In industries like food processing, pharmaceuticals, and biotechnology, maintaining the highest standards of hygiene is critical. EHEDG (European Hygienic Engineering and Design Group) Hygienic welded spacers in stainless steel are specifically designed to meet these stringent standards. These components ensure cleanliness, durability, and compliance with hygiene regulations, making them indispensable for various industrial applications.

What Are EHEDG Hygienic Welded Spacers?

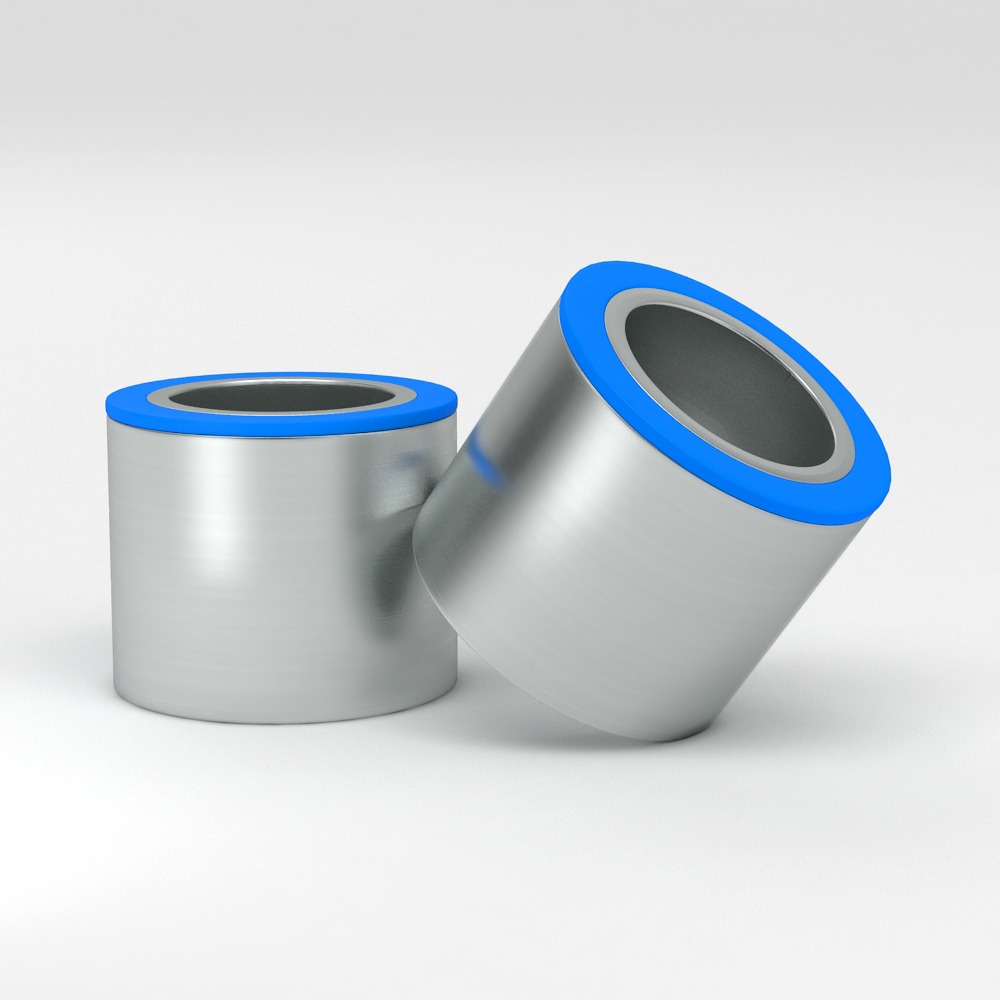

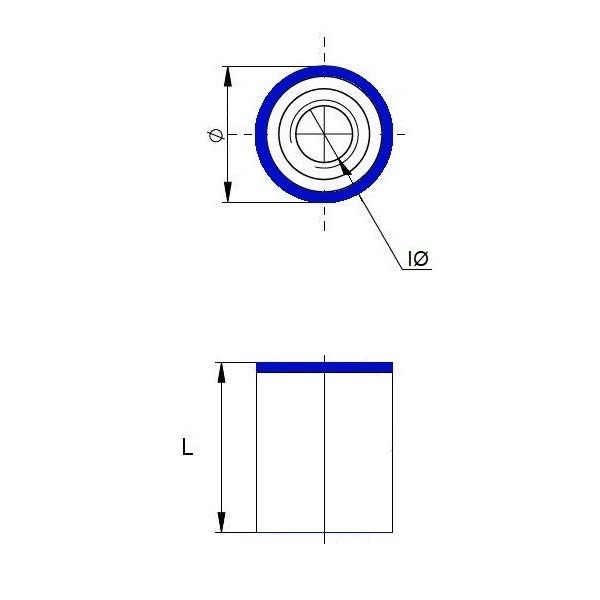

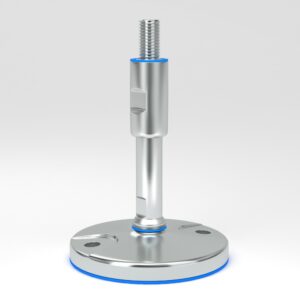

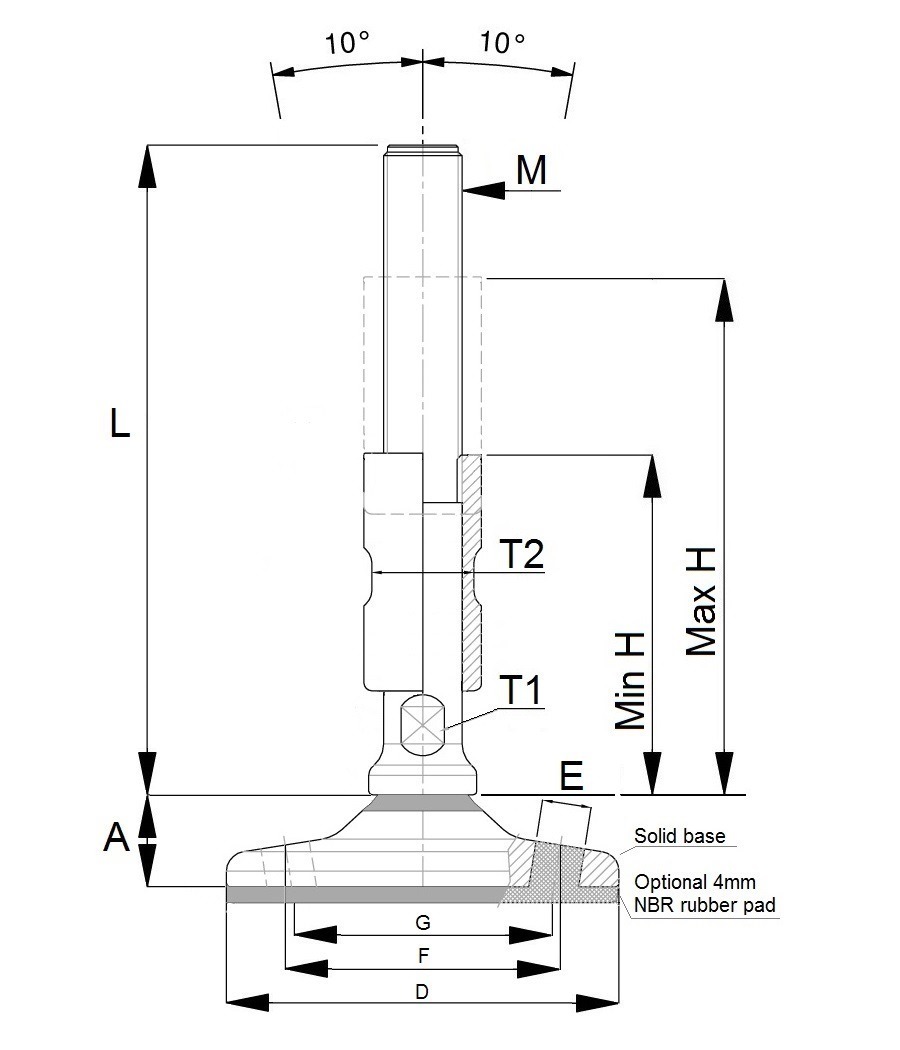

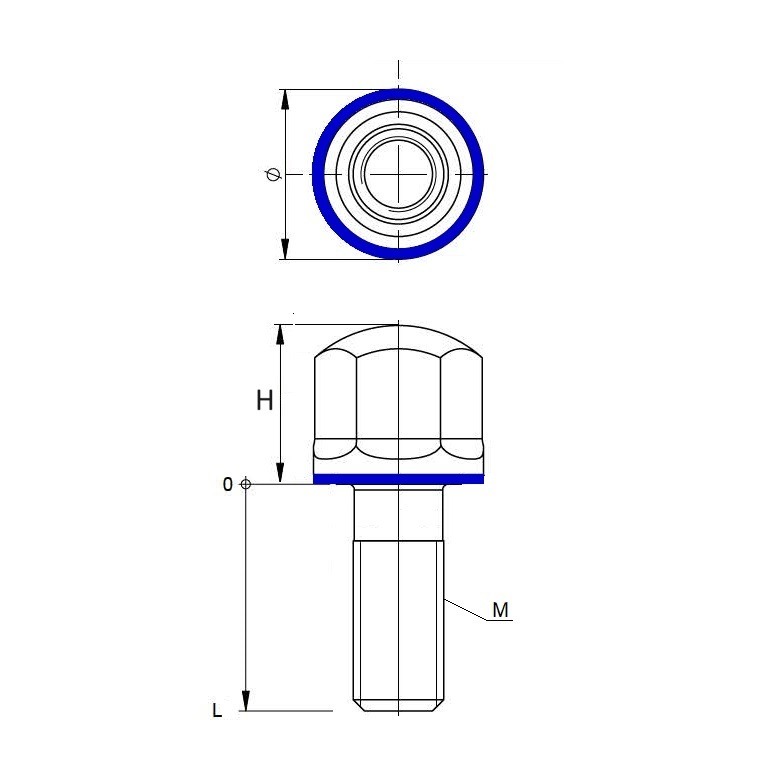

EHEDG Hygienic welded spacers are precision-engineered stainless steel components designed to bridge gaps or provide spacing in machinery while adhering to strict hygienic standards. The sanitary standard certification guarantees compliance with global sanitary requirements, making these spacers suitable for industries that require contamination-free environments.

Key Features of EHEDG Hygienic Welded Spacers:

- Material: Made from high-grade stainless steel, typically AISI 304 or AISI 316, to resist corrosion and withstand harsh cleaning procedures.

- Welded Design: Seamless and smooth surfaces prevent the accumulation of dirt, bacteria, and other contaminants.

- Easy-to-Clean: Designed according to EHEDG guidelines for maximum cleanability, reducing downtime and enhancing productivity.

- Durability: Engineered to withstand extreme temperatures, chemical exposure, and mechanical stress.

Applications of EHEDG Hygienic Welded Spacers

EHEDG Hygienic welded spacers find applications across various industries where hygiene and durability are non-negotiable.

Food Processing Industry

From dairy plants to bakeries, these spacers ensure machinery components remain hygienically spaced, reducing the risk of contamination. They are ideal for environments where frequent cleaning and sanitation are required.

Pharmaceutical Industry

In pharmaceutical production, these spacers help maintain sterile conditions in equipment such as reactors, mixers, and packaging systems. Their stainless steel construction ensures compatibility with cleanroom environments and harsh sterilization methods.

Beverage Industry

For bottling and filling lines, EHEDG Hygienic welded spacers are used to maintain alignment in conveyor systems and other machinery. Their robust design withstands exposure to liquids, carbonation, and cleaning agents.

Biotechnology Industry

In biotechnology, where precision and cleanliness are paramount, these spacers support the operation of sensitive equipment like bioreactors and filtration systems.

Benefits of EHEDG Hygienic Welded Spacers

1. Unmatched Hygiene Standards

The EHEDG and sanitary standard certifications guarantee that these spacers meet global sanitary standards, providing peace of mind for industries where hygiene is a priority.

2. Long-Lasting Durability

Made from corrosion-resistant stainless steel, these spacers deliver long service life, even in challenging environments involving high temperatures and aggressive cleaning chemicals.

3. Cost-Efficiency

The high durability and minimal maintenance requirements of these spacers reduce operational costs in the long run.

4. Improved Operational Efficiency

The easy-to-clean design ensures quicker cleaning cycles, leading to reduced downtime and higher productivity.

Compliance and Certification

EHEDG Hygienic welded spacers are rigorously tested to meet both EHEDG and sanitary standards. These certifications ensure that the spacers are designed for cleanability and are compatible with CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems.

Optimizing Hygiene with EHEDG Hygienic Welded Spacers in Stainless Steel

EHEDG Hygienic welded spacers in stainless steel are an essential component for industries that demand the highest standards of hygiene and durability. Their innovative design, superior materials, and global certifications make them a reliable choice for enhancing cleanliness, efficiency, and compliance in industrial applications.

These components are perfect for food, beverage, and pharmaceutical industries.

By incorporating these welded spacers into your systems, you ensure not only optimal performance but also adherence to the most stringent hygiene standards, protecting both your products and your brand reputation.

See our durable in Extreme Conditions products line here