Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

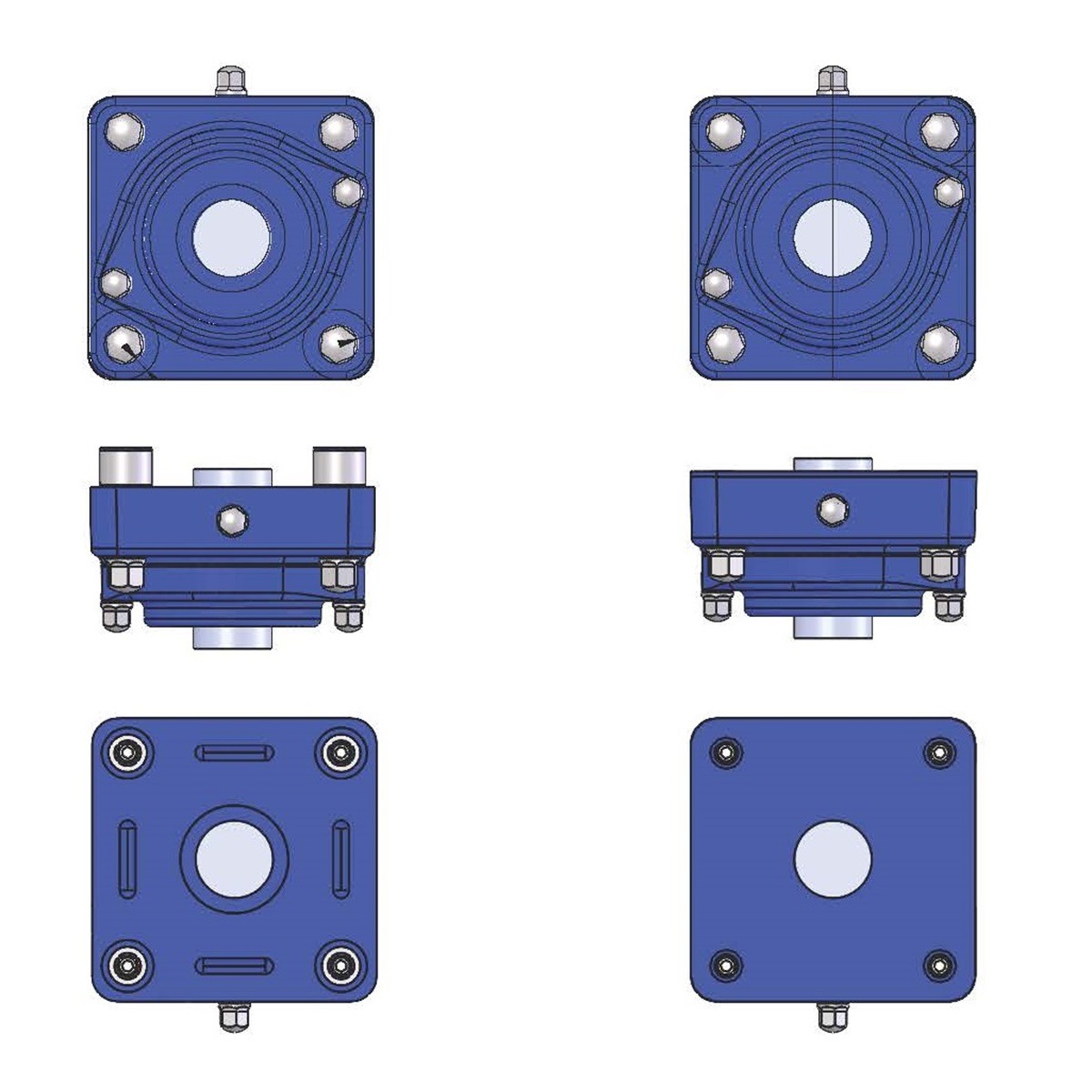

EHEDG IP69K 4-Hole Square Flange Bearing Units

Unmatched Durability for Extreme Conditions

In industries such as food processing, pharmaceuticals, and chemicals, machinery components face intense challenges. High-pressure cleaning, exposure to aggressive chemicals, extreme temperatures, and demanding workloads necessitate robust and reliable components. EHEDG IP69K 4-hole square flange bearing units are the pinnacle of innovation and engineering, designed to withstand these extreme conditions while adhering to stringent hygienic standards. This article explores the Experience, Expertise, Authoritativeness and Trustworthiness behind these bearing units and their critical role in maintaining operational excellence in harsh environments.

Experience in Designing EHEDG IP69K Flange Bearing Units

EHEDG-certified components are crafted to meet the strict hygiene and safety requirements of industries where contamination is not an option. The experience behind the development of IP69K flange bearing units stems from decades of collaboration with industry leaders, engineers, and regulatory bodies.

Manufacturers of these bearing units have accumulated years of expertise in tackling challenges posed by high-pressure washing, thermal cycling, and corrosive environments. Their extensive field research and real-world testing ensure that every flange bearing unit delivers unmatched reliability and longevity.

Key Features Derived from Experience:

- Seamless Construction: Minimized crevices prevent the buildup of contaminants.

- Corrosion Resistance: High-grade stainless steel and surface treatments ensure durability against chemical exposure.

- Efficient Cleaning: Rounded edges and polished surfaces enable faster, more effective cleaning.

Expertise Behind IP69K Flange Bearing Units

The expertise driving the design of these components is rooted in advanced engineering principles and rigorous testing. Each EHEDG IP69K 4-hole square flange bearing unit is designed to function under extreme conditions, from high-pressure washdowns at 1,450 psi to sustained exposure to temperatures as low as -40°C or as high as 120°C.

Material Expertise:

- High-Grade Stainless Steel: Prevents corrosion, ensuring long-term performance even when exposed to cleaning agents or saline solutions.

- Food-Grade Seals: Prevent ingress of water, dust, and contaminants, meeting IP69K standards for protection.

Design Expertise:

- Enhanced Mounting Stability: The 4-hole square flange configuration ensures secure attachment, reducing vibration and wear.

- Self-Lubricating Bearings: These reduce maintenance needs while offering consistent performance.

Authoritativeness in Hygienic Standards

The EHEDG certification establishes these bearing units as authoritative components in hygienic machinery. EHEDG (European Hygienic Engineering & Design Group) is a globally recognized organization dedicated to promoting food safety by improving the design of equipment used in food production.

IP69K certification further underscores the reliability of these bearing units. This rating guarantees resistance to water and dust ingress, making them ideal for high-pressure and high-temperature cleaning environments. By combining these certifications, manufacturers demonstrate their commitment to adhering to the highest standards of hygiene, safety, and durability.

Benefits of Compliance:

- Improved Food Safety: Reduces risks of contamination in food and pharmaceutical production.

- Enhanced Durability: Prolongs equipment lifespan, reducing downtime and maintenance costs.

- Regulatory Compliance: Simplifies adherence to industry regulations like FDA and EU standards.

Trustworthiness Through Rigorous Testing and Real-World Applications

The trustworthiness of EHEDG IP69K 4-hole square flange bearing units lies in their rigorous testing and proven performance in demanding environments. Manufacturers subject these units to a variety of tests, including:

- Thermal Shock Testing: To assess performance in fluctuating temperatures.

- Chemical Resistance Testing: Ensuring resistance to aggressive cleaning agents and corrosive substances.

- Ingress Protection Testing: Verifying compliance with IP69K standards against water and dust penetration.

Real-World Applications:

- Food Processing: Withstand frequent washdowns and exposure to oils, sauces, and other food residues.

- Pharmaceutical Industry: Meet sterile conditions required for drug manufacturing and packaging.

- Chemical Industry: Resist corrosive chemicals in harsh production environments.

Why EHEDG IP69K Flange Bearing Units Are the Ultimate Solution

EHEDG IP69K 4-hole square flange bearing units are not just components; they are investments in reliability, safety, and efficiency. Their advanced features and robust design offer unparalleled advantages:

Reduced Maintenance

The self-lubricating design and high-quality materials minimize wear and tear, ensuring consistent performance and lower operating costs.

Enhanced Hygiene

These units are specifically designed to eliminate contamination risks, thanks to their seamless construction and hygienic certifications.

Exceptional Durability

Built to handle extreme environments, they deliver long-lasting performance under high pressure, extreme temperatures, and chemical exposure.

EHEDG IP69K 4-hole square flange bearing units

EHEDG IP69K 4-hole square flange bearing units represent the epitome of engineering excellence. With decades of experience, material and design expertise, authoritative certifications, and proven trustworthiness, these units are indispensable for industries operating in harsh and extreme conditions. Their ability to meet rigorous hygiene standards, withstand environmental challenges, and deliver reliable performance makes them a cornerstone of modern hygienic machinery.

By investing in these flange bearing units, companies can ensure compliance with global hygiene regulations, enhance equipment longevity, and reduce downtime—all while safeguarding the integrity of their products.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Unmatched Durability for Extreme Conditions

In industries such as food processing, pharmaceuticals, and chemicals, machinery components face intense challenges. High-pressure cleaning, exposure to aggressive chemicals, extreme temperatures, and demanding workloads necessitate robust and reliable components. EHEDG IP69K 4-hole square flange bearing units are the pinnacle of innovation and engineering, designed to withstand these extreme conditions while adhering to stringent hygienic standards. This article explores the Experience, Expertise, Authoritativeness and Trustworthiness behind these bearing units and their critical role in maintaining operational excellence in harsh environments.

Experience in Designing EHEDG IP69K Flange Bearing Units

EHEDG-certified components are crafted to meet the strict hygiene and safety requirements of industries where contamination is not an option. The experience behind the development of IP69K flange bearing units stems from decades of collaboration with industry leaders, engineers, and regulatory bodies.

Manufacturers of these bearing units have accumulated years of expertise in tackling challenges posed by high-pressure washing, thermal cycling, and corrosive environments. Their extensive field research and real-world testing ensure that every flange bearing unit delivers unmatched reliability and longevity.

Key Features Derived from Experience:

- Seamless Construction: Minimized crevices prevent the buildup of contaminants.

- Corrosion Resistance: High-grade stainless steel and surface treatments ensure durability against chemical exposure.

- Efficient Cleaning: Rounded edges and polished surfaces enable faster, more effective cleaning.

Expertise Behind IP69K Flange Bearing Units

The expertise driving the design of these components is rooted in advanced engineering principles and rigorous testing. Each EHEDG IP69K 4-hole square flange bearing unit is designed to function under extreme conditions, from high-pressure washdowns at 1,450 psi to sustained exposure to temperatures as low as -40°C or as high as 120°C.

Material Expertise:

- High-Grade Stainless Steel: Prevents corrosion, ensuring long-term performance even when exposed to cleaning agents or saline solutions.

- Food-Grade Seals: Prevent ingress of water, dust, and contaminants, meeting IP69K standards for protection.

Design Expertise:

- Enhanced Mounting Stability: The 4-hole square flange configuration ensures secure attachment, reducing vibration and wear.

- Self-Lubricating Bearings: These reduce maintenance needs while offering consistent performance.

Authoritativeness in Hygienic Standards

The EHEDG certification establishes these bearing units as authoritative components in hygienic machinery. EHEDG (European Hygienic Engineering & Design Group) is a globally recognized organization dedicated to promoting food safety by improving the design of equipment used in food production.

IP69K certification further underscores the reliability of these bearing units. This rating guarantees resistance to water and dust ingress, making them ideal for high-pressure and high-temperature cleaning environments. By combining these certifications, manufacturers demonstrate their commitment to adhering to the highest standards of hygiene, safety, and durability.

Benefits of Compliance:

- Improved Food Safety: Reduces risks of contamination in food and pharmaceutical production.

- Enhanced Durability: Prolongs equipment lifespan, reducing downtime and maintenance costs.

- Regulatory Compliance: Simplifies adherence to industry regulations like FDA and EU standards.

Trustworthiness Through Rigorous Testing and Real-World Applications

The trustworthiness of EHEDG IP69K 4-hole square flange bearing units lies in their rigorous testing and proven performance in demanding environments. Manufacturers subject these units to a variety of tests, including:

- Thermal Shock Testing: To assess performance in fluctuating temperatures.

- Chemical Resistance Testing: Ensuring resistance to aggressive cleaning agents and corrosive substances.

- Ingress Protection Testing: Verifying compliance with IP69K standards against water and dust penetration.

Real-World Applications:

- Food Processing: Withstand frequent washdowns and exposure to oils, sauces, and other food residues.

- Pharmaceutical Industry: Meet sterile conditions required for drug manufacturing and packaging.

- Chemical Industry: Resist corrosive chemicals in harsh production environments.

Why EHEDG IP69K Flange Bearing Units Are the Ultimate Solution

EHEDG IP69K 4-hole square flange bearing units are not just components; they are investments in reliability, safety, and efficiency. Their advanced features and robust design offer unparalleled advantages:

Reduced Maintenance

The self-lubricating design and high-quality materials minimize wear and tear, ensuring consistent performance and lower operating costs.

Enhanced Hygiene

These units are specifically designed to eliminate contamination risks, thanks to their seamless construction and hygienic certifications.

Exceptional Durability

Built to handle extreme environments, they deliver long-lasting performance under high pressure, extreme temperatures, and chemical exposure.

EHEDG IP69K 4-hole square flange bearing units

EHEDG IP69K 4-hole square flange bearing units represent the epitome of engineering excellence. With decades of experience, material and design expertise, authoritative certifications, and proven trustworthiness, these units are indispensable for industries operating in harsh and extreme conditions. Their ability to meet rigorous hygiene standards, withstand environmental challenges, and deliver reliable performance makes them a cornerstone of modern hygienic machinery.

By investing in these flange bearing units, companies can ensure compliance with global hygiene regulations, enhance equipment longevity, and reduce downtime—all while safeguarding the integrity of their products.

Unmatched Durability for Extreme Conditions

In industries such as food processing, pharmaceuticals, and chemicals, machinery components face intense challenges. High-pressure cleaning, exposure to aggressive chemicals, extreme temperatures, and demanding workloads necessitate robust and reliable components. EHEDG IP69K 4-hole square flange bearing units are the pinnacle of innovation and engineering, designed to withstand these extreme conditions while adhering to stringent hygienic standards. This article explores the Experience, Expertise, Authoritativeness and Trustworthiness behind these bearing units and their critical role in maintaining operational excellence in harsh environments.

Experience in Designing EHEDG IP69K Flange Bearing Units

EHEDG-certified components are crafted to meet the strict hygiene and safety requirements of industries where contamination is not an option. The experience behind the development of IP69K flange bearing units stems from decades of collaboration with industry leaders, engineers, and regulatory bodies.

Manufacturers of these bearing units have accumulated years of expertise in tackling challenges posed by high-pressure washing, thermal cycling, and corrosive environments. Their extensive field research and real-world testing ensure that every flange bearing unit delivers unmatched reliability and longevity.

Key Features Derived from Experience:

- Seamless Construction: Minimized crevices prevent the buildup of contaminants.

- Corrosion Resistance: High-grade stainless steel and surface treatments ensure durability against chemical exposure.

- Efficient Cleaning: Rounded edges and polished surfaces enable faster, more effective cleaning.

Expertise Behind IP69K Flange Bearing Units

The expertise driving the design of these components is rooted in advanced engineering principles and rigorous testing. Each EHEDG IP69K 4-hole square flange bearing unit is designed to function under extreme conditions, from high-pressure washdowns at 1,450 psi to sustained exposure to temperatures as low as -40°C or as high as 120°C.

Material Expertise:

- High-Grade Stainless Steel: Prevents corrosion, ensuring long-term performance even when exposed to cleaning agents or saline solutions.

- Food-Grade Seals: Prevent ingress of water, dust, and contaminants, meeting IP69K standards for protection.

Design Expertise:

- Enhanced Mounting Stability: The 4-hole square flange configuration ensures secure attachment, reducing vibration and wear.

- Self-Lubricating Bearings: These reduce maintenance needs while offering consistent performance.

Authoritativeness in Hygienic Standards

The EHEDG certification establishes these bearing units as authoritative components in hygienic machinery. EHEDG (European Hygienic Engineering & Design Group) is a globally recognized organization dedicated to promoting food safety by improving the design of equipment used in food production.

IP69K certification further underscores the reliability of these bearing units. This rating guarantees resistance to water and dust ingress, making them ideal for high-pressure and high-temperature cleaning environments. By combining these certifications, manufacturers demonstrate their commitment to adhering to the highest standards of hygiene, safety, and durability.

Benefits of Compliance:

- Improved Food Safety: Reduces risks of contamination in food and pharmaceutical production.

- Enhanced Durability: Prolongs equipment lifespan, reducing downtime and maintenance costs.

- Regulatory Compliance: Simplifies adherence to industry regulations like FDA and EU standards.

Trustworthiness Through Rigorous Testing and Real-World Applications

The trustworthiness of EHEDG IP69K 4-hole square flange bearing units lies in their rigorous testing and proven performance in demanding environments. Manufacturers subject these units to a variety of tests, including:

- Thermal Shock Testing: To assess performance in fluctuating temperatures.

- Chemical Resistance Testing: Ensuring resistance to aggressive cleaning agents and corrosive substances.

- Ingress Protection Testing: Verifying compliance with IP69K standards against water and dust penetration.

Real-World Applications:

- Food Processing: Withstand frequent washdowns and exposure to oils, sauces, and other food residues.

- Pharmaceutical Industry: Meet sterile conditions required for drug manufacturing and packaging.

- Chemical Industry: Resist corrosive chemicals in harsh production environments.

Why EHEDG IP69K Flange Bearing Units Are the Ultimate Solution

EHEDG IP69K 4-hole square flange bearing units are not just components; they are investments in reliability, safety, and efficiency. Their advanced features and robust design offer unparalleled advantages:

Reduced Maintenance

The self-lubricating design and high-quality materials minimize wear and tear, ensuring consistent performance and lower operating costs.

Enhanced Hygiene

These units are specifically designed to eliminate contamination risks, thanks to their seamless construction and hygienic certifications.

Exceptional Durability

Built to handle extreme environments, they deliver long-lasting performance under high pressure, extreme temperatures, and chemical exposure.

EHEDG IP69K 4-hole square flange bearing units

EHEDG IP69K 4-hole square flange bearing units represent the epitome of engineering excellence. With decades of experience, material and design expertise, authoritative certifications, and proven trustworthiness, these units are indispensable for industries operating in harsh and extreme conditions. Their ability to meet rigorous hygiene standards, withstand environmental challenges, and deliver reliable performance makes them a cornerstone of modern hygienic machinery.

By investing in these flange bearing units, companies can ensure compliance with global hygiene regulations, enhance equipment longevity, and reduce downtime—all while safeguarding the integrity of their products.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.