Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Enhancing Stability and Hygiene with Seismic Leveling Feet

The Cornerstones of Stability and Hygiene in Industrial Applications

Seismic leveling feet and heavy-duty hinged joint machinery feet are essential components in industrial applications, providing stability, vibration reduction, and compliance with stringent hygienic standards. These specialized feet are designed to support heavy machinery, ensuring optimal performance even in challenging environments.

Seismic Leveling Feet: Ensuring Stability in Seismic Zones

Seismic leveling feet are engineered to withstand the dynamic forces encountered during earthquakes. Developed and tested using the Finite Element Method (FEA), these feet comply with international seismic standards, such as the New Zealand Standard NZS 4219:2009. They are capable of handling combinations of vertical and horizontal loads, ensuring machinery remains anchored during seismic events.

In industries with strict hygiene requirements, such as food processing and pharmaceuticals, hygienic seismic leveling feet are indispensable. Designed in accordance with 3-A and EHEDG hygienic standards and certified by USDA, these feet feature self-draining surfaces, sealed movable parts, and no exposed threads. This design minimizes cleaning efforts and maximizes sanitary safety.

Heavy-Duty Hinged Joint Machinery Feet: Versatility and Durability

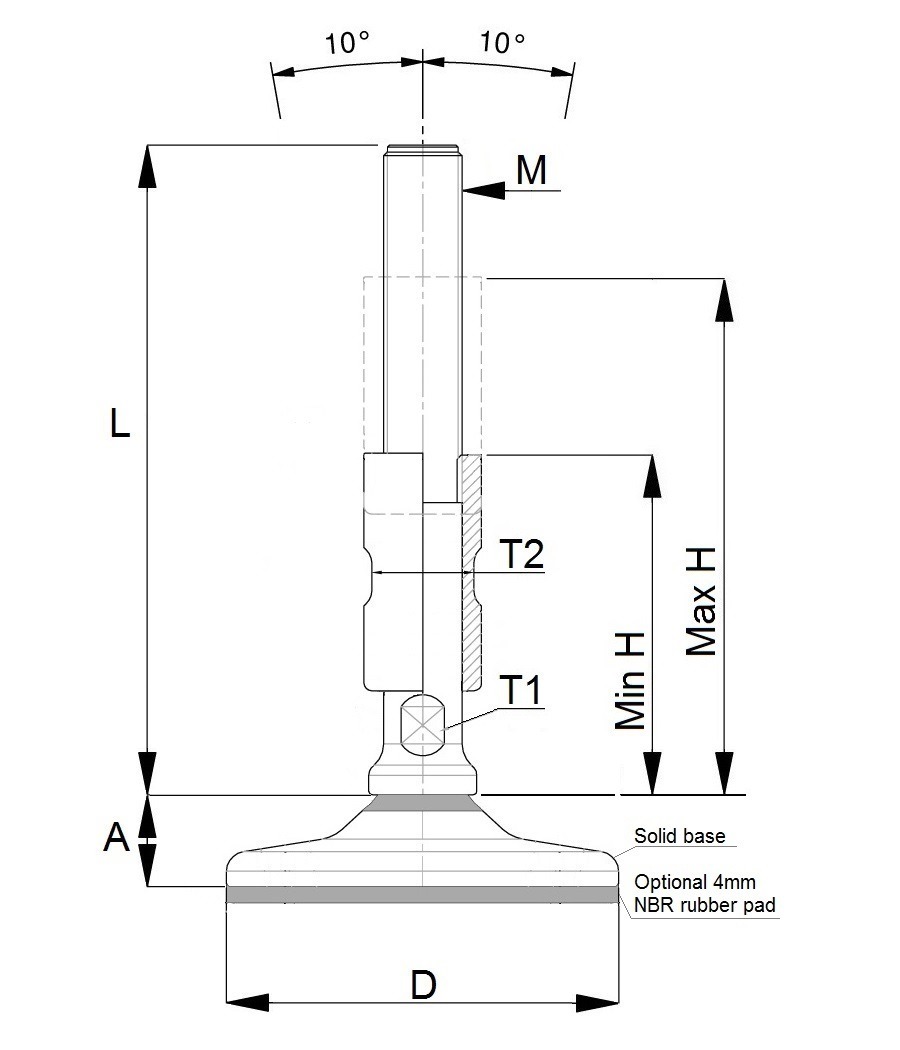

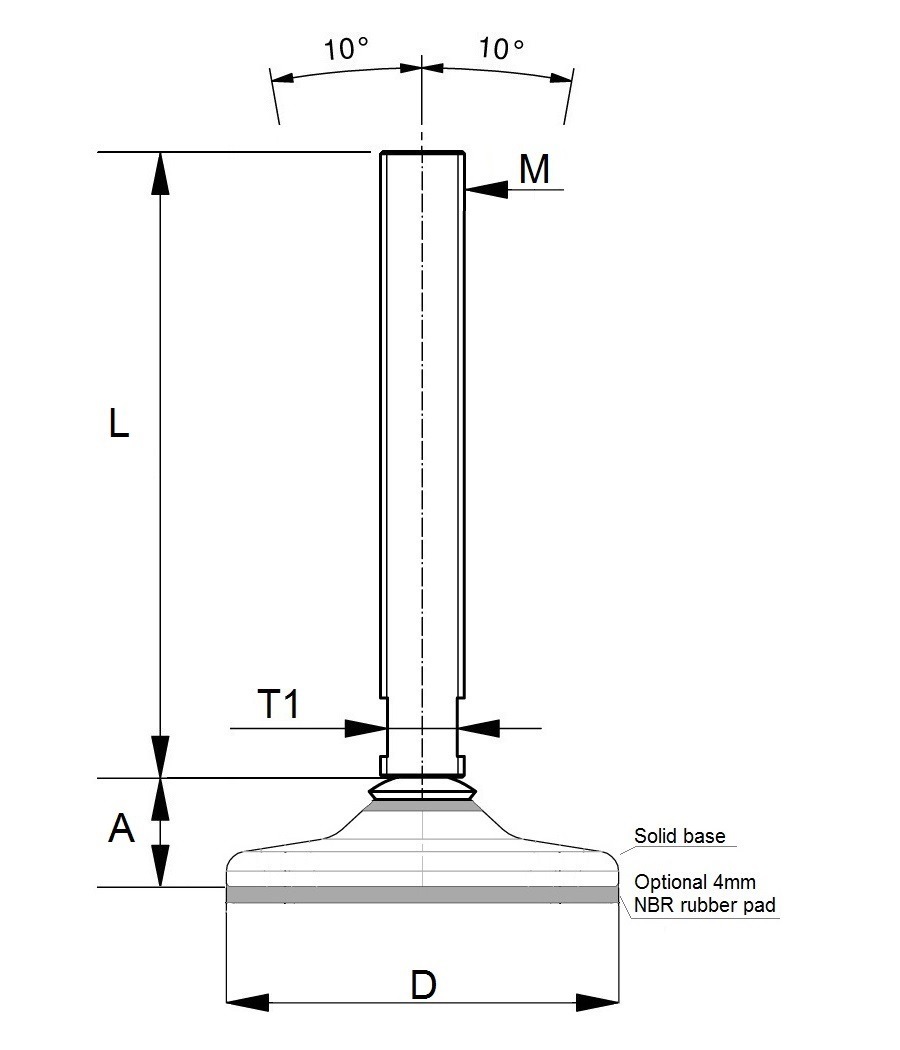

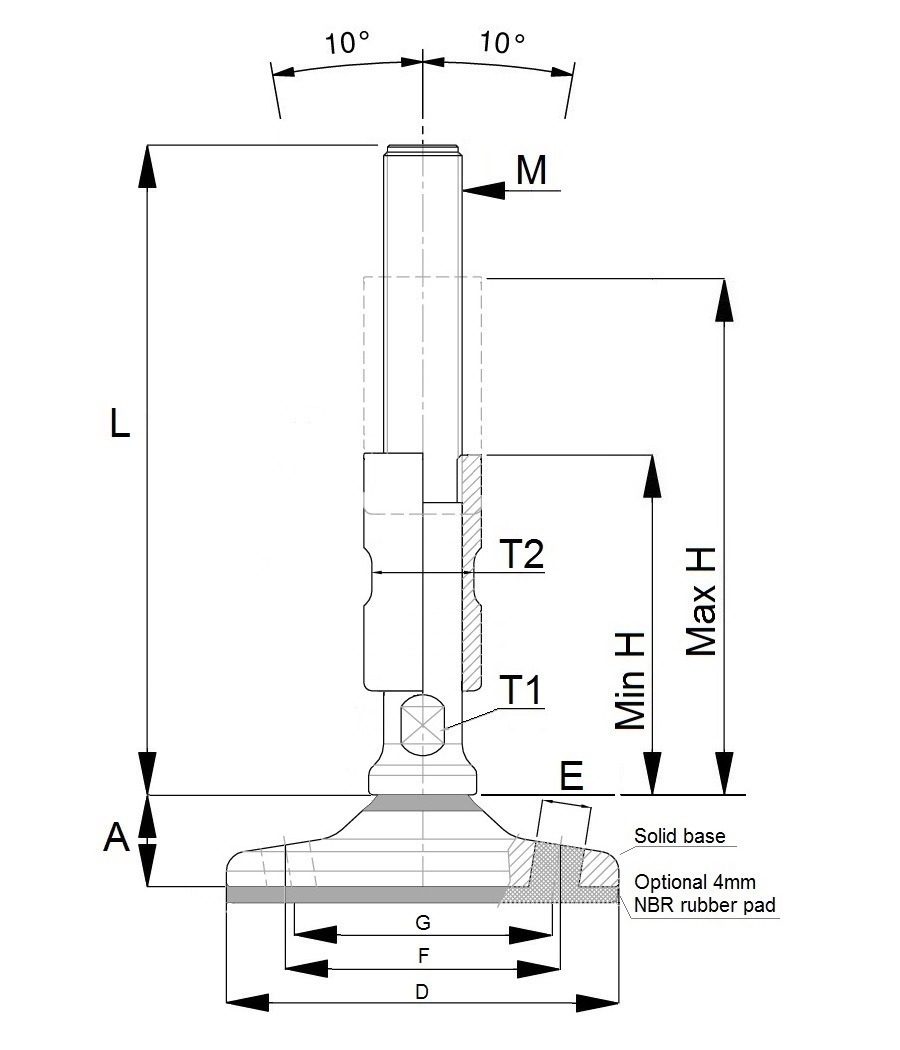

Heavy-duty hinged joint machinery feet, also known as articulated leveling feet, are designed to provide stability and support for heavy machinery across various industries. These feet feature a ball-and-socket joint, allowing for adjustments to uneven floors and accommodating floor slopes. This design ensures that machinery remains level, reducing vibrations and enhancing operational efficiency.

Manufactured from high-grade stainless steel, these feet offer excellent corrosion resistance, making them suitable for use in harsh environments. Some models are designed with a solid base plate and fully-threaded spindle, providing robust support and easy adjustability. Additionally, hygienic designs are available, featuring smooth surfaces and protective sleeves to prevent dirt accumulation, ensuring compliance with stringent sanitary standards.

Expertise in Design and Compliance

Leading manufacturers of seismic leveling feet and heavy-duty hinged joint machinery feet invest heavily in research and development to ensure their products meet international standards. For instance, NGI’s seismic leveling feet are verified through Finite Element Analysis and calculated according to the New Zealand seismic standard NZS 4219. They also collaborate with partners like Hilti to select and approve seismic anchors, enhancing the stability and safety of their products.

Similarly, companies like NHK Machinery Parts focus on producing hygienic stainless steel machine feet that comply with EHEDG and 3-A design guidelines. Their products are designed for easy cleaning, reducing maintenance costs, and ensuring high standards of hygiene in industries such as food processing and pharmaceuticals.

Trustworthiness Through Certification and Testing

The trustworthiness of these components is established through rigorous testing and certification processes. Products that comply with international standards, such as 3-A, EHEDG, and USDA certifications, provide assurance of their suitability for use in hygienic environments. Additionally, compliance with seismic standards like NZS 4219:2009 ensures that the leveling feet can withstand the forces encountered during earthquakes, providing peace of mind in seismic zones.

Reliable Solutions for Industrial Stability and Performance

Seismic leveling feet and heavy-duty hinged joint machinery feet are critical components in ensuring the stability, safety, and hygiene of industrial machinery. Their specialized designs cater to the demands of various industries, providing solutions that enhance operational efficiency and comply with international standards. By investing in these high-quality components, businesses can ensure the longevity and reliability of their machinery, even in challenging environments.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

The Cornerstones of Stability and Hygiene in Industrial Applications

Seismic leveling feet and heavy-duty hinged joint machinery feet are essential components in industrial applications, providing stability, vibration reduction, and compliance with stringent hygienic standards. These specialized feet are designed to support heavy machinery, ensuring optimal performance even in challenging environments.

Seismic Leveling Feet: Ensuring Stability in Seismic Zones

Seismic leveling feet are engineered to withstand the dynamic forces encountered during earthquakes. Developed and tested using the Finite Element Method (FEA), these feet comply with international seismic standards, such as the New Zealand Standard NZS 4219:2009. They are capable of handling combinations of vertical and horizontal loads, ensuring machinery remains anchored during seismic events.

In industries with strict hygiene requirements, such as food processing and pharmaceuticals, hygienic seismic leveling feet are indispensable. Designed in accordance with 3-A and EHEDG hygienic standards and certified by USDA, these feet feature self-draining surfaces, sealed movable parts, and no exposed threads. This design minimizes cleaning efforts and maximizes sanitary safety.

Heavy-Duty Hinged Joint Machinery Feet: Versatility and Durability

Heavy-duty hinged joint machinery feet, also known as articulated leveling feet, are designed to provide stability and support for heavy machinery across various industries. These feet feature a ball-and-socket joint, allowing for adjustments to uneven floors and accommodating floor slopes. This design ensures that machinery remains level, reducing vibrations and enhancing operational efficiency.

Manufactured from high-grade stainless steel, these feet offer excellent corrosion resistance, making them suitable for use in harsh environments. Some models are designed with a solid base plate and fully-threaded spindle, providing robust support and easy adjustability. Additionally, hygienic designs are available, featuring smooth surfaces and protective sleeves to prevent dirt accumulation, ensuring compliance with stringent sanitary standards.

Expertise in Design and Compliance

Leading manufacturers of seismic leveling feet and heavy-duty hinged joint machinery feet invest heavily in research and development to ensure their products meet international standards. For instance, NGI’s seismic leveling feet are verified through Finite Element Analysis and calculated according to the New Zealand seismic standard NZS 4219. They also collaborate with partners like Hilti to select and approve seismic anchors, enhancing the stability and safety of their products.

Similarly, companies like NHK Machinery Parts focus on producing hygienic stainless steel machine feet that comply with EHEDG and 3-A design guidelines. Their products are designed for easy cleaning, reducing maintenance costs, and ensuring high standards of hygiene in industries such as food processing and pharmaceuticals.

Trustworthiness Through Certification and Testing

The trustworthiness of these components is established through rigorous testing and certification processes. Products that comply with international standards, such as 3-A, EHEDG, and USDA certifications, provide assurance of their suitability for use in hygienic environments. Additionally, compliance with seismic standards like NZS 4219:2009 ensures that the leveling feet can withstand the forces encountered during earthquakes, providing peace of mind in seismic zones.

Reliable Solutions for Industrial Stability and Performance

Seismic leveling feet and heavy-duty hinged joint machinery feet are critical components in ensuring the stability, safety, and hygiene of industrial machinery. Their specialized designs cater to the demands of various industries, providing solutions that enhance operational efficiency and comply with international standards. By investing in these high-quality components, businesses can ensure the longevity and reliability of their machinery, even in challenging environments.

The Cornerstones of Stability and Hygiene in Industrial Applications

Seismic leveling feet and heavy-duty hinged joint machinery feet are essential components in industrial applications, providing stability, vibration reduction, and compliance with stringent hygienic standards. These specialized feet are designed to support heavy machinery, ensuring optimal performance even in challenging environments.

Seismic Leveling Feet: Ensuring Stability in Seismic Zones

Seismic leveling feet are engineered to withstand the dynamic forces encountered during earthquakes. Developed and tested using the Finite Element Method (FEA), these feet comply with international seismic standards, such as the New Zealand Standard NZS 4219:2009. They are capable of handling combinations of vertical and horizontal loads, ensuring machinery remains anchored during seismic events.

In industries with strict hygiene requirements, such as food processing and pharmaceuticals, hygienic seismic leveling feet are indispensable. Designed in accordance with 3-A and EHEDG hygienic standards and certified by USDA, these feet feature self-draining surfaces, sealed movable parts, and no exposed threads. This design minimizes cleaning efforts and maximizes sanitary safety.

Heavy-Duty Hinged Joint Machinery Feet: Versatility and Durability

Heavy-duty hinged joint machinery feet, also known as articulated leveling feet, are designed to provide stability and support for heavy machinery across various industries. These feet feature a ball-and-socket joint, allowing for adjustments to uneven floors and accommodating floor slopes. This design ensures that machinery remains level, reducing vibrations and enhancing operational efficiency.

Manufactured from high-grade stainless steel, these feet offer excellent corrosion resistance, making them suitable for use in harsh environments. Some models are designed with a solid base plate and fully-threaded spindle, providing robust support and easy adjustability. Additionally, hygienic designs are available, featuring smooth surfaces and protective sleeves to prevent dirt accumulation, ensuring compliance with stringent sanitary standards.

Expertise in Design and Compliance

Leading manufacturers of seismic leveling feet and heavy-duty hinged joint machinery feet invest heavily in research and development to ensure their products meet international standards. For instance, NGI’s seismic leveling feet are verified through Finite Element Analysis and calculated according to the New Zealand seismic standard NZS 4219. They also collaborate with partners like Hilti to select and approve seismic anchors, enhancing the stability and safety of their products.

Similarly, companies like NHK Machinery Parts focus on producing hygienic stainless steel machine feet that comply with EHEDG and 3-A design guidelines. Their products are designed for easy cleaning, reducing maintenance costs, and ensuring high standards of hygiene in industries such as food processing and pharmaceuticals.

Trustworthiness Through Certification and Testing

The trustworthiness of these components is established through rigorous testing and certification processes. Products that comply with international standards, such as 3-A, EHEDG, and USDA certifications, provide assurance of their suitability for use in hygienic environments. Additionally, compliance with seismic standards like NZS 4219:2009 ensures that the leveling feet can withstand the forces encountered during earthquakes, providing peace of mind in seismic zones.

Reliable Solutions for Industrial Stability and Performance

Seismic leveling feet and heavy-duty hinged joint machinery feet are critical components in ensuring the stability, safety, and hygiene of industrial machinery. Their specialized designs cater to the demands of various industries, providing solutions that enhance operational efficiency and comply with international standards. By investing in these high-quality components, businesses can ensure the longevity and reliability of their machinery, even in challenging environments.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.