Stainless Steel Hinges for Enclosures and Cabinets

Superior Durability and Performance

When it comes to selecting hinges for enclosures and cabinets, stainless steel is the preferred choice across various industries. These hinges are engineered for strength, corrosion resistance, and long-lasting performance, making them ideal for demanding environments such as food processing, pharmaceuticals, and heavy-duty manufacturing.

Why Choose Stainless Steel Hinges?

Corrosion Resistance

Stainless steel hinges are known for their exceptional resistance to rust and corrosion. This makes them suitable for use in environments exposed to moisture, chemicals, or extreme temperatures. In industries such as food and beverage processing or outdoor applications, stainless steel hinges ensure longevity without compromising functionality.

Strength and Durability

Designed to withstand significant weight and stress, stainless steel hinges provide unparalleled strength. Whether used in industrial machinery enclosures or heavy-duty cabinets, these hinges maintain their structural integrity under rigorous conditions.

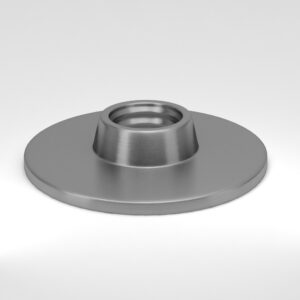

Aesthetic Appeal

Stainless steel hinges offer a sleek and polished appearance, making them not only functional but also visually appealing. Their clean look is ideal for environments where aesthetics are a priority, such as in high-end medical or commercial applications.

Applications of Stainless Steel Hinges

Industrial Equipment

Stainless steel hinges are a staple in industrial settings, providing secure closures for machinery enclosures, control panels, and heavy-duty cabinets. Their robust construction ensures they can handle the wear and tear of daily operations.

Food and Pharmaceutical Industries

In industries where hygiene is critical, stainless steel hinges stand out for their easy-to-clean surfaces and compliance with strict sanitary standards. These hinges are often used in enclosures for food processing equipment and pharmaceutical storage units.

Outdoor and Marine Use

Thanks to their resistance to corrosion and harsh weather conditions, stainless steel hinges are commonly used in outdoor and marine applications. They are perfect for enclosures exposed to saltwater, UV radiation, and fluctuating temperatures.

Types of Stainless Steel Hinges

Continuous Hinges

Also known as piano hinges, continuous hinges provide uniform strength along the entire length of an enclosure or cabinet door. They are ideal for applications requiring stable support for long or heavy panels.

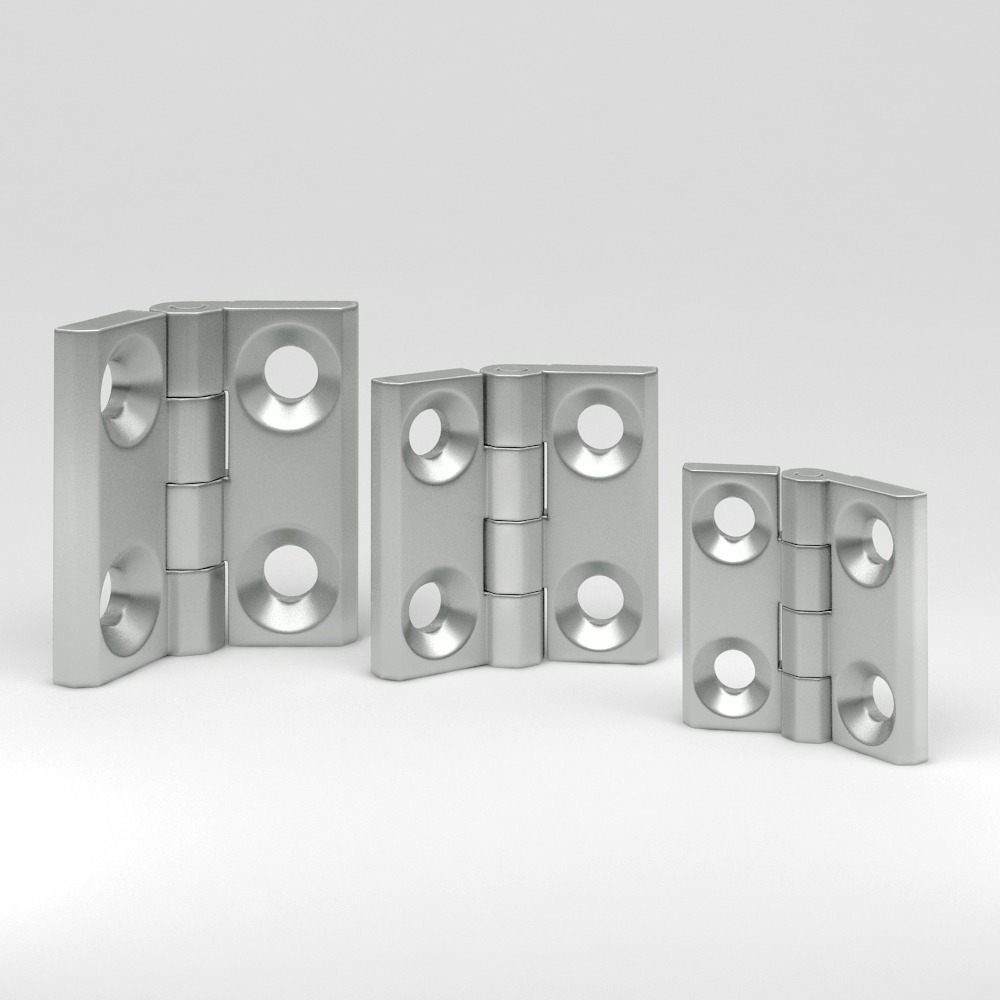

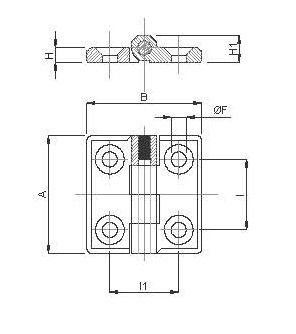

Butt Hinges

Butt hinges are compact and versatile, suitable for lightweight cabinets and enclosures. Their simplicity and reliability make them a popular choice across various industries.

Concealed Hinges

For applications where aesthetics are a priority, concealed hinges offer a clean and seamless look. These hinges are hidden when the door is closed, ensuring a sleek and modern appearance.

Advantages of Using Stainless Steel Hinges in Industrial Applications

- Longevity: Stainless steel hinges have a long lifespan, reducing the need for frequent replacements.

- Hygiene Compliance: Their smooth, non-porous surface meets stringent hygiene standards.

- Versatility: Stainless steel hinges are suitable for various industrial, commercial, and outdoor applications.

- Sustainability: Stainless steel is a recyclable material, contributing to environmentally conscious manufacturing practices.

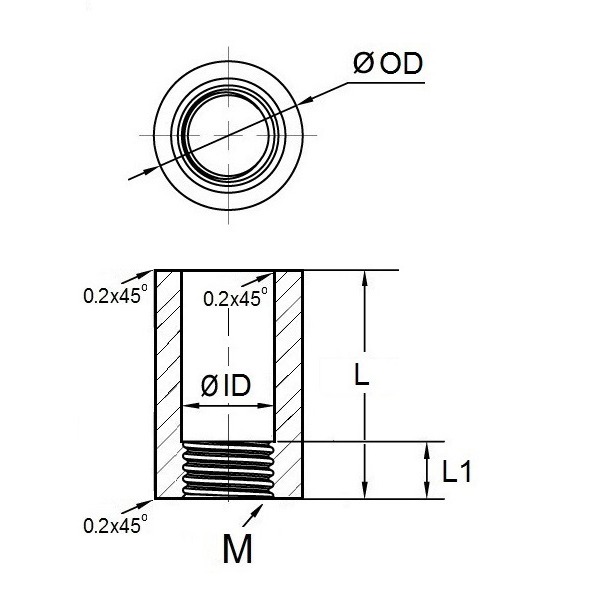

How to Choose the Right Stainless Steel Hinges

- Assess the Environment: Consider factors like exposure to moisture, chemicals, or extreme temperatures.

- Determine Load Capacity: Select hinges that can handle the weight and stress of your application.

- Consider Aesthetics: Opt for concealed or polished hinges for a modern look in visible installations.

- Certifications: Ensure the hinges meet industry-specific standards, such as FDA or EHEDG compliance for hygienic applications.

Stainless Steel Hinges for Enclosures and Cabinets

A Durable Choice for Industrial Applications

Stainless steel hinges for enclosures and cabinets are a reliable and durable solution for various industrial applications. Their resistance to corrosion, strength, and hygienic properties make them indispensable in industries such as food processing, pharmaceuticals, and outdoor installations. By selecting the right type of stainless steel hinge, you can enhance the performance and longevity of your equipment and enclosures.

Make the switch to stainless steel hinges for unmatched performance and peace of mind in even the most demanding environments.