Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

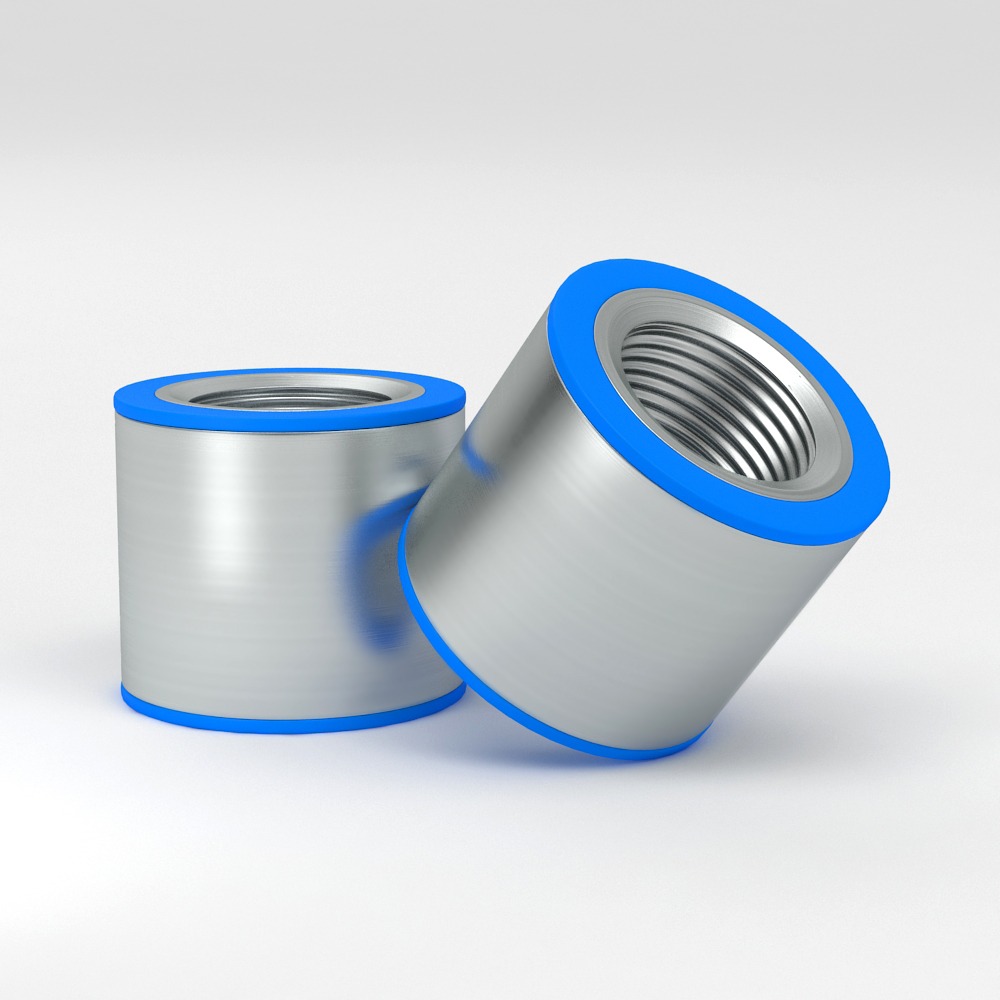

EHEDG-certified spacer nut

Ensuring High Hygiene and Performance

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

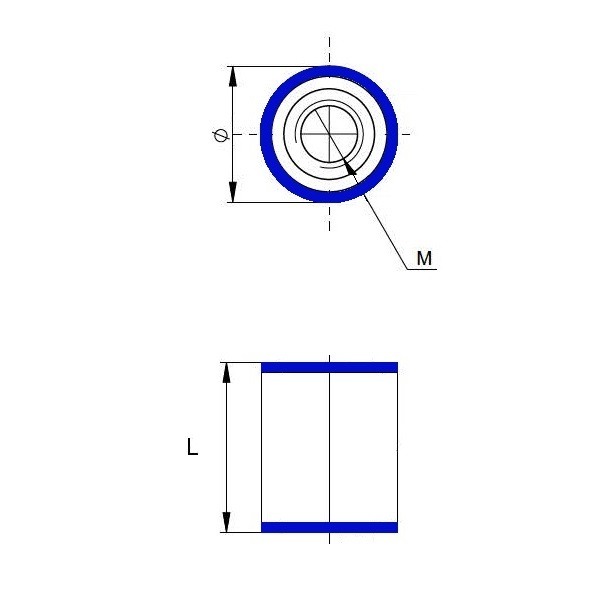

EHEDG Hygienic spacer nut

3A SN M5-L10 Ø12

3A SN M5-L20 Ø12

3A SN M5-L30 Ø12

3A SN M6-L10 Ø12

3A SN M6-L20 Ø12

3A SN M6-L30 Ø12

3A SN M8-L10 Ø15

3A SN M8-L20 Ø15

3A SN M8-L30 Ø15

3A SN M10-L10 Ø20

3A SN M10-L20 Ø20

3A SN M10-L30 Ø20

3A SN M12-L10 Ø22

3A SN M12-L20 Ø22

3A SN M12-L30 Ø22

3A SN M16-L10 Ø28

3A SN M16-L20 Ø28

3A SN M16-L30 Ø28

3A SN M20-L10 Ø32

3A SN M20-L20 Ø32

3A SN M20-L30 Ø32

3A SN M24-L20 Ø36

3A SN M24-L30 Ø36

3A SN M24-L40 Ø36

3A SN M30-L20 Ø46

3A SN M30-L30 Ø46

3A SN M30-L40 Ø46

Avoiding Contamination: see our product line here

Contact us for hygienic solution

What are EHEDG Hygienic Spacer Nuts in Stainless Steel?

EHEDG Hygienic spacer nuts are specially designed components that play a crucial role in maintaining hygienic conditions in equipment used within the food processing, pharmaceutical, and biotechnology industries. Made from high-quality stainless steel, these spacer nuts comply with the stringent hygiene standards set by EHEDG (European Hygienic Engineering & Design Group) and sanitary standard. These certifications ensure that the spacer nuts are resistant to bacteria, corrosion, and other contaminants, which are critical in environments where sanitation is a top priority.

Why Choose EHEDG Hygienic Spacer Nuts for Hygienic Applications?

Spacer nuts are essential in machinery assemblies, especially in industries where cleanliness and the prevention of contamination are paramount. By opting for EHEDG and sanitary standard certified spacer nuts, manufacturers ensure that their equipment complies with the highest hygiene standards. Here are some key reasons why these spacer nuts are favored in hygienic applications:

- Superior Hygiene Standards Compliance: The EHEDG and sanitary standard certifications guarantee that these spacer nuts meet the rigorous cleanliness and hygiene requirements for equipment used in sensitive industries. They are designed to minimize the risk of microbial growth and contamination.

- Corrosion and Rust Resistance: Stainless steel spacer nuts are known for their excellent corrosion resistance. This is especially important in environments where cleaning and sanitizing processes are frequent. These spacer nuts ensure longevity and durability, even in the most challenging conditions.

- Ease of Cleaning: One of the standout features of EHEDG Hygienic spacer nuts is their ease of cleaning. Their smooth surface and design prevent the accumulation of dirt, debris, and bacteria, making them ideal for use in industries where equipment must be sanitized regularly.

- Durability and Strength: Stainless steel spacer nuts are highly durable and can withstand the mechanical stresses found in industrial applications. This makes them an excellent choice for equipment that requires robust, long-lasting components.

Applications of EHEDG Hygienic Spacer Nuts

EHEDG Hygienic spacer nuts are widely used in various sectors where hygiene and cleanliness are critical. Some common applications include:

- Food Processing: In food manufacturing plants, where contamination can be a serious concern, EHEDG Hygienic spacer nuts help ensure that equipment meets food safety regulations. They are used in machinery such as mixers, blenders, conveyors, and filling machines.

- Pharmaceutical Industry: Pharmaceutical manufacturing requires equipment that can be easily cleaned and sanitized to avoid contamination of products. EHEDG Hygienic spacer nuts are frequently used in mixers, homogenizers, and other machines within pharmaceutical facilities.

- Biotechnology: Biotechnology industries also benefit from the hygienic properties of these spacer nuts, particularly in systems that process biologics or medical devices. They ensure the equipment remains free of any contaminants during the production process.

Benefits of Stainless Steel Material

The choice of stainless steel for EHEDG Hygienic spacer nuts provides several significant advantages:

- Non-reactive Surface: Stainless steel is non-reactive, making it resistant to various chemicals, acids, and cleaning agents commonly used in industrial applications. This ensures that the spacer nuts maintain their integrity over time and do not contaminate the products they come in contact with.

- Resilience in Harsh Environments: Stainless steel can handle extreme temperatures and harsh conditions, making it suitable for use in both hot and cold environments where the equipment may be exposed to frequent cycles of cleaning or sterilization.

- Aesthetic Appeal: Stainless steel also offers an aesthetically pleasing finish that is often required in industries where visible parts of the equipment need to be clean and free of any rust or stains.

Ensuring High Hygiene and Performance with EHEDG Hygienic Spacer Nuts

EHEDG Hygienic spacer nuts in stainless steel are indispensable components for industries that require strict hygiene standards, such as food processing, pharmaceuticals, and biotechnology. Their corrosion resistance, easy cleaning properties, and compliance with high sanitary standards make them a reliable choice for ensuring both the cleanliness and performance of industrial equipment. By incorporating these spacer nuts into machinery designs, manufacturers can safeguard product quality, prevent contamination, and extend the lifespan of their equipment.

Whether you’re involved in food production or pharmaceutical manufacturing, opting for EHEDG Hygienic spacer nuts in stainless steel is a smart investment in maintaining high levels of sanitation and operational efficiency.

Avoiding Contamination: see our product line here

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Ensuring High Hygiene and Performance

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

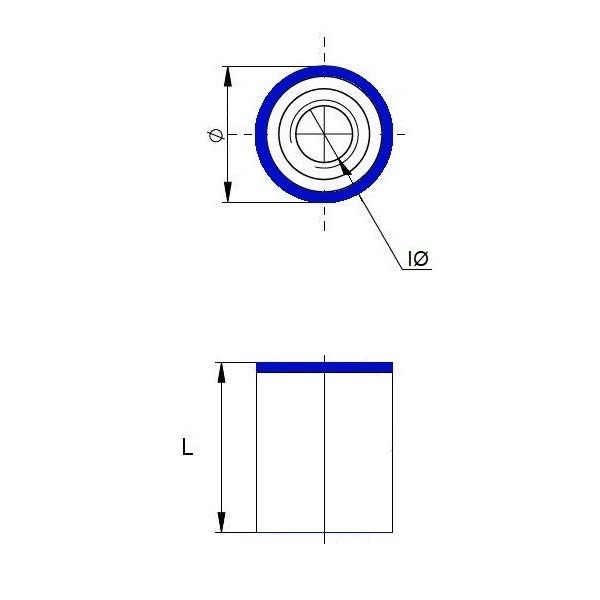

EHEDG Hygienic spacer nut

3A SN M5-L10 Ø12

3A SN M5-L20 Ø12

3A SN M5-L30 Ø12

3A SN M6-L10 Ø12

3A SN M6-L20 Ø12

3A SN M6-L30 Ø12

3A SN M8-L10 Ø15

3A SN M8-L20 Ø15

3A SN M8-L30 Ø15

3A SN M10-L10 Ø20

3A SN M10-L20 Ø20

3A SN M10-L30 Ø20

3A SN M12-L10 Ø22

3A SN M12-L20 Ø22

3A SN M12-L30 Ø22

3A SN M16-L10 Ø28

3A SN M16-L20 Ø28

3A SN M16-L30 Ø28

3A SN M20-L10 Ø32

3A SN M20-L20 Ø32

3A SN M20-L30 Ø32

3A SN M24-L20 Ø36

3A SN M24-L30 Ø36

3A SN M24-L40 Ø36

3A SN M30-L20 Ø46

3A SN M30-L30 Ø46

3A SN M30-L40 Ø46

Avoiding Contamination: see our product line here

Contact us for hygienic solution

What are EHEDG Hygienic Spacer Nuts in Stainless Steel?

EHEDG Hygienic spacer nuts are specially designed components that play a crucial role in maintaining hygienic conditions in equipment used within the food processing, pharmaceutical, and biotechnology industries. Made from high-quality stainless steel, these spacer nuts comply with the stringent hygiene standards set by EHEDG (European Hygienic Engineering & Design Group) and sanitary standard. These certifications ensure that the spacer nuts are resistant to bacteria, corrosion, and other contaminants, which are critical in environments where sanitation is a top priority.

Why Choose EHEDG Hygienic Spacer Nuts for Hygienic Applications?

Spacer nuts are essential in machinery assemblies, especially in industries where cleanliness and the prevention of contamination are paramount. By opting for EHEDG and sanitary standard certified spacer nuts, manufacturers ensure that their equipment complies with the highest hygiene standards. Here are some key reasons why these spacer nuts are favored in hygienic applications:

- Superior Hygiene Standards Compliance: The EHEDG and sanitary standard certifications guarantee that these spacer nuts meet the rigorous cleanliness and hygiene requirements for equipment used in sensitive industries. They are designed to minimize the risk of microbial growth and contamination.

- Corrosion and Rust Resistance: Stainless steel spacer nuts are known for their excellent corrosion resistance. This is especially important in environments where cleaning and sanitizing processes are frequent. These spacer nuts ensure longevity and durability, even in the most challenging conditions.

- Ease of Cleaning: One of the standout features of EHEDG Hygienic spacer nuts is their ease of cleaning. Their smooth surface and design prevent the accumulation of dirt, debris, and bacteria, making them ideal for use in industries where equipment must be sanitized regularly.

- Durability and Strength: Stainless steel spacer nuts are highly durable and can withstand the mechanical stresses found in industrial applications. This makes them an excellent choice for equipment that requires robust, long-lasting components.

Applications of EHEDG Hygienic Spacer Nuts

EHEDG Hygienic spacer nuts are widely used in various sectors where hygiene and cleanliness are critical. Some common applications include:

- Food Processing: In food manufacturing plants, where contamination can be a serious concern, EHEDG Hygienic spacer nuts help ensure that equipment meets food safety regulations. They are used in machinery such as mixers, blenders, conveyors, and filling machines.

- Pharmaceutical Industry: Pharmaceutical manufacturing requires equipment that can be easily cleaned and sanitized to avoid contamination of products. EHEDG Hygienic spacer nuts are frequently used in mixers, homogenizers, and other machines within pharmaceutical facilities.

- Biotechnology: Biotechnology industries also benefit from the hygienic properties of these spacer nuts, particularly in systems that process biologics or medical devices. They ensure the equipment remains free of any contaminants during the production process.

Benefits of Stainless Steel Material

The choice of stainless steel for EHEDG Hygienic spacer nuts provides several significant advantages:

- Non-reactive Surface: Stainless steel is non-reactive, making it resistant to various chemicals, acids, and cleaning agents commonly used in industrial applications. This ensures that the spacer nuts maintain their integrity over time and do not contaminate the products they come in contact with.

- Resilience in Harsh Environments: Stainless steel can handle extreme temperatures and harsh conditions, making it suitable for use in both hot and cold environments where the equipment may be exposed to frequent cycles of cleaning or sterilization.

- Aesthetic Appeal: Stainless steel also offers an aesthetically pleasing finish that is often required in industries where visible parts of the equipment need to be clean and free of any rust or stains.

Ensuring High Hygiene and Performance with EHEDG Hygienic Spacer Nuts

EHEDG Hygienic spacer nuts in stainless steel are indispensable components for industries that require strict hygiene standards, such as food processing, pharmaceuticals, and biotechnology. Their corrosion resistance, easy cleaning properties, and compliance with high sanitary standards make them a reliable choice for ensuring both the cleanliness and performance of industrial equipment. By incorporating these spacer nuts into machinery designs, manufacturers can safeguard product quality, prevent contamination, and extend the lifespan of their equipment.

Whether you’re involved in food production or pharmaceutical manufacturing, opting for EHEDG Hygienic spacer nuts in stainless steel is a smart investment in maintaining high levels of sanitation and operational efficiency.

Avoiding Contamination: see our product line here

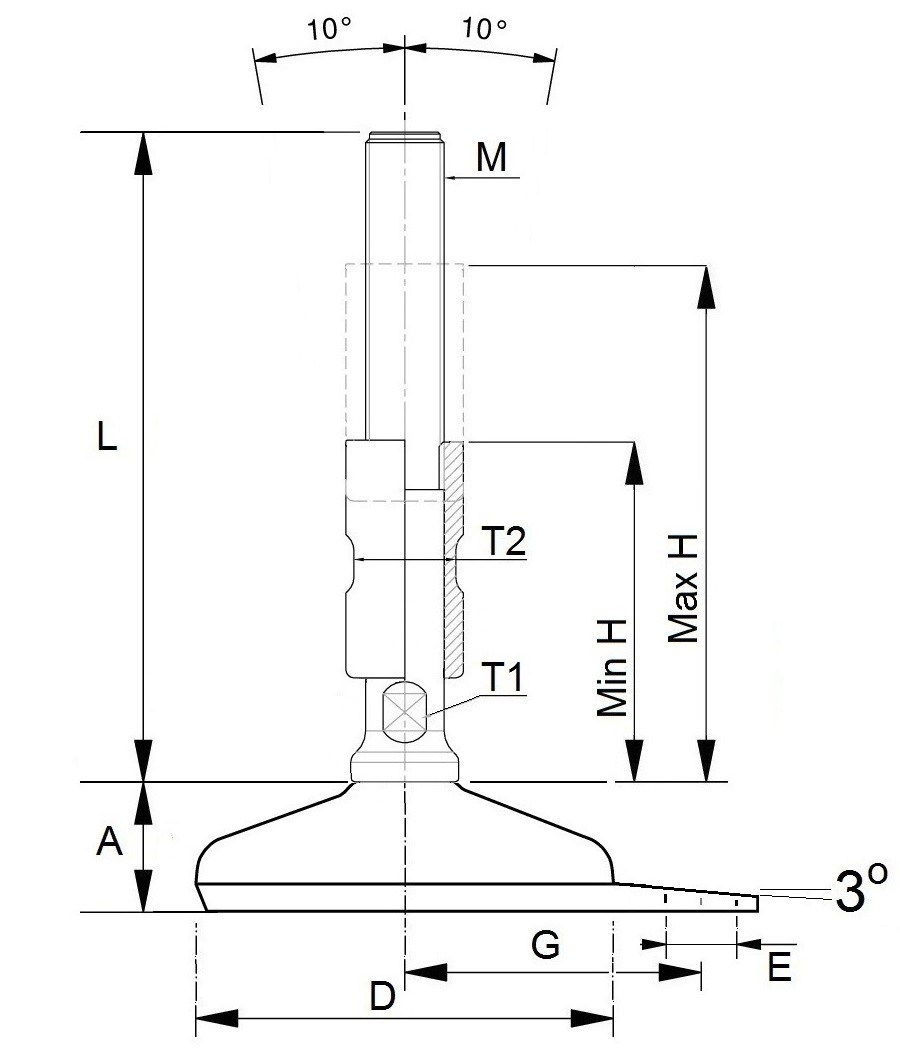

Ensuring High Hygiene and Performance

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic spacer nut

3A SN M5-L10 Ø12

3A SN M5-L20 Ø12

3A SN M5-L30 Ø12

3A SN M6-L10 Ø12

3A SN M6-L20 Ø12

3A SN M6-L30 Ø12

3A SN M8-L10 Ø15

3A SN M8-L20 Ø15

3A SN M8-L30 Ø15

3A SN M10-L10 Ø20

3A SN M10-L20 Ø20

3A SN M10-L30 Ø20

3A SN M12-L10 Ø22

3A SN M12-L20 Ø22

3A SN M12-L30 Ø22

3A SN M16-L10 Ø28

3A SN M16-L20 Ø28

3A SN M16-L30 Ø28

3A SN M20-L10 Ø32

3A SN M20-L20 Ø32

3A SN M20-L30 Ø32

3A SN M24-L20 Ø36

3A SN M24-L30 Ø36

3A SN M24-L40 Ø36

3A SN M30-L20 Ø46

3A SN M30-L30 Ø46

3A SN M30-L40 Ø46

Avoiding Contamination: see our product line here

Contact us for hygienic solution

What are EHEDG Hygienic Spacer Nuts in Stainless Steel?

EHEDG Hygienic spacer nuts are specially designed components that play a crucial role in maintaining hygienic conditions in equipment used within the food processing, pharmaceutical, and biotechnology industries. Made from high-quality stainless steel, these spacer nuts comply with the stringent hygiene standards set by EHEDG (European Hygienic Engineering & Design Group) and sanitary standard. These certifications ensure that the spacer nuts are resistant to bacteria, corrosion, and other contaminants, which are critical in environments where sanitation is a top priority.

Why Choose EHEDG Hygienic Spacer Nuts for Hygienic Applications?

Spacer nuts are essential in machinery assemblies, especially in industries where cleanliness and the prevention of contamination are paramount. By opting for EHEDG and sanitary standard certified spacer nuts, manufacturers ensure that their equipment complies with the highest hygiene standards. Here are some key reasons why these spacer nuts are favored in hygienic applications:

- Superior Hygiene Standards Compliance: The EHEDG and sanitary standard certifications guarantee that these spacer nuts meet the rigorous cleanliness and hygiene requirements for equipment used in sensitive industries. They are designed to minimize the risk of microbial growth and contamination.

- Corrosion and Rust Resistance: Stainless steel spacer nuts are known for their excellent corrosion resistance. This is especially important in environments where cleaning and sanitizing processes are frequent. These spacer nuts ensure longevity and durability, even in the most challenging conditions.

- Ease of Cleaning: One of the standout features of EHEDG Hygienic spacer nuts is their ease of cleaning. Their smooth surface and design prevent the accumulation of dirt, debris, and bacteria, making them ideal for use in industries where equipment must be sanitized regularly.

- Durability and Strength: Stainless steel spacer nuts are highly durable and can withstand the mechanical stresses found in industrial applications. This makes them an excellent choice for equipment that requires robust, long-lasting components.

Applications of EHEDG Hygienic Spacer Nuts

EHEDG Hygienic spacer nuts are widely used in various sectors where hygiene and cleanliness are critical. Some common applications include:

- Food Processing: In food manufacturing plants, where contamination can be a serious concern, EHEDG Hygienic spacer nuts help ensure that equipment meets food safety regulations. They are used in machinery such as mixers, blenders, conveyors, and filling machines.

- Pharmaceutical Industry: Pharmaceutical manufacturing requires equipment that can be easily cleaned and sanitized to avoid contamination of products. EHEDG Hygienic spacer nuts are frequently used in mixers, homogenizers, and other machines within pharmaceutical facilities.

- Biotechnology: Biotechnology industries also benefit from the hygienic properties of these spacer nuts, particularly in systems that process biologics or medical devices. They ensure the equipment remains free of any contaminants during the production process.

Benefits of Stainless Steel Material

The choice of stainless steel for EHEDG Hygienic spacer nuts provides several significant advantages:

- Non-reactive Surface: Stainless steel is non-reactive, making it resistant to various chemicals, acids, and cleaning agents commonly used in industrial applications. This ensures that the spacer nuts maintain their integrity over time and do not contaminate the products they come in contact with.

- Resilience in Harsh Environments: Stainless steel can handle extreme temperatures and harsh conditions, making it suitable for use in both hot and cold environments where the equipment may be exposed to frequent cycles of cleaning or sterilization.

- Aesthetic Appeal: Stainless steel also offers an aesthetically pleasing finish that is often required in industries where visible parts of the equipment need to be clean and free of any rust or stains.

Ensuring High Hygiene and Performance with EHEDG Hygienic Spacer Nuts

EHEDG Hygienic spacer nuts in stainless steel are indispensable components for industries that require strict hygiene standards, such as food processing, pharmaceuticals, and biotechnology. Their corrosion resistance, easy cleaning properties, and compliance with high sanitary standards make them a reliable choice for ensuring both the cleanliness and performance of industrial equipment. By incorporating these spacer nuts into machinery designs, manufacturers can safeguard product quality, prevent contamination, and extend the lifespan of their equipment.

Whether you’re involved in food production or pharmaceutical manufacturing, opting for EHEDG Hygienic spacer nuts in stainless steel is a smart investment in maintaining high levels of sanitation and operational efficiency.

Avoiding Contamination: see our product line here

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.