Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

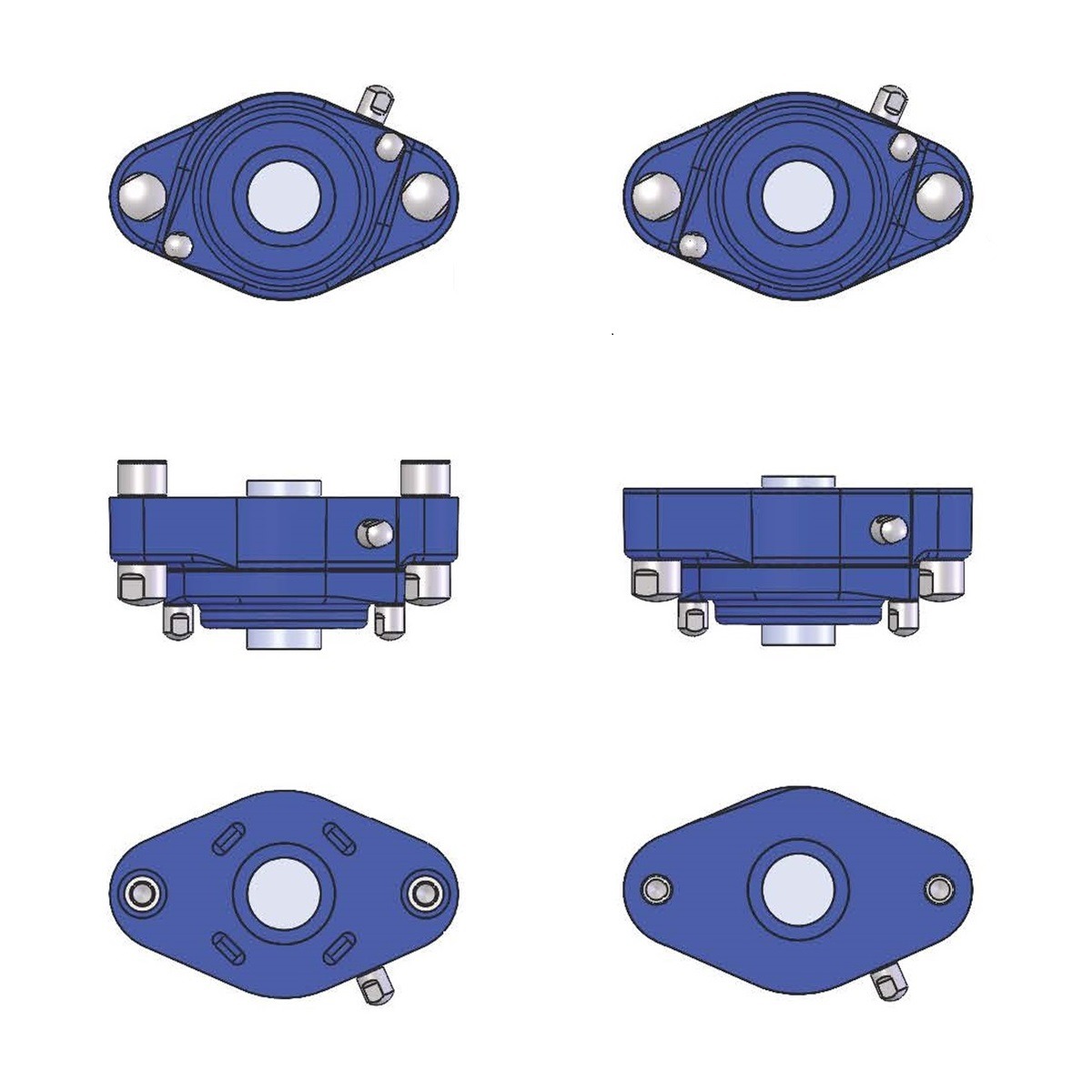

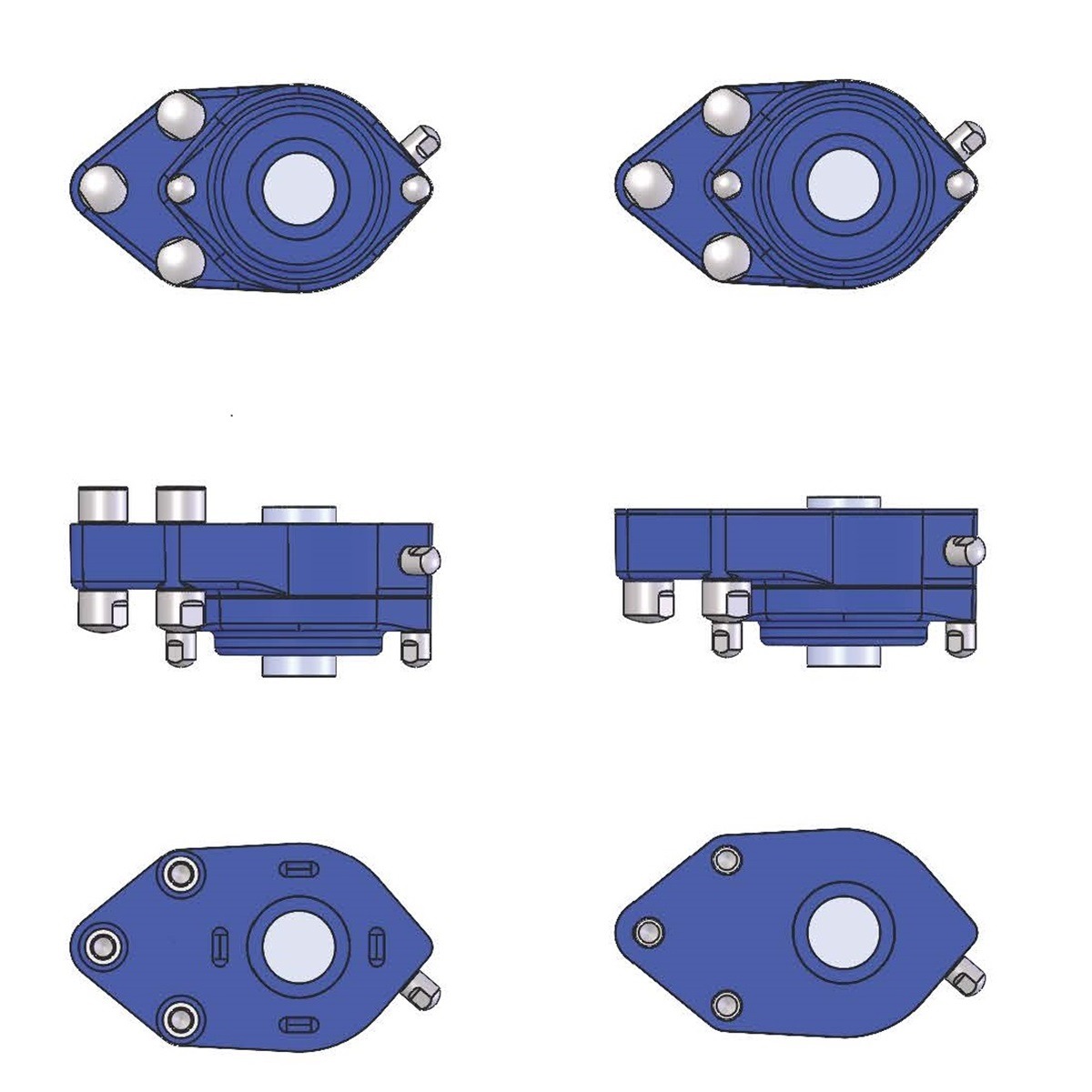

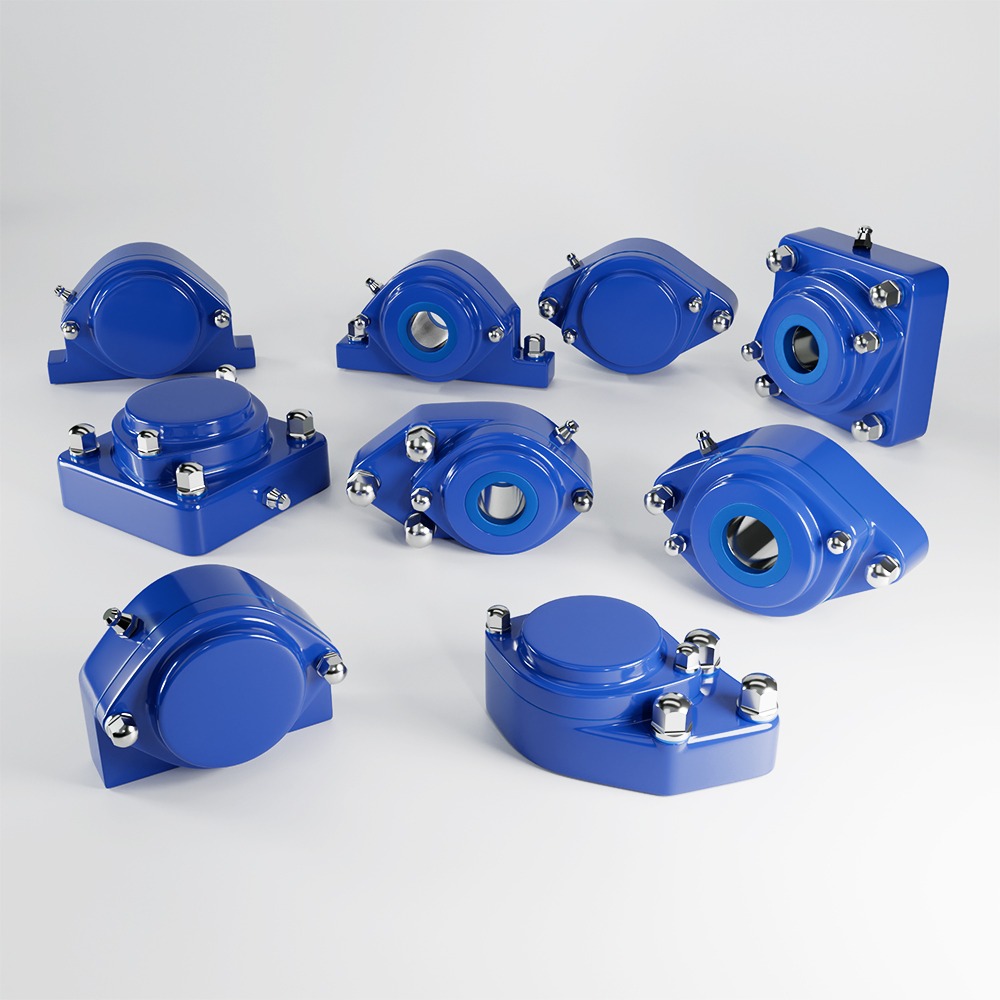

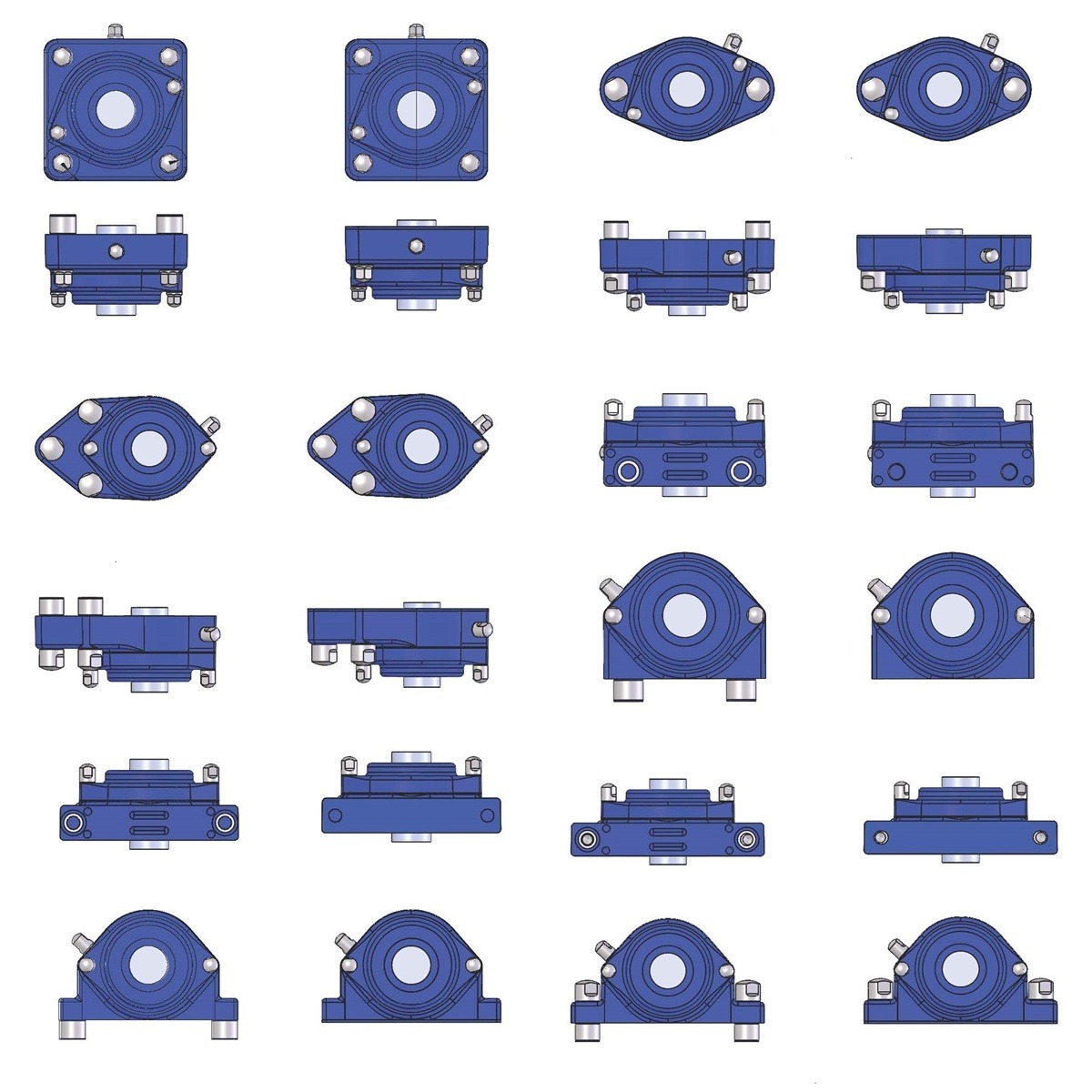

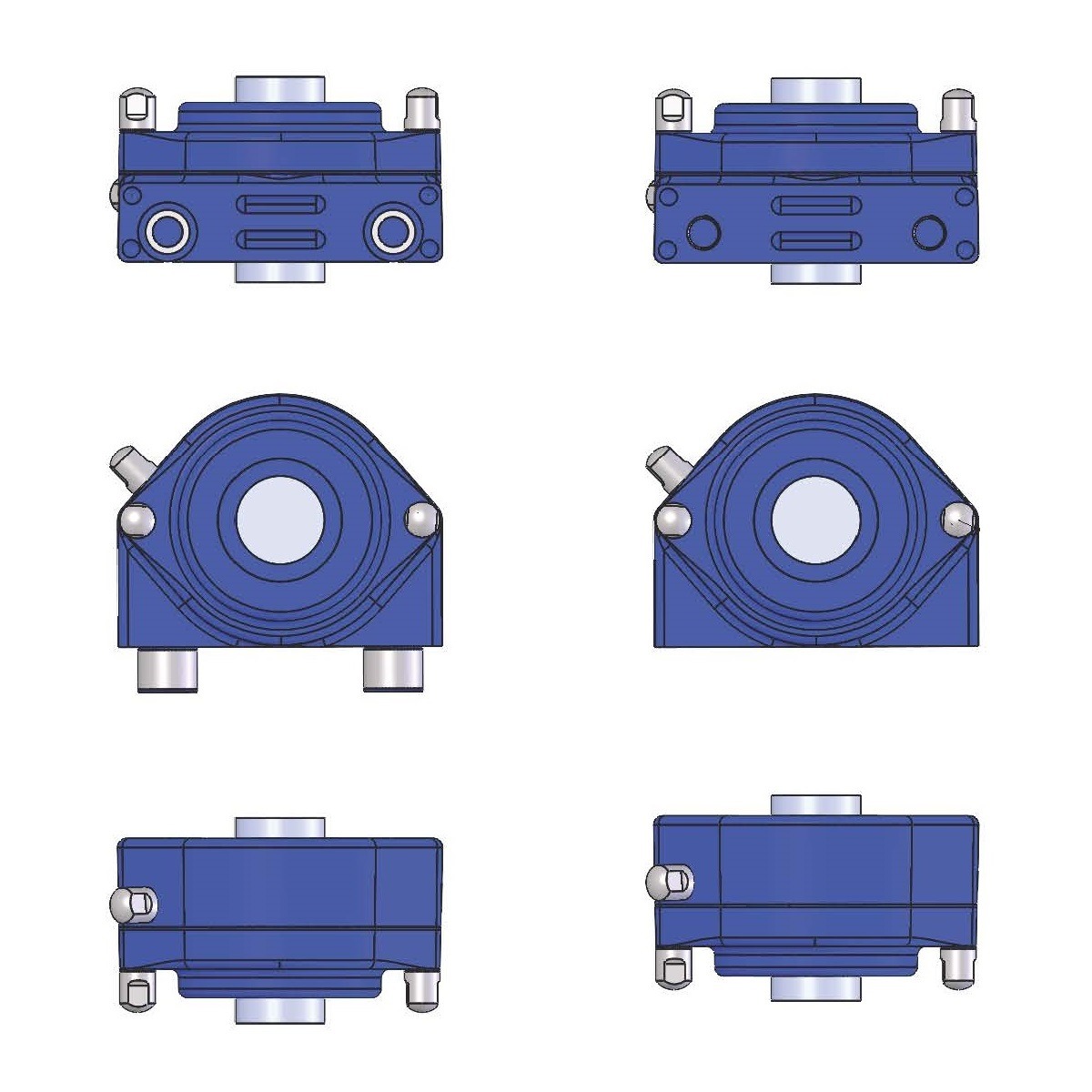

EHEDG IP69K 2-Hole Oval Flange Bearing Units

Expertise in Extreme Conditions

In demanding industries like food processing, pharmaceuticals, and biotechnology, operating conditions can be extreme, requiring machinery components that deliver uncompromising reliability. EHEDG IP69K-certified 2-hole oval flange bearing units are essential for such environments, offering unparalleled durability, hygiene, and precision. This article delves into their design, purpose, and benefits, focusing on how these components excel in challenging settings while emphasizing Experience, Expertise, Authoritativeness, and Trustworthiness.

Experience: Mastering Hygienic Design

EHEDG IP69K 2-hole oval flange bearing units are the result of decades of innovation and hands-on experience in hygienic engineering. These bearing units are specifically crafted to meet stringent sanitation standards, ensuring they perform flawlessly in environments prone to high moisture, aggressive cleaning processes, and contamination risks.

Manufacturers have refined their designs to eliminate gaps, crevices, and flat surfaces where contaminants could accumulate. Rounded edges, smooth finishes, and stainless steel construction ensure these bearings can withstand high-pressure washdowns, detergents, and harsh chemicals without compromising structural integrity.

With roots in industries requiring precision and hygiene, such as dairy, meat processing, and pharmaceuticals, these bearing units demonstrate the expertise of manufacturers who understand the demands of extreme operating conditions.

Expertise: Uncompromising Precision and Reliability

EHEDG IP69K flange bearing units are engineered with expert precision to meet the most rigorous hygienic standards. Certified by EHEDG (European Hygienic Engineering & Design Group), these units ensure compliance with global hygiene protocols, providing peace of mind for operators in regulated industries.

Key design features include:

- IP69K Rating: Guarantees resistance to high-pressure, high-temperature washdowns, making these bearings suitable for environments that require daily or even hourly cleaning.

- 2-Hole Oval Flange Design: Facilitates easy installation, reduces mounting complexity, and ensures optimal alignment for mechanical systems.

- Corrosion Resistance: Crafted from food-grade stainless steel, these bearings resist corrosion even in harsh environments exposed to brine, chemicals, or caustic cleaning agents.

- Hygienic Seals: Special seals prevent ingress of water, dirt, and bacteria, maintaining sterility in critical applications.

This level of expertise ensures reliable performance, minimal downtime, and extended service life, making these bearings indispensable for facilities striving for operational efficiency.

Authoritativeness: Trusted in Critical Industries

EHEDG-certified IP69K bearing units have established themselves as authoritative components in industries that cannot compromise on hygiene or reliability. Their adoption across global manufacturing plants demonstrates the confidence placed in their design and performance.

Industries benefiting from these bearings include:

- Food Processing: Protecting against contamination in meat, dairy, beverage, and snack production lines.

- Pharmaceuticals: Ensuring sterility in cleanrooms and critical drug manufacturing facilities.

- Beverage Production: Enhancing durability in high-speed bottling and canning lines exposed to constant moisture.

- Biotechnology: Providing precise functionality in research and production settings where cleanliness is paramount.

These industries demand components that meet and exceed international hygiene standards, and EHEDG IP69K 2-hole oval flange bearing units consistently deliver.

Trustworthiness: Building Confidence in Harsh Environments

Trustworthiness is a cornerstone of any hygienic machinery component, and EHEDG IP69K-certified bearing units excel in this regard. They are trusted by operators and manufacturers worldwide due to their proven reliability in extreme conditions.

Why These Bearings Are Trusted:

- Rigorous Testing: EHEDG certification ensures the bearings have been tested under extreme conditions, including steam cleaning, high-pressure washdowns, and exposure to harsh chemicals.

- Ease of Maintenance: Their design simplifies cleaning processes, reducing downtime and lowering operational costs while maintaining hygiene standards.

- Longevity: Their robust construction extends lifespan even in the harshest environments, reducing replacement frequency and saving costs.

- Compliance with Regulations: These bearing units meet FDA, EHEDG, and ISO standards, ensuring facilities remain compliant with global regulatory requirements.

By choosing EHEDG IP69K 2-hole oval flange bearing units, businesses enhance their reputation for hygiene, quality, and reliability.

Advantages of EHEDG IP69K 2-Hole Oval Flange Bearing Units

- Enhanced Hygiene: Certified for use in environments requiring the highest sanitary standards.

- Superior Durability: Designed to withstand harsh conditions, including extreme temperatures, aggressive chemicals, and frequent cleaning cycles.

- Operational Efficiency: Reduced maintenance requirements and extended service life minimize unplanned downtime.

- Sustainability: Their robust design supports eco-friendly operations by reducing waste from frequent replacements.

Applications in Extreme Conditions

EHEDG IP69K 2-hole oval flange bearing units are integral to industries where hygiene and reliability intersect with extreme environmental conditions. Common applications include:

- High-Pressure Washdowns: In food and beverage plants that undergo daily sanitation.

- Cold and Wet Environments: In refrigerated warehouses, dairy processing plants, and seafood facilities.

- Heavy Chemical Exposure: In chemical and personal care product manufacturing where caustic cleaners are used.

These bearings are engineered to thrive in the harshest conditions while maintaining peak performance.

EHEDG IP69K 2-hole oval flange bearing units

EHEDG IP69K 2-hole oval flange bearing units embody the principles of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T). Their hygienic design, unmatched durability, and compliance with international standards make them a cornerstone for industries operating in extreme environments.

By investing in these bearing units, businesses not only ensure the safety and efficiency of their operations but also demonstrate their commitment to quality and sustainability. When hygiene and reliability are non-negotiable, EHEDG IP69K 2-hole oval flange bearing units are the ultimate solution.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Expertise in Extreme Conditions

In demanding industries like food processing, pharmaceuticals, and biotechnology, operating conditions can be extreme, requiring machinery components that deliver uncompromising reliability. EHEDG IP69K-certified 2-hole oval flange bearing units are essential for such environments, offering unparalleled durability, hygiene, and precision. This article delves into their design, purpose, and benefits, focusing on how these components excel in challenging settings while emphasizing Experience, Expertise, Authoritativeness, and Trustworthiness.

Experience: Mastering Hygienic Design

EHEDG IP69K 2-hole oval flange bearing units are the result of decades of innovation and hands-on experience in hygienic engineering. These bearing units are specifically crafted to meet stringent sanitation standards, ensuring they perform flawlessly in environments prone to high moisture, aggressive cleaning processes, and contamination risks.

Manufacturers have refined their designs to eliminate gaps, crevices, and flat surfaces where contaminants could accumulate. Rounded edges, smooth finishes, and stainless steel construction ensure these bearings can withstand high-pressure washdowns, detergents, and harsh chemicals without compromising structural integrity.

With roots in industries requiring precision and hygiene, such as dairy, meat processing, and pharmaceuticals, these bearing units demonstrate the expertise of manufacturers who understand the demands of extreme operating conditions.

Expertise: Uncompromising Precision and Reliability

EHEDG IP69K flange bearing units are engineered with expert precision to meet the most rigorous hygienic standards. Certified by EHEDG (European Hygienic Engineering & Design Group), these units ensure compliance with global hygiene protocols, providing peace of mind for operators in regulated industries.

Key design features include:

- IP69K Rating: Guarantees resistance to high-pressure, high-temperature washdowns, making these bearings suitable for environments that require daily or even hourly cleaning.

- 2-Hole Oval Flange Design: Facilitates easy installation, reduces mounting complexity, and ensures optimal alignment for mechanical systems.

- Corrosion Resistance: Crafted from food-grade stainless steel, these bearings resist corrosion even in harsh environments exposed to brine, chemicals, or caustic cleaning agents.

- Hygienic Seals: Special seals prevent ingress of water, dirt, and bacteria, maintaining sterility in critical applications.

This level of expertise ensures reliable performance, minimal downtime, and extended service life, making these bearings indispensable for facilities striving for operational efficiency.

Authoritativeness: Trusted in Critical Industries

EHEDG-certified IP69K bearing units have established themselves as authoritative components in industries that cannot compromise on hygiene or reliability. Their adoption across global manufacturing plants demonstrates the confidence placed in their design and performance.

Industries benefiting from these bearings include:

- Food Processing: Protecting against contamination in meat, dairy, beverage, and snack production lines.

- Pharmaceuticals: Ensuring sterility in cleanrooms and critical drug manufacturing facilities.

- Beverage Production: Enhancing durability in high-speed bottling and canning lines exposed to constant moisture.

- Biotechnology: Providing precise functionality in research and production settings where cleanliness is paramount.

These industries demand components that meet and exceed international hygiene standards, and EHEDG IP69K 2-hole oval flange bearing units consistently deliver.

Trustworthiness: Building Confidence in Harsh Environments

Trustworthiness is a cornerstone of any hygienic machinery component, and EHEDG IP69K-certified bearing units excel in this regard. They are trusted by operators and manufacturers worldwide due to their proven reliability in extreme conditions.

Why These Bearings Are Trusted:

- Rigorous Testing: EHEDG certification ensures the bearings have been tested under extreme conditions, including steam cleaning, high-pressure washdowns, and exposure to harsh chemicals.

- Ease of Maintenance: Their design simplifies cleaning processes, reducing downtime and lowering operational costs while maintaining hygiene standards.

- Longevity: Their robust construction extends lifespan even in the harshest environments, reducing replacement frequency and saving costs.

- Compliance with Regulations: These bearing units meet FDA, EHEDG, and ISO standards, ensuring facilities remain compliant with global regulatory requirements.

By choosing EHEDG IP69K 2-hole oval flange bearing units, businesses enhance their reputation for hygiene, quality, and reliability.

Advantages of EHEDG IP69K 2-Hole Oval Flange Bearing Units

- Enhanced Hygiene: Certified for use in environments requiring the highest sanitary standards.

- Superior Durability: Designed to withstand harsh conditions, including extreme temperatures, aggressive chemicals, and frequent cleaning cycles.

- Operational Efficiency: Reduced maintenance requirements and extended service life minimize unplanned downtime.

- Sustainability: Their robust design supports eco-friendly operations by reducing waste from frequent replacements.

Applications in Extreme Conditions

EHEDG IP69K 2-hole oval flange bearing units are integral to industries where hygiene and reliability intersect with extreme environmental conditions. Common applications include:

- High-Pressure Washdowns: In food and beverage plants that undergo daily sanitation.

- Cold and Wet Environments: In refrigerated warehouses, dairy processing plants, and seafood facilities.

- Heavy Chemical Exposure: In chemical and personal care product manufacturing where caustic cleaners are used.

These bearings are engineered to thrive in the harshest conditions while maintaining peak performance.

EHEDG IP69K 2-hole oval flange bearing units

EHEDG IP69K 2-hole oval flange bearing units embody the principles of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T). Their hygienic design, unmatched durability, and compliance with international standards make them a cornerstone for industries operating in extreme environments.

By investing in these bearing units, businesses not only ensure the safety and efficiency of their operations but also demonstrate their commitment to quality and sustainability. When hygiene and reliability are non-negotiable, EHEDG IP69K 2-hole oval flange bearing units are the ultimate solution.

Expertise in Extreme Conditions

In demanding industries like food processing, pharmaceuticals, and biotechnology, operating conditions can be extreme, requiring machinery components that deliver uncompromising reliability. EHEDG IP69K-certified 2-hole oval flange bearing units are essential for such environments, offering unparalleled durability, hygiene, and precision. This article delves into their design, purpose, and benefits, focusing on how these components excel in challenging settings while emphasizing Experience, Expertise, Authoritativeness, and Trustworthiness.

Experience: Mastering Hygienic Design

EHEDG IP69K 2-hole oval flange bearing units are the result of decades of innovation and hands-on experience in hygienic engineering. These bearing units are specifically crafted to meet stringent sanitation standards, ensuring they perform flawlessly in environments prone to high moisture, aggressive cleaning processes, and contamination risks.

Manufacturers have refined their designs to eliminate gaps, crevices, and flat surfaces where contaminants could accumulate. Rounded edges, smooth finishes, and stainless steel construction ensure these bearings can withstand high-pressure washdowns, detergents, and harsh chemicals without compromising structural integrity.

With roots in industries requiring precision and hygiene, such as dairy, meat processing, and pharmaceuticals, these bearing units demonstrate the expertise of manufacturers who understand the demands of extreme operating conditions.

Expertise: Uncompromising Precision and Reliability

EHEDG IP69K flange bearing units are engineered with expert precision to meet the most rigorous hygienic standards. Certified by EHEDG (European Hygienic Engineering & Design Group), these units ensure compliance with global hygiene protocols, providing peace of mind for operators in regulated industries.

Key design features include:

- IP69K Rating: Guarantees resistance to high-pressure, high-temperature washdowns, making these bearings suitable for environments that require daily or even hourly cleaning.

- 2-Hole Oval Flange Design: Facilitates easy installation, reduces mounting complexity, and ensures optimal alignment for mechanical systems.

- Corrosion Resistance: Crafted from food-grade stainless steel, these bearings resist corrosion even in harsh environments exposed to brine, chemicals, or caustic cleaning agents.

- Hygienic Seals: Special seals prevent ingress of water, dirt, and bacteria, maintaining sterility in critical applications.

This level of expertise ensures reliable performance, minimal downtime, and extended service life, making these bearings indispensable for facilities striving for operational efficiency.

Authoritativeness: Trusted in Critical Industries

EHEDG-certified IP69K bearing units have established themselves as authoritative components in industries that cannot compromise on hygiene or reliability. Their adoption across global manufacturing plants demonstrates the confidence placed in their design and performance.

Industries benefiting from these bearings include:

- Food Processing: Protecting against contamination in meat, dairy, beverage, and snack production lines.

- Pharmaceuticals: Ensuring sterility in cleanrooms and critical drug manufacturing facilities.

- Beverage Production: Enhancing durability in high-speed bottling and canning lines exposed to constant moisture.

- Biotechnology: Providing precise functionality in research and production settings where cleanliness is paramount.

These industries demand components that meet and exceed international hygiene standards, and EHEDG IP69K 2-hole oval flange bearing units consistently deliver.

Trustworthiness: Building Confidence in Harsh Environments

Trustworthiness is a cornerstone of any hygienic machinery component, and EHEDG IP69K-certified bearing units excel in this regard. They are trusted by operators and manufacturers worldwide due to their proven reliability in extreme conditions.

Why These Bearings Are Trusted:

- Rigorous Testing: EHEDG certification ensures the bearings have been tested under extreme conditions, including steam cleaning, high-pressure washdowns, and exposure to harsh chemicals.

- Ease of Maintenance: Their design simplifies cleaning processes, reducing downtime and lowering operational costs while maintaining hygiene standards.

- Longevity: Their robust construction extends lifespan even in the harshest environments, reducing replacement frequency and saving costs.

- Compliance with Regulations: These bearing units meet FDA, EHEDG, and ISO standards, ensuring facilities remain compliant with global regulatory requirements.

By choosing EHEDG IP69K 2-hole oval flange bearing units, businesses enhance their reputation for hygiene, quality, and reliability.

Advantages of EHEDG IP69K 2-Hole Oval Flange Bearing Units

- Enhanced Hygiene: Certified for use in environments requiring the highest sanitary standards.

- Superior Durability: Designed to withstand harsh conditions, including extreme temperatures, aggressive chemicals, and frequent cleaning cycles.

- Operational Efficiency: Reduced maintenance requirements and extended service life minimize unplanned downtime.

- Sustainability: Their robust design supports eco-friendly operations by reducing waste from frequent replacements.

Applications in Extreme Conditions

EHEDG IP69K 2-hole oval flange bearing units are integral to industries where hygiene and reliability intersect with extreme environmental conditions. Common applications include:

- High-Pressure Washdowns: In food and beverage plants that undergo daily sanitation.

- Cold and Wet Environments: In refrigerated warehouses, dairy processing plants, and seafood facilities.

- Heavy Chemical Exposure: In chemical and personal care product manufacturing where caustic cleaners are used.

These bearings are engineered to thrive in the harshest conditions while maintaining peak performance.

EHEDG IP69K 2-hole oval flange bearing units

EHEDG IP69K 2-hole oval flange bearing units embody the principles of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T). Their hygienic design, unmatched durability, and compliance with international standards make them a cornerstone for industries operating in extreme environments.

By investing in these bearing units, businesses not only ensure the safety and efficiency of their operations but also demonstrate their commitment to quality and sustainability. When hygiene and reliability are non-negotiable, EHEDG IP69K 2-hole oval flange bearing units are the ultimate solution.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.