Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

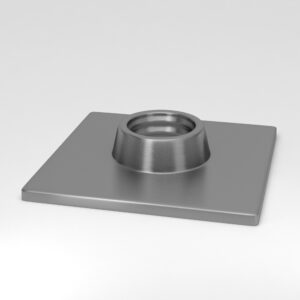

Hygienic corner nut in stainless steel

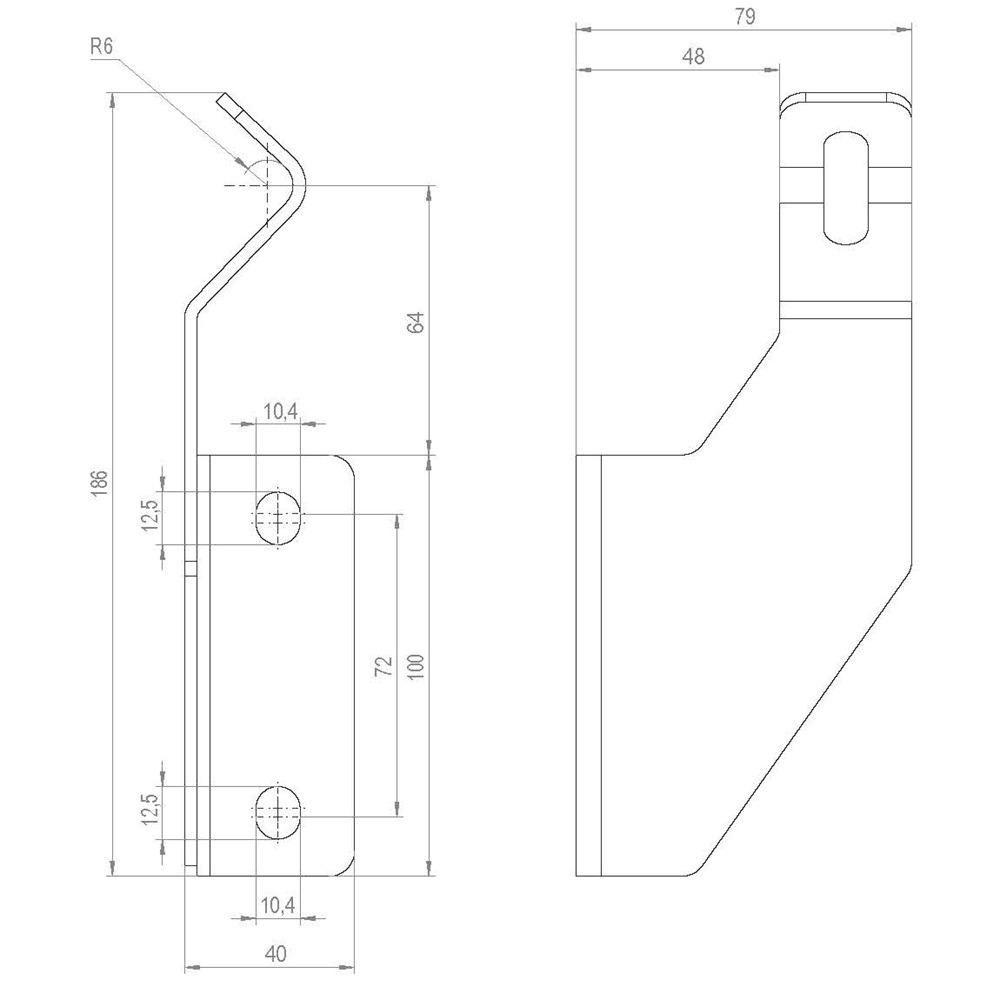

Corner nut

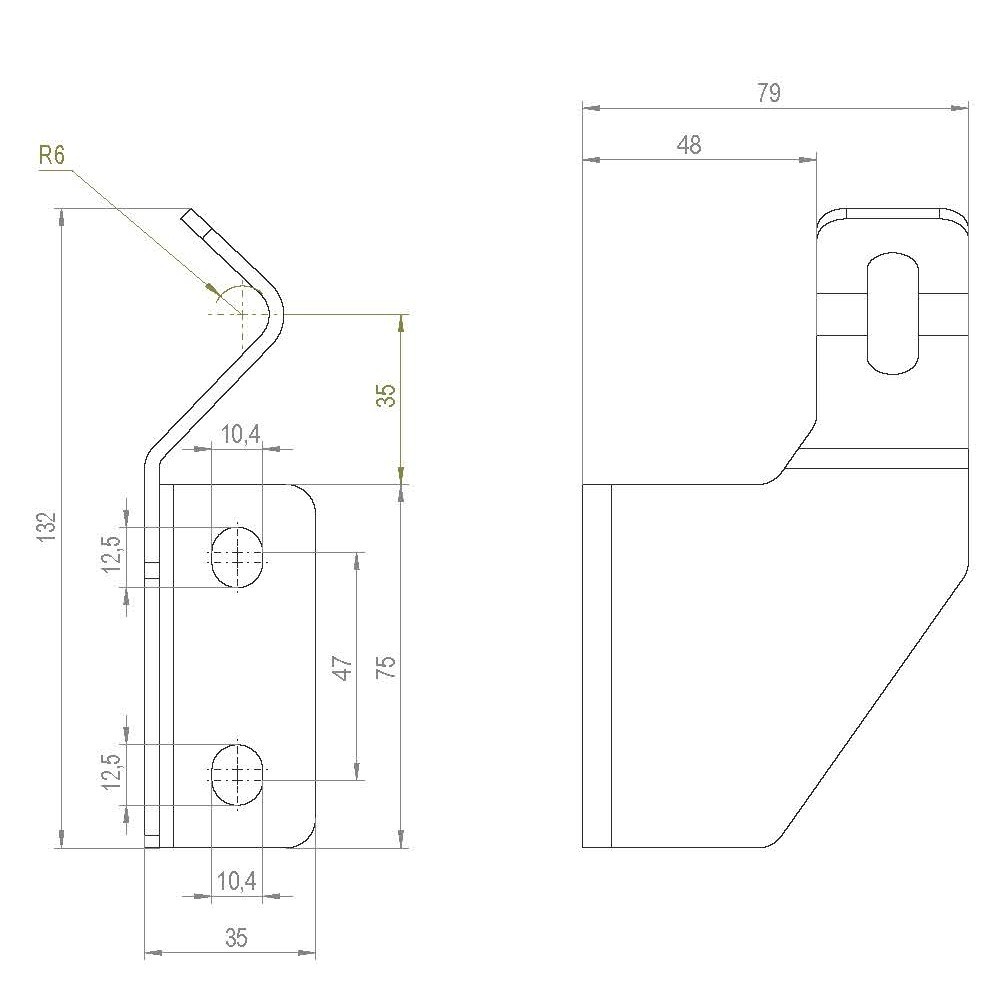

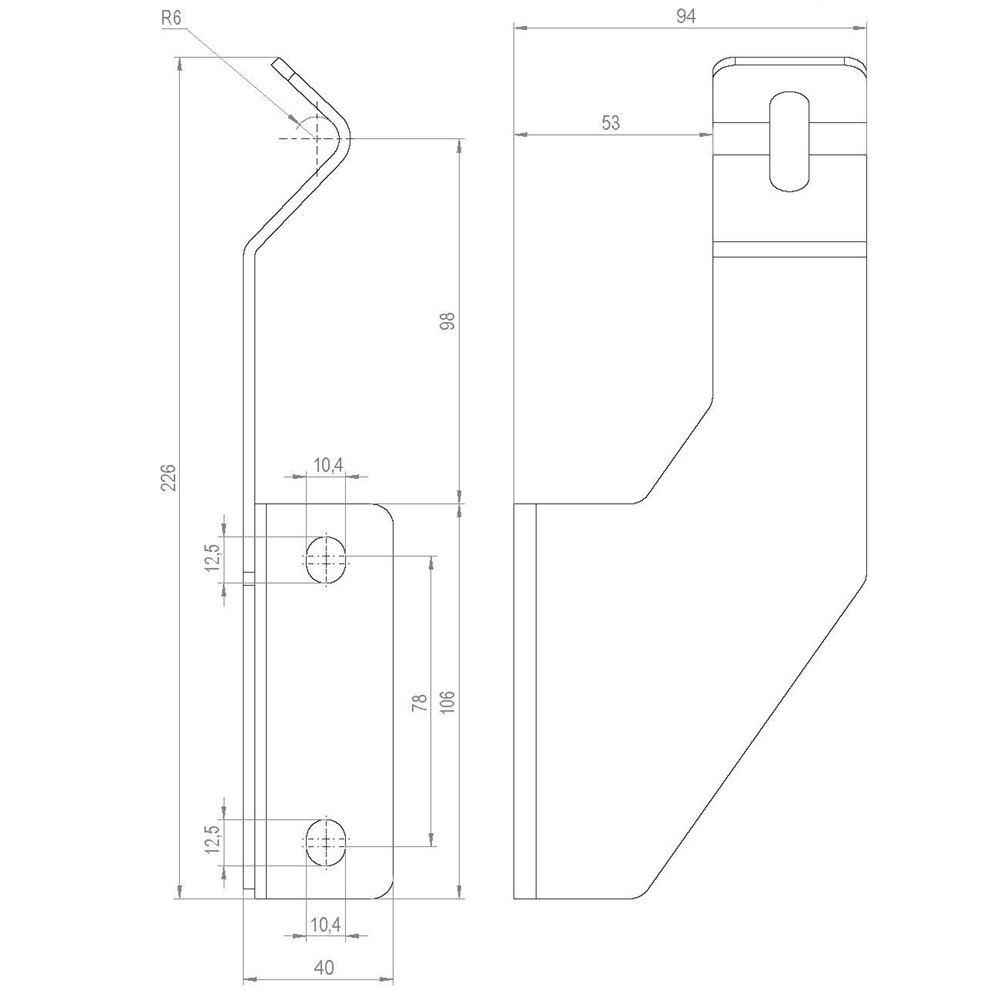

Our corner nut and spacer series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: medical equipment, food & pharmaceutical processing equipment, packaging machinery, 3A design-meat & poultry processing equipment, dairy processing machines.

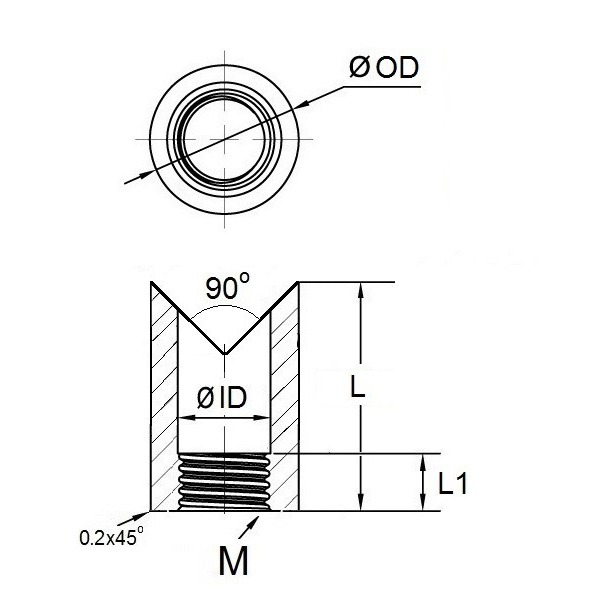

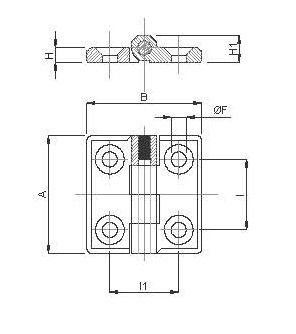

Threaded stainless steel corner nut (Aisi 1.4301)

Corner nut in stainless steel (Aisi 1.4301)

Corner nut M8-16-15 – ID=8.2 – OD=16.0 – L=15 – L1=6

Corner nut M8-16-20 – ID=8.2 – OD=16.0 – L=20 – L1=6

Corner nut M8-16-25 – ID=8.2 – OD=16.0 – L=25 – L1=10

Corner nut M10-18-15 – ID=10.2 – OD=18.0 – L=15 – L1=6

Corner nut M10-18-25 – ID=10.2 – OD=18.0 – L=25 – L1=10

Corner nut M12-22-15 – ID=12.2 – OD=22.0 – L=15 – L1=6

Corner nut M12-22-25 – ID=12.2 – OD=22.0 – L=25 – L1=10

Corner nut M16-26-15 – ID=16.2 – OD=26.0 – L=15 – L1=6

Corner nut M16-26-25 – ID=16.2 – OD=26.0 – L=25 – L1=10

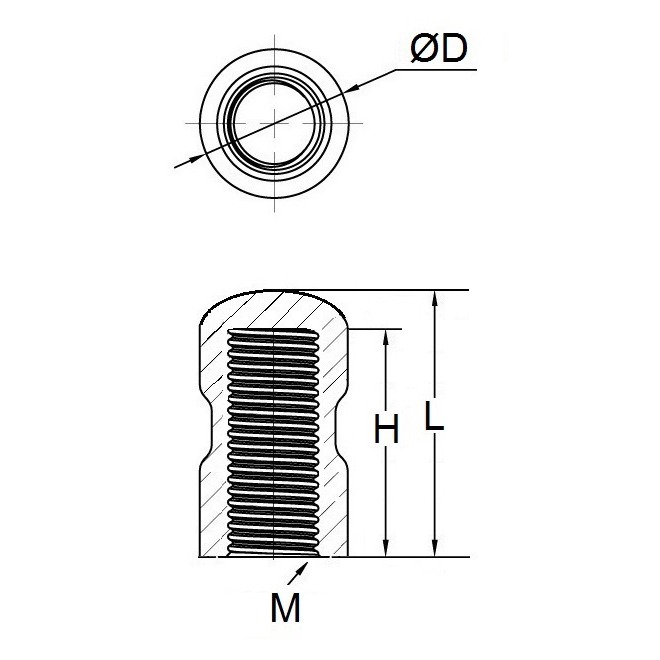

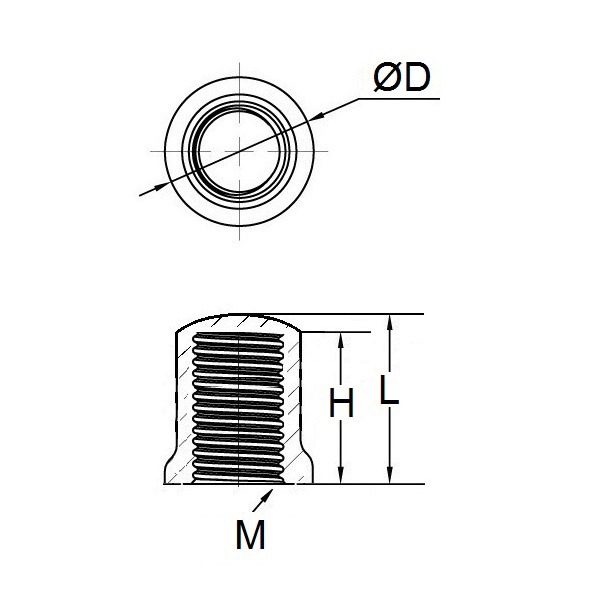

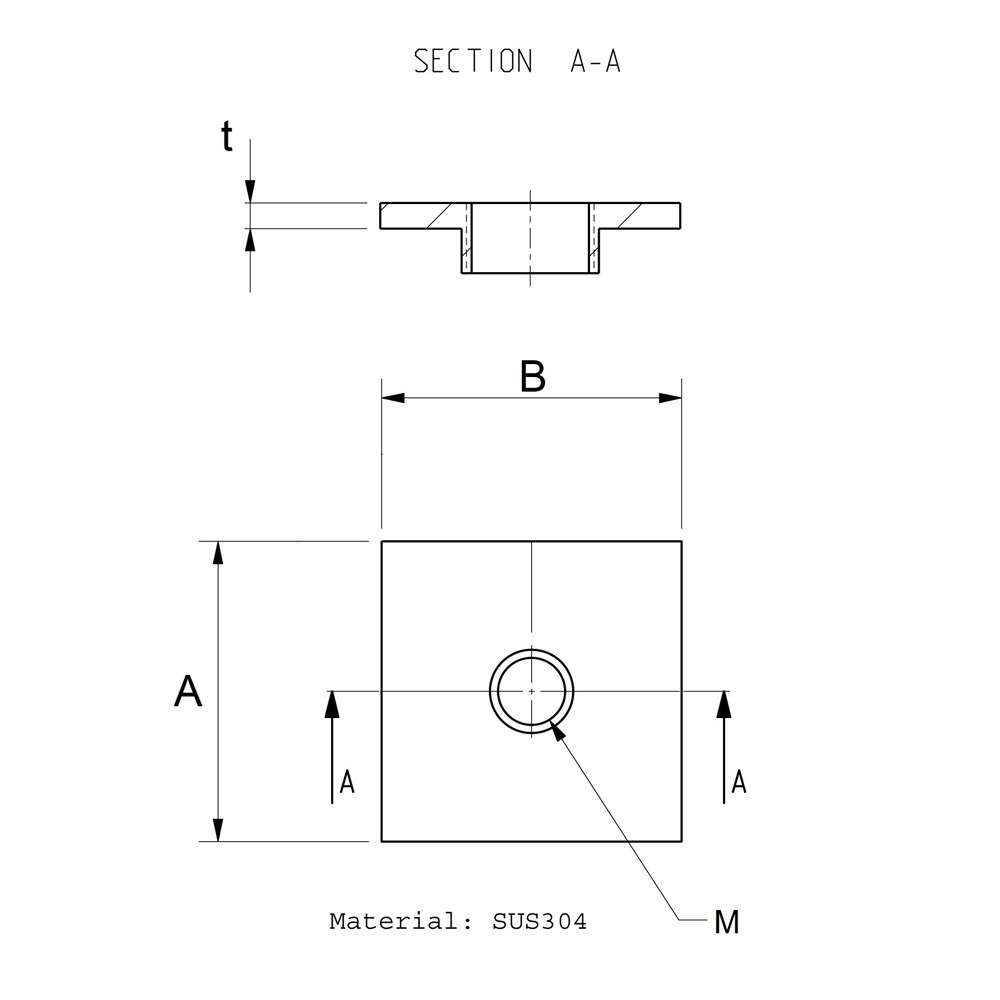

Corner spacer in stainless steel (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Corner spacer 6.8-16-15 – ID=6.8 – OD=16.0 – L=15

Corner spacer 6.8-16-25 – ID=6.8 – OD=16.0 – L=25

Corner spacer 8.5-18-15 – ID=8.5 – OD=18.0 – L=15

Corner spacer 8.5-18-25 – ID=8.5 – OD=18.0 – L=25

Corner spacer 10.2-22-15 – ID=10.2 – OD=22.0 – L=15

Corner spacer 10.2-22-25 – ID=10.2 – OD=22.0 – L=25

Corner spacer 14.0-26-15 – ID=14.0 – OD=26.0 – L=15

Corner spacer 14.0-26-25 – ID=14.0 – OD=26.0 – L=25

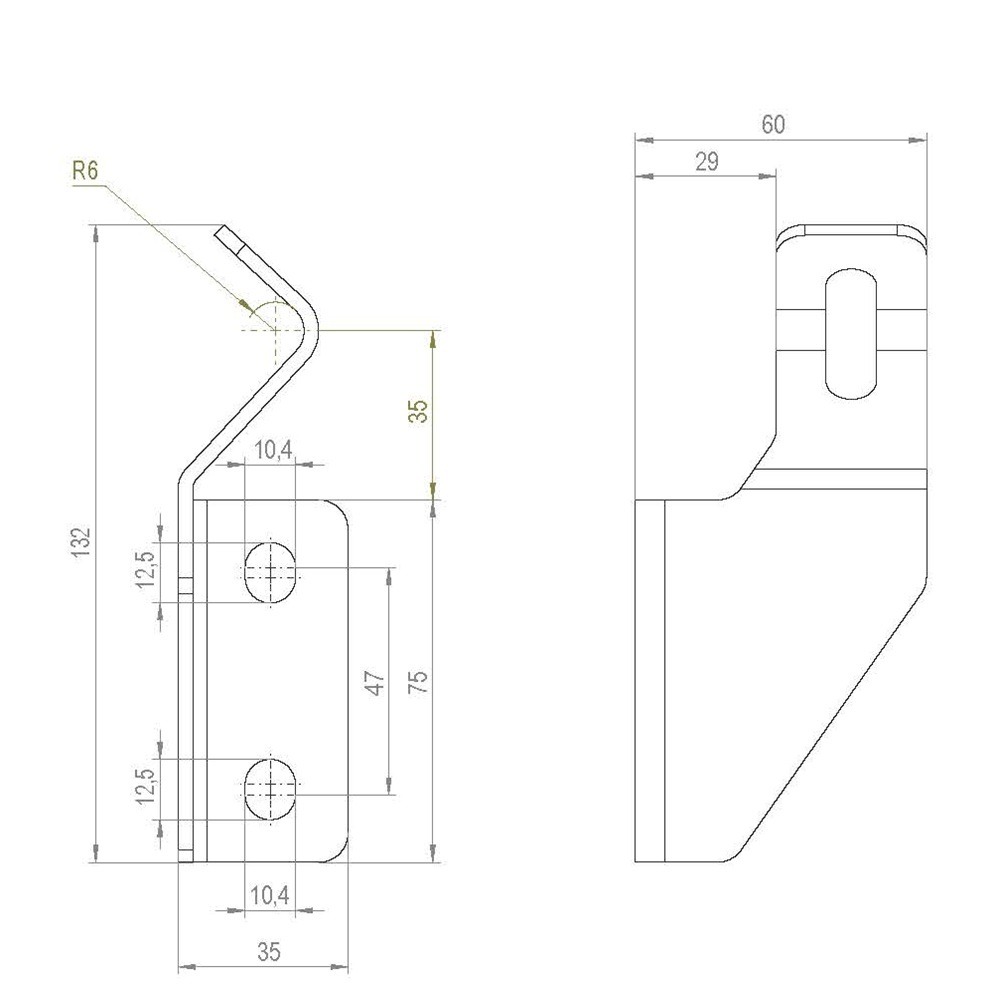

Conveyor components in hygienic design

For other size, please contact us.

Corner Nut in Stainless Steel

The Ideal Solution for Easy-to-Clean Applications

In industries where hygiene and cleanliness are paramount, such as food processing, pharmaceuticals, and cleanrooms, every component used must meet rigorous standards. Corner nuts in stainless steel have emerged as a vital component in such settings. Their robust design, coupled with easy-to-clean features, ensures they meet the strict requirements of these industries while offering superior performance.

Why Stainless Steel is the Material of Choice

Stainless steel is renowned for its exceptional properties, making it the ideal material for corner nuts used in demanding environments:

- Corrosion Resistance: Stainless steel resists rust and corrosion, even in moist or chemical-laden environments, ensuring a longer lifespan.

- Hygienic Surface: The smooth and non-porous surface of stainless steel prevents bacteria and contaminants from adhering.

- Durability: With high tensile strength, stainless steel corner nuts withstand heavy loads and challenging conditions.

- Eco-Friendly: Stainless steel is recyclable, aligning with sustainability goals in modern industries.

Easy-to-Clean Design for Hygienic Applications

Corner nuts in stainless steel are specifically designed for easy cleaning, a critical feature in hygiene-sensitive environments. Key design elements include:

- Smooth Surfaces: Minimized crevices prevent dirt and contaminants from accumulating.

- Rounded Edges: Easier to sanitize and reduces the risk of trapping debris.

- Polished Finish: A high-polish finish not only enhances appearance but also improves cleanability.

These features make stainless steel corner nuts perfect for environments where sanitation protocols are rigorous, such as food production lines or pharmaceutical labs.

Applications in High-Hygiene Industries

Stainless steel corner nuts play an essential role in various sectors:

- Food and Beverage Industry: Used in conveyor systems, packaging equipment, and processing machinery, where cleanliness directly impacts product safety.

- Pharmaceutical and Biotechnology: Integral to equipment and assemblies where sterility is non-negotiable.

- Cleanrooms: Perfect for fastening systems in environments with controlled contamination levels.

In these industries, their easy-to-clean nature ensures compliance with strict standards like EHEDG and FDA guidelines.

Advantages Over Traditional Fasteners

While standard fasteners might suffice in less critical applications, stainless steel corner nuts offer distinct advantages for high-hygiene settings:

- Ease of Maintenance: Designed for rapid disassembly and cleaning, minimizing downtime.

- Regulatory Compliance: Meet international hygiene standards, providing peace of mind to operators.

- Aesthetic Appeal: The polished finish not only improves functionality but also lends a professional appearance to equipment.

How to Choose the Right Stainless Steel Corner Nut

When selecting corner nuts for your application, consider the following factors:

- Grade of Stainless Steel: Grades like 304 and 316 are excellent choices for corrosion resistance.

- Size and Fit: Ensure compatibility with your existing equipment or system.

- Certifications: Look for products certified by EHEDG, 3A, or FDA for hygienic applications.

Stainless Steel Corner Nuts: The Hygienic Solution for Easy-to-Clean Applications

Stainless steel corner nuts are a small but indispensable component in industries that prioritize hygiene, safety, and efficiency. Their durability, easy-to-clean design, and compliance with international standards make them the perfect choice for demanding environments.

By investing in high-quality stainless steel corner nuts, businesses can enhance operational reliability and ensure they meet the stringent requirements of their respective industries.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

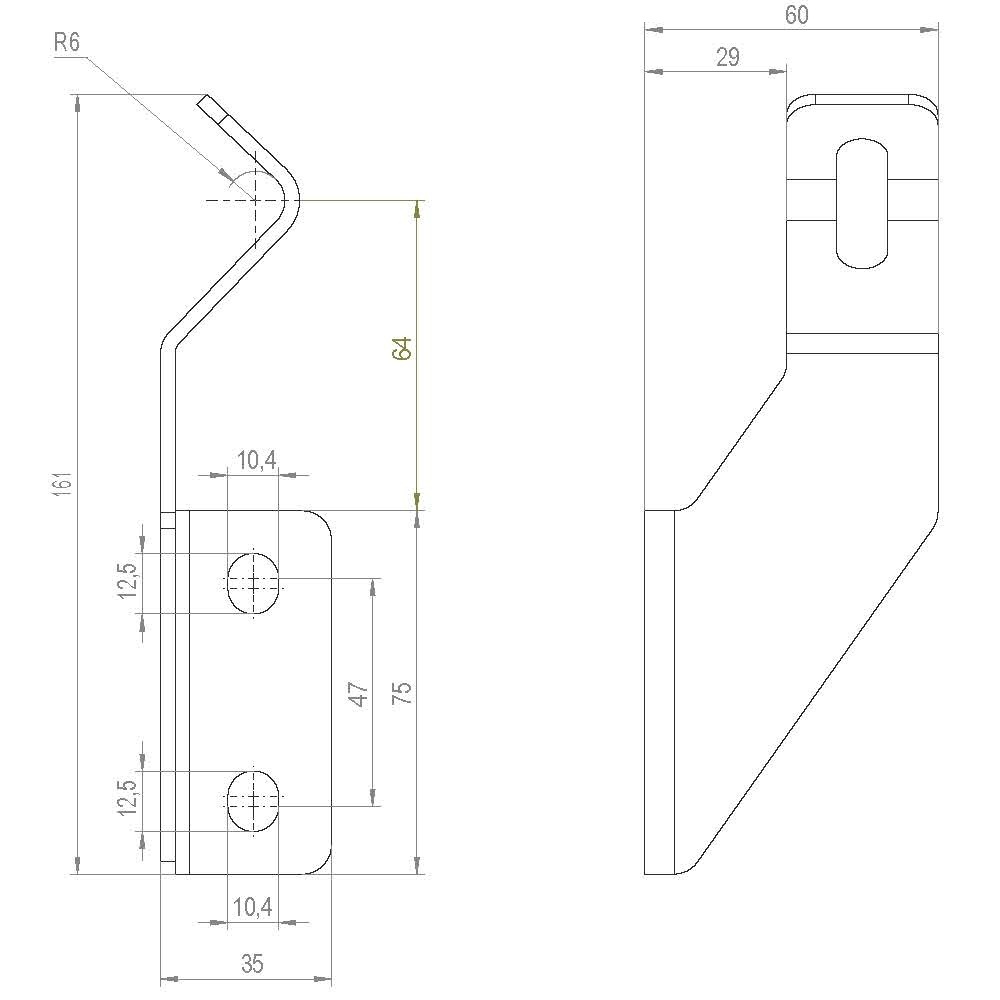

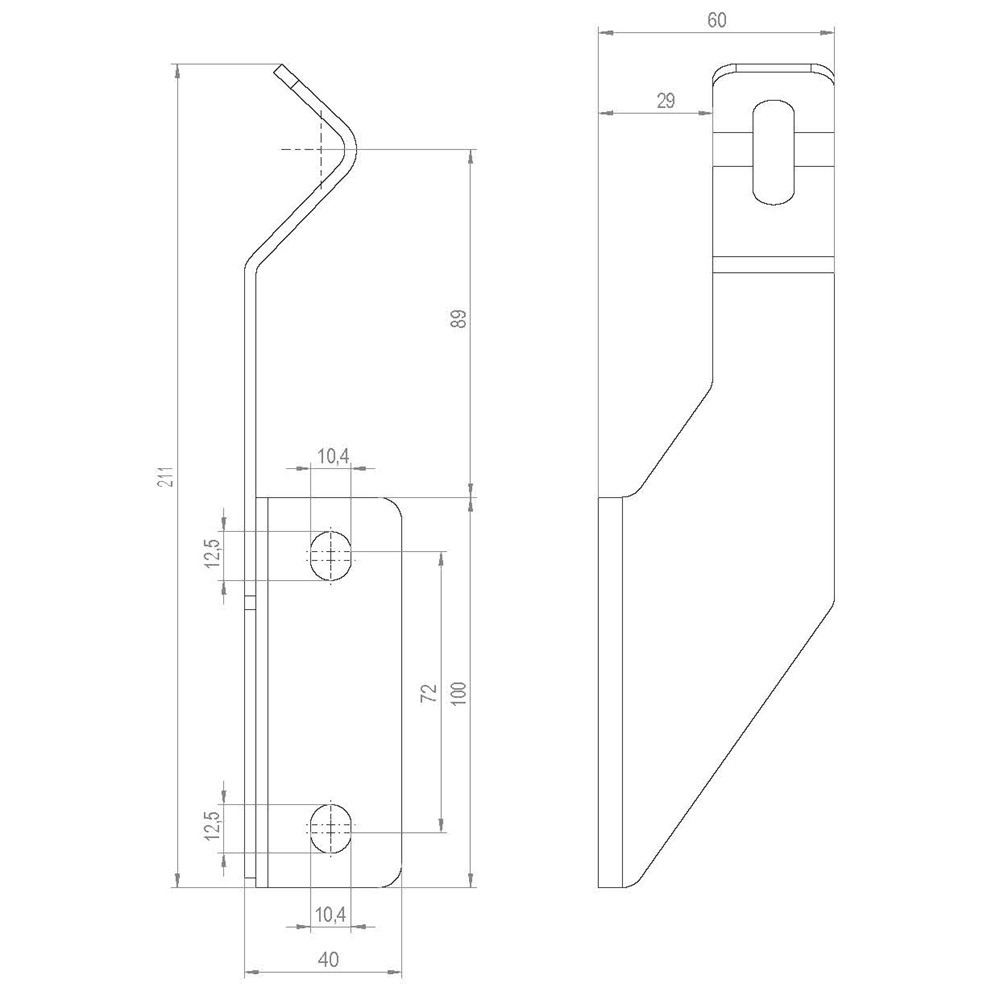

Corner nut

Our corner nut and spacer series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: medical equipment, food & pharmaceutical processing equipment, packaging machinery, 3A design-meat & poultry processing equipment, dairy processing machines.

Threaded stainless steel corner nut (Aisi 1.4301)

Corner nut in stainless steel (Aisi 1.4301)

Corner nut M8-16-15 – ID=8.2 – OD=16.0 – L=15 – L1=6

Corner nut M8-16-20 – ID=8.2 – OD=16.0 – L=20 – L1=6

Corner nut M8-16-25 – ID=8.2 – OD=16.0 – L=25 – L1=10

Corner nut M10-18-15 – ID=10.2 – OD=18.0 – L=15 – L1=6

Corner nut M10-18-25 – ID=10.2 – OD=18.0 – L=25 – L1=10

Corner nut M12-22-15 – ID=12.2 – OD=22.0 – L=15 – L1=6

Corner nut M12-22-25 – ID=12.2 – OD=22.0 – L=25 – L1=10

Corner nut M16-26-15 – ID=16.2 – OD=26.0 – L=15 – L1=6

Corner nut M16-26-25 – ID=16.2 – OD=26.0 – L=25 – L1=10

Corner spacer in stainless steel (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Corner spacer 6.8-16-15 – ID=6.8 – OD=16.0 – L=15

Corner spacer 6.8-16-25 – ID=6.8 – OD=16.0 – L=25

Corner spacer 8.5-18-15 – ID=8.5 – OD=18.0 – L=15

Corner spacer 8.5-18-25 – ID=8.5 – OD=18.0 – L=25

Corner spacer 10.2-22-15 – ID=10.2 – OD=22.0 – L=15

Corner spacer 10.2-22-25 – ID=10.2 – OD=22.0 – L=25

Corner spacer 14.0-26-15 – ID=14.0 – OD=26.0 – L=15

Corner spacer 14.0-26-25 – ID=14.0 – OD=26.0 – L=25

Conveyor components in hygienic design

For other size, please contact us.

Corner Nut in Stainless Steel

The Ideal Solution for Easy-to-Clean Applications

In industries where hygiene and cleanliness are paramount, such as food processing, pharmaceuticals, and cleanrooms, every component used must meet rigorous standards. Corner nuts in stainless steel have emerged as a vital component in such settings. Their robust design, coupled with easy-to-clean features, ensures they meet the strict requirements of these industries while offering superior performance.

Why Stainless Steel is the Material of Choice

Stainless steel is renowned for its exceptional properties, making it the ideal material for corner nuts used in demanding environments:

- Corrosion Resistance: Stainless steel resists rust and corrosion, even in moist or chemical-laden environments, ensuring a longer lifespan.

- Hygienic Surface: The smooth and non-porous surface of stainless steel prevents bacteria and contaminants from adhering.

- Durability: With high tensile strength, stainless steel corner nuts withstand heavy loads and challenging conditions.

- Eco-Friendly: Stainless steel is recyclable, aligning with sustainability goals in modern industries.

Easy-to-Clean Design for Hygienic Applications

Corner nuts in stainless steel are specifically designed for easy cleaning, a critical feature in hygiene-sensitive environments. Key design elements include:

- Smooth Surfaces: Minimized crevices prevent dirt and contaminants from accumulating.

- Rounded Edges: Easier to sanitize and reduces the risk of trapping debris.

- Polished Finish: A high-polish finish not only enhances appearance but also improves cleanability.

These features make stainless steel corner nuts perfect for environments where sanitation protocols are rigorous, such as food production lines or pharmaceutical labs.

Applications in High-Hygiene Industries

Stainless steel corner nuts play an essential role in various sectors:

- Food and Beverage Industry: Used in conveyor systems, packaging equipment, and processing machinery, where cleanliness directly impacts product safety.

- Pharmaceutical and Biotechnology: Integral to equipment and assemblies where sterility is non-negotiable.

- Cleanrooms: Perfect for fastening systems in environments with controlled contamination levels.

In these industries, their easy-to-clean nature ensures compliance with strict standards like EHEDG and FDA guidelines.

Advantages Over Traditional Fasteners

While standard fasteners might suffice in less critical applications, stainless steel corner nuts offer distinct advantages for high-hygiene settings:

- Ease of Maintenance: Designed for rapid disassembly and cleaning, minimizing downtime.

- Regulatory Compliance: Meet international hygiene standards, providing peace of mind to operators.

- Aesthetic Appeal: The polished finish not only improves functionality but also lends a professional appearance to equipment.

How to Choose the Right Stainless Steel Corner Nut

When selecting corner nuts for your application, consider the following factors:

- Grade of Stainless Steel: Grades like 304 and 316 are excellent choices for corrosion resistance.

- Size and Fit: Ensure compatibility with your existing equipment or system.

- Certifications: Look for products certified by EHEDG, 3A, or FDA for hygienic applications.

Stainless Steel Corner Nuts: The Hygienic Solution for Easy-to-Clean Applications

Stainless steel corner nuts are a small but indispensable component in industries that prioritize hygiene, safety, and efficiency. Their durability, easy-to-clean design, and compliance with international standards make them the perfect choice for demanding environments.

By investing in high-quality stainless steel corner nuts, businesses can enhance operational reliability and ensure they meet the stringent requirements of their respective industries.

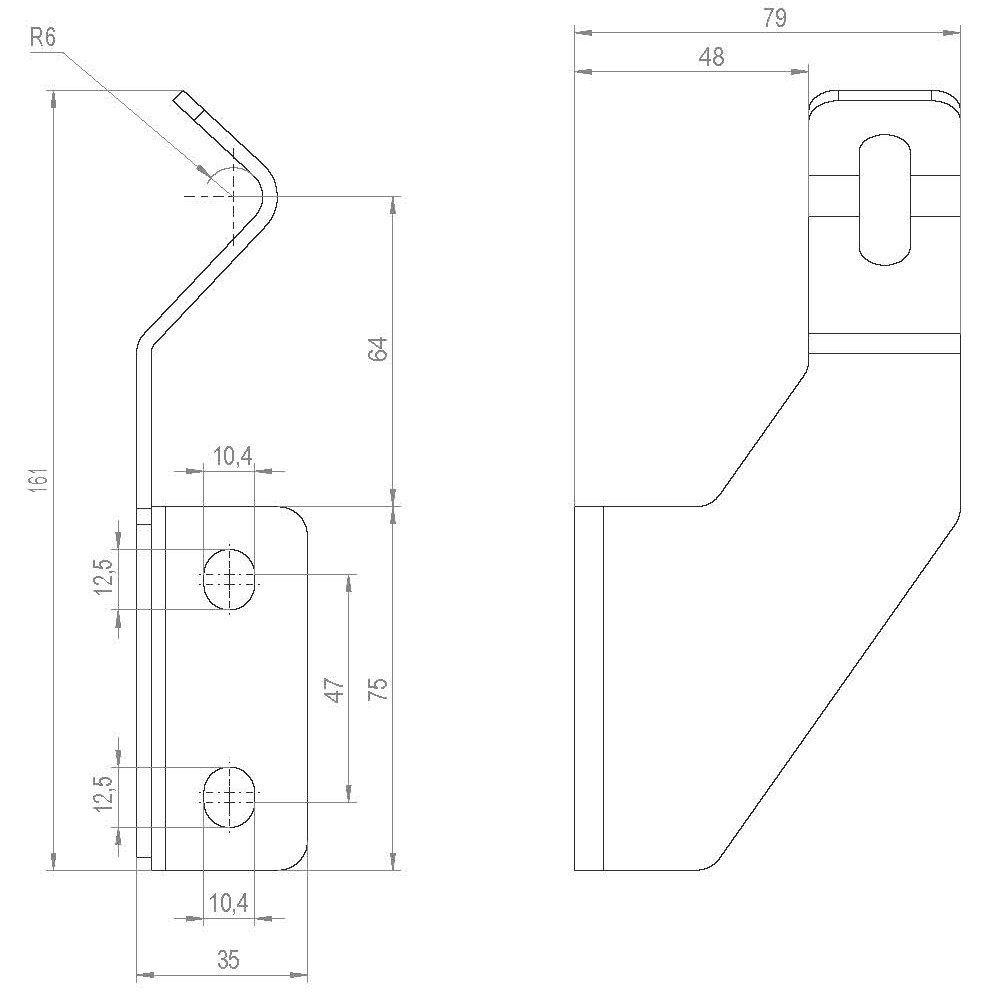

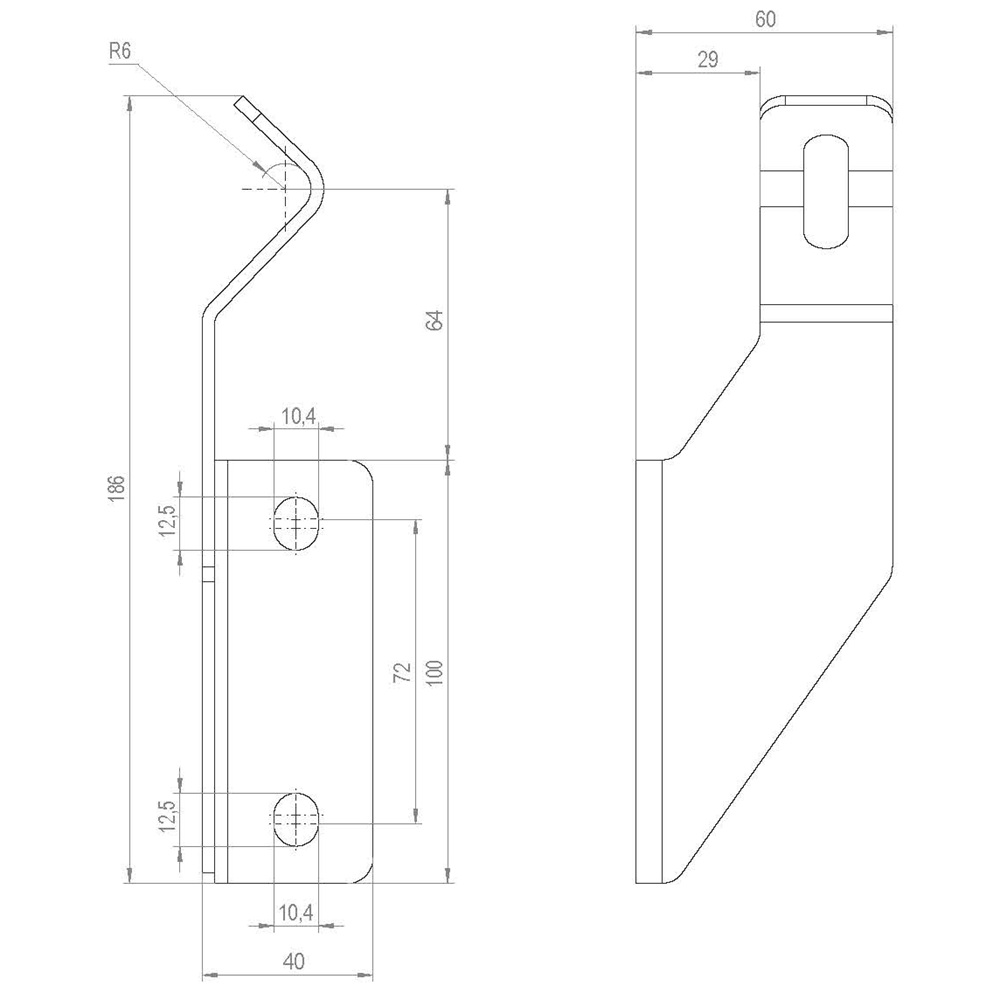

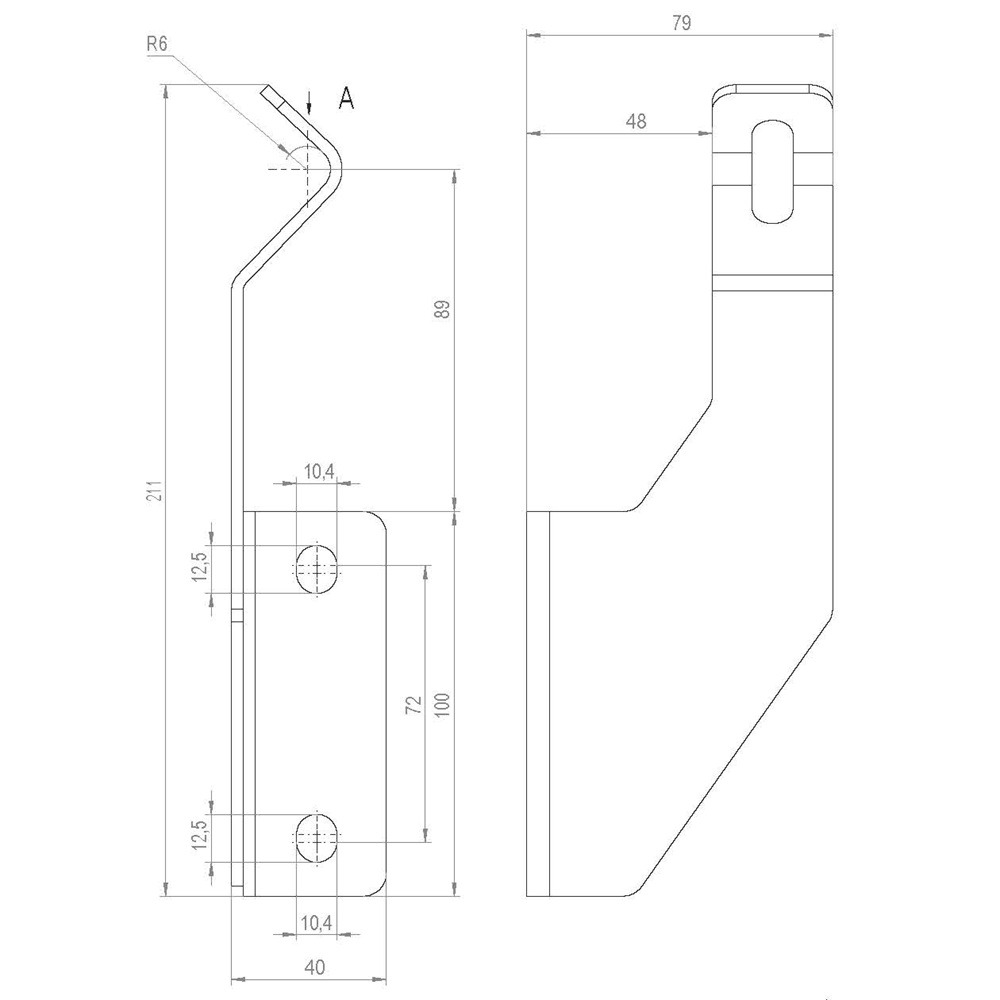

Corner nut

Our corner nut and spacer series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: medical equipment, food & pharmaceutical processing equipment, packaging machinery, 3A design-meat & poultry processing equipment, dairy processing machines.

Threaded stainless steel corner nut (Aisi 1.4301)

Corner nut in stainless steel (Aisi 1.4301)

Corner nut M8-16-15 – ID=8.2 – OD=16.0 – L=15 – L1=6

Corner nut M8-16-20 – ID=8.2 – OD=16.0 – L=20 – L1=6

Corner nut M8-16-25 – ID=8.2 – OD=16.0 – L=25 – L1=10

Corner nut M10-18-15 – ID=10.2 – OD=18.0 – L=15 – L1=6

Corner nut M10-18-25 – ID=10.2 – OD=18.0 – L=25 – L1=10

Corner nut M12-22-15 – ID=12.2 – OD=22.0 – L=15 – L1=6

Corner nut M12-22-25 – ID=12.2 – OD=22.0 – L=25 – L1=10

Corner nut M16-26-15 – ID=16.2 – OD=26.0 – L=15 – L1=6

Corner nut M16-26-25 – ID=16.2 – OD=26.0 – L=25 – L1=10

Corner spacer in stainless steel (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Corner spacer 6.8-16-15 – ID=6.8 – OD=16.0 – L=15

Corner spacer 6.8-16-25 – ID=6.8 – OD=16.0 – L=25

Corner spacer 8.5-18-15 – ID=8.5 – OD=18.0 – L=15

Corner spacer 8.5-18-25 – ID=8.5 – OD=18.0 – L=25

Corner spacer 10.2-22-15 – ID=10.2 – OD=22.0 – L=15

Corner spacer 10.2-22-25 – ID=10.2 – OD=22.0 – L=25

Corner spacer 14.0-26-15 – ID=14.0 – OD=26.0 – L=15

Corner spacer 14.0-26-25 – ID=14.0 – OD=26.0 – L=25

Conveyor components in hygienic design

For other size, please contact us.

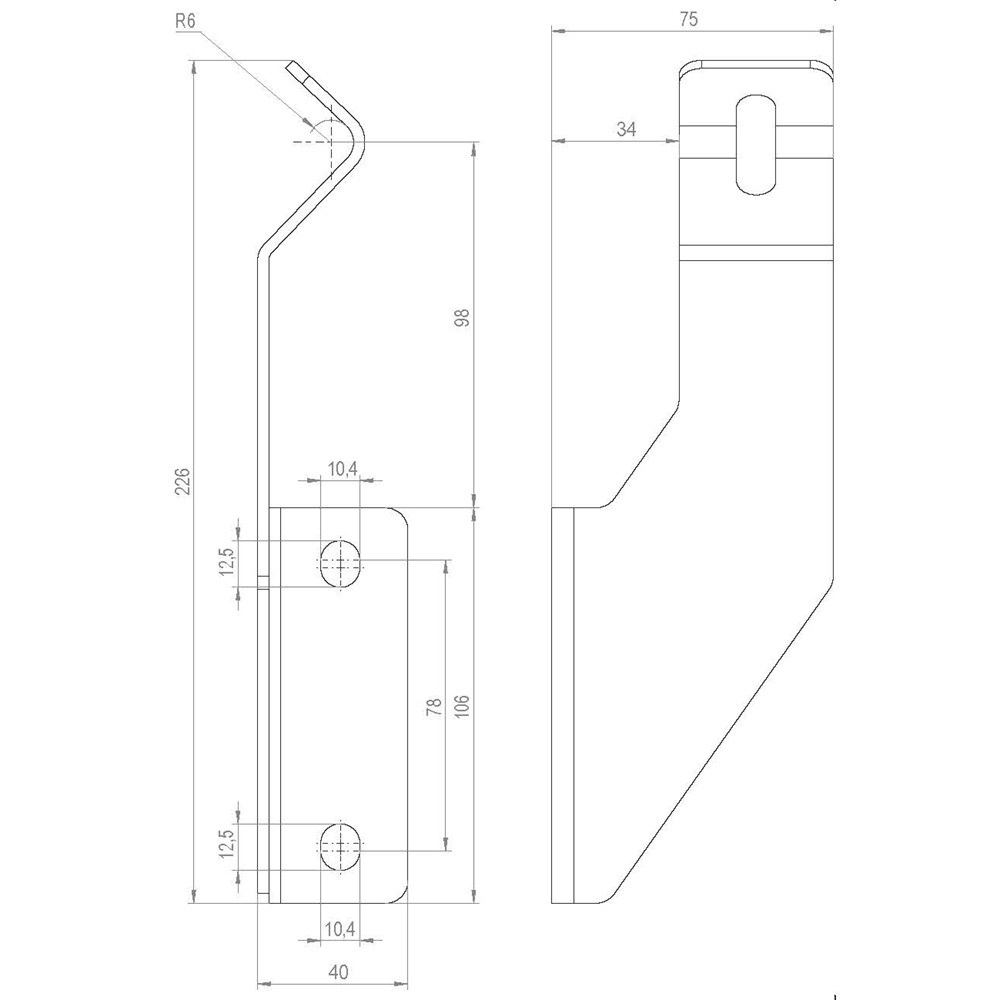

Corner Nut in Stainless Steel

The Ideal Solution for Easy-to-Clean Applications

In industries where hygiene and cleanliness are paramount, such as food processing, pharmaceuticals, and cleanrooms, every component used must meet rigorous standards. Corner nuts in stainless steel have emerged as a vital component in such settings. Their robust design, coupled with easy-to-clean features, ensures they meet the strict requirements of these industries while offering superior performance.

Why Stainless Steel is the Material of Choice

Stainless steel is renowned for its exceptional properties, making it the ideal material for corner nuts used in demanding environments:

- Corrosion Resistance: Stainless steel resists rust and corrosion, even in moist or chemical-laden environments, ensuring a longer lifespan.

- Hygienic Surface: The smooth and non-porous surface of stainless steel prevents bacteria and contaminants from adhering.

- Durability: With high tensile strength, stainless steel corner nuts withstand heavy loads and challenging conditions.

- Eco-Friendly: Stainless steel is recyclable, aligning with sustainability goals in modern industries.

Easy-to-Clean Design for Hygienic Applications

Corner nuts in stainless steel are specifically designed for easy cleaning, a critical feature in hygiene-sensitive environments. Key design elements include:

- Smooth Surfaces: Minimized crevices prevent dirt and contaminants from accumulating.

- Rounded Edges: Easier to sanitize and reduces the risk of trapping debris.

- Polished Finish: A high-polish finish not only enhances appearance but also improves cleanability.

These features make stainless steel corner nuts perfect for environments where sanitation protocols are rigorous, such as food production lines or pharmaceutical labs.

Applications in High-Hygiene Industries

Stainless steel corner nuts play an essential role in various sectors:

- Food and Beverage Industry: Used in conveyor systems, packaging equipment, and processing machinery, where cleanliness directly impacts product safety.

- Pharmaceutical and Biotechnology: Integral to equipment and assemblies where sterility is non-negotiable.

- Cleanrooms: Perfect for fastening systems in environments with controlled contamination levels.

In these industries, their easy-to-clean nature ensures compliance with strict standards like EHEDG and FDA guidelines.

Advantages Over Traditional Fasteners

While standard fasteners might suffice in less critical applications, stainless steel corner nuts offer distinct advantages for high-hygiene settings:

- Ease of Maintenance: Designed for rapid disassembly and cleaning, minimizing downtime.

- Regulatory Compliance: Meet international hygiene standards, providing peace of mind to operators.

- Aesthetic Appeal: The polished finish not only improves functionality but also lends a professional appearance to equipment.

How to Choose the Right Stainless Steel Corner Nut

When selecting corner nuts for your application, consider the following factors:

- Grade of Stainless Steel: Grades like 304 and 316 are excellent choices for corrosion resistance.

- Size and Fit: Ensure compatibility with your existing equipment or system.

- Certifications: Look for products certified by EHEDG, 3A, or FDA for hygienic applications.

Stainless Steel Corner Nuts: The Hygienic Solution for Easy-to-Clean Applications

Stainless steel corner nuts are a small but indispensable component in industries that prioritize hygiene, safety, and efficiency. Their durability, easy-to-clean design, and compliance with international standards make them the perfect choice for demanding environments.

By investing in high-quality stainless steel corner nuts, businesses can enhance operational reliability and ensure they meet the stringent requirements of their respective industries.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.