Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

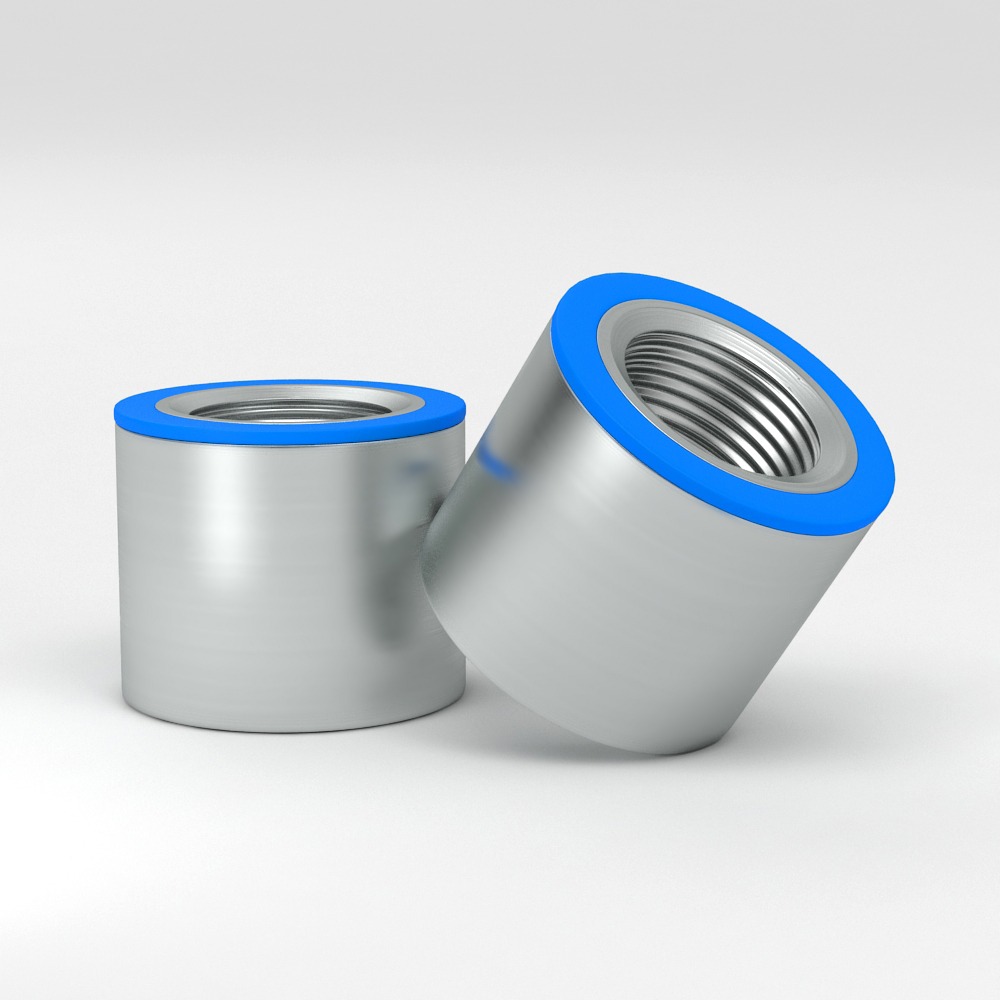

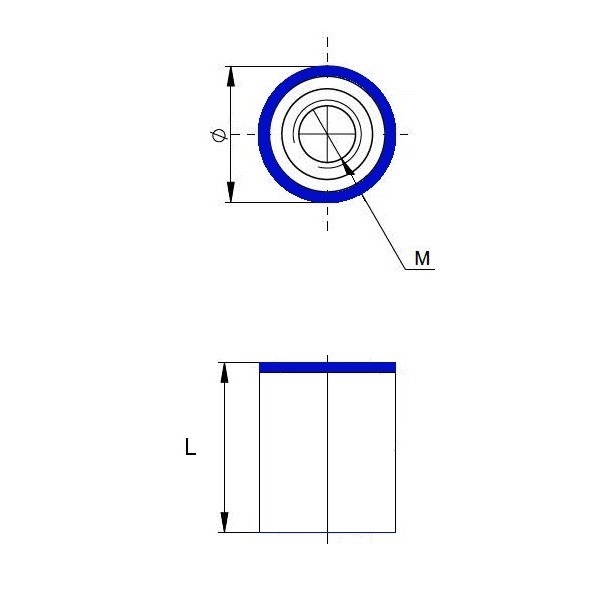

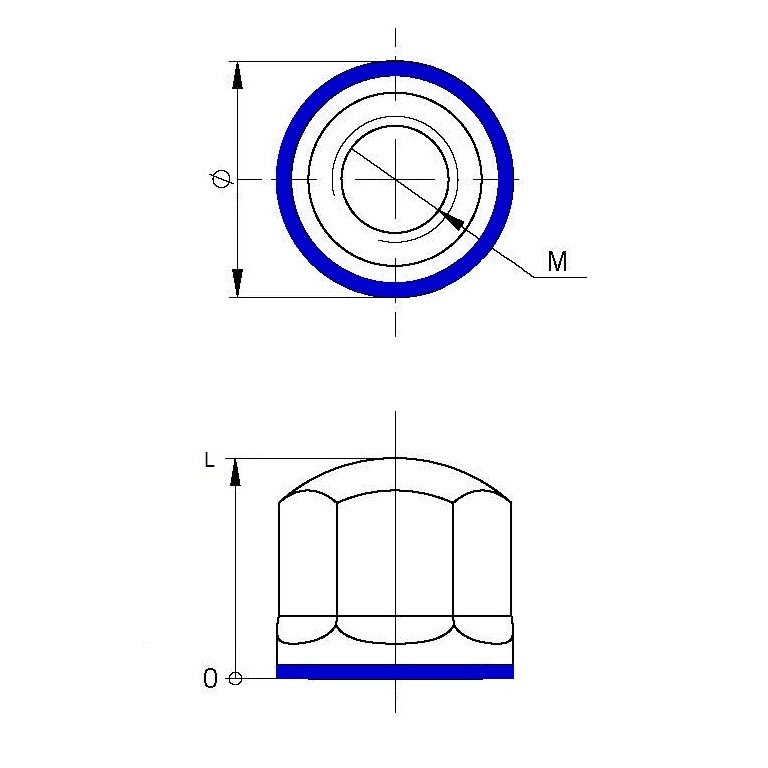

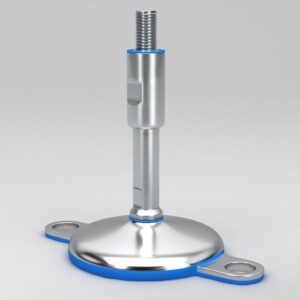

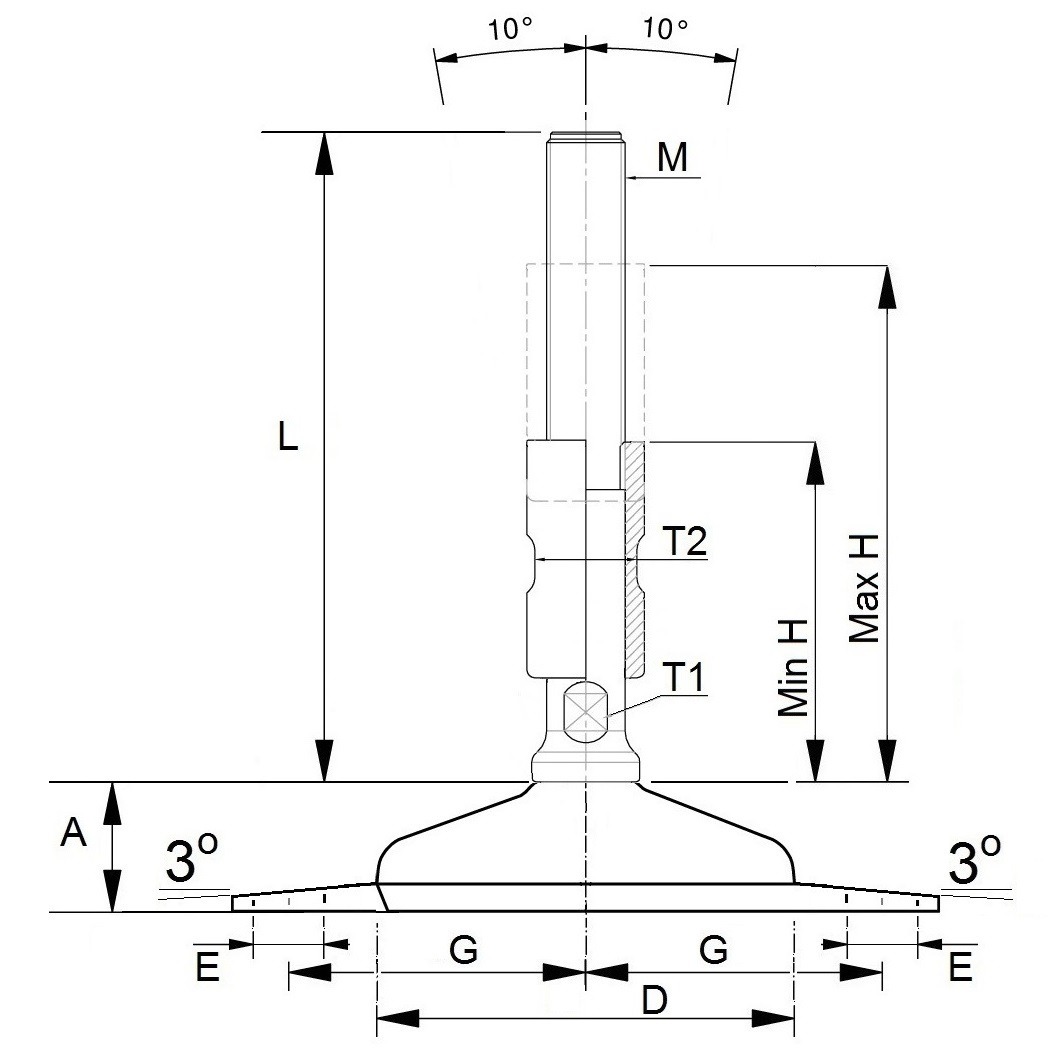

EHEDG-certified spacer nut welded

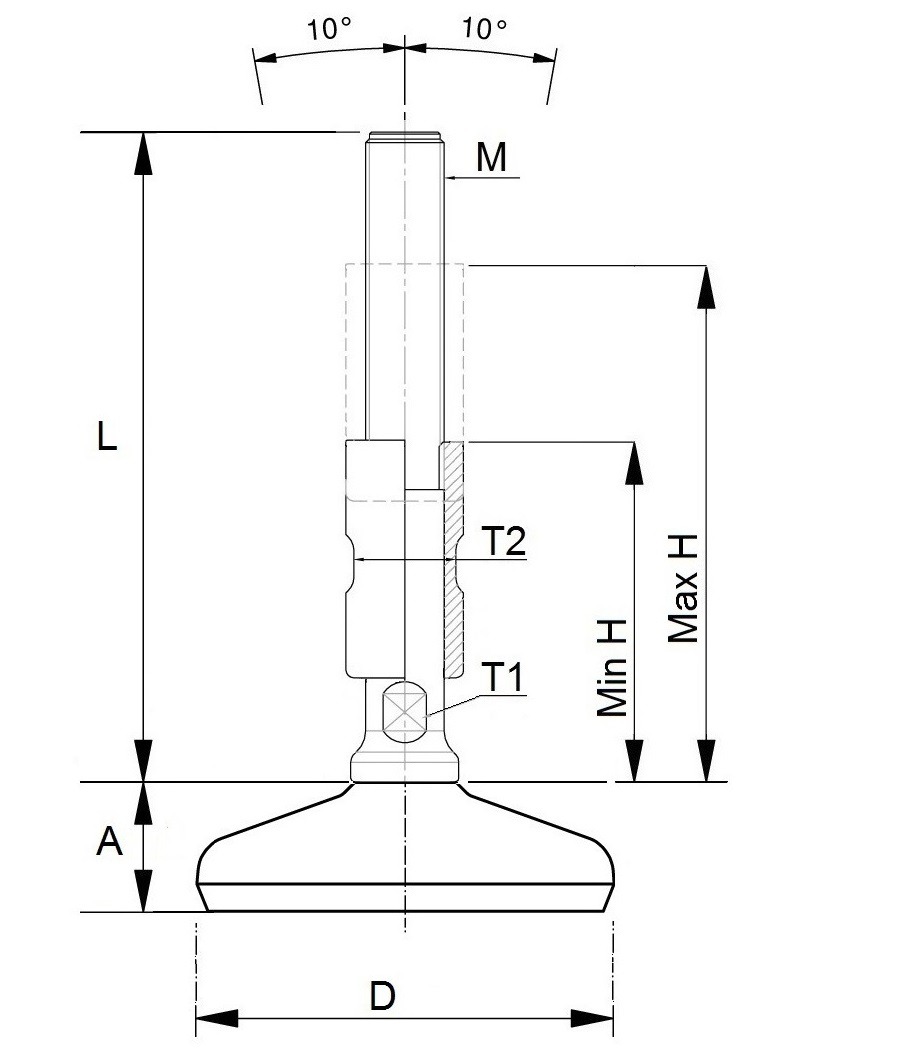

A Critical Component for Sanitary Machinery

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

EHEDG Hygienic spacer nut weld

3A SNW M5-L10 Ø12

3A SNW M5-L20 Ø12

3A SNW M5-L30 Ø12

3A SNW M6-L10 Ø12

3A SNW M6-L20 Ø12

3A SNW M6-L30 Ø12

3A SNW M8-L10 Ø15

3A SNW M8-L20 Ø15

3A SNW M8-L30 Ø15

3A SNW M10-L10 Ø20

3A SNW M10-L20 Ø20

3A SNW M10-L30 Ø20

3A SNW M12-L10 Ø22

3A SNW M12-L20 Ø22

3A SNW M12-L30 Ø22

3A SNW M16-L10 Ø28

3A SNW M16-L20 Ø28

3A SNW M16-L30 Ø28

3A SNW M20-L10 Ø32

3A SNW M20-L20 Ø32

3A SNW M20-L30 Ø32

3A SNW M24-L20 Ø36

3A SNW M24-L30 Ø36

3A SNW M24-L40 Ø36

3A SNW M30-L20 Ø46

3A SNW M30-L30 Ø46

3A SNW M30-L40 Ø46

See our products which reduce downtime and maintenance costs here

Contact us for hygienic solution

EHEDG Hygienic Spacer Nut Welded in Stainless Steel

The Essential Component for Sanitary Machinery

In industries such as food processing, pharmaceuticals, and biotechnology, maintaining strict hygiene standards is paramount. This is where EHEDG (European Hygienic Engineering & Design Group) and Sanitary Standards certified components come into play. Among these components, the EHEDG Hygienic spacer nut welded in stainless steel stands out as a crucial element for ensuring sanitary conditions and reliable machine performance.

What Is an EHEDG Hygienic Spacer Nut?

An EHEDG Hygienic spacer nut welded in stainless steel is a specialized component used to secure parts in machinery while meeting stringent hygiene standards. These spacer nuts are welded directly into the machinery framework, preventing the accumulation of bacteria, dirt, and other contaminants. Their hygienic design makes them ideal for use in environments that require rigorous cleanliness, such as food and beverage production lines, pharmaceutical manufacturing, and biotech facilities.

EHEDG and Sanitary Standards certifications ensure that these spacer nuts meet high hygiene and safety standards. The key feature of these spacer nuts is their smooth, crevice-free surfaces, which are designed to minimize places where bacteria can hide, making them easy to clean and maintain.

Benefits of EHEDG Hygienic Spacer Nuts

1. Hygienic Design

The primary advantage of the EHEDG Hygienic spacer nut is its hygienic design. The smooth, welded surface ensures that no grooves or crevices are present where food particles or bacteria can collect. This reduces the risk of contamination, which is crucial for industries like food processing, where cross-contamination can compromise product quality and safety.

2. Corrosion Resistance

Made from high-quality stainless steel, these spacer nuts offer excellent corrosion resistance. Stainless steel is known for its durability, making it the perfect material for machinery used in harsh environments like high-moisture food production lines or areas exposed to chemicals in pharmaceutical and biotech applications. This resistance helps ensure the longevity of the component, reducing the need for frequent replacements.

3. Ease of Cleaning and Maintenance

Given the importance of cleanliness in hygienic industries, the design of the spacer nut plays a key role in ensuring easy cleaning. Since these nuts have no gaps or threads that could trap dirt, they are simple to wash and disinfect, aligning with the strict hygiene protocols required in food processing, pharmaceuticals, and biotechnology.

4. Compliance with Industry Standards

EHEDG and Sanitary Standards certifications provide assurance that the spacer nuts meet the highest hygiene and safety standards. These certifications are globally recognized and help businesses comply with regulatory requirements, ensuring that machinery components are suitable for use in sanitary environments.

5. Versatility Across Industries

Although the EHEDG Hygienic spacer nut welded in stainless steel is most commonly used in food processing, it is also essential in other sectors, such as pharmaceuticals, biotechnology, and personal care. These spacer nuts are used in a wide range of equipment, from conveyors to mixers and packaging systems.

Applications in Key Industries

Food Processing

In food processing, ensuring the safety and quality of products is of utmost importance. EHEDG Hygienic spacer nuts help prevent contamination during manufacturing processes by providing a secure, easy-to-clean solution for machinery components. Whether it’s used in beverage production lines, dairy processing, or confectionery manufacturing, these spacer nuts contribute to a safe and hygienic environment.

Pharmaceutical and Biotech Industries

The pharmaceutical and biotech industries face strict regulations concerning equipment cleanliness. EHEDG Hygienic spacer nuts meet these standards, making them ideal for use in the production of medicines, vaccines, and laboratory equipment. They provide the reliability and sanitation required in these sensitive environments.

Personal Care and Household Products

In the production of personal care products such as shampoos, lotions, and cosmetics, maintaining cleanliness is crucial. EHEDG Hygienic spacer nuts help ensure that manufacturing machinery operates within the necessary hygiene standards, minimizing the risk of contamination and ensuring high-quality output.

Ensuring Long-term cost savings and improve competitive edge

The EHEDG Hygienic spacer nut welded in stainless steel is an indispensable component for industries that require high levels of hygiene and sanitation. Its hygienic design, corrosion resistance, and ease of maintenance make it a crucial part of machinery used in food processing, pharmaceuticals, biotechnology, and more. By using these certified components, companies can ensure their equipment meets global hygiene standards and contributes to safe and efficient manufacturing processes.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

A Critical Component for Sanitary Machinery

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

EHEDG Hygienic spacer nut weld

3A SNW M5-L10 Ø12

3A SNW M5-L20 Ø12

3A SNW M5-L30 Ø12

3A SNW M6-L10 Ø12

3A SNW M6-L20 Ø12

3A SNW M6-L30 Ø12

3A SNW M8-L10 Ø15

3A SNW M8-L20 Ø15

3A SNW M8-L30 Ø15

3A SNW M10-L10 Ø20

3A SNW M10-L20 Ø20

3A SNW M10-L30 Ø20

3A SNW M12-L10 Ø22

3A SNW M12-L20 Ø22

3A SNW M12-L30 Ø22

3A SNW M16-L10 Ø28

3A SNW M16-L20 Ø28

3A SNW M16-L30 Ø28

3A SNW M20-L10 Ø32

3A SNW M20-L20 Ø32

3A SNW M20-L30 Ø32

3A SNW M24-L20 Ø36

3A SNW M24-L30 Ø36

3A SNW M24-L40 Ø36

3A SNW M30-L20 Ø46

3A SNW M30-L30 Ø46

3A SNW M30-L40 Ø46

See our products which reduce downtime and maintenance costs here

Contact us for hygienic solution

EHEDG Hygienic Spacer Nut Welded in Stainless Steel

The Essential Component for Sanitary Machinery

In industries such as food processing, pharmaceuticals, and biotechnology, maintaining strict hygiene standards is paramount. This is where EHEDG (European Hygienic Engineering & Design Group) and Sanitary Standards certified components come into play. Among these components, the EHEDG Hygienic spacer nut welded in stainless steel stands out as a crucial element for ensuring sanitary conditions and reliable machine performance.

What Is an EHEDG Hygienic Spacer Nut?

An EHEDG Hygienic spacer nut welded in stainless steel is a specialized component used to secure parts in machinery while meeting stringent hygiene standards. These spacer nuts are welded directly into the machinery framework, preventing the accumulation of bacteria, dirt, and other contaminants. Their hygienic design makes them ideal for use in environments that require rigorous cleanliness, such as food and beverage production lines, pharmaceutical manufacturing, and biotech facilities.

EHEDG and Sanitary Standards certifications ensure that these spacer nuts meet high hygiene and safety standards. The key feature of these spacer nuts is their smooth, crevice-free surfaces, which are designed to minimize places where bacteria can hide, making them easy to clean and maintain.

Benefits of EHEDG Hygienic Spacer Nuts

1. Hygienic Design

The primary advantage of the EHEDG Hygienic spacer nut is its hygienic design. The smooth, welded surface ensures that no grooves or crevices are present where food particles or bacteria can collect. This reduces the risk of contamination, which is crucial for industries like food processing, where cross-contamination can compromise product quality and safety.

2. Corrosion Resistance

Made from high-quality stainless steel, these spacer nuts offer excellent corrosion resistance. Stainless steel is known for its durability, making it the perfect material for machinery used in harsh environments like high-moisture food production lines or areas exposed to chemicals in pharmaceutical and biotech applications. This resistance helps ensure the longevity of the component, reducing the need for frequent replacements.

3. Ease of Cleaning and Maintenance

Given the importance of cleanliness in hygienic industries, the design of the spacer nut plays a key role in ensuring easy cleaning. Since these nuts have no gaps or threads that could trap dirt, they are simple to wash and disinfect, aligning with the strict hygiene protocols required in food processing, pharmaceuticals, and biotechnology.

4. Compliance with Industry Standards

EHEDG and Sanitary Standards certifications provide assurance that the spacer nuts meet the highest hygiene and safety standards. These certifications are globally recognized and help businesses comply with regulatory requirements, ensuring that machinery components are suitable for use in sanitary environments.

5. Versatility Across Industries

Although the EHEDG Hygienic spacer nut welded in stainless steel is most commonly used in food processing, it is also essential in other sectors, such as pharmaceuticals, biotechnology, and personal care. These spacer nuts are used in a wide range of equipment, from conveyors to mixers and packaging systems.

Applications in Key Industries

Food Processing

In food processing, ensuring the safety and quality of products is of utmost importance. EHEDG Hygienic spacer nuts help prevent contamination during manufacturing processes by providing a secure, easy-to-clean solution for machinery components. Whether it’s used in beverage production lines, dairy processing, or confectionery manufacturing, these spacer nuts contribute to a safe and hygienic environment.

Pharmaceutical and Biotech Industries

The pharmaceutical and biotech industries face strict regulations concerning equipment cleanliness. EHEDG Hygienic spacer nuts meet these standards, making them ideal for use in the production of medicines, vaccines, and laboratory equipment. They provide the reliability and sanitation required in these sensitive environments.

Personal Care and Household Products

In the production of personal care products such as shampoos, lotions, and cosmetics, maintaining cleanliness is crucial. EHEDG Hygienic spacer nuts help ensure that manufacturing machinery operates within the necessary hygiene standards, minimizing the risk of contamination and ensuring high-quality output.

Ensuring Long-term cost savings and improve competitive edge

The EHEDG Hygienic spacer nut welded in stainless steel is an indispensable component for industries that require high levels of hygiene and sanitation. Its hygienic design, corrosion resistance, and ease of maintenance make it a crucial part of machinery used in food processing, pharmaceuticals, biotechnology, and more. By using these certified components, companies can ensure their equipment meets global hygiene standards and contributes to safe and efficient manufacturing processes.

A Critical Component for Sanitary Machinery

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

EHEDG Hygienic spacer nut weld

3A SNW M5-L10 Ø12

3A SNW M5-L20 Ø12

3A SNW M5-L30 Ø12

3A SNW M6-L10 Ø12

3A SNW M6-L20 Ø12

3A SNW M6-L30 Ø12

3A SNW M8-L10 Ø15

3A SNW M8-L20 Ø15

3A SNW M8-L30 Ø15

3A SNW M10-L10 Ø20

3A SNW M10-L20 Ø20

3A SNW M10-L30 Ø20

3A SNW M12-L10 Ø22

3A SNW M12-L20 Ø22

3A SNW M12-L30 Ø22

3A SNW M16-L10 Ø28

3A SNW M16-L20 Ø28

3A SNW M16-L30 Ø28

3A SNW M20-L10 Ø32

3A SNW M20-L20 Ø32

3A SNW M20-L30 Ø32

3A SNW M24-L20 Ø36

3A SNW M24-L30 Ø36

3A SNW M24-L40 Ø36

3A SNW M30-L20 Ø46

3A SNW M30-L30 Ø46

3A SNW M30-L40 Ø46

See our products which reduce downtime and maintenance costs here

Contact us for hygienic solution

EHEDG Hygienic Spacer Nut Welded in Stainless Steel

The Essential Component for Sanitary Machinery

In industries such as food processing, pharmaceuticals, and biotechnology, maintaining strict hygiene standards is paramount. This is where EHEDG (European Hygienic Engineering & Design Group) and Sanitary Standards certified components come into play. Among these components, the EHEDG Hygienic spacer nut welded in stainless steel stands out as a crucial element for ensuring sanitary conditions and reliable machine performance.

What Is an EHEDG Hygienic Spacer Nut?

An EHEDG Hygienic spacer nut welded in stainless steel is a specialized component used to secure parts in machinery while meeting stringent hygiene standards. These spacer nuts are welded directly into the machinery framework, preventing the accumulation of bacteria, dirt, and other contaminants. Their hygienic design makes them ideal for use in environments that require rigorous cleanliness, such as food and beverage production lines, pharmaceutical manufacturing, and biotech facilities.

EHEDG and Sanitary Standards certifications ensure that these spacer nuts meet high hygiene and safety standards. The key feature of these spacer nuts is their smooth, crevice-free surfaces, which are designed to minimize places where bacteria can hide, making them easy to clean and maintain.

Benefits of EHEDG Hygienic Spacer Nuts

1. Hygienic Design

The primary advantage of the EHEDG Hygienic spacer nut is its hygienic design. The smooth, welded surface ensures that no grooves or crevices are present where food particles or bacteria can collect. This reduces the risk of contamination, which is crucial for industries like food processing, where cross-contamination can compromise product quality and safety.

2. Corrosion Resistance

Made from high-quality stainless steel, these spacer nuts offer excellent corrosion resistance. Stainless steel is known for its durability, making it the perfect material for machinery used in harsh environments like high-moisture food production lines or areas exposed to chemicals in pharmaceutical and biotech applications. This resistance helps ensure the longevity of the component, reducing the need for frequent replacements.

3. Ease of Cleaning and Maintenance

Given the importance of cleanliness in hygienic industries, the design of the spacer nut plays a key role in ensuring easy cleaning. Since these nuts have no gaps or threads that could trap dirt, they are simple to wash and disinfect, aligning with the strict hygiene protocols required in food processing, pharmaceuticals, and biotechnology.

4. Compliance with Industry Standards

EHEDG and Sanitary Standards certifications provide assurance that the spacer nuts meet the highest hygiene and safety standards. These certifications are globally recognized and help businesses comply with regulatory requirements, ensuring that machinery components are suitable for use in sanitary environments.

5. Versatility Across Industries

Although the EHEDG Hygienic spacer nut welded in stainless steel is most commonly used in food processing, it is also essential in other sectors, such as pharmaceuticals, biotechnology, and personal care. These spacer nuts are used in a wide range of equipment, from conveyors to mixers and packaging systems.

Applications in Key Industries

Food Processing

In food processing, ensuring the safety and quality of products is of utmost importance. EHEDG Hygienic spacer nuts help prevent contamination during manufacturing processes by providing a secure, easy-to-clean solution for machinery components. Whether it’s used in beverage production lines, dairy processing, or confectionery manufacturing, these spacer nuts contribute to a safe and hygienic environment.

Pharmaceutical and Biotech Industries

The pharmaceutical and biotech industries face strict regulations concerning equipment cleanliness. EHEDG Hygienic spacer nuts meet these standards, making them ideal for use in the production of medicines, vaccines, and laboratory equipment. They provide the reliability and sanitation required in these sensitive environments.

Personal Care and Household Products

In the production of personal care products such as shampoos, lotions, and cosmetics, maintaining cleanliness is crucial. EHEDG Hygienic spacer nuts help ensure that manufacturing machinery operates within the necessary hygiene standards, minimizing the risk of contamination and ensuring high-quality output.

Ensuring Long-term cost savings and improve competitive edge

The EHEDG Hygienic spacer nut welded in stainless steel is an indispensable component for industries that require high levels of hygiene and sanitation. Its hygienic design, corrosion resistance, and ease of maintenance make it a crucial part of machinery used in food processing, pharmaceuticals, biotechnology, and more. By using these certified components, companies can ensure their equipment meets global hygiene standards and contributes to safe and efficient manufacturing processes.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.