Elevating Hygiene Standards with EHEDG IP69K Bearing Units

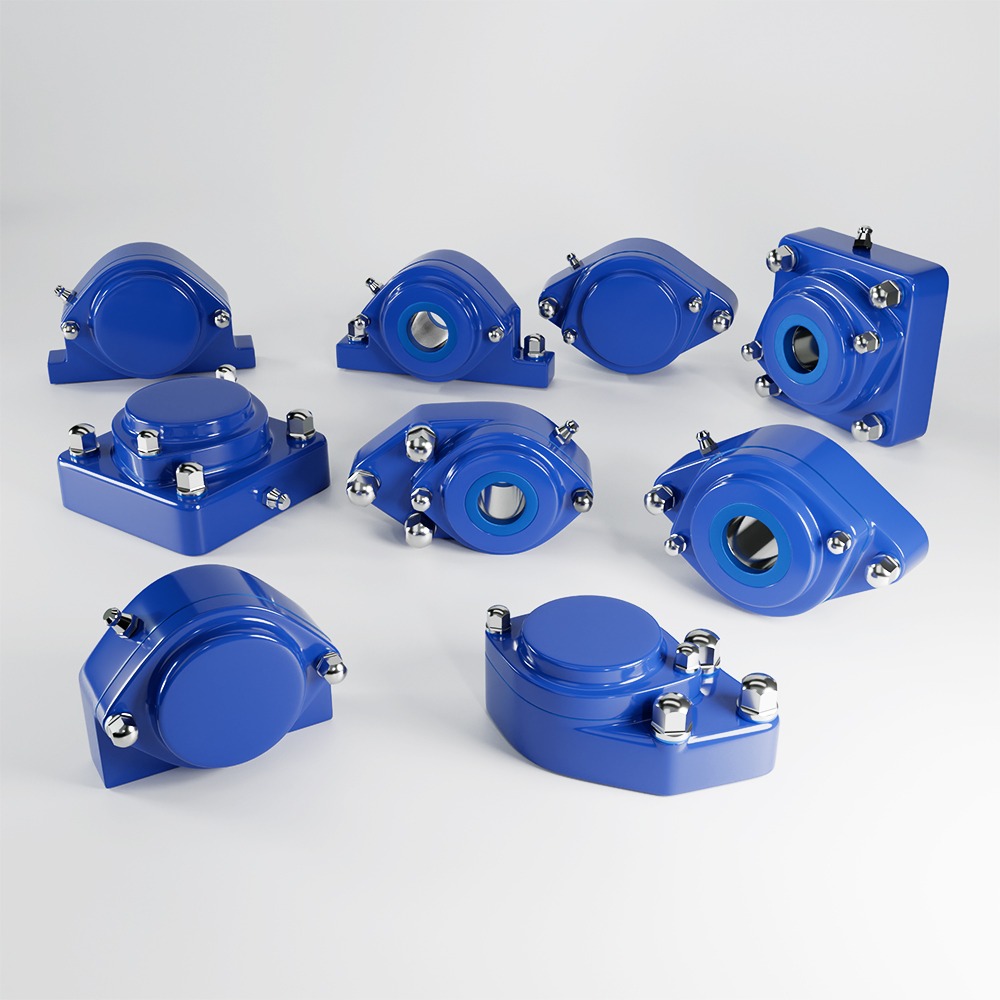

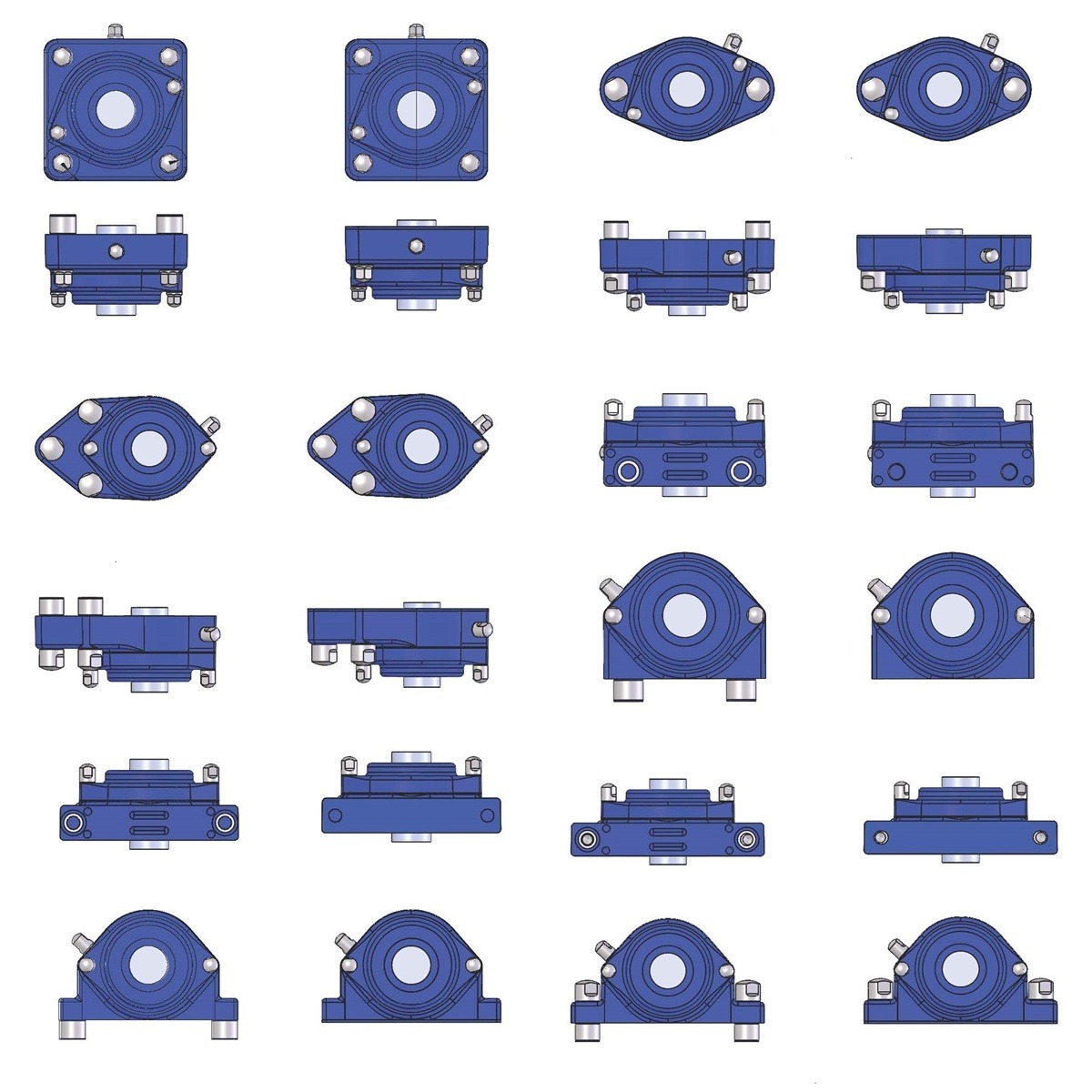

In industries such as food processing, pharmaceuticals, and biotechnology, maintaining hygiene and operational efficiency is paramount. EHEDG IP69K-certified bearing units provide the highest level of cleanliness, reliability, and resistance to harsh cleaning processes. Proper installation and maintenance of these components are essential to ensure peak performance and extend their operational lifespan.

This article explores the Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) aspects of EHEDG IP69K bearing units, focusing on how installation and maintenance practices impact their efficiency and reliability.

Understanding EHEDG and IP69K Certifications

EHEDG (European Hygienic Engineering & Design Group) certification ensures that equipment is designed for easy cleaning and optimal hygiene, meeting the stringent requirements of food safety. IP69K, the highest ingress protection rating, guarantees resistance to high-pressure and high-temperature water jets, making these bearing units ideal for industries with rigorous cleaning protocols.

Why Choose EHEDG IP69K Bearing Units?

Experience: Proven Performance in Hygienic Applications

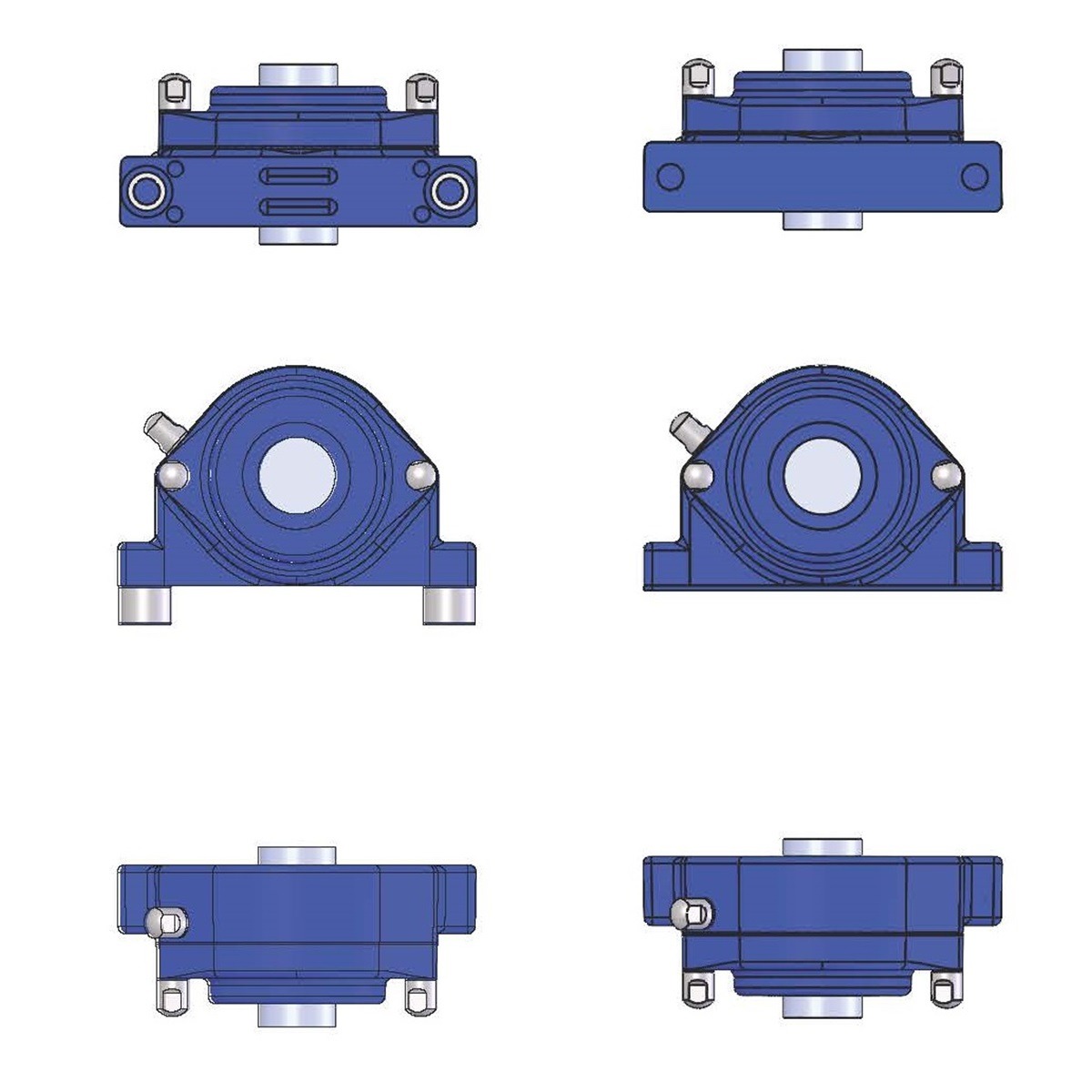

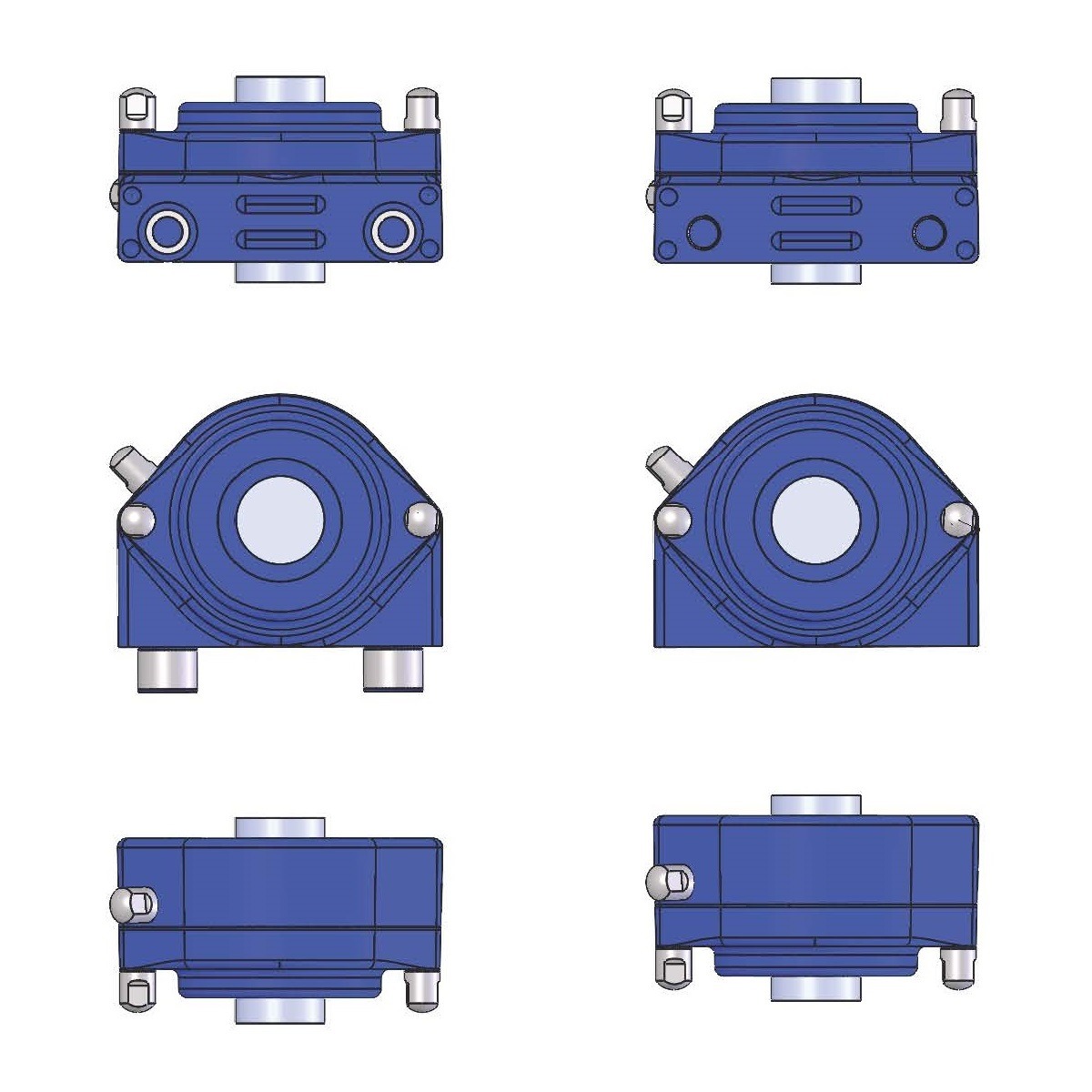

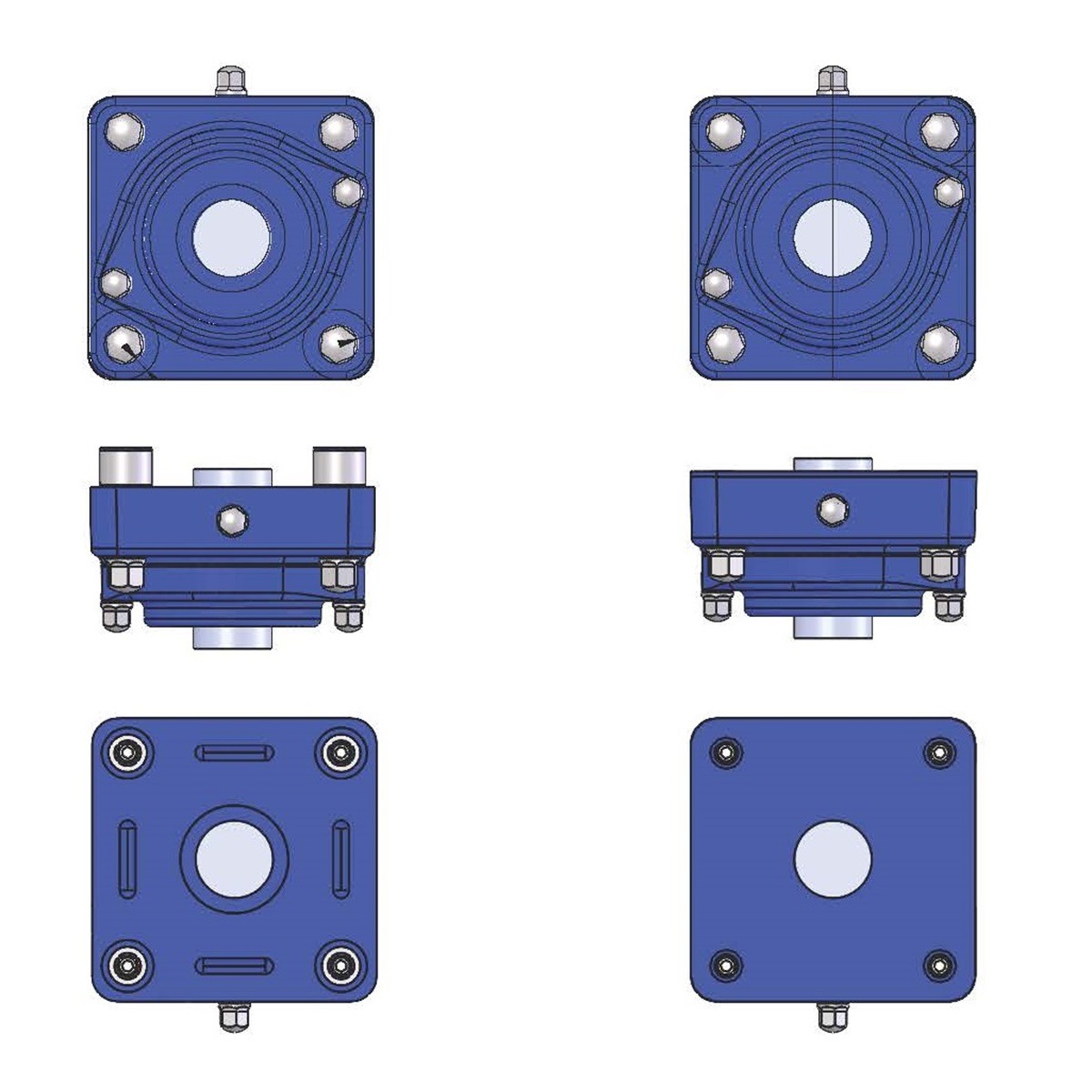

EHEDG IP69K bearing units are built to withstand extreme cleaning conditions while preventing contamination. Their stainless-steel construction, combined with advanced sealing technology, ensures durability and reliability in food and pharmaceutical environments.

Expertise: Engineered for Harsh Environments

These bearing units are engineered to meet the challenges of hygienic applications, including exposure to chemicals, high-pressure cleaning, and fluctuating temperatures. Their precision design reduces the risk of bacterial growth, ensuring compliance with global safety standards.

Authoritativeness: Trusted by Leading Industries

EHEDG IP69K-certified components are trusted by leading manufacturers and industries worldwide. Their proven track record of reliability and compliance establishes them as essential components in maintaining product integrity.

Trustworthiness: Ensuring Compliance and Safety

With EHEDG and IP69K certifications, these bearing units provide assurance of meeting the highest safety and hygiene standards. They contribute to building consumer confidence and protecting brand reputation by minimizing contamination risks.

Installation Best Practices for EHEDG IP69K Bearing Units

Proper installation is critical for maximizing the performance and lifespan of EHEDG IP69K bearing units. Follow these best practices:

1. Assess the Application Environment

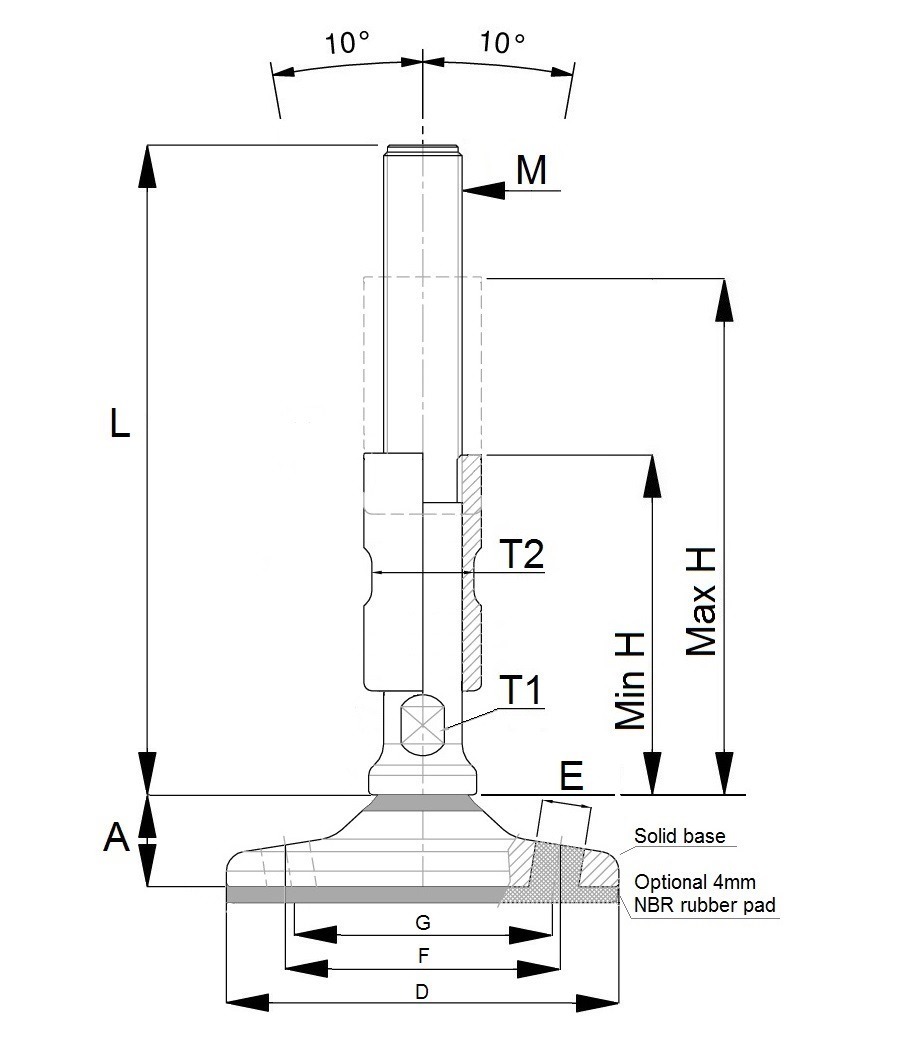

Before installation, evaluate the operational environment, including exposure to water, cleaning agents, and temperature variations. Ensure the bearing unit’s specifications align with the application requirements.

2. Use Compatible Tools and Mounting Hardware

Use tools and mounting hardware compatible with stainless steel to prevent corrosion and damage during installation. This ensures a secure fit and prevents premature wear.

3. Align for Optimal Performance

Precision alignment is crucial to reduce wear and tear. Misalignment can lead to uneven load distribution, causing premature failure.

4. Ensure Hygienic Sealing

Check the seals for proper fitment to maintain a hygienic barrier. Improper sealing can lead to contamination and compromise the bearing’s performance.

5. Follow Manufacturer Guidelines

Adhere to the manufacturer’s installation guidelines and specifications to ensure optimal functionality and compliance with EHEDG and IP69K standards.

Maintenance Tips to Maximize Performance and Longevity

Regular maintenance is essential to ensure EHEDG IP69K bearing units perform at their best. These practices enhance reliability and reduce operational downtime:

1. Routine Cleaning and Inspection

Clean the bearing units using approved cleaning agents and methods that comply with EHEDG standards. Inspect seals, housings, and surfaces for wear, cracks, or contamination.

2. Monitor Lubrication

Use food-grade lubricants that meet industry standards. Monitor lubrication levels and ensure the lubricant remains clean and free from contamination.

3. Replace Worn Components Promptly

Replace worn or damaged components, including seals and housings, to maintain the unit’s hygienic properties. Regular replacements prevent potential contamination and breakdowns.

4. Verify Seal Integrity

Check seals regularly for cracks or degradation caused by high-pressure cleaning. Replace seals promptly to maintain the barrier against contaminants.

5. Document Maintenance Activities

Maintain detailed records of maintenance activities, including cleaning, inspections, and replacements. This ensures traceability and compliance with audit requirements.

Key Benefits of Proper Installation and Maintenance

Enhanced Hygiene and Safety

Proper care of EHEDG IP69K bearing units minimizes contamination risks and ensures compliance with safety standards, protecting end consumers.

Improved Equipment Reliability

Regular maintenance reduces the likelihood of unexpected failures, enhancing equipment uptime and productivity.

Extended Component Lifespan

With proper installation and care, these bearing units deliver long-lasting performance, reducing replacement costs and downtime.

Regulatory Compliance

Meeting hygiene and safety standards is critical in regulated industries. EHEDG IP69K-certified components, when properly installed and maintained, ensure compliance with global regulations.

Trust in EHEDG IP69K Bearing Units

EHEDG IP69K bearing units are indispensable in industries where hygiene, safety, and reliability are non-negotiable. By leveraging expertise in their installation and maintenance, manufacturers can maximize their performance, minimize risks, and ensure compliance with industry standards.

Investing in high-quality components, combined with best practices in care, enhances efficiency, safeguards product quality, and builds trust with consumers. Rely on the proven Experience, Expertise, Authoritativeness, and Trustworthiness of EHEDG IP69K bearing units to set your operations apart in today’s competitive marketplace.