Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

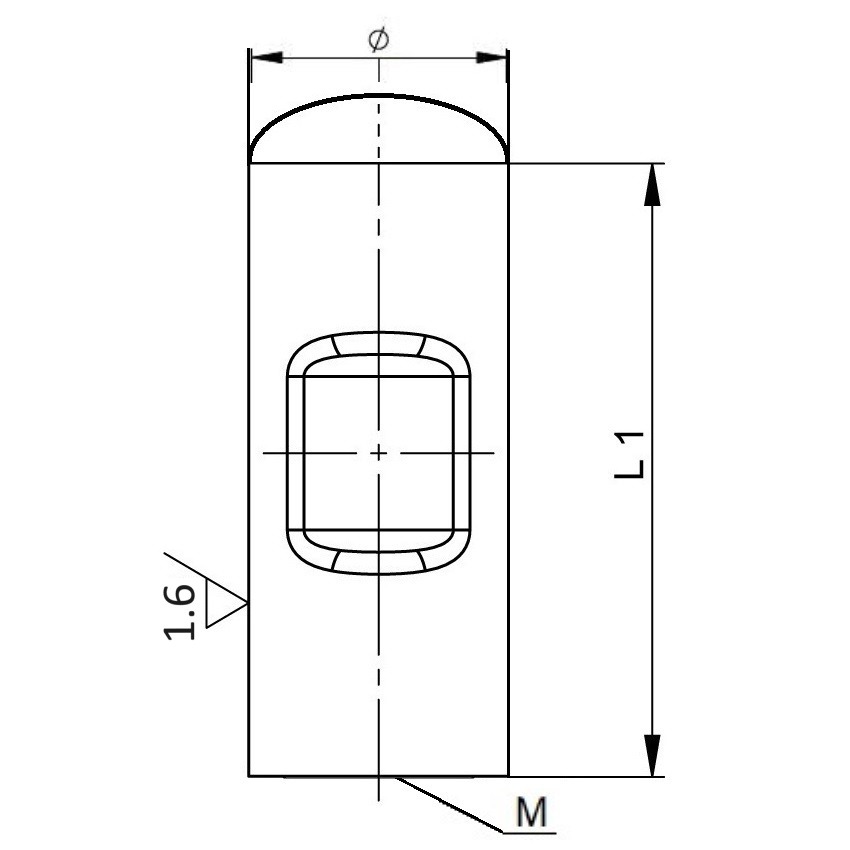

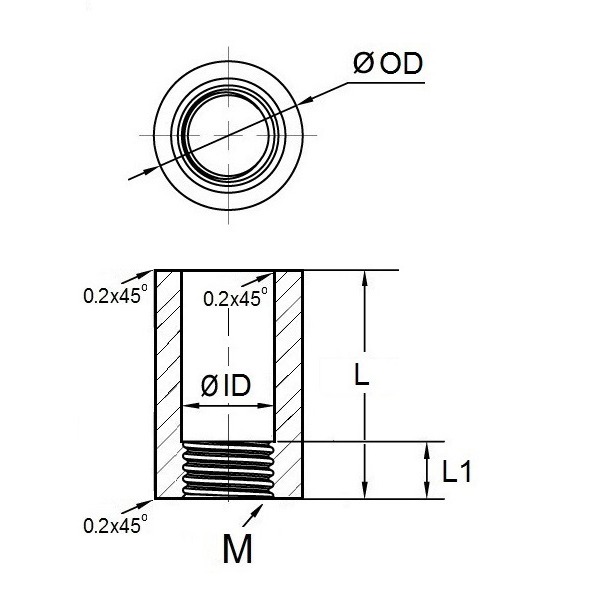

Hygienic spindle top cover in stainless steel

Durability in harsh and extreme environments

The Hygienic Spindle Top Cover in stainless steel is an essential component for industries requiring high levels of sanitation, such as food processing, pharmaceuticals, and biotechnology. Designed with superior hygiene in mind, these covers protect spindle tops from contamination and corrosion while ensuring easy cleanability. Made from certified stainless steel, the spindle top covers meet strict hygiene standards, offering excellent resistance to chemicals, moisture, and wear, making them ideal for harsh environments.

| Spindle top cover LC M12-L50 |

| Spindle top cover LC M12-L70 |

| Spindle top cover LC M12-L90 |

| Spindle top cover LC M12-L110 |

| Spindle top cover LC M16-L50 |

| Spindle top cover LC M16-L70 |

| Spindle top cover LC M16-L90 |

| Spindle top cover LC M16-L110 |

| Spindle top cover LC M20-L50 |

| Spindle top cover LC M20-L70 |

| Spindle top cover LC M20-L90 |

| Spindle top cover LC M20-L110 |

| Spindle top cover LC M24-L50 |

| Spindle top cover LC M24-L70 |

| Spindle top cover LC M24-L90 |

| Spindle top cover LC M24-L110 |

| Spindle top cover LC M30-L50 |

| Spindle top cover LC M30-L70 |

| Spindle top cover LC M30-L90 |

| Spindle top cover LC M30-L110 |

| Spindle top cover LC M36-L50 |

| Spindle top cover LC M36-L70 |

| Spindle top cover LC M36-L90 |

| Spindle top cover LC M36-L110 |

Self-draining surfaces with a maximal roughness of 1.6 µm Ra.

Enhancing Cleanliness and Durability

Their smooth, crevice-free design prevents bacteria buildup, ensuring compliance with global hygiene regulations. These covers not only enhance operational efficiency but also contribute to extended equipment lifespan by protecting mechanical components from external damage. Stainless steel’s robustness and anti-corrosive properties ensure long-term reliability, making it a key choice for companies aiming to maintain strict hygiene standards while optimizing production processes.

Incorporating hygienic spindle top covers into machinery promotes cleanliness, reduces maintenance downtime, and boosts productivity, making them indispensable for industries that prioritize hygiene and safety. Discover how these stainless steel components can elevate your operations, ensuring both quality and compliance.

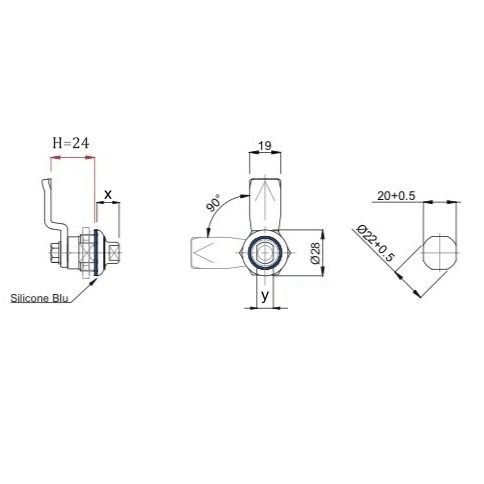

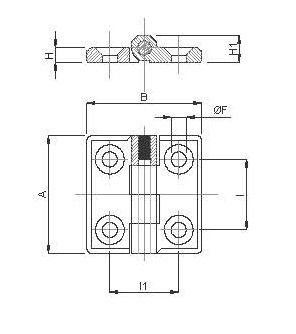

Other hygienic parts in stainless steel

Hygienic Spindle Top Cover in Stainless Steel

Revolutionizing Cleanroom Applications

In industries that demand impeccable hygiene and cleanliness, such as food processing, pharmaceuticals, and biotechnology, the importance of hygienic components cannot be overstated. One such essential component is the Hygienic Spindle Top Cover in stainless steel. These covers play a pivotal role in maintaining a sterile environment, ensuring operational efficiency, and meeting stringent compliance standards.

What Is a Hygienic Spindle Top Cover?

The spindle top cover is a critical accessory designed to cover and protect spindles in equipment used across various industries. Made of high-grade stainless steel, this cover offers a hygienic solution to prevent contamination, enhance durability, and facilitate easy cleaning.

Key features include:

- Material Composition: Typically constructed from AISI 304 or 316 stainless steel, ensuring resistance to corrosion and chemicals.

- Smooth Finish: Polished surfaces minimize microbial adhesion and simplify cleaning.

- Hygienic Design: Meets international standards such as EHEDG and 3-A Sanitary Standards, ensuring compliance with hygiene regulations.

Applications of Hygienic Spindle Top Covers

Hygienic spindle top covers are integral in maintaining cleanliness and ensuring safety in various industries, including:

Food and Beverage Processing

In food production facilities, these covers help safeguard against contamination from dust, grease, and other particles. They are particularly beneficial in environments with frequent washdowns.

Pharmaceutical and Biotechnology

The pharmaceutical industry operates under stringent cleanliness standards. Hygienic spindle top covers contribute to creating sterile environments essential for the production of medicines and vaccines.

Packaging Industry

In high-speed automated packaging lines, spindle top covers protect equipment from wear and tear, ensuring consistent performance and prolonged machine life.

Benefits of Stainless Steel Hygienic Spindle Top Covers

1. Corrosion Resistance

Stainless steel’s natural resistance to corrosion makes these spindle covers ideal for environments exposed to moisture, chemicals, or saline conditions.

2. Durability and Longevity

The robust nature of stainless steel ensures that these covers withstand rigorous cleaning processes and long-term use without degradation.

3. Ease of Maintenance

With a smooth, non-porous surface, these covers are simple to clean and maintain. They prevent the buildup of contaminants, reducing downtime for cleaning and maintenance.

4. Compliance with Hygiene Standards

Certified designs ensure that these covers meet EHEDG and 3-A Sanitary Standards, offering peace of mind in regulated industries.

5. Enhanced Operational Efficiency

By protecting critical components from external damage and contamination, spindle covers contribute to uninterrupted operations and reduced maintenance costs.

Choosing the Right Hygienic Spindle Top Cover

When selecting a hygienic spindle top cover, consider the following factors:

- Material Grade: Opt for AISI 316 stainless steel for enhanced corrosion resistance in demanding environments.

- Size and Compatibility: Ensure the cover fits seamlessly with your equipment.

- Certification: Verify compliance with industry standards such as EHEDG or 3-A Sanitary Standards.

- Surface Finish: Choose polished surfaces to optimize hygiene.

Hygienic Spindle Top Cover

Stainless Steel Excellence for Cleanroom Efficiency

The Hygienic Spindle Top Cover in stainless steel is a crucial innovation for industries that prioritize cleanliness and operational efficiency. Its durable, corrosion-resistant design ensures seamless performance in even the most demanding environments. By investing in these hygienic components, businesses can achieve compliance with industry regulations while boosting productivity and reducing maintenance costs.

Make the smart choice today and enhance your equipment with top-quality hygienic spindle top covers, tailored for your industry’s unique needs.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Durability in harsh and extreme environments

The Hygienic Spindle Top Cover in stainless steel is an essential component for industries requiring high levels of sanitation, such as food processing, pharmaceuticals, and biotechnology. Designed with superior hygiene in mind, these covers protect spindle tops from contamination and corrosion while ensuring easy cleanability. Made from certified stainless steel, the spindle top covers meet strict hygiene standards, offering excellent resistance to chemicals, moisture, and wear, making them ideal for harsh environments.

| Spindle top cover LC M12-L50 |

| Spindle top cover LC M12-L70 |

| Spindle top cover LC M12-L90 |

| Spindle top cover LC M12-L110 |

| Spindle top cover LC M16-L50 |

| Spindle top cover LC M16-L70 |

| Spindle top cover LC M16-L90 |

| Spindle top cover LC M16-L110 |

| Spindle top cover LC M20-L50 |

| Spindle top cover LC M20-L70 |

| Spindle top cover LC M20-L90 |

| Spindle top cover LC M20-L110 |

| Spindle top cover LC M24-L50 |

| Spindle top cover LC M24-L70 |

| Spindle top cover LC M24-L90 |

| Spindle top cover LC M24-L110 |

| Spindle top cover LC M30-L50 |

| Spindle top cover LC M30-L70 |

| Spindle top cover LC M30-L90 |

| Spindle top cover LC M30-L110 |

| Spindle top cover LC M36-L50 |

| Spindle top cover LC M36-L70 |

| Spindle top cover LC M36-L90 |

| Spindle top cover LC M36-L110 |

Self-draining surfaces with a maximal roughness of 1.6 µm Ra.

Enhancing Cleanliness and Durability

Their smooth, crevice-free design prevents bacteria buildup, ensuring compliance with global hygiene regulations. These covers not only enhance operational efficiency but also contribute to extended equipment lifespan by protecting mechanical components from external damage. Stainless steel’s robustness and anti-corrosive properties ensure long-term reliability, making it a key choice for companies aiming to maintain strict hygiene standards while optimizing production processes.

Incorporating hygienic spindle top covers into machinery promotes cleanliness, reduces maintenance downtime, and boosts productivity, making them indispensable for industries that prioritize hygiene and safety. Discover how these stainless steel components can elevate your operations, ensuring both quality and compliance.

Other hygienic parts in stainless steel

Hygienic Spindle Top Cover in Stainless Steel

Revolutionizing Cleanroom Applications

In industries that demand impeccable hygiene and cleanliness, such as food processing, pharmaceuticals, and biotechnology, the importance of hygienic components cannot be overstated. One such essential component is the Hygienic Spindle Top Cover in stainless steel. These covers play a pivotal role in maintaining a sterile environment, ensuring operational efficiency, and meeting stringent compliance standards.

What Is a Hygienic Spindle Top Cover?

The spindle top cover is a critical accessory designed to cover and protect spindles in equipment used across various industries. Made of high-grade stainless steel, this cover offers a hygienic solution to prevent contamination, enhance durability, and facilitate easy cleaning.

Key features include:

- Material Composition: Typically constructed from AISI 304 or 316 stainless steel, ensuring resistance to corrosion and chemicals.

- Smooth Finish: Polished surfaces minimize microbial adhesion and simplify cleaning.

- Hygienic Design: Meets international standards such as EHEDG and 3-A Sanitary Standards, ensuring compliance with hygiene regulations.

Applications of Hygienic Spindle Top Covers

Hygienic spindle top covers are integral in maintaining cleanliness and ensuring safety in various industries, including:

Food and Beverage Processing

In food production facilities, these covers help safeguard against contamination from dust, grease, and other particles. They are particularly beneficial in environments with frequent washdowns.

Pharmaceutical and Biotechnology

The pharmaceutical industry operates under stringent cleanliness standards. Hygienic spindle top covers contribute to creating sterile environments essential for the production of medicines and vaccines.

Packaging Industry

In high-speed automated packaging lines, spindle top covers protect equipment from wear and tear, ensuring consistent performance and prolonged machine life.

Benefits of Stainless Steel Hygienic Spindle Top Covers

1. Corrosion Resistance

Stainless steel’s natural resistance to corrosion makes these spindle covers ideal for environments exposed to moisture, chemicals, or saline conditions.

2. Durability and Longevity

The robust nature of stainless steel ensures that these covers withstand rigorous cleaning processes and long-term use without degradation.

3. Ease of Maintenance

With a smooth, non-porous surface, these covers are simple to clean and maintain. They prevent the buildup of contaminants, reducing downtime for cleaning and maintenance.

4. Compliance with Hygiene Standards

Certified designs ensure that these covers meet EHEDG and 3-A Sanitary Standards, offering peace of mind in regulated industries.

5. Enhanced Operational Efficiency

By protecting critical components from external damage and contamination, spindle covers contribute to uninterrupted operations and reduced maintenance costs.

Choosing the Right Hygienic Spindle Top Cover

When selecting a hygienic spindle top cover, consider the following factors:

- Material Grade: Opt for AISI 316 stainless steel for enhanced corrosion resistance in demanding environments.

- Size and Compatibility: Ensure the cover fits seamlessly with your equipment.

- Certification: Verify compliance with industry standards such as EHEDG or 3-A Sanitary Standards.

- Surface Finish: Choose polished surfaces to optimize hygiene.

Hygienic Spindle Top Cover

Stainless Steel Excellence for Cleanroom Efficiency

The Hygienic Spindle Top Cover in stainless steel is a crucial innovation for industries that prioritize cleanliness and operational efficiency. Its durable, corrosion-resistant design ensures seamless performance in even the most demanding environments. By investing in these hygienic components, businesses can achieve compliance with industry regulations while boosting productivity and reducing maintenance costs.

Make the smart choice today and enhance your equipment with top-quality hygienic spindle top covers, tailored for your industry’s unique needs.

Durability in harsh and extreme environments

The Hygienic Spindle Top Cover in stainless steel is an essential component for industries requiring high levels of sanitation, such as food processing, pharmaceuticals, and biotechnology. Designed with superior hygiene in mind, these covers protect spindle tops from contamination and corrosion while ensuring easy cleanability. Made from certified stainless steel, the spindle top covers meet strict hygiene standards, offering excellent resistance to chemicals, moisture, and wear, making them ideal for harsh environments.

| Spindle top cover LC M12-L50 |

| Spindle top cover LC M12-L70 |

| Spindle top cover LC M12-L90 |

| Spindle top cover LC M12-L110 |

| Spindle top cover LC M16-L50 |

| Spindle top cover LC M16-L70 |

| Spindle top cover LC M16-L90 |

| Spindle top cover LC M16-L110 |

| Spindle top cover LC M20-L50 |

| Spindle top cover LC M20-L70 |

| Spindle top cover LC M20-L90 |

| Spindle top cover LC M20-L110 |

| Spindle top cover LC M24-L50 |

| Spindle top cover LC M24-L70 |

| Spindle top cover LC M24-L90 |

| Spindle top cover LC M24-L110 |

| Spindle top cover LC M30-L50 |

| Spindle top cover LC M30-L70 |

| Spindle top cover LC M30-L90 |

| Spindle top cover LC M30-L110 |

| Spindle top cover LC M36-L50 |

| Spindle top cover LC M36-L70 |

| Spindle top cover LC M36-L90 |

| Spindle top cover LC M36-L110 |

Self-draining surfaces with a maximal roughness of 1.6 µm Ra.

Enhancing Cleanliness and Durability

Their smooth, crevice-free design prevents bacteria buildup, ensuring compliance with global hygiene regulations. These covers not only enhance operational efficiency but also contribute to extended equipment lifespan by protecting mechanical components from external damage. Stainless steel’s robustness and anti-corrosive properties ensure long-term reliability, making it a key choice for companies aiming to maintain strict hygiene standards while optimizing production processes.

Incorporating hygienic spindle top covers into machinery promotes cleanliness, reduces maintenance downtime, and boosts productivity, making them indispensable for industries that prioritize hygiene and safety. Discover how these stainless steel components can elevate your operations, ensuring both quality and compliance.

Other hygienic parts in stainless steel

Hygienic Spindle Top Cover in Stainless Steel

Revolutionizing Cleanroom Applications

In industries that demand impeccable hygiene and cleanliness, such as food processing, pharmaceuticals, and biotechnology, the importance of hygienic components cannot be overstated. One such essential component is the Hygienic Spindle Top Cover in stainless steel. These covers play a pivotal role in maintaining a sterile environment, ensuring operational efficiency, and meeting stringent compliance standards.

What Is a Hygienic Spindle Top Cover?

The spindle top cover is a critical accessory designed to cover and protect spindles in equipment used across various industries. Made of high-grade stainless steel, this cover offers a hygienic solution to prevent contamination, enhance durability, and facilitate easy cleaning.

Key features include:

- Material Composition: Typically constructed from AISI 304 or 316 stainless steel, ensuring resistance to corrosion and chemicals.

- Smooth Finish: Polished surfaces minimize microbial adhesion and simplify cleaning.

- Hygienic Design: Meets international standards such as EHEDG and 3-A Sanitary Standards, ensuring compliance with hygiene regulations.

Applications of Hygienic Spindle Top Covers

Hygienic spindle top covers are integral in maintaining cleanliness and ensuring safety in various industries, including:

Food and Beverage Processing

In food production facilities, these covers help safeguard against contamination from dust, grease, and other particles. They are particularly beneficial in environments with frequent washdowns.

Pharmaceutical and Biotechnology

The pharmaceutical industry operates under stringent cleanliness standards. Hygienic spindle top covers contribute to creating sterile environments essential for the production of medicines and vaccines.

Packaging Industry

In high-speed automated packaging lines, spindle top covers protect equipment from wear and tear, ensuring consistent performance and prolonged machine life.

Benefits of Stainless Steel Hygienic Spindle Top Covers

1. Corrosion Resistance

Stainless steel’s natural resistance to corrosion makes these spindle covers ideal for environments exposed to moisture, chemicals, or saline conditions.

2. Durability and Longevity

The robust nature of stainless steel ensures that these covers withstand rigorous cleaning processes and long-term use without degradation.

3. Ease of Maintenance

With a smooth, non-porous surface, these covers are simple to clean and maintain. They prevent the buildup of contaminants, reducing downtime for cleaning and maintenance.

4. Compliance with Hygiene Standards

Certified designs ensure that these covers meet EHEDG and 3-A Sanitary Standards, offering peace of mind in regulated industries.

5. Enhanced Operational Efficiency

By protecting critical components from external damage and contamination, spindle covers contribute to uninterrupted operations and reduced maintenance costs.

Choosing the Right Hygienic Spindle Top Cover

When selecting a hygienic spindle top cover, consider the following factors:

- Material Grade: Opt for AISI 316 stainless steel for enhanced corrosion resistance in demanding environments.

- Size and Compatibility: Ensure the cover fits seamlessly with your equipment.

- Certification: Verify compliance with industry standards such as EHEDG or 3-A Sanitary Standards.

- Surface Finish: Choose polished surfaces to optimize hygiene.

Hygienic Spindle Top Cover

Stainless Steel Excellence for Cleanroom Efficiency

The Hygienic Spindle Top Cover in stainless steel is a crucial innovation for industries that prioritize cleanliness and operational efficiency. Its durable, corrosion-resistant design ensures seamless performance in even the most demanding environments. By investing in these hygienic components, businesses can achieve compliance with industry regulations while boosting productivity and reducing maintenance costs.

Make the smart choice today and enhance your equipment with top-quality hygienic spindle top covers, tailored for your industry’s unique needs.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.