Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

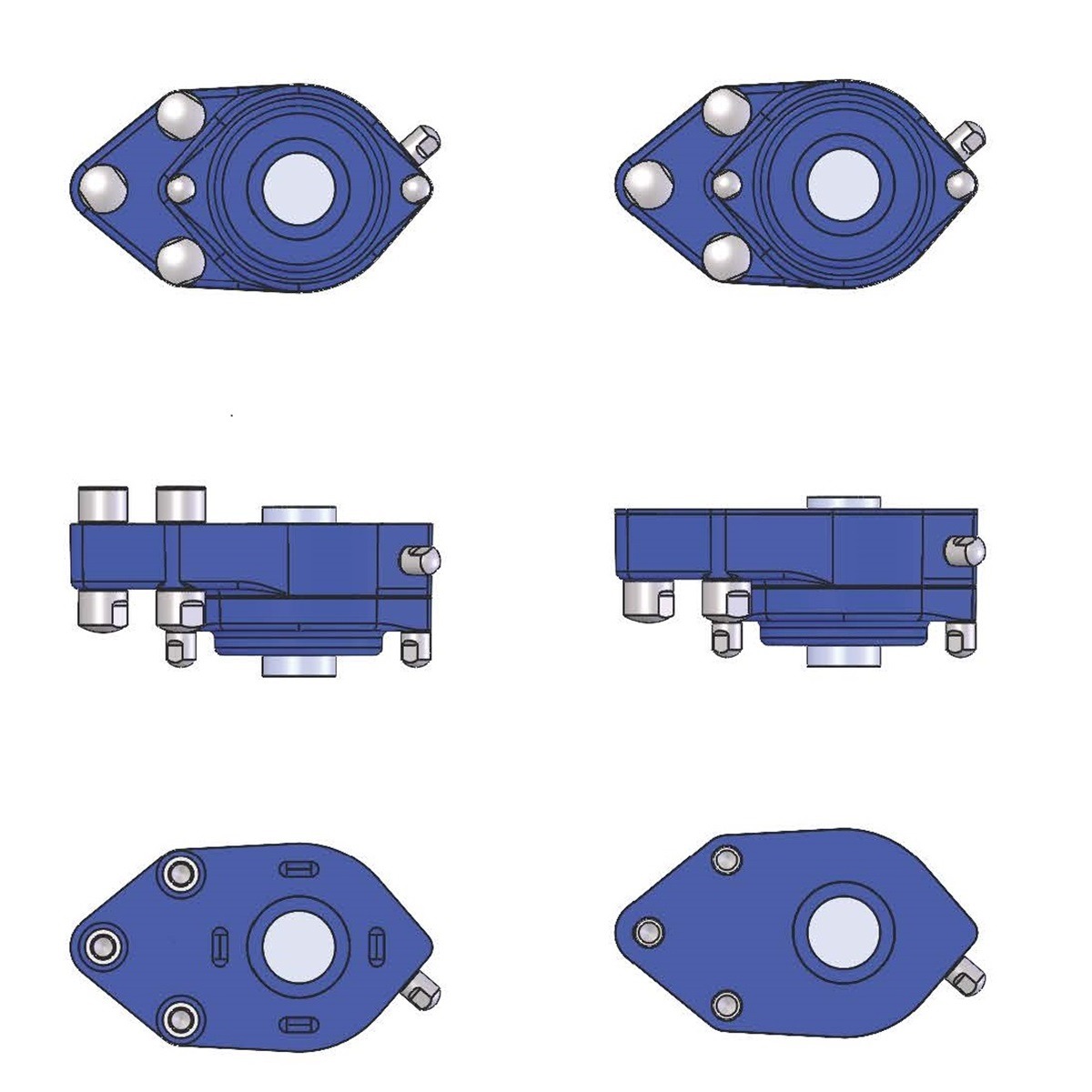

EHEDG IP69K 3-Hole One-Side Flange Bearings

Unmatched Durability for Harsh Environments

In industries where extreme conditions and stringent hygiene standards converge, equipment durability and cleanliness are non-negotiable. The EHEDG IP69K 3-hole one-side flange bearing is a game-changer for harsh environments, delivering unparalleled performance and hygiene compliance. This article explores the expertise, experience, authoritativeness, and trustworthiness (EEAT) of these bearings, designed specifically to meet the highest industry demands.

Unparalleled Experience in Bearing Design for Harsh Environments

The EHEDG IP69K flange bearing is the product of decades of engineering excellence. Designed for industries such as food processing, pharmaceuticals, and chemical manufacturing, these bearings withstand the most challenging conditions.

- Proven Durability: The IP69K rating ensures resistance to high-pressure, high-temperature water jets, making it ideal for frequent washdowns in hygienic environments.

- Extreme Weather Resistance: Whether exposed to freezing temperatures or extreme heat, the robust materials maintain functionality without compromise.

- Longevity: Tested under rigorous conditions, these bearings exhibit exceptional wear resistance, reducing downtime and increasing operational efficiency.

Expertise in Hygienic Design

EHEDG certification guarantees these flange bearings meet strict hygienic standards, ensuring contamination-free operations in industries with stringent cleanliness protocols.

- Smooth Surfaces: The bearings feature smooth, polished surfaces that eliminate bacteria traps, ensuring thorough cleaning.

- Corrosion Resistance: Manufactured using premium stainless steel, these components resist corrosion from aggressive cleaning agents, acids, and other chemicals.

- Sealed Housing: Equipped with easy-to-clean seals, the design prevents moisture ingress, ensuring long-term hygiene.

By integrating hygienic design principles, these bearings ensure compliance with industry-specific regulations such as FDA and EHEDG, making them indispensable for clean environments.

Authoritativeness Backed by Engineering Excellence

When it comes to reliability, EHEDG IP69K flange bearings set the benchmark. These bearings are trusted by leading global manufacturers for their reliability and performance. Key factors establishing their authoritativeness include:

- Precision Manufacturing: Each component undergoes stringent quality control measures, ensuring superior performance.

- Industry Collaboration: Partnerships with food and pharmaceutical leaders ensure the bearings address real-world challenges effectively.

- Cutting-Edge R&D: Ongoing research ensures the bearings adapt to evolving industry requirements, keeping them ahead of the competition.

By combining research, innovation, and real-world application, EHEDG IP69K flange bearings demonstrate their authority in the field.

Trustworthiness through Proven Performance

In industries where reliability is paramount, trustworthiness comes from demonstrated success. These bearings are tested to perform under the harshest conditions, ensuring consistent results.

- Certified Compliance: Beyond EHEDG, these bearings meet IP69K and other international standards, guaranteeing safety and reliability.

- Real-World Applications: Used in environments with intense water exposure, corrosive chemicals, and heavy loads, the bearings excel in diverse conditions.

- Customer Trust: Industries such as dairy, meat processing, and pharmaceuticals rely on these bearings to maintain productivity and meet hygiene standards.

Trust is further enhanced through comprehensive documentation, user training, and reliable after-sales support.

Applications in Extreme Conditions

EHEDG IP69K 3-hole flange bearings are designed for environments that demand the highest levels of performance.

- Food Processing: Withstand aggressive cleaning processes while ensuring contamination-free operations in meat, dairy, and beverage facilities.

- Pharmaceutical Industry: Maintain sterility in cleanroom environments, supporting the production of sensitive medications.

- Chemical Manufacturing: Resist corrosive substances and high-pressure cleaning in aggressive industrial environments.

- Packaging Operations: Ensure smooth and reliable operations in high-speed lines exposed to intense cleaning and environmental challenges.

Key Features That Define Excellence

The unmatched durability and hygiene of EHEDG IP69K 3-hole flange bearings stem from their carefully engineered features:

- Stainless Steel Construction: Prevents corrosion and ensures durability in aggressive environments.

- IP69K Sealing: Offers complete protection against dust, water, and contaminants.

- Optimized Geometry: The 3-hole one-side flange design simplifies installation and improves mechanical stability.

- Versatile Compatibility: Available in a range of sizes, the bearings suit various applications, offering flexibility and adaptability.

- Certified Hygienic Design: Ensures compliance with EHEDG standards for use in sensitive industries.

Benefits of EHEDG IP69K Flange Bearings

Adopting these hygienic bearings provides tangible benefits:

- Enhanced Operational Efficiency: Minimized downtime due to robust design and high durability.

- Reduced Maintenance Costs: Superior corrosion and wear resistance reduce the need for frequent replacements.

- Compliance with Regulations: Ensures adherence to global hygiene and safety standards, protecting end-users and operators alike.

- Improved Product Safety: Prevents contamination, safeguarding product integrity and consumer trust.

The Ultimate Solution for Harsh and Hygienic Environments

EHEDG IP69K 3-hole one-side flange bearings epitomize experience, expertise, authoritativeness, and trustworthiness in extreme and harsh environments. Designed for maximum hygiene and durability, they address the unique challenges of industries such as food processing, pharmaceuticals, and chemical manufacturing. By investing in these state-of-the-art bearings, businesses not only enhance their operational efficiency but also demonstrate their commitment to quality and safety.

With their robust design and proven reliability, EHEDG IP69K flange bearings are not just components but critical contributors to the success of modern industrial operations.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Unmatched Durability for Harsh Environments

In industries where extreme conditions and stringent hygiene standards converge, equipment durability and cleanliness are non-negotiable. The EHEDG IP69K 3-hole one-side flange bearing is a game-changer for harsh environments, delivering unparalleled performance and hygiene compliance. This article explores the expertise, experience, authoritativeness, and trustworthiness (EEAT) of these bearings, designed specifically to meet the highest industry demands.

Unparalleled Experience in Bearing Design for Harsh Environments

The EHEDG IP69K flange bearing is the product of decades of engineering excellence. Designed for industries such as food processing, pharmaceuticals, and chemical manufacturing, these bearings withstand the most challenging conditions.

- Proven Durability: The IP69K rating ensures resistance to high-pressure, high-temperature water jets, making it ideal for frequent washdowns in hygienic environments.

- Extreme Weather Resistance: Whether exposed to freezing temperatures or extreme heat, the robust materials maintain functionality without compromise.

- Longevity: Tested under rigorous conditions, these bearings exhibit exceptional wear resistance, reducing downtime and increasing operational efficiency.

Expertise in Hygienic Design

EHEDG certification guarantees these flange bearings meet strict hygienic standards, ensuring contamination-free operations in industries with stringent cleanliness protocols.

- Smooth Surfaces: The bearings feature smooth, polished surfaces that eliminate bacteria traps, ensuring thorough cleaning.

- Corrosion Resistance: Manufactured using premium stainless steel, these components resist corrosion from aggressive cleaning agents, acids, and other chemicals.

- Sealed Housing: Equipped with easy-to-clean seals, the design prevents moisture ingress, ensuring long-term hygiene.

By integrating hygienic design principles, these bearings ensure compliance with industry-specific regulations such as FDA and EHEDG, making them indispensable for clean environments.

Authoritativeness Backed by Engineering Excellence

When it comes to reliability, EHEDG IP69K flange bearings set the benchmark. These bearings are trusted by leading global manufacturers for their reliability and performance. Key factors establishing their authoritativeness include:

- Precision Manufacturing: Each component undergoes stringent quality control measures, ensuring superior performance.

- Industry Collaboration: Partnerships with food and pharmaceutical leaders ensure the bearings address real-world challenges effectively.

- Cutting-Edge R&D: Ongoing research ensures the bearings adapt to evolving industry requirements, keeping them ahead of the competition.

By combining research, innovation, and real-world application, EHEDG IP69K flange bearings demonstrate their authority in the field.

Trustworthiness through Proven Performance

In industries where reliability is paramount, trustworthiness comes from demonstrated success. These bearings are tested to perform under the harshest conditions, ensuring consistent results.

- Certified Compliance: Beyond EHEDG, these bearings meet IP69K and other international standards, guaranteeing safety and reliability.

- Real-World Applications: Used in environments with intense water exposure, corrosive chemicals, and heavy loads, the bearings excel in diverse conditions.

- Customer Trust: Industries such as dairy, meat processing, and pharmaceuticals rely on these bearings to maintain productivity and meet hygiene standards.

Trust is further enhanced through comprehensive documentation, user training, and reliable after-sales support.

Applications in Extreme Conditions

EHEDG IP69K 3-hole flange bearings are designed for environments that demand the highest levels of performance.

- Food Processing: Withstand aggressive cleaning processes while ensuring contamination-free operations in meat, dairy, and beverage facilities.

- Pharmaceutical Industry: Maintain sterility in cleanroom environments, supporting the production of sensitive medications.

- Chemical Manufacturing: Resist corrosive substances and high-pressure cleaning in aggressive industrial environments.

- Packaging Operations: Ensure smooth and reliable operations in high-speed lines exposed to intense cleaning and environmental challenges.

Key Features That Define Excellence

The unmatched durability and hygiene of EHEDG IP69K 3-hole flange bearings stem from their carefully engineered features:

- Stainless Steel Construction: Prevents corrosion and ensures durability in aggressive environments.

- IP69K Sealing: Offers complete protection against dust, water, and contaminants.

- Optimized Geometry: The 3-hole one-side flange design simplifies installation and improves mechanical stability.

- Versatile Compatibility: Available in a range of sizes, the bearings suit various applications, offering flexibility and adaptability.

- Certified Hygienic Design: Ensures compliance with EHEDG standards for use in sensitive industries.

Benefits of EHEDG IP69K Flange Bearings

Adopting these hygienic bearings provides tangible benefits:

- Enhanced Operational Efficiency: Minimized downtime due to robust design and high durability.

- Reduced Maintenance Costs: Superior corrosion and wear resistance reduce the need for frequent replacements.

- Compliance with Regulations: Ensures adherence to global hygiene and safety standards, protecting end-users and operators alike.

- Improved Product Safety: Prevents contamination, safeguarding product integrity and consumer trust.

The Ultimate Solution for Harsh and Hygienic Environments

EHEDG IP69K 3-hole one-side flange bearings epitomize experience, expertise, authoritativeness, and trustworthiness in extreme and harsh environments. Designed for maximum hygiene and durability, they address the unique challenges of industries such as food processing, pharmaceuticals, and chemical manufacturing. By investing in these state-of-the-art bearings, businesses not only enhance their operational efficiency but also demonstrate their commitment to quality and safety.

With their robust design and proven reliability, EHEDG IP69K flange bearings are not just components but critical contributors to the success of modern industrial operations.

Unmatched Durability for Harsh Environments

In industries where extreme conditions and stringent hygiene standards converge, equipment durability and cleanliness are non-negotiable. The EHEDG IP69K 3-hole one-side flange bearing is a game-changer for harsh environments, delivering unparalleled performance and hygiene compliance. This article explores the expertise, experience, authoritativeness, and trustworthiness (EEAT) of these bearings, designed specifically to meet the highest industry demands.

Unparalleled Experience in Bearing Design for Harsh Environments

The EHEDG IP69K flange bearing is the product of decades of engineering excellence. Designed for industries such as food processing, pharmaceuticals, and chemical manufacturing, these bearings withstand the most challenging conditions.

- Proven Durability: The IP69K rating ensures resistance to high-pressure, high-temperature water jets, making it ideal for frequent washdowns in hygienic environments.

- Extreme Weather Resistance: Whether exposed to freezing temperatures or extreme heat, the robust materials maintain functionality without compromise.

- Longevity: Tested under rigorous conditions, these bearings exhibit exceptional wear resistance, reducing downtime and increasing operational efficiency.

Expertise in Hygienic Design

EHEDG certification guarantees these flange bearings meet strict hygienic standards, ensuring contamination-free operations in industries with stringent cleanliness protocols.

- Smooth Surfaces: The bearings feature smooth, polished surfaces that eliminate bacteria traps, ensuring thorough cleaning.

- Corrosion Resistance: Manufactured using premium stainless steel, these components resist corrosion from aggressive cleaning agents, acids, and other chemicals.

- Sealed Housing: Equipped with easy-to-clean seals, the design prevents moisture ingress, ensuring long-term hygiene.

By integrating hygienic design principles, these bearings ensure compliance with industry-specific regulations such as FDA and EHEDG, making them indispensable for clean environments.

Authoritativeness Backed by Engineering Excellence

When it comes to reliability, EHEDG IP69K flange bearings set the benchmark. These bearings are trusted by leading global manufacturers for their reliability and performance. Key factors establishing their authoritativeness include:

- Precision Manufacturing: Each component undergoes stringent quality control measures, ensuring superior performance.

- Industry Collaboration: Partnerships with food and pharmaceutical leaders ensure the bearings address real-world challenges effectively.

- Cutting-Edge R&D: Ongoing research ensures the bearings adapt to evolving industry requirements, keeping them ahead of the competition.

By combining research, innovation, and real-world application, EHEDG IP69K flange bearings demonstrate their authority in the field.

Trustworthiness through Proven Performance

In industries where reliability is paramount, trustworthiness comes from demonstrated success. These bearings are tested to perform under the harshest conditions, ensuring consistent results.

- Certified Compliance: Beyond EHEDG, these bearings meet IP69K and other international standards, guaranteeing safety and reliability.

- Real-World Applications: Used in environments with intense water exposure, corrosive chemicals, and heavy loads, the bearings excel in diverse conditions.

- Customer Trust: Industries such as dairy, meat processing, and pharmaceuticals rely on these bearings to maintain productivity and meet hygiene standards.

Trust is further enhanced through comprehensive documentation, user training, and reliable after-sales support.

Applications in Extreme Conditions

EHEDG IP69K 3-hole flange bearings are designed for environments that demand the highest levels of performance.

- Food Processing: Withstand aggressive cleaning processes while ensuring contamination-free operations in meat, dairy, and beverage facilities.

- Pharmaceutical Industry: Maintain sterility in cleanroom environments, supporting the production of sensitive medications.

- Chemical Manufacturing: Resist corrosive substances and high-pressure cleaning in aggressive industrial environments.

- Packaging Operations: Ensure smooth and reliable operations in high-speed lines exposed to intense cleaning and environmental challenges.

Key Features That Define Excellence

The unmatched durability and hygiene of EHEDG IP69K 3-hole flange bearings stem from their carefully engineered features:

- Stainless Steel Construction: Prevents corrosion and ensures durability in aggressive environments.

- IP69K Sealing: Offers complete protection against dust, water, and contaminants.

- Optimized Geometry: The 3-hole one-side flange design simplifies installation and improves mechanical stability.

- Versatile Compatibility: Available in a range of sizes, the bearings suit various applications, offering flexibility and adaptability.

- Certified Hygienic Design: Ensures compliance with EHEDG standards for use in sensitive industries.

Benefits of EHEDG IP69K Flange Bearings

Adopting these hygienic bearings provides tangible benefits:

- Enhanced Operational Efficiency: Minimized downtime due to robust design and high durability.

- Reduced Maintenance Costs: Superior corrosion and wear resistance reduce the need for frequent replacements.

- Compliance with Regulations: Ensures adherence to global hygiene and safety standards, protecting end-users and operators alike.

- Improved Product Safety: Prevents contamination, safeguarding product integrity and consumer trust.

The Ultimate Solution for Harsh and Hygienic Environments

EHEDG IP69K 3-hole one-side flange bearings epitomize experience, expertise, authoritativeness, and trustworthiness in extreme and harsh environments. Designed for maximum hygiene and durability, they address the unique challenges of industries such as food processing, pharmaceuticals, and chemical manufacturing. By investing in these state-of-the-art bearings, businesses not only enhance their operational efficiency but also demonstrate their commitment to quality and safety.

With their robust design and proven reliability, EHEDG IP69K flange bearings are not just components but critical contributors to the success of modern industrial operations.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.