Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

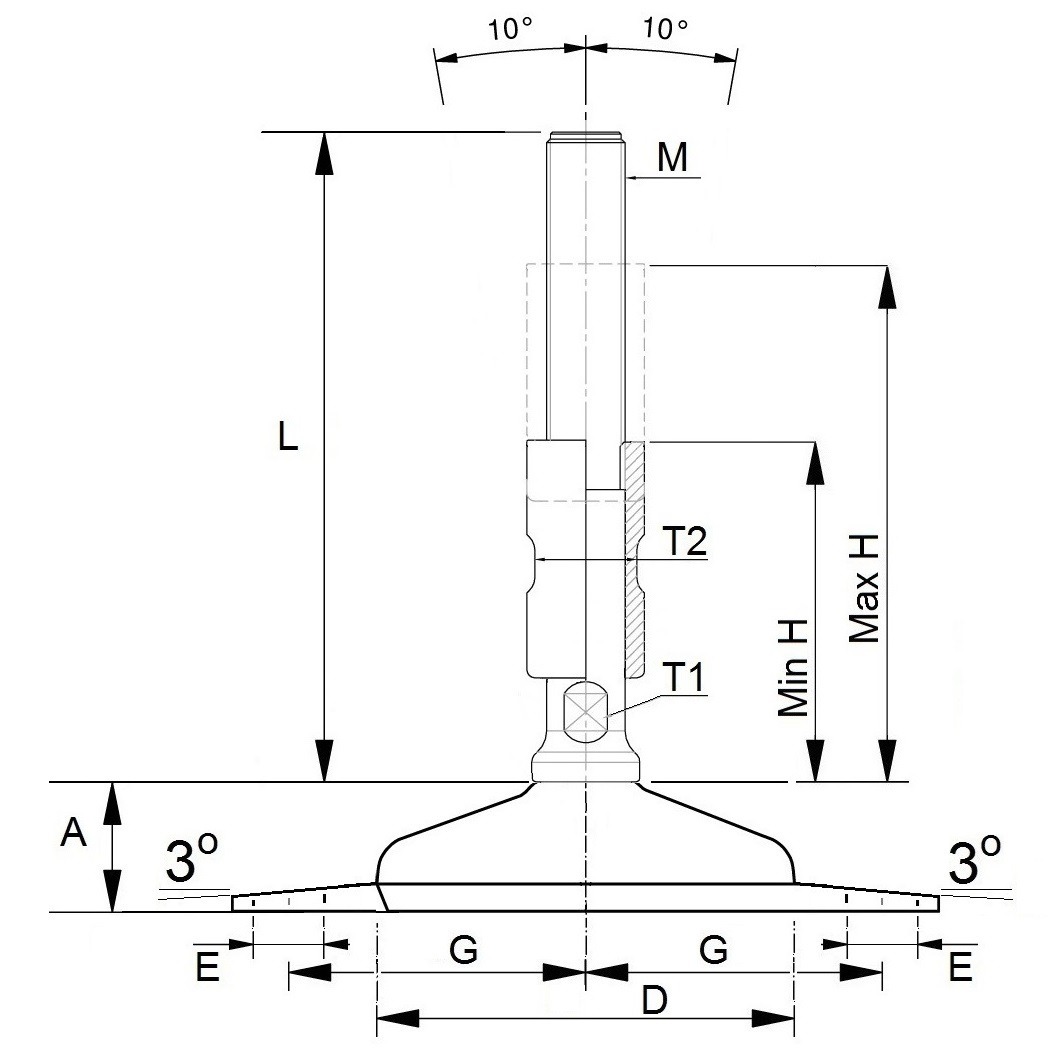

Hygienic machine feet with 2 floor locking plates and sealed protected spindle

Tailored Excellence: Bespoke Industrial Solutions for Sanitary Need

Machine feet in sealed hygienic design with rubber base for vibration reduction and anti-slip properties

Our sealed hygienic machine feet are provided with FDA certificate (FDA CFR 21 177 2600) with unique batch ID number for food safety traceability

Machine feet in sealed hygienic design features and advantages

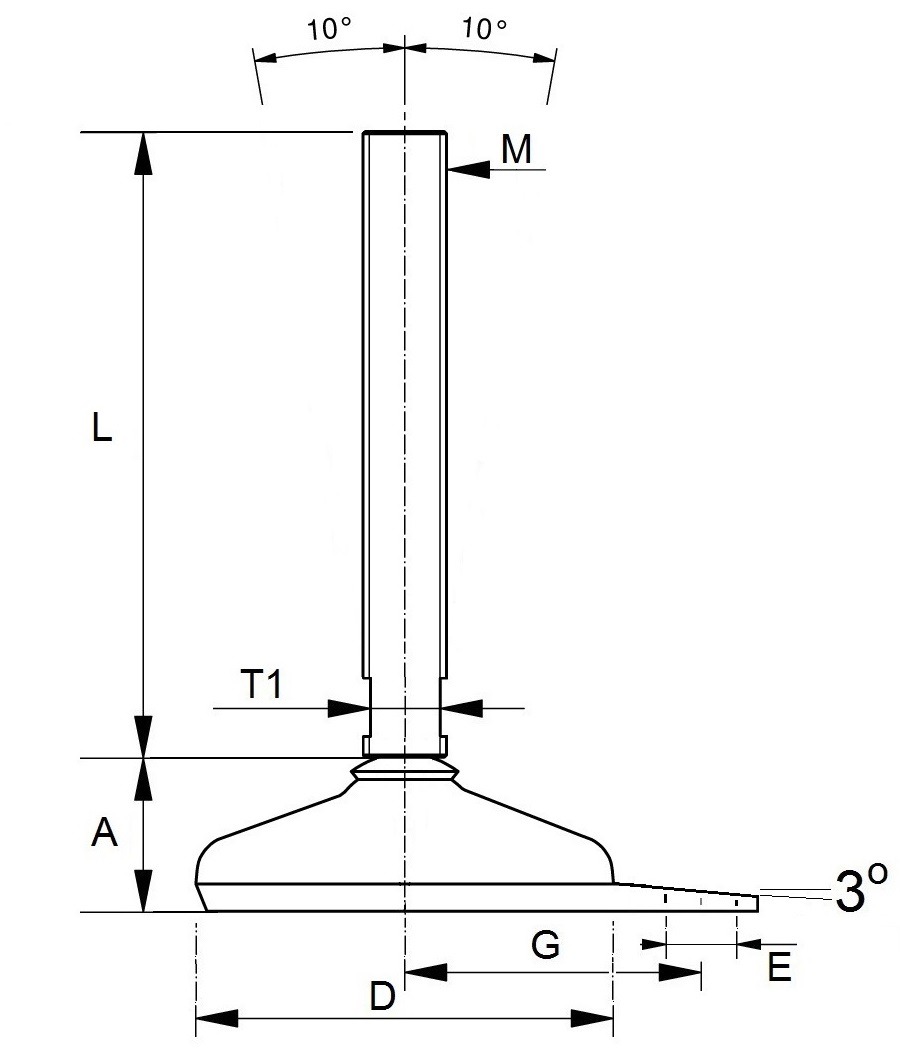

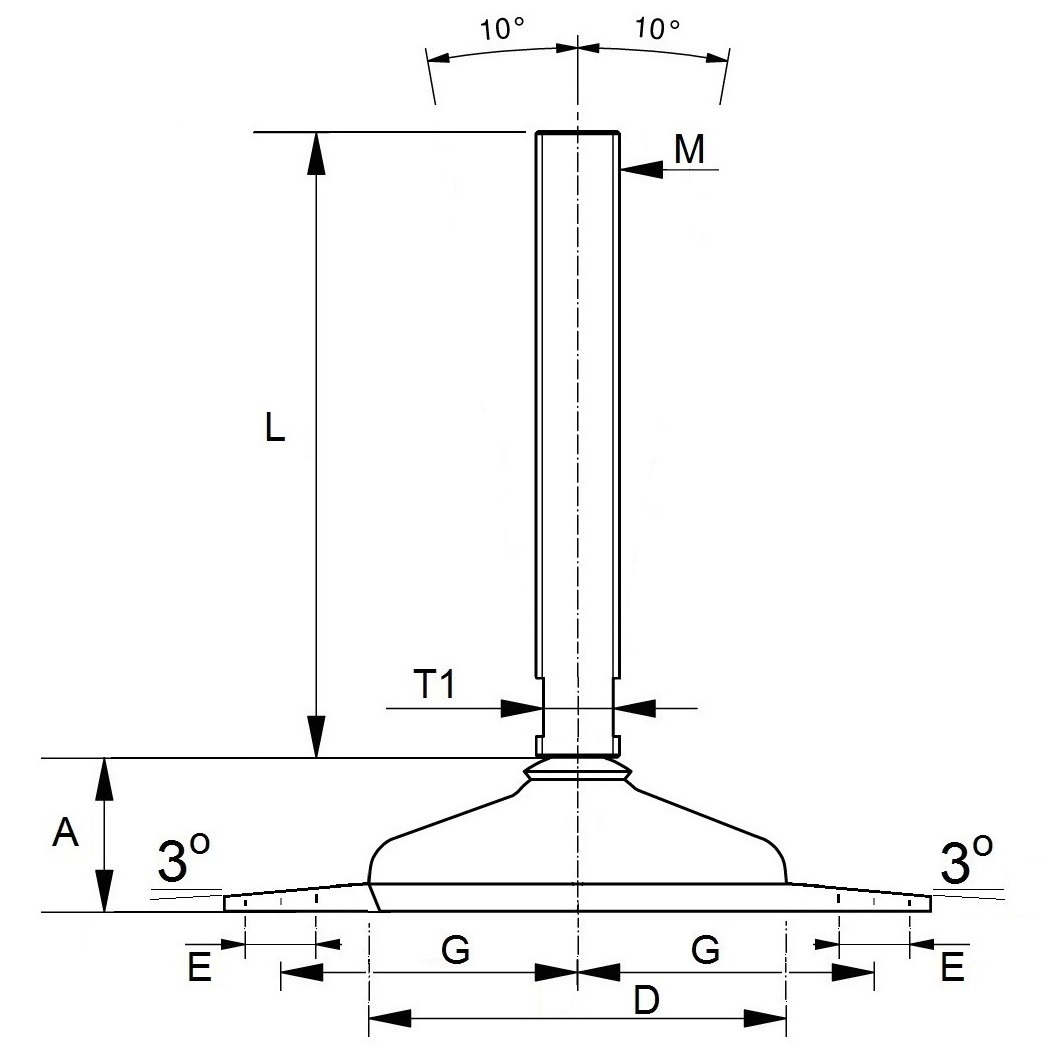

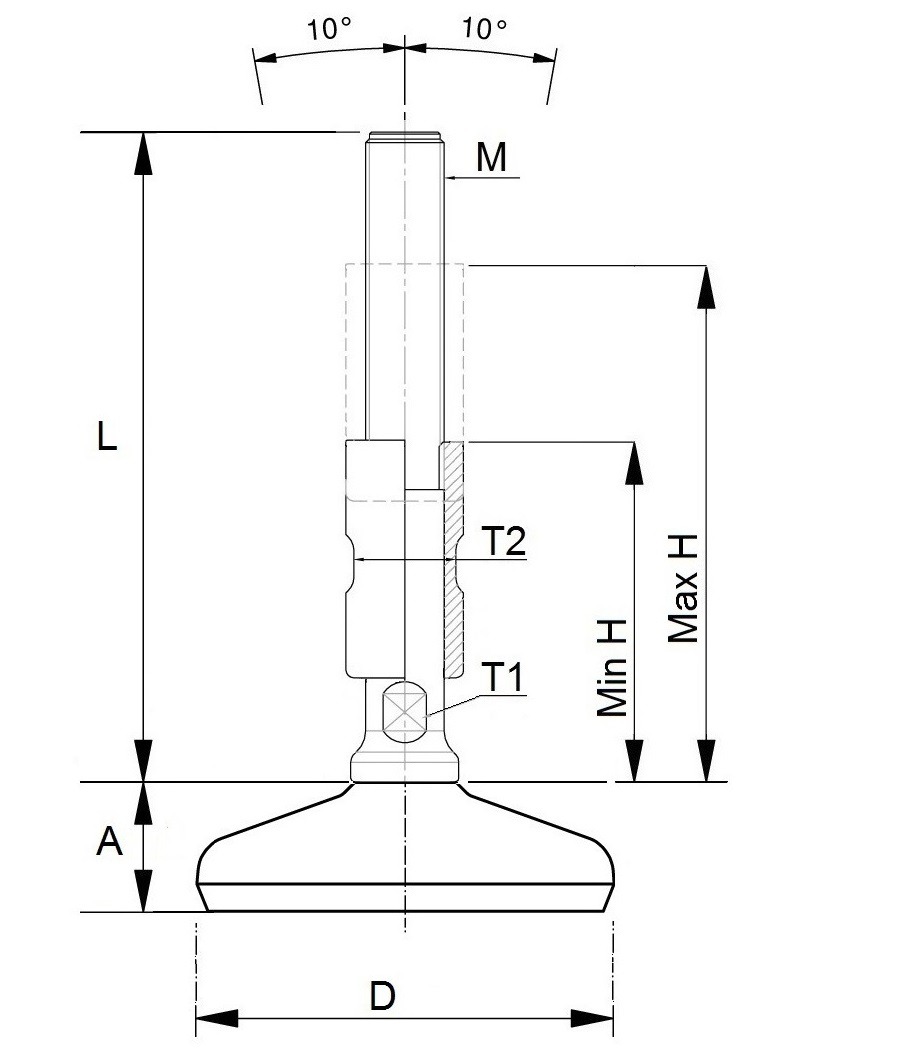

Sealed hygienic machine feet have a rounded, hygienic design which makes it easy to clean.

Sealed hygienic machine feet can cope with up to 10 degree slopes on floors and equipment.

Machine feet in sealed hygienic design materials

Sealed hygienic machine feet vulcanized rubber part with FDA certificate according to FDA CFR 21 177 2600.

Base plate material description:

Stainless steel Aisi 304 or Aisi 316

Spindle material description:

Stainless steel A2-70 or A4-70

Rubber base material description:

NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

Machine feet in sealed hygienic design sizes

Sealed hygienic machine feet base are available in a wide range, giving the optimal flexibility and choice.

| Base type | Base Diameter D | Nom. Load |

|---|---|---|

| HMF 62 | 60mm | 7.000 N |

| HMF 82 | 80mm | 15.000 N |

| HMF 102 | 100mm | 20.000 N |

| HMF 122 | 120mm | 30.000 N |

Sealed hygienic machine feet spindle with protecting sleeve are available in a wide range, giving the optimal flexibility and choice.

| M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| L=135 mm H=55 mm | Min 80 mm to Max 120 mm |

| L=175 mm H=75 mm | Min 100 mm to Max 160 mm |

| L=215 mm H=95 mm | Min 120 mm to Max 200 mm |

| L=255 mm H=115 mm | Min 140 mm to Max 240 mm |

| L=295 mm H=125 mm | Min 180 mm to Max 280 mm |

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

Machine feet in sealed hygienic design delivery option

For large orders we offer to supply the base and spindles separate

The advantage is flexibility for the costumer which are using many different sizes of spindles.

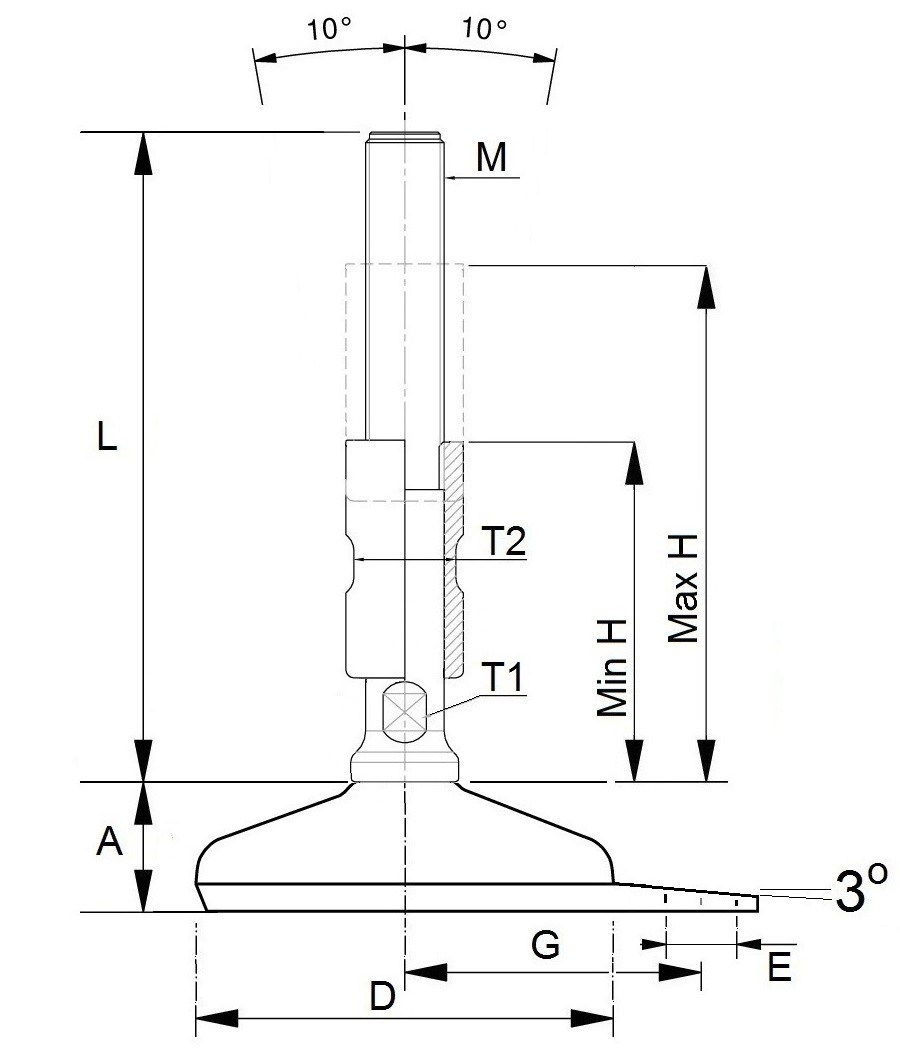

Hygienic machine feet with 2 floor locking plates and sealed protected spindle

Optimal Stability with Dual Floor Locking Plates

Our innovative hygienic machine feet are designed for superior stability in demanding industrial environments. Featuring two robust floor locking plates, these machine feet secure heavy equipment firmly in place. The dual locking system evenly distributes weight, minimizes vibrations, and prevents unwanted movement, ensuring optimal operational safety and performance.

Enhanced Hygiene and Easy Maintenance

Engineered for clean environments, our hygienic machine feet are ideal for industries requiring strict sanitation standards, such as food processing, pharmaceuticals, and cleanrooms. The smooth, contaminant-resistant surface design not only meets hygiene requirements but also simplifies cleaning and maintenance. Reduced downtime and lower maintenance costs are significant benefits of this state-of-the-art design.

Advanced Sealed Protected Spindle Technology

A key feature of our system is the sealed protected spindle, which is built to endure harsh conditions. This advanced technology prevents the ingress of dust, moisture, and chemicals, ensuring that the spindle remains in peak condition. The sealed design extends the lifespan of the equipment while maintaining consistent performance under high stress and challenging environments.

Customised Bespoke Solutions for Industrial Excellence

We understand that every industrial application has unique demands. That’s why our hygienic machine feet are available as bespoke solutions tailored to your specific needs. Whether you require enhanced stability for heavy-duty machinery or advanced hygiene standards for sensitive production areas, our custom options deliver unmatched reliability. Invest in our innovative machine feet to boost operational efficiency, reduce maintenance costs, and achieve long-term durability in your facility.

Innovative Hygienic Machine Feet for Enhanced Stability

Our commitment to quality and precision is evident in every aspect of our machine feet design. By integrating engineering, dual locking mechanisms, and sealed spindle technology, we deliver solutions that meet the highest industry standards. Choose our hygienic machine feet for a safer, cleaner, and efficient operation.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Tailored Excellence: Bespoke Industrial Solutions for Sanitary Need

Machine feet in sealed hygienic design with rubber base for vibration reduction and anti-slip properties

Our sealed hygienic machine feet are provided with FDA certificate (FDA CFR 21 177 2600) with unique batch ID number for food safety traceability

Machine feet in sealed hygienic design features and advantages

Sealed hygienic machine feet have a rounded, hygienic design which makes it easy to clean.

Sealed hygienic machine feet can cope with up to 10 degree slopes on floors and equipment.

Machine feet in sealed hygienic design materials

Sealed hygienic machine feet vulcanized rubber part with FDA certificate according to FDA CFR 21 177 2600.

Base plate material description:

Stainless steel Aisi 304 or Aisi 316

Spindle material description:

Stainless steel A2-70 or A4-70

Rubber base material description:

NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

Machine feet in sealed hygienic design sizes

Sealed hygienic machine feet base are available in a wide range, giving the optimal flexibility and choice.

| Base type | Base Diameter D | Nom. Load |

|---|---|---|

| HMF 62 | 60mm | 7.000 N |

| HMF 82 | 80mm | 15.000 N |

| HMF 102 | 100mm | 20.000 N |

| HMF 122 | 120mm | 30.000 N |

Sealed hygienic machine feet spindle with protecting sleeve are available in a wide range, giving the optimal flexibility and choice.

| M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| L=135 mm H=55 mm | Min 80 mm to Max 120 mm |

| L=175 mm H=75 mm | Min 100 mm to Max 160 mm |

| L=215 mm H=95 mm | Min 120 mm to Max 200 mm |

| L=255 mm H=115 mm | Min 140 mm to Max 240 mm |

| L=295 mm H=125 mm | Min 180 mm to Max 280 mm |

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

Machine feet in sealed hygienic design delivery option

For large orders we offer to supply the base and spindles separate

The advantage is flexibility for the costumer which are using many different sizes of spindles.

Hygienic machine feet with 2 floor locking plates and sealed protected spindle

Optimal Stability with Dual Floor Locking Plates

Our innovative hygienic machine feet are designed for superior stability in demanding industrial environments. Featuring two robust floor locking plates, these machine feet secure heavy equipment firmly in place. The dual locking system evenly distributes weight, minimizes vibrations, and prevents unwanted movement, ensuring optimal operational safety and performance.

Enhanced Hygiene and Easy Maintenance

Engineered for clean environments, our hygienic machine feet are ideal for industries requiring strict sanitation standards, such as food processing, pharmaceuticals, and cleanrooms. The smooth, contaminant-resistant surface design not only meets hygiene requirements but also simplifies cleaning and maintenance. Reduced downtime and lower maintenance costs are significant benefits of this state-of-the-art design.

Advanced Sealed Protected Spindle Technology

A key feature of our system is the sealed protected spindle, which is built to endure harsh conditions. This advanced technology prevents the ingress of dust, moisture, and chemicals, ensuring that the spindle remains in peak condition. The sealed design extends the lifespan of the equipment while maintaining consistent performance under high stress and challenging environments.

Customised Bespoke Solutions for Industrial Excellence

We understand that every industrial application has unique demands. That’s why our hygienic machine feet are available as bespoke solutions tailored to your specific needs. Whether you require enhanced stability for heavy-duty machinery or advanced hygiene standards for sensitive production areas, our custom options deliver unmatched reliability. Invest in our innovative machine feet to boost operational efficiency, reduce maintenance costs, and achieve long-term durability in your facility.

Innovative Hygienic Machine Feet for Enhanced Stability

Our commitment to quality and precision is evident in every aspect of our machine feet design. By integrating engineering, dual locking mechanisms, and sealed spindle technology, we deliver solutions that meet the highest industry standards. Choose our hygienic machine feet for a safer, cleaner, and efficient operation.

Tailored Excellence: Bespoke Industrial Solutions for Sanitary Need

Machine feet in sealed hygienic design with rubber base for vibration reduction and anti-slip properties

Our sealed hygienic machine feet are provided with FDA certificate (FDA CFR 21 177 2600) with unique batch ID number for food safety traceability

Machine feet in sealed hygienic design features and advantages

Sealed hygienic machine feet have a rounded, hygienic design which makes it easy to clean.

Sealed hygienic machine feet can cope with up to 10 degree slopes on floors and equipment.

Machine feet in sealed hygienic design materials

Sealed hygienic machine feet vulcanized rubber part with FDA certificate according to FDA CFR 21 177 2600.

Base plate material description:

Stainless steel Aisi 304 or Aisi 316

Spindle material description:

Stainless steel A2-70 or A4-70

Rubber base material description:

NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

Machine feet in sealed hygienic design sizes

Sealed hygienic machine feet base are available in a wide range, giving the optimal flexibility and choice.

| Base type | Base Diameter D | Nom. Load |

|---|---|---|

| HMF 62 | 60mm | 7.000 N |

| HMF 82 | 80mm | 15.000 N |

| HMF 102 | 100mm | 20.000 N |

| HMF 122 | 120mm | 30.000 N |

Sealed hygienic machine feet spindle with protecting sleeve are available in a wide range, giving the optimal flexibility and choice.

| M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| L=135 mm H=55 mm | Min 80 mm to Max 120 mm |

| L=175 mm H=75 mm | Min 100 mm to Max 160 mm |

| L=215 mm H=95 mm | Min 120 mm to Max 200 mm |

| L=255 mm H=115 mm | Min 140 mm to Max 240 mm |

| L=295 mm H=125 mm | Min 180 mm to Max 280 mm |

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

Machine feet in sealed hygienic design delivery option

For large orders we offer to supply the base and spindles separate

The advantage is flexibility for the costumer which are using many different sizes of spindles.

Hygienic machine feet with 2 floor locking plates and sealed protected spindle

Optimal Stability with Dual Floor Locking Plates

Our innovative hygienic machine feet are designed for superior stability in demanding industrial environments. Featuring two robust floor locking plates, these machine feet secure heavy equipment firmly in place. The dual locking system evenly distributes weight, minimizes vibrations, and prevents unwanted movement, ensuring optimal operational safety and performance.

Enhanced Hygiene and Easy Maintenance

Engineered for clean environments, our hygienic machine feet are ideal for industries requiring strict sanitation standards, such as food processing, pharmaceuticals, and cleanrooms. The smooth, contaminant-resistant surface design not only meets hygiene requirements but also simplifies cleaning and maintenance. Reduced downtime and lower maintenance costs are significant benefits of this state-of-the-art design.

Advanced Sealed Protected Spindle Technology

A key feature of our system is the sealed protected spindle, which is built to endure harsh conditions. This advanced technology prevents the ingress of dust, moisture, and chemicals, ensuring that the spindle remains in peak condition. The sealed design extends the lifespan of the equipment while maintaining consistent performance under high stress and challenging environments.

Customised Bespoke Solutions for Industrial Excellence

We understand that every industrial application has unique demands. That’s why our hygienic machine feet are available as bespoke solutions tailored to your specific needs. Whether you require enhanced stability for heavy-duty machinery or advanced hygiene standards for sensitive production areas, our custom options deliver unmatched reliability. Invest in our innovative machine feet to boost operational efficiency, reduce maintenance costs, and achieve long-term durability in your facility.

Innovative Hygienic Machine Feet for Enhanced Stability

Our commitment to quality and precision is evident in every aspect of our machine feet design. By integrating engineering, dual locking mechanisms, and sealed spindle technology, we deliver solutions that meet the highest industry standards. Choose our hygienic machine feet for a safer, cleaner, and efficient operation.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.