Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

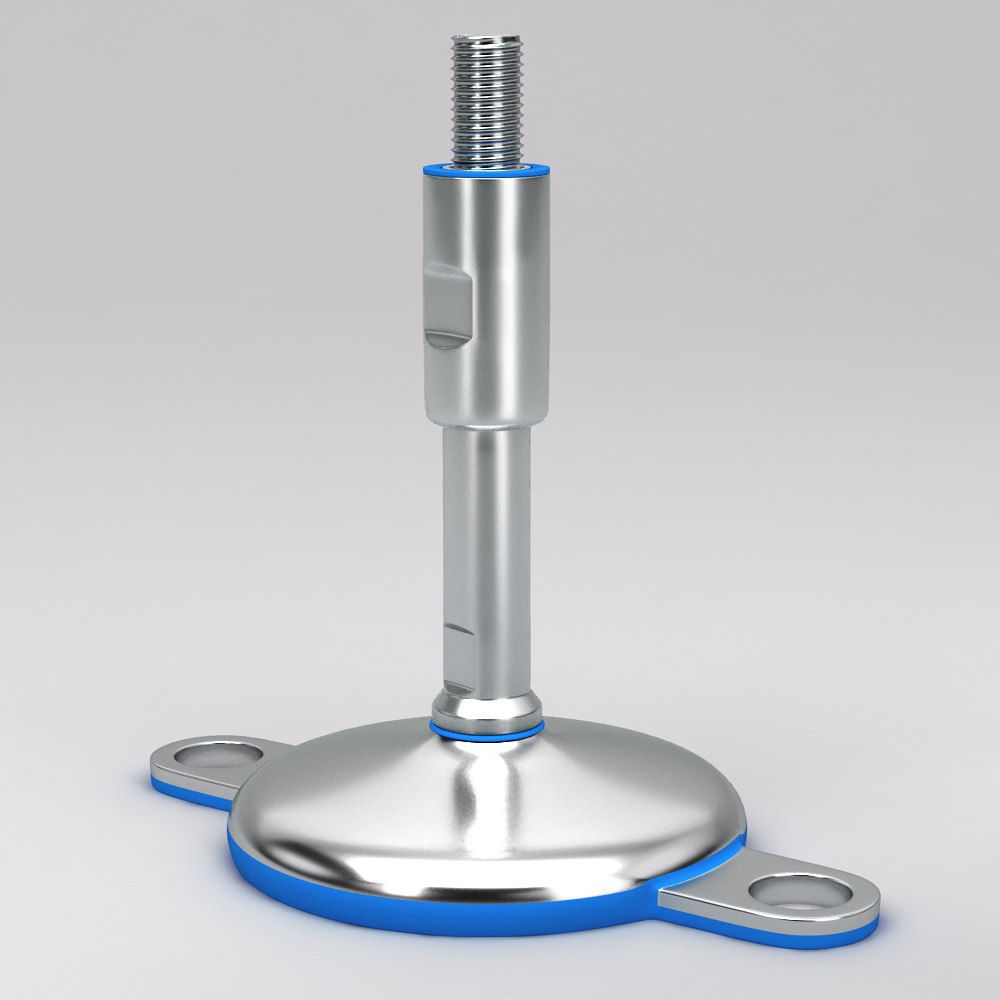

Hygienic levelling feet with 2 floor locking plates and sealed protected spindle

Boost Facility Hygiene with Advanced Levelling System Solutions

Levelling feet in sealed hygienic design with rubber base for vibration reduction and anti-slip properties

Our sealed hygienic levelling feet are provided with FDA certificate (FDA CFR 21 177 2600) with unique batch ID number for food safety traceability

Levelling feet in sealed hygienic design features and advantages

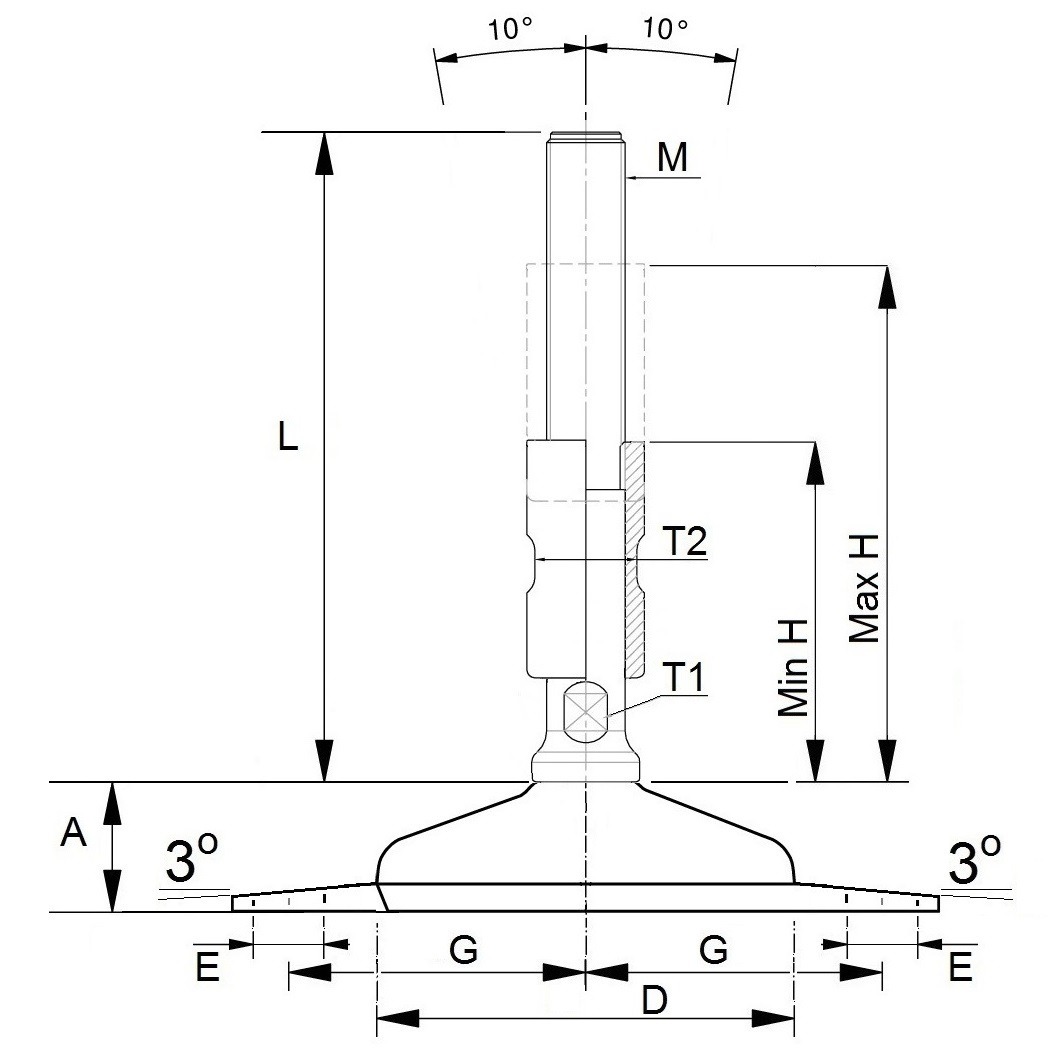

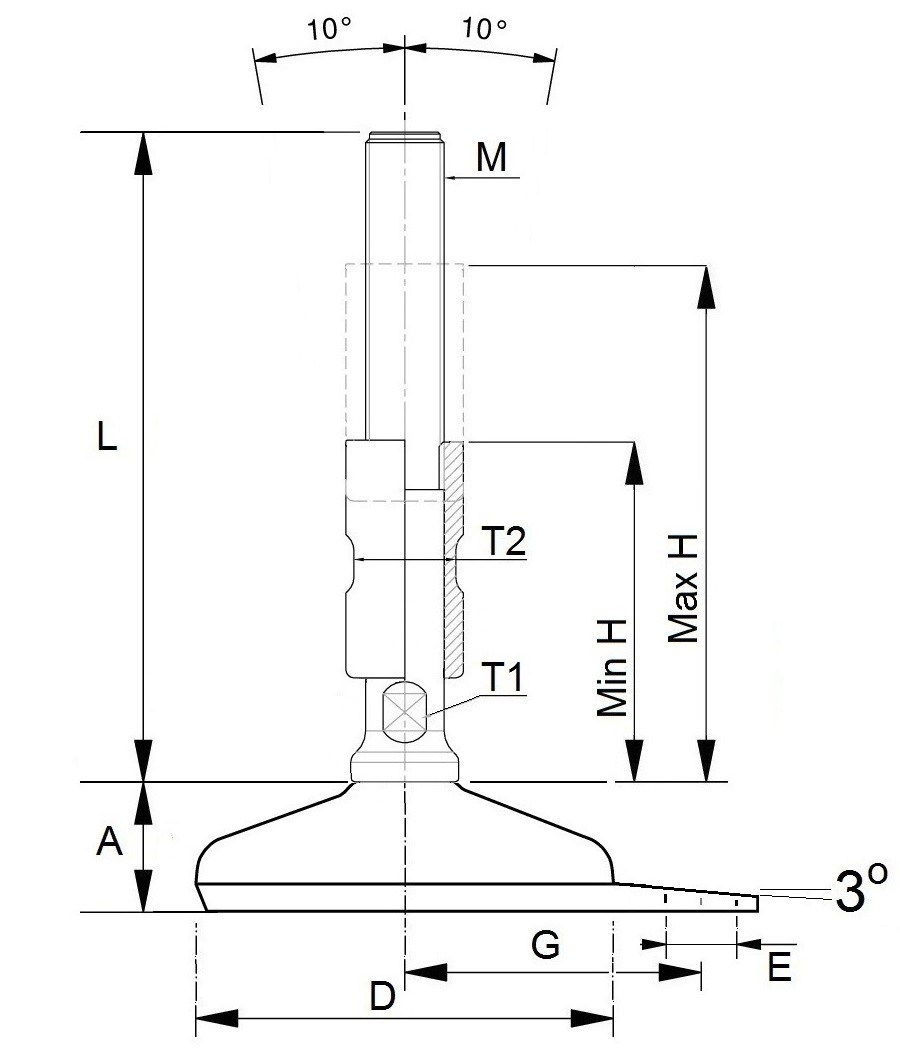

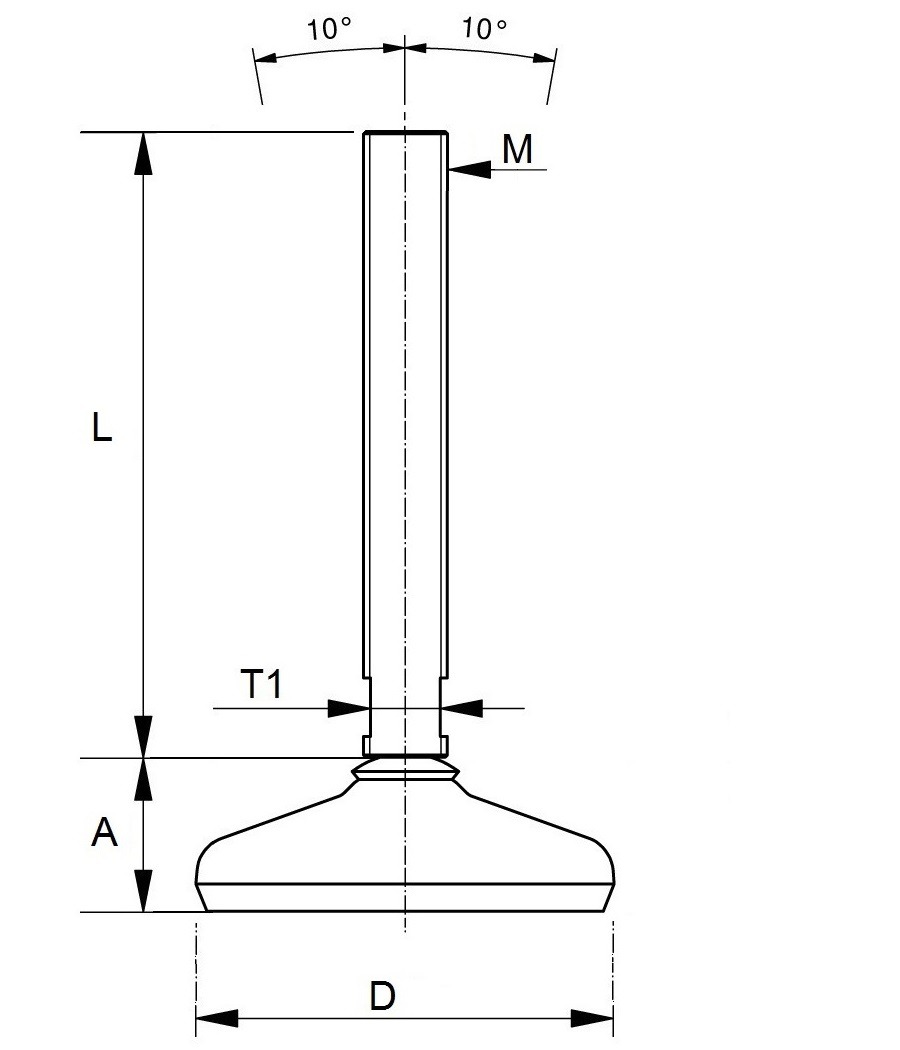

Sealed hygienic levelling feet have a rounded, hygienic design which makes it easy to clean.

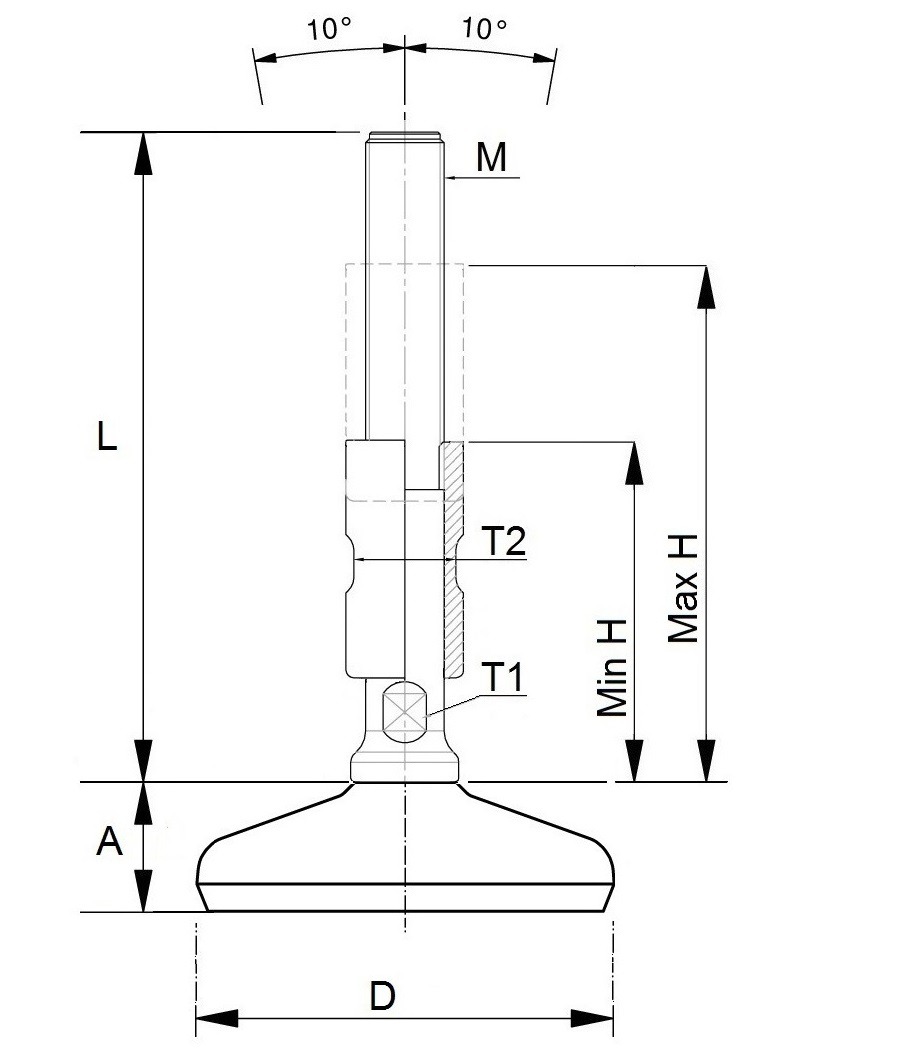

Sealed hygienic levelling feet can cope with up to 10 degree slopes on floors and equipment.

Levelling feet in sealed hygienic design materials

Sealed hygienic levelling feet vulcanized rubber part with FDA certificate according to FDA CFR 21 177 2600.

Base plate material description:

Stainless steel Aisi 304 or Aisi 316

Spindle material description:

Stainless steel A2-70 or A4-70

Rubber base material description:

NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

Levelling feet in sealed hygienic design sizes

Sealed hygienic machine feet base are available in a wide range, giving the optimal flexibility and choice.

| Base type | Base Diameter D | Nom. Load |

|---|---|---|

| HLF 62 | 60mm | 7.000 N |

| HLF 82 | 80mm | 15.000 N |

| HLF 102 | 100mm | 20.000 N |

| HLF 122 | 120mm | 30.000 N |

Sealed hygienic levelling feet spindle with protecting sleeve are available in a wide range, giving the optimal flexibility and choice.

| M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| L=135 mm H=55 mm | Min 80 mm to Max 120 mm |

| L=175 mm H=75 mm | Min 100 mm to Max 160 mm |

| L=215 mm H=95 mm | Min 120 mm to Max 200 mm |

| L=255 mm H=115 mm | Min 140 mm to Max 240 mm |

| L=295 mm H=125 mm | Min 180 mm to Max 280 mm |

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

Levelling feet in sealed hygienic design delivery option

For large orders we offer to supply the base and spindles separate

The advantage is flexibility for the costumer which are using many different sizes of spindles.

Hygienic Levelling Feet with 2 Floor Locking Plates and Sealed Protected Spindle

The Importance of Hygienic Levelling Feet in Clean Environments

Hygienic levelling feet play a crucial role in industries where cleanliness and safety are top priorities, such as food processing, pharmaceuticals, and biotechnology. Designed to provide stable support while minimizing contamination risks, these components ensure machinery remains level and secure.

Advantages of Dual Floor Locking Plates

Levelling feet with two floor locking plates enhance stability and prevent unwanted movement or vibration. This design is particularly beneficial in high-traffic environments where machinery must remain in a fixed position to avoid operational disruptions. Additionally, the dual-locking system reinforces hygiene by eliminating gaps where dirt and bacteria could accumulate.

Sealed Protected Spindle for Maximum Hygiene

A sealed protected spindle prevents dirt, moisture, and contaminants from penetrating critical components. This feature significantly reduces maintenance efforts and prolongs the lifespan of the levelling foot. In industries where sanitation is paramount, a fully enclosed spindle ensures compliance with strict hygiene regulations, including EHEDG and 3-A standards.

Applications in Hygienic and Industrial Sectors

These advanced levelling feet are widely used in food processing lines, pharmaceutical production facilities, and packaging machinery. Their hygienic design ensures compliance with regulatory requirements, making them a trusted choice for cleanroom and sterile environments.

Optimizing Performance with Certified Components

Choosing levelling feet made from high-grade stainless steel with hygienic sealing materials ensures durability and corrosion resistance. When combined with proper floor anchoring and cleaning protocols, these components help maintain an efficient, contamination-free production environment.

Customised Hygienic Levelling Feet for Optimal Operational Efficiency

The benefits of hygienic levelling feet with 2 floor locking plates and a sealed protected spindle, ensuring stability, durability, and compliance in clean environments and industries.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Boost Facility Hygiene with Advanced Levelling System Solutions

Levelling feet in sealed hygienic design with rubber base for vibration reduction and anti-slip properties

Our sealed hygienic levelling feet are provided with FDA certificate (FDA CFR 21 177 2600) with unique batch ID number for food safety traceability

Levelling feet in sealed hygienic design features and advantages

Sealed hygienic levelling feet have a rounded, hygienic design which makes it easy to clean.

Sealed hygienic levelling feet can cope with up to 10 degree slopes on floors and equipment.

Levelling feet in sealed hygienic design materials

Sealed hygienic levelling feet vulcanized rubber part with FDA certificate according to FDA CFR 21 177 2600.

Base plate material description:

Stainless steel Aisi 304 or Aisi 316

Spindle material description:

Stainless steel A2-70 or A4-70

Rubber base material description:

NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

Levelling feet in sealed hygienic design sizes

Sealed hygienic machine feet base are available in a wide range, giving the optimal flexibility and choice.

| Base type | Base Diameter D | Nom. Load |

|---|---|---|

| HLF 62 | 60mm | 7.000 N |

| HLF 82 | 80mm | 15.000 N |

| HLF 102 | 100mm | 20.000 N |

| HLF 122 | 120mm | 30.000 N |

Sealed hygienic levelling feet spindle with protecting sleeve are available in a wide range, giving the optimal flexibility and choice.

| M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| L=135 mm H=55 mm | Min 80 mm to Max 120 mm |

| L=175 mm H=75 mm | Min 100 mm to Max 160 mm |

| L=215 mm H=95 mm | Min 120 mm to Max 200 mm |

| L=255 mm H=115 mm | Min 140 mm to Max 240 mm |

| L=295 mm H=125 mm | Min 180 mm to Max 280 mm |

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

Levelling feet in sealed hygienic design delivery option

For large orders we offer to supply the base and spindles separate

The advantage is flexibility for the costumer which are using many different sizes of spindles.

Hygienic Levelling Feet with 2 Floor Locking Plates and Sealed Protected Spindle

The Importance of Hygienic Levelling Feet in Clean Environments

Hygienic levelling feet play a crucial role in industries where cleanliness and safety are top priorities, such as food processing, pharmaceuticals, and biotechnology. Designed to provide stable support while minimizing contamination risks, these components ensure machinery remains level and secure.

Advantages of Dual Floor Locking Plates

Levelling feet with two floor locking plates enhance stability and prevent unwanted movement or vibration. This design is particularly beneficial in high-traffic environments where machinery must remain in a fixed position to avoid operational disruptions. Additionally, the dual-locking system reinforces hygiene by eliminating gaps where dirt and bacteria could accumulate.

Sealed Protected Spindle for Maximum Hygiene

A sealed protected spindle prevents dirt, moisture, and contaminants from penetrating critical components. This feature significantly reduces maintenance efforts and prolongs the lifespan of the levelling foot. In industries where sanitation is paramount, a fully enclosed spindle ensures compliance with strict hygiene regulations, including EHEDG and 3-A standards.

Applications in Hygienic and Industrial Sectors

These advanced levelling feet are widely used in food processing lines, pharmaceutical production facilities, and packaging machinery. Their hygienic design ensures compliance with regulatory requirements, making them a trusted choice for cleanroom and sterile environments.

Optimizing Performance with Certified Components

Choosing levelling feet made from high-grade stainless steel with hygienic sealing materials ensures durability and corrosion resistance. When combined with proper floor anchoring and cleaning protocols, these components help maintain an efficient, contamination-free production environment.

Customised Hygienic Levelling Feet for Optimal Operational Efficiency

The benefits of hygienic levelling feet with 2 floor locking plates and a sealed protected spindle, ensuring stability, durability, and compliance in clean environments and industries.

Boost Facility Hygiene with Advanced Levelling System Solutions

Levelling feet in sealed hygienic design with rubber base for vibration reduction and anti-slip properties

Our sealed hygienic levelling feet are provided with FDA certificate (FDA CFR 21 177 2600) with unique batch ID number for food safety traceability

Levelling feet in sealed hygienic design features and advantages

Sealed hygienic levelling feet have a rounded, hygienic design which makes it easy to clean.

Sealed hygienic levelling feet can cope with up to 10 degree slopes on floors and equipment.

Levelling feet in sealed hygienic design materials

Sealed hygienic levelling feet vulcanized rubber part with FDA certificate according to FDA CFR 21 177 2600.

Base plate material description:

Stainless steel Aisi 304 or Aisi 316

Spindle material description:

Stainless steel A2-70 or A4-70

Rubber base material description:

NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

Levelling feet in sealed hygienic design sizes

Sealed hygienic machine feet base are available in a wide range, giving the optimal flexibility and choice.

| Base type | Base Diameter D | Nom. Load |

|---|---|---|

| HLF 62 | 60mm | 7.000 N |

| HLF 82 | 80mm | 15.000 N |

| HLF 102 | 100mm | 20.000 N |

| HLF 122 | 120mm | 30.000 N |

Sealed hygienic levelling feet spindle with protecting sleeve are available in a wide range, giving the optimal flexibility and choice.

| M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| L=135 mm H=55 mm | Min 80 mm to Max 120 mm |

| L=175 mm H=75 mm | Min 100 mm to Max 160 mm |

| L=215 mm H=95 mm | Min 120 mm to Max 200 mm |

| L=255 mm H=115 mm | Min 140 mm to Max 240 mm |

| L=295 mm H=125 mm | Min 180 mm to Max 280 mm |

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

Levelling feet in sealed hygienic design delivery option

For large orders we offer to supply the base and spindles separate

The advantage is flexibility for the costumer which are using many different sizes of spindles.

Hygienic Levelling Feet with 2 Floor Locking Plates and Sealed Protected Spindle

The Importance of Hygienic Levelling Feet in Clean Environments

Hygienic levelling feet play a crucial role in industries where cleanliness and safety are top priorities, such as food processing, pharmaceuticals, and biotechnology. Designed to provide stable support while minimizing contamination risks, these components ensure machinery remains level and secure.

Advantages of Dual Floor Locking Plates

Levelling feet with two floor locking plates enhance stability and prevent unwanted movement or vibration. This design is particularly beneficial in high-traffic environments where machinery must remain in a fixed position to avoid operational disruptions. Additionally, the dual-locking system reinforces hygiene by eliminating gaps where dirt and bacteria could accumulate.

Sealed Protected Spindle for Maximum Hygiene

A sealed protected spindle prevents dirt, moisture, and contaminants from penetrating critical components. This feature significantly reduces maintenance efforts and prolongs the lifespan of the levelling foot. In industries where sanitation is paramount, a fully enclosed spindle ensures compliance with strict hygiene regulations, including EHEDG and 3-A standards.

Applications in Hygienic and Industrial Sectors

These advanced levelling feet are widely used in food processing lines, pharmaceutical production facilities, and packaging machinery. Their hygienic design ensures compliance with regulatory requirements, making them a trusted choice for cleanroom and sterile environments.

Optimizing Performance with Certified Components

Choosing levelling feet made from high-grade stainless steel with hygienic sealing materials ensures durability and corrosion resistance. When combined with proper floor anchoring and cleaning protocols, these components help maintain an efficient, contamination-free production environment.

Customised Hygienic Levelling Feet for Optimal Operational Efficiency

The benefits of hygienic levelling feet with 2 floor locking plates and a sealed protected spindle, ensuring stability, durability, and compliance in clean environments and industries.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.