Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

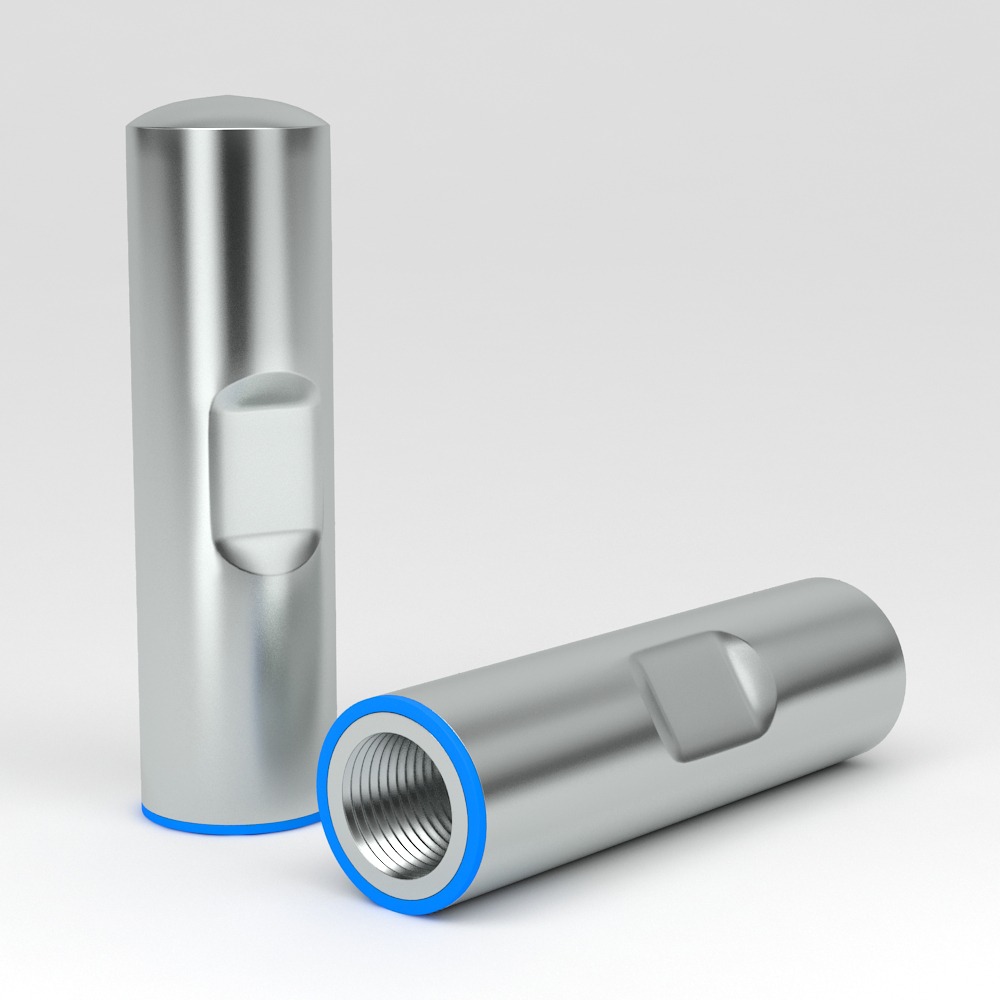

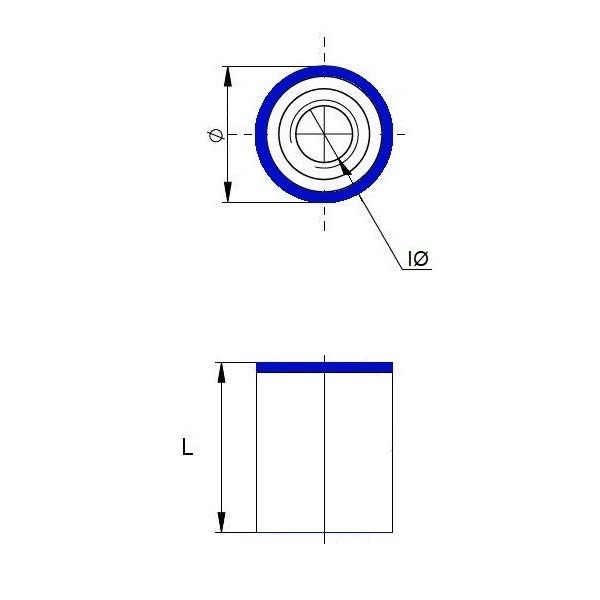

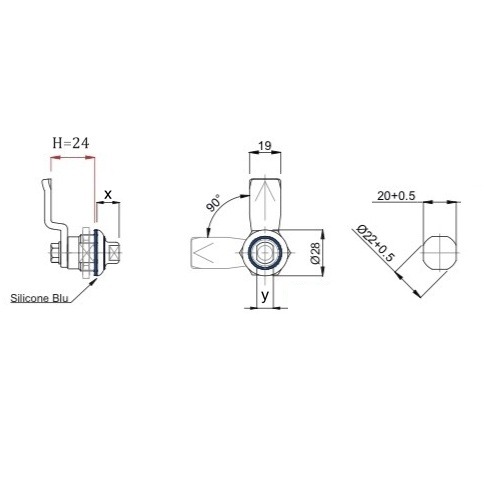

EHEDG Hygienic spindle top cover in stainless steel

Meets rigorous hygiene and environmental standards

The EHEDG Hygienic spindle top cover in stainless steel is designed to meet the highest standards in hygienic environments, particularly in industries like food, pharmaceuticals, and biotechnology. Engineered with precision, this top cover ensures easy cleanability while preventing contamination, crucial for maintaining sanitation during processing.

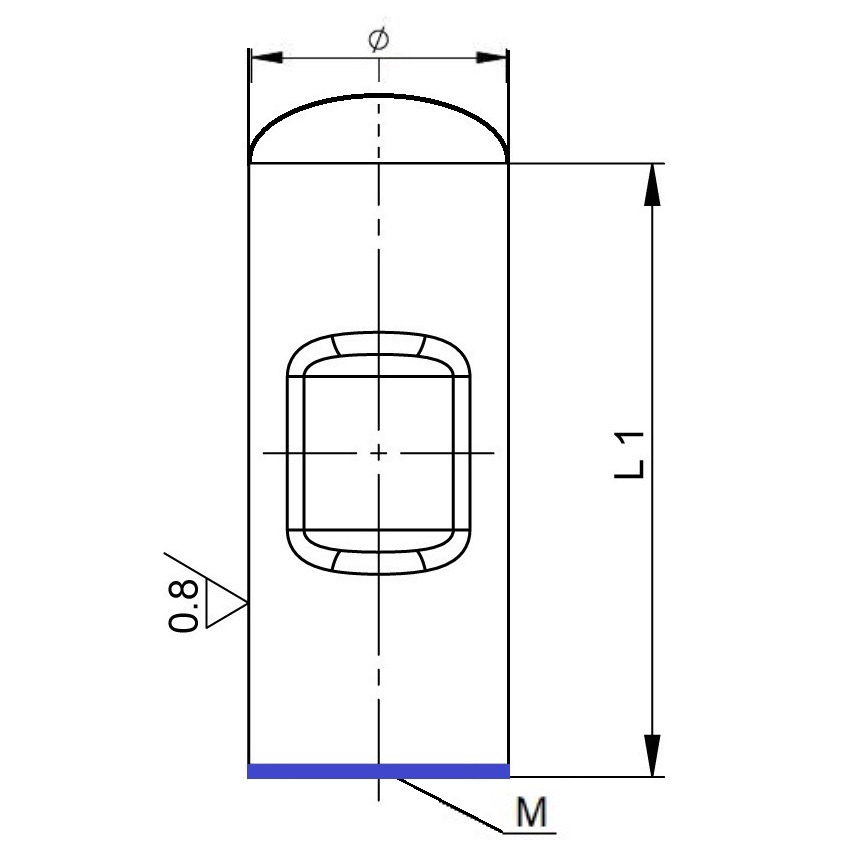

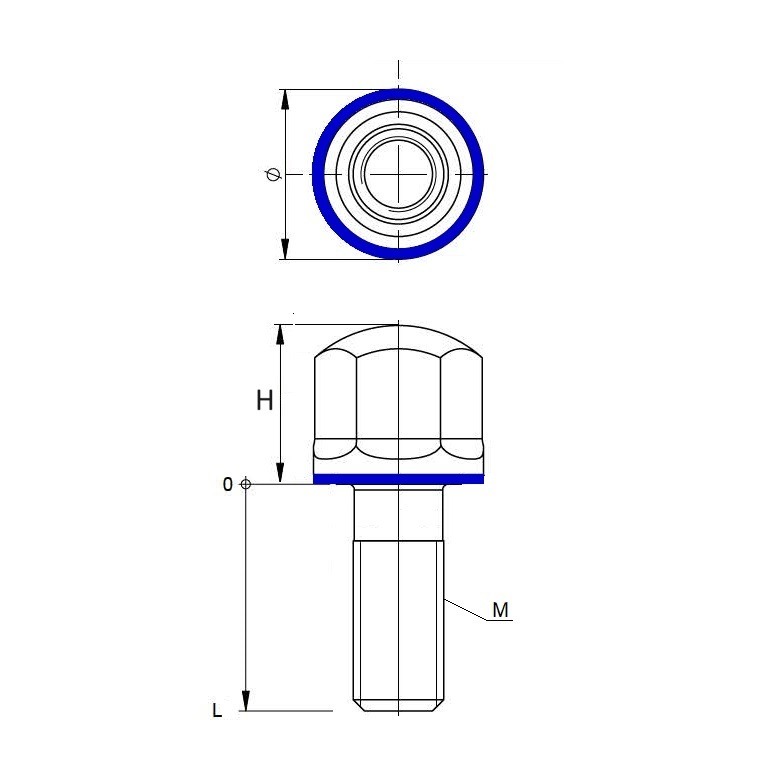

EHEDG Hygienic spindle top cover

| Spindle top cover 3A M12-L50 |

| Spindle top cover 3A M12-L70 |

| Spindle top cover 3A M12-L90 |

| Spindle top cover 3A M12-L110 |

| Spindle top cover 3A M16-L50 |

| Spindle top cover 3A M16-L70 |

| Spindle top cover 3A M16-L90 |

| Spindle top cover 3A M16-L110 |

| Spindle top cover 3A M20-L50 |

| Spindle top cover 3A M20-L70 |

| Spindle top cover 3A M20-L90 |

| Spindle top cover 3A M20-L110 |

| Spindle top cover 3A M24-L50 |

| Spindle top cover 3A M24-L70 |

| Spindle top cover 3A M24-L90 |

| Spindle top cover 3A M24-L110 |

| Spindle top cover 3A M30-L50 |

| Spindle top cover 3A M30-L70 |

| Spindle top cover 3A M30-L90 |

| Spindle top cover 3A M30-L110 |

| Spindle top cover 3A M36-L50 |

| Spindle top cover 3A M36-L70 |

| Spindle top cover 3A M36-L90 |

| Spindle top cover 3A M36-L110 |

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

A Standard for Cleanability

Revolutionizing Hygiene Standards

Crafted from high-grade stainless steel, the EHEDG Hygienic spindle top cover adheres to EHEDG (European Hygienic Engineering & Design Group) guidelines, promoting hygienic design and safe food production. Its robust stainless steel construction offers superior corrosion resistance, ideal for use in extreme conditions where frequent cleaning is required.

EHEDG Hygienic spindle top cover which also meets sanitary standards, ensuring it aligns with global industry requirements. The smooth surface design prevents the buildup of bacteria and contaminants, while its durability ensures long-lasting performance in high-pressure cleaning environments.

For industries that prioritize hygiene, the EHEDG Hygienic spindle top cover in stainless steel is a crucial component. It helps maintain compliance with strict hygiene regulations while enhancing the overall safety and efficiency of processing lines.

See our easy to clean products line here

Contact us for hygienic solution

EHEDG Hygienic Spindle Top Cover: A Game-Changer in Hygiene Standards

In industries where hygiene is paramount, such as food processing, pharmaceuticals, and biotechnology, every component plays a critical role in maintaining cleanliness and safety. The EHEDG Hygienic spindle top cover, crafted from high-quality stainless steel, has emerged as an essential component for ensuring optimal hygiene and compliance with stringent industry standards.

Why Stainless Steel is the Preferred Material

1. Superior Corrosion Resistance

Stainless steel is renowned for its excellent resistance to corrosion, making it ideal for environments exposed to moisture, chemicals, and extreme temperatures. This ensures that the EHEDG Hygienic spindle top cover remains durable and maintains its structural integrity over time.

2. Easy-to-Clean Surface

The smooth, non-porous surface of stainless steel facilitates easy cleaning and prevents the buildup of contaminants. This is particularly critical in food and pharmaceutical processing, where residue can compromise product safety.

3. Longevity and Sustainability

Stainless steel is not only long-lasting but also recyclable, making it an environmentally friendly choice. Its durability reduces the need for frequent replacements, lowering operational costs.

Features of the EHEDG Hygienic Spindle Top Cover

Certified Hygienic Design

The EHEDG (European Hygienic Engineering & Design Group) and sanitary standard certification guarantee that the spindle top cover meets the highest standards of hygiene. These certifications ensure compliance with industry regulations, minimizing the risk of contamination.

Seamless Construction

The seamless design eliminates crevices where bacteria and other contaminants could hide, making it exceptionally easy to clean and sanitize. This feature is especially important in industries requiring aseptic conditions.

Resistance to Harsh Cleaning Agents

Designed to withstand aggressive cleaning procedures, including high-pressure washing and the use of strong detergents, the EHEDG Hygienic spindle top cover ensures consistent performance without degradation.

Universal Compatibility

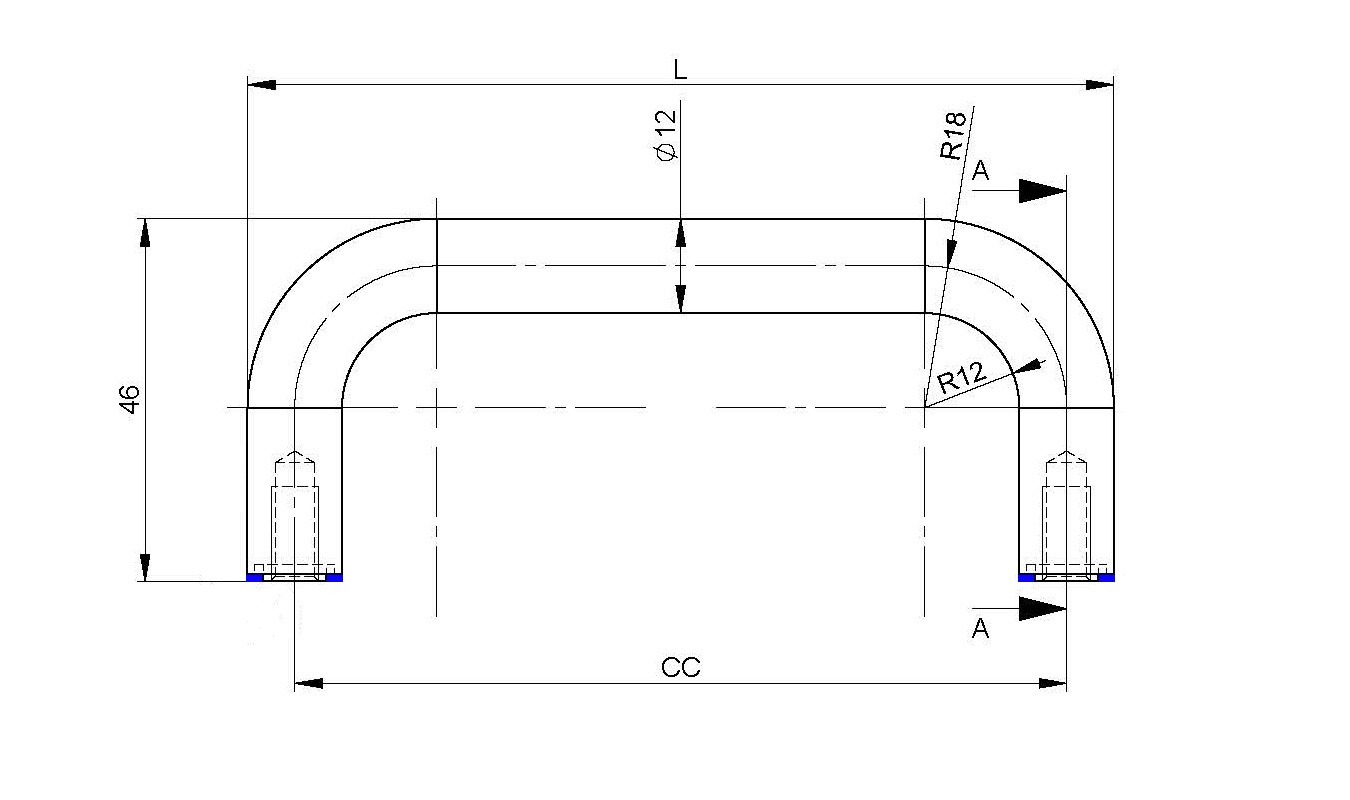

This spindle top cover is compatible with various types of equipment, making it a versatile solution for manufacturers seeking to upgrade their existing systems to meet modern hygienic requirements.

Applications Across Industries

1. Food Processing

From dairy to confectionery, the EHEDG Hygienic spindle top cover is essential for maintaining hygiene during production. Its robust design ensures compliance with food safety standards, protecting both consumers and brands.

2. Pharmaceutical Industry

In pharmaceutical manufacturing, where precision and sterility are non-negotiable, this spindle top cover prevents contamination and supports cleanroom requirements.

3. Biotechnology

The biotechnology industry often involves the handling of sensitive materials. The spindle top cover’s hygienic design ensures that operations remain safe and compliant, even in complex processes.

Benefits of Implementing the EHEDG Hygienic Spindle Top Cover

Enhanced Product Safety

By minimizing contamination risks, this spindle top cover helps manufacturers deliver safer products, boosting consumer trust and loyalty.

Regulatory Compliance

Adhering to EHEDG and Sanitary standards reduces the risk of regulatory penalties and ensures smooth operation in global markets.

Increased Operational Efficiency

The easy-to-clean design reduces downtime for maintenance and cleaning, allowing production lines to run more efficiently.

The Future of Hygienic Components

As industries continue to prioritize hygiene, the demand for certified components like the EHEDG Hygienic spindle top cover will only grow. Its stainless steel construction, innovative design, and unparalleled performance make it a cornerstone of hygienic engineering.

Investing in such components not only ensures compliance but also underscores a commitment to quality, safety, and sustainability—values that resonate with consumers and stakeholders alike.

By choosing the EHEDG Hygienic spindle top cover, businesses can enhance their competitive edge while contributing to a cleaner, safer future for their industries.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Meets rigorous hygiene and environmental standards

The EHEDG Hygienic spindle top cover in stainless steel is designed to meet the highest standards in hygienic environments, particularly in industries like food, pharmaceuticals, and biotechnology. Engineered with precision, this top cover ensures easy cleanability while preventing contamination, crucial for maintaining sanitation during processing.

EHEDG Hygienic spindle top cover

| Spindle top cover 3A M12-L50 |

| Spindle top cover 3A M12-L70 |

| Spindle top cover 3A M12-L90 |

| Spindle top cover 3A M12-L110 |

| Spindle top cover 3A M16-L50 |

| Spindle top cover 3A M16-L70 |

| Spindle top cover 3A M16-L90 |

| Spindle top cover 3A M16-L110 |

| Spindle top cover 3A M20-L50 |

| Spindle top cover 3A M20-L70 |

| Spindle top cover 3A M20-L90 |

| Spindle top cover 3A M20-L110 |

| Spindle top cover 3A M24-L50 |

| Spindle top cover 3A M24-L70 |

| Spindle top cover 3A M24-L90 |

| Spindle top cover 3A M24-L110 |

| Spindle top cover 3A M30-L50 |

| Spindle top cover 3A M30-L70 |

| Spindle top cover 3A M30-L90 |

| Spindle top cover 3A M30-L110 |

| Spindle top cover 3A M36-L50 |

| Spindle top cover 3A M36-L70 |

| Spindle top cover 3A M36-L90 |

| Spindle top cover 3A M36-L110 |

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

A Standard for Cleanability

Revolutionizing Hygiene Standards

Crafted from high-grade stainless steel, the EHEDG Hygienic spindle top cover adheres to EHEDG (European Hygienic Engineering & Design Group) guidelines, promoting hygienic design and safe food production. Its robust stainless steel construction offers superior corrosion resistance, ideal for use in extreme conditions where frequent cleaning is required.

EHEDG Hygienic spindle top cover which also meets sanitary standards, ensuring it aligns with global industry requirements. The smooth surface design prevents the buildup of bacteria and contaminants, while its durability ensures long-lasting performance in high-pressure cleaning environments.

For industries that prioritize hygiene, the EHEDG Hygienic spindle top cover in stainless steel is a crucial component. It helps maintain compliance with strict hygiene regulations while enhancing the overall safety and efficiency of processing lines.

See our easy to clean products line here

Contact us for hygienic solution

EHEDG Hygienic Spindle Top Cover: A Game-Changer in Hygiene Standards

In industries where hygiene is paramount, such as food processing, pharmaceuticals, and biotechnology, every component plays a critical role in maintaining cleanliness and safety. The EHEDG Hygienic spindle top cover, crafted from high-quality stainless steel, has emerged as an essential component for ensuring optimal hygiene and compliance with stringent industry standards.

Why Stainless Steel is the Preferred Material

1. Superior Corrosion Resistance

Stainless steel is renowned for its excellent resistance to corrosion, making it ideal for environments exposed to moisture, chemicals, and extreme temperatures. This ensures that the EHEDG Hygienic spindle top cover remains durable and maintains its structural integrity over time.

2. Easy-to-Clean Surface

The smooth, non-porous surface of stainless steel facilitates easy cleaning and prevents the buildup of contaminants. This is particularly critical in food and pharmaceutical processing, where residue can compromise product safety.

3. Longevity and Sustainability

Stainless steel is not only long-lasting but also recyclable, making it an environmentally friendly choice. Its durability reduces the need for frequent replacements, lowering operational costs.

Features of the EHEDG Hygienic Spindle Top Cover

Certified Hygienic Design

The EHEDG (European Hygienic Engineering & Design Group) and sanitary standard certification guarantee that the spindle top cover meets the highest standards of hygiene. These certifications ensure compliance with industry regulations, minimizing the risk of contamination.

Seamless Construction

The seamless design eliminates crevices where bacteria and other contaminants could hide, making it exceptionally easy to clean and sanitize. This feature is especially important in industries requiring aseptic conditions.

Resistance to Harsh Cleaning Agents

Designed to withstand aggressive cleaning procedures, including high-pressure washing and the use of strong detergents, the EHEDG Hygienic spindle top cover ensures consistent performance without degradation.

Universal Compatibility

This spindle top cover is compatible with various types of equipment, making it a versatile solution for manufacturers seeking to upgrade their existing systems to meet modern hygienic requirements.

Applications Across Industries

1. Food Processing

From dairy to confectionery, the EHEDG Hygienic spindle top cover is essential for maintaining hygiene during production. Its robust design ensures compliance with food safety standards, protecting both consumers and brands.

2. Pharmaceutical Industry

In pharmaceutical manufacturing, where precision and sterility are non-negotiable, this spindle top cover prevents contamination and supports cleanroom requirements.

3. Biotechnology

The biotechnology industry often involves the handling of sensitive materials. The spindle top cover’s hygienic design ensures that operations remain safe and compliant, even in complex processes.

Benefits of Implementing the EHEDG Hygienic Spindle Top Cover

Enhanced Product Safety

By minimizing contamination risks, this spindle top cover helps manufacturers deliver safer products, boosting consumer trust and loyalty.

Regulatory Compliance

Adhering to EHEDG and Sanitary standards reduces the risk of regulatory penalties and ensures smooth operation in global markets.

Increased Operational Efficiency

The easy-to-clean design reduces downtime for maintenance and cleaning, allowing production lines to run more efficiently.

The Future of Hygienic Components

As industries continue to prioritize hygiene, the demand for certified components like the EHEDG Hygienic spindle top cover will only grow. Its stainless steel construction, innovative design, and unparalleled performance make it a cornerstone of hygienic engineering.

Investing in such components not only ensures compliance but also underscores a commitment to quality, safety, and sustainability—values that resonate with consumers and stakeholders alike.

By choosing the EHEDG Hygienic spindle top cover, businesses can enhance their competitive edge while contributing to a cleaner, safer future for their industries.

Meets rigorous hygiene and environmental standards

The EHEDG Hygienic spindle top cover in stainless steel is designed to meet the highest standards in hygienic environments, particularly in industries like food, pharmaceuticals, and biotechnology. Engineered with precision, this top cover ensures easy cleanability while preventing contamination, crucial for maintaining sanitation during processing.

EHEDG Hygienic spindle top cover

| Spindle top cover 3A M12-L50 |

| Spindle top cover 3A M12-L70 |

| Spindle top cover 3A M12-L90 |

| Spindle top cover 3A M12-L110 |

| Spindle top cover 3A M16-L50 |

| Spindle top cover 3A M16-L70 |

| Spindle top cover 3A M16-L90 |

| Spindle top cover 3A M16-L110 |

| Spindle top cover 3A M20-L50 |

| Spindle top cover 3A M20-L70 |

| Spindle top cover 3A M20-L90 |

| Spindle top cover 3A M20-L110 |

| Spindle top cover 3A M24-L50 |

| Spindle top cover 3A M24-L70 |

| Spindle top cover 3A M24-L90 |

| Spindle top cover 3A M24-L110 |

| Spindle top cover 3A M30-L50 |

| Spindle top cover 3A M30-L70 |

| Spindle top cover 3A M30-L90 |

| Spindle top cover 3A M30-L110 |

| Spindle top cover 3A M36-L50 |

| Spindle top cover 3A M36-L70 |

| Spindle top cover 3A M36-L90 |

| Spindle top cover 3A M36-L110 |

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

A Standard for Cleanability

Revolutionizing Hygiene Standards

Crafted from high-grade stainless steel, the EHEDG Hygienic spindle top cover adheres to EHEDG (European Hygienic Engineering & Design Group) guidelines, promoting hygienic design and safe food production. Its robust stainless steel construction offers superior corrosion resistance, ideal for use in extreme conditions where frequent cleaning is required.

EHEDG Hygienic spindle top cover which also meets sanitary standards, ensuring it aligns with global industry requirements. The smooth surface design prevents the buildup of bacteria and contaminants, while its durability ensures long-lasting performance in high-pressure cleaning environments.

For industries that prioritize hygiene, the EHEDG Hygienic spindle top cover in stainless steel is a crucial component. It helps maintain compliance with strict hygiene regulations while enhancing the overall safety and efficiency of processing lines.

See our easy to clean products line here

Contact us for hygienic solution

EHEDG Hygienic Spindle Top Cover: A Game-Changer in Hygiene Standards

In industries where hygiene is paramount, such as food processing, pharmaceuticals, and biotechnology, every component plays a critical role in maintaining cleanliness and safety. The EHEDG Hygienic spindle top cover, crafted from high-quality stainless steel, has emerged as an essential component for ensuring optimal hygiene and compliance with stringent industry standards.

Why Stainless Steel is the Preferred Material

1. Superior Corrosion Resistance

Stainless steel is renowned for its excellent resistance to corrosion, making it ideal for environments exposed to moisture, chemicals, and extreme temperatures. This ensures that the EHEDG Hygienic spindle top cover remains durable and maintains its structural integrity over time.

2. Easy-to-Clean Surface

The smooth, non-porous surface of stainless steel facilitates easy cleaning and prevents the buildup of contaminants. This is particularly critical in food and pharmaceutical processing, where residue can compromise product safety.

3. Longevity and Sustainability

Stainless steel is not only long-lasting but also recyclable, making it an environmentally friendly choice. Its durability reduces the need for frequent replacements, lowering operational costs.

Features of the EHEDG Hygienic Spindle Top Cover

Certified Hygienic Design

The EHEDG (European Hygienic Engineering & Design Group) and sanitary standard certification guarantee that the spindle top cover meets the highest standards of hygiene. These certifications ensure compliance with industry regulations, minimizing the risk of contamination.

Seamless Construction

The seamless design eliminates crevices where bacteria and other contaminants could hide, making it exceptionally easy to clean and sanitize. This feature is especially important in industries requiring aseptic conditions.

Resistance to Harsh Cleaning Agents

Designed to withstand aggressive cleaning procedures, including high-pressure washing and the use of strong detergents, the EHEDG Hygienic spindle top cover ensures consistent performance without degradation.

Universal Compatibility

This spindle top cover is compatible with various types of equipment, making it a versatile solution for manufacturers seeking to upgrade their existing systems to meet modern hygienic requirements.

Applications Across Industries

1. Food Processing

From dairy to confectionery, the EHEDG Hygienic spindle top cover is essential for maintaining hygiene during production. Its robust design ensures compliance with food safety standards, protecting both consumers and brands.

2. Pharmaceutical Industry

In pharmaceutical manufacturing, where precision and sterility are non-negotiable, this spindle top cover prevents contamination and supports cleanroom requirements.

3. Biotechnology

The biotechnology industry often involves the handling of sensitive materials. The spindle top cover’s hygienic design ensures that operations remain safe and compliant, even in complex processes.

Benefits of Implementing the EHEDG Hygienic Spindle Top Cover

Enhanced Product Safety

By minimizing contamination risks, this spindle top cover helps manufacturers deliver safer products, boosting consumer trust and loyalty.

Regulatory Compliance

Adhering to EHEDG and Sanitary standards reduces the risk of regulatory penalties and ensures smooth operation in global markets.

Increased Operational Efficiency

The easy-to-clean design reduces downtime for maintenance and cleaning, allowing production lines to run more efficiently.

The Future of Hygienic Components

As industries continue to prioritize hygiene, the demand for certified components like the EHEDG Hygienic spindle top cover will only grow. Its stainless steel construction, innovative design, and unparalleled performance make it a cornerstone of hygienic engineering.

Investing in such components not only ensures compliance but also underscores a commitment to quality, safety, and sustainability—values that resonate with consumers and stakeholders alike.

By choosing the EHEDG Hygienic spindle top cover, businesses can enhance their competitive edge while contributing to a cleaner, safer future for their industries.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.