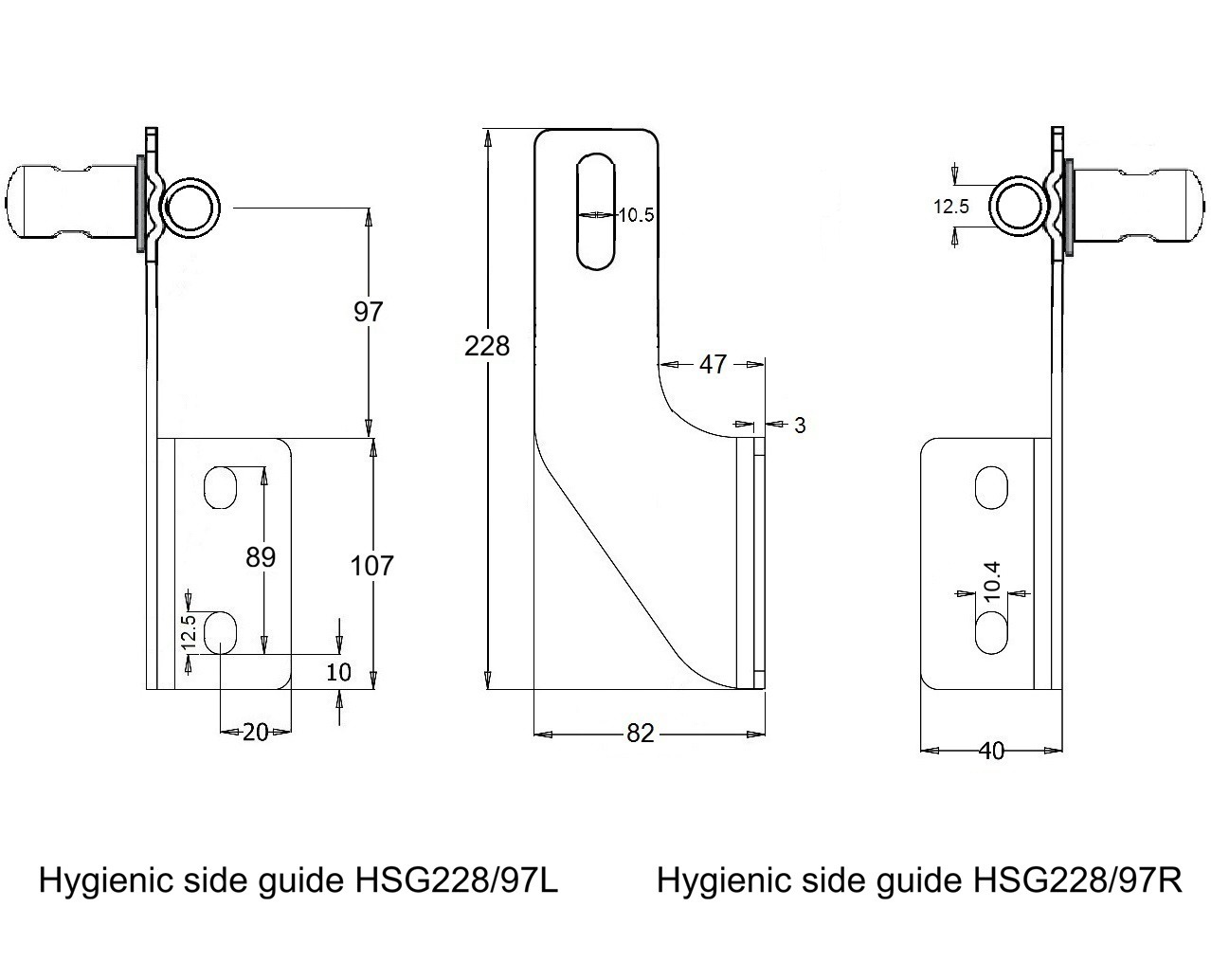

- HSG228-97

Crucial components

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

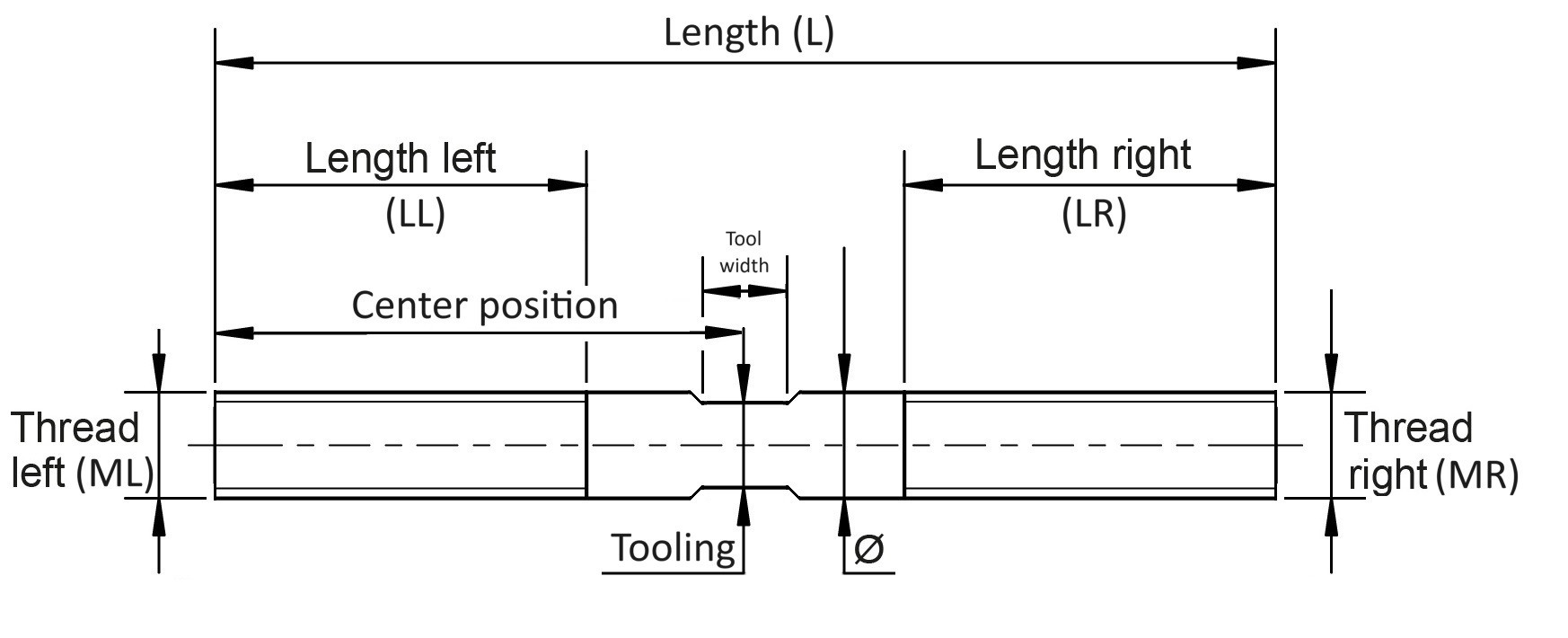

Hygienic side guide bracket in stainless steel 304 (Aisi 1.4301)

HSG side guide bracket with nut, eyebolt and washer in stainless steel AISI 304 (Aisi 1.4301).

Side guide in hygienic stainless steel design

All the hygienic side guide HSG are designed with a smooth surface without any unnecessary ribs, flanges, recesses or mounting holes, minimizing the risk of hidden sources of contamination. The smooth surface makes the cleaning easier and minimizes the risk of hidden contamination.

Stainless steel side guide brackets

Our side guide series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: Medical equipment, Food & drug processing equipment, Packaging machinery, 3A design-meat & poultry processing equipment, Dairy processing machines.

Hygienic side guide bracket in stainless steel available types

HSG side guide bracket with nut, eyebolt and washer in stainless steel AISI 304 (Aisi 1.4301).

HSG155-60

HSG178-83

- HSG228-97

Crucial components

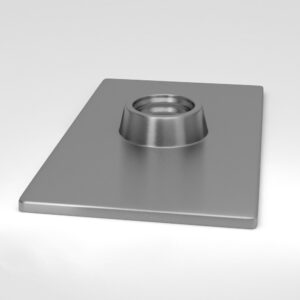

Hygienic side guide bracket in stainless steel 304 (Aisi 1.4301)

HSG side guide bracket with nut, eyebolt and washer in stainless steel AISI 304 (Aisi 1.4301).

Side guide in hygienic stainless steel design

All the hygienic side guide HSG are designed with a smooth surface without any unnecessary ribs, flanges, recesses or mounting holes, minimizing the risk of hidden sources of contamination. The smooth surface makes the cleaning easier and minimizes the risk of hidden contamination.

Stainless steel side guide brackets

Our side guide series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: Medical equipment, Food & drug processing equipment, Packaging machinery, 3A design-meat & poultry processing equipment, Dairy processing machines.

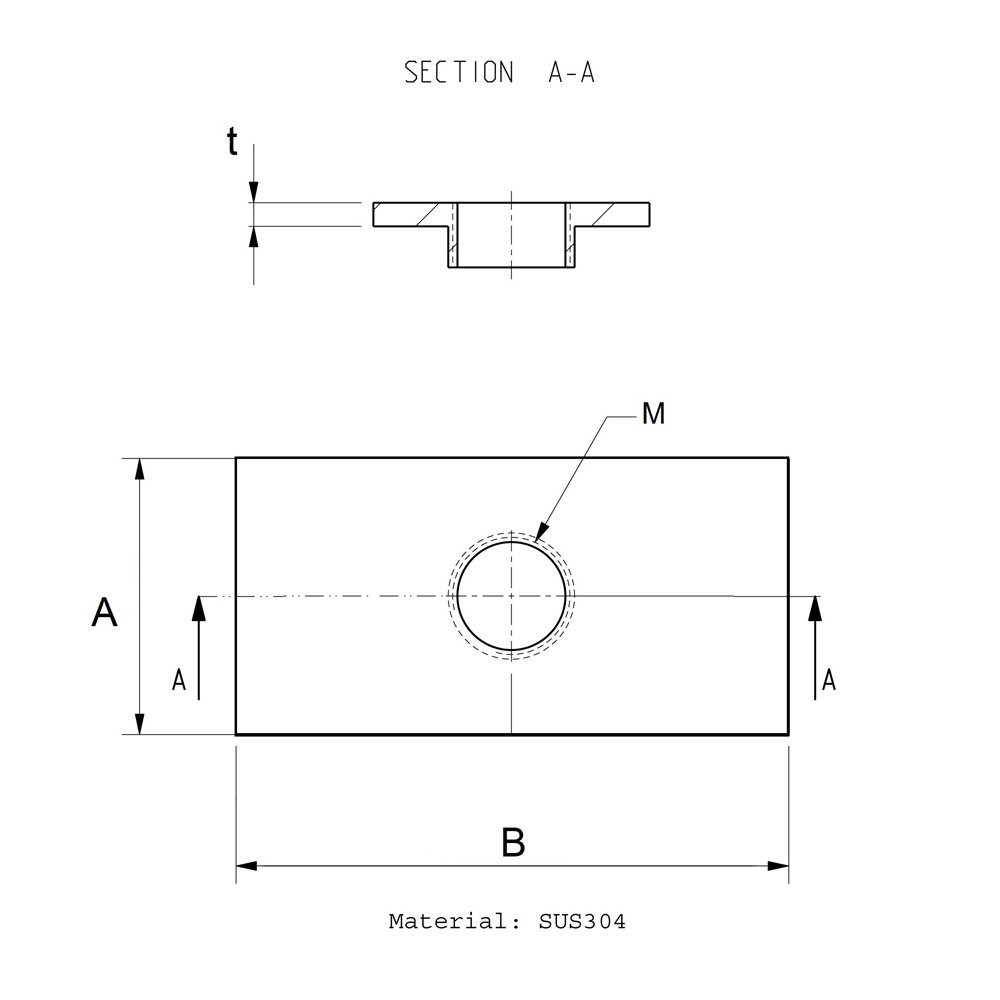

Hygienic side guide bracket in stainless steel available types

HSG side guide bracket with nut, eyebolt and washer in stainless steel AISI 304 (Aisi 1.4301).

HSG155-60

HSG178-83

- HSG228-97

Crucial components

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.