Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

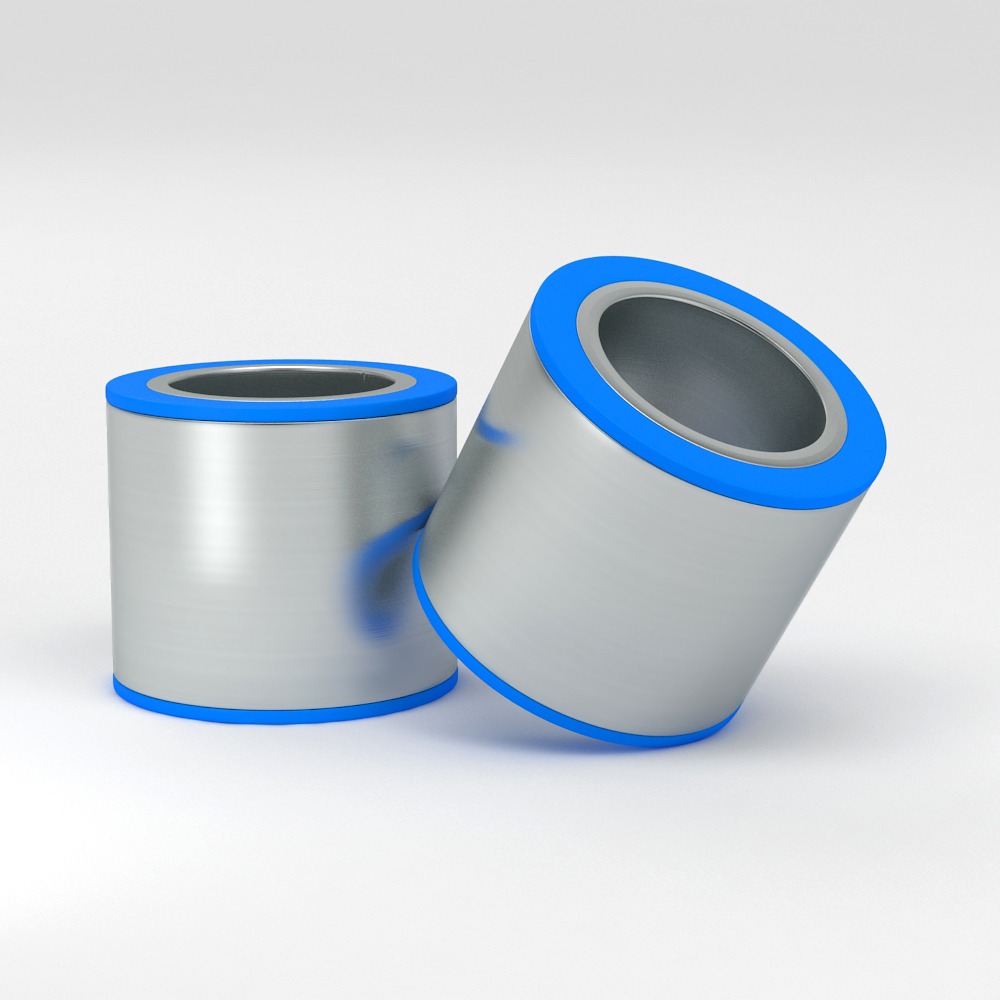

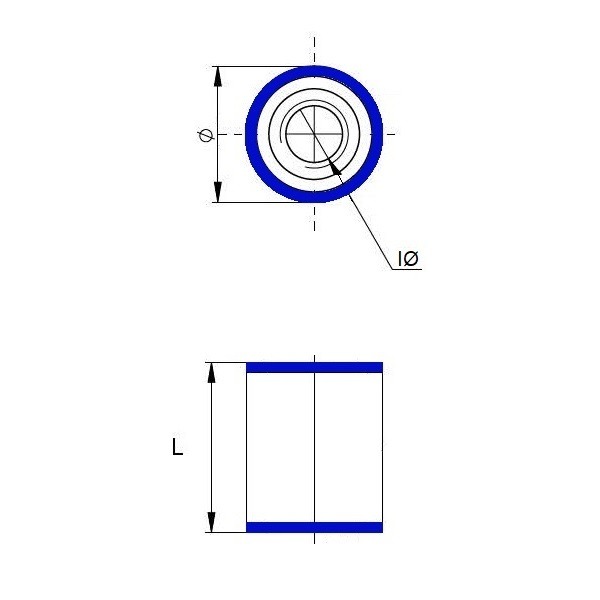

EHEDG Hygienic spacer in stainless steel

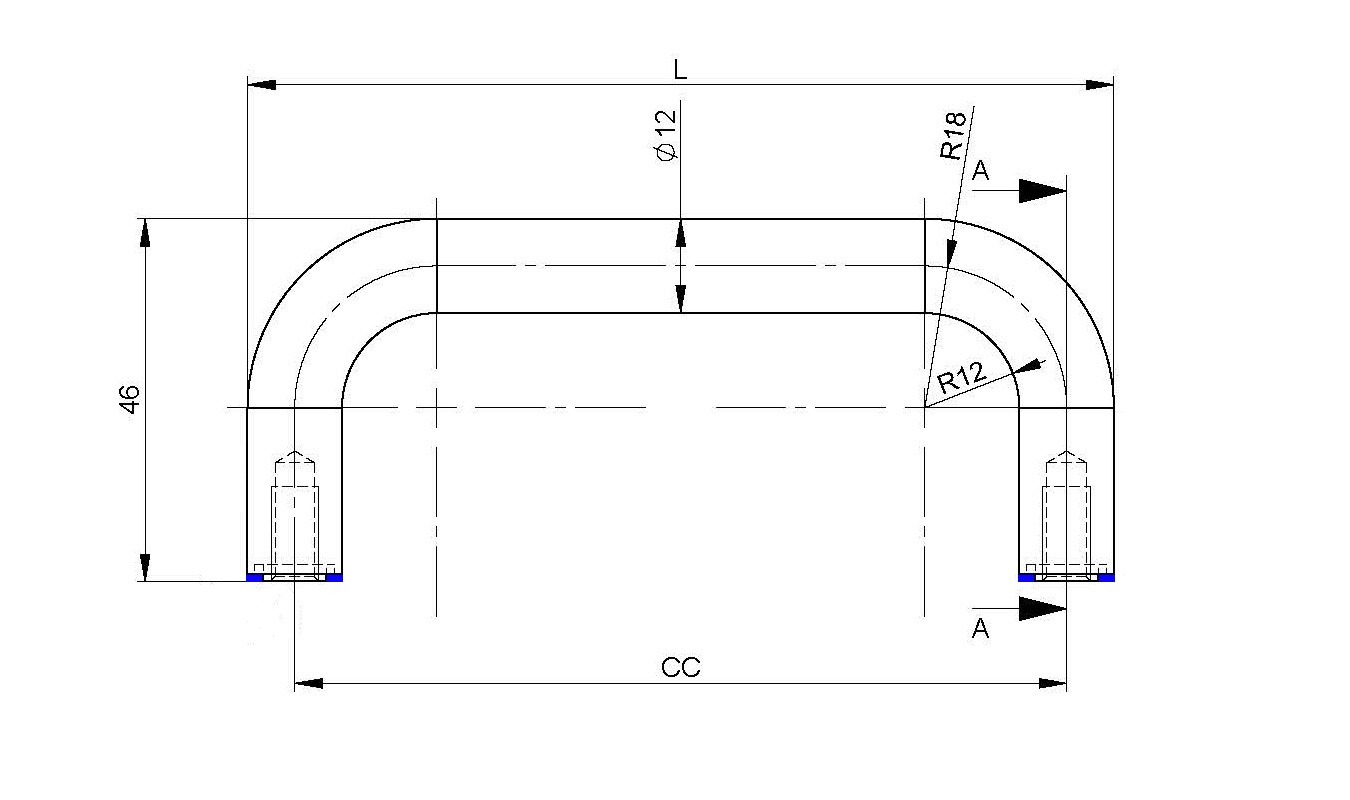

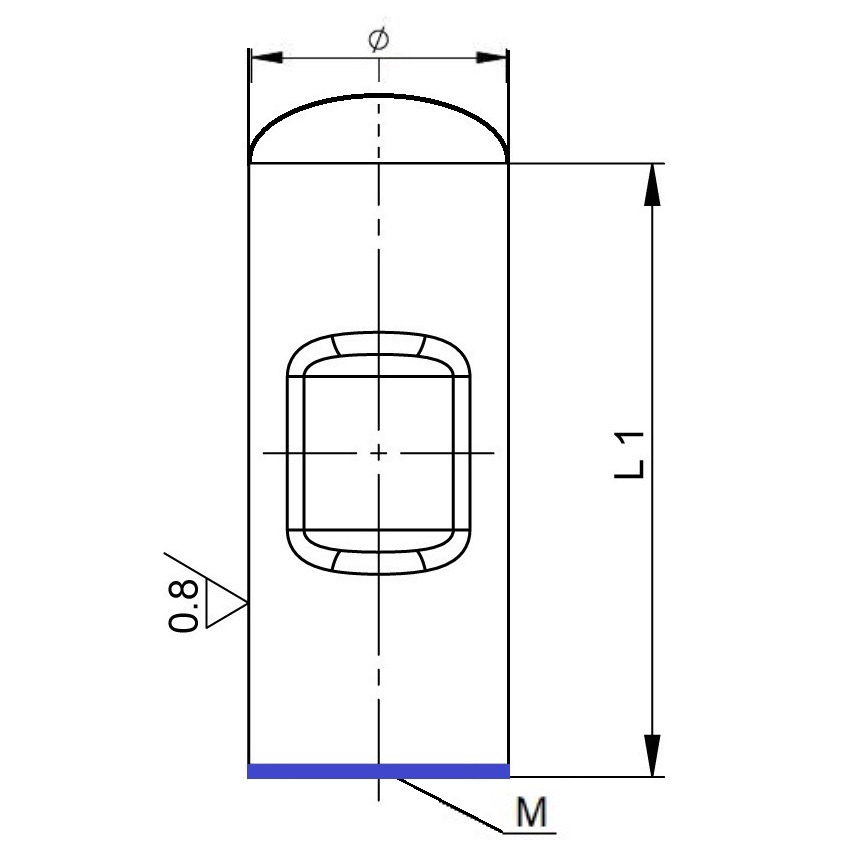

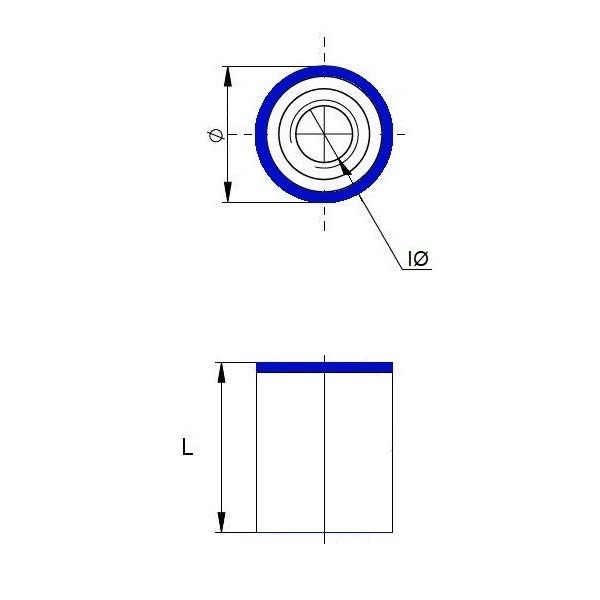

A Vital Component for Hygiene and Performance

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic Spacer

3A SB IØ5-L10 Ø12

3A SB IØ5-L20 Ø12

3A SB IØ5-L30 Ø12

3A SB IØ6-L10 Ø12

3A SB IØ6-L20 Ø12

3A SB IØ6-L30 Ø12

3A SB IØ8-L10 Ø15

3A SB IØ8-L20 Ø15

3A SB IØ8-L30 Ø15

3A SB IØ10-L10 Ø20

3A SB IØ10-L20 Ø20

3A SB IØ10-L30 Ø20

3A SB IØ12-L10 Ø22

3A SB IØ12-L20 Ø22

3A SB IØ12-L30 Ø22

3A SB IØ16-L10 Ø28

3A SB IØ16-L20 Ø28

3A SB IØ16-L30 Ø28

3A SB IØ20-L10 Ø32

3A SB IØ20-L20 Ø32

3A SB IØ20-L30 Ø32

3A SB IØ24-L20 Ø36

3A SB IØ24-L30 Ø36

3A SB IØ24-L40 Ø36

3A SB IØ30-L20 Ø46

3A SB IØ30-L30 Ø46

3A SB IØ30-L40 Ø46

See our products which reduces maintenance costs here

Contact us for hygienic solution

EHEDG Hygienic Spacer in Stainless Steel

Ensuring Hygiene and Performance

In industries where hygiene is paramount, particularly in food processing, pharmaceuticals, and biotechnology, the use of certified components is crucial. The EHEDG hygienic spacer in stainless steel stands out as a key component in achieving the highest standards of cleanliness, safety, and performance. This article explores the essential role of these spacers, their features, and the industries that benefit from their use.

What is an EHEDG Hygienic Spacer?

An EHEDG hygienic spacer is a high-quality component made of stainless steel designed to meet the strict hygiene standards set by both the EHEDG (European Hygienic Engineering & Design Group) and Sanitary Standards. These spacers are engineered to ensure that machinery and equipment remain free of contaminants, preventing the buildup of dirt, bacteria, or other harmful substances that can compromise product quality or safety.

The spacer’s design focuses on smooth surfaces, easy-to-clean edges, and non-porous materials that prevent the accumulation of contaminants. By using stainless steel, which is resistant to corrosion, the spacer provides durability and reliability in harsh working environments.

Features and Benefits of EHEDG Hygienic Spacers

1. Corrosion Resistance

Stainless steel is renowned for its resistance to corrosion, making it ideal for use in environments where cleaning agents, moisture, and extreme temperatures are common. Whether used in the food processing industry or the pharmaceutical sector, these spacers retain their integrity over time, ensuring consistent performance.

2. Easy to Clean

One of the most significant advantages of the EHEDG hygienic spacer is its ease of cleaning. The smooth surface eliminates crevices or grooves where dirt or bacteria could accumulate, making the spacer suitable for industries that require frequent and rigorous cleaning protocols.

3. Hygienic Design

The spacer’s hygienic design is compliant with both EHEDG and Sanitary Standards, which are globally recognized certifications for hygienic equipment used in food and beverage processing, as well as pharmaceuticals. This ensures that the spacer contributes to overall sanitation and safety during manufacturing processes.

4. Durability

The stainless steel construction of the EHEDG spacer ensures durability under tough working conditions. Resistant to wear, mechanical stress, and high temperatures, the spacer maintains its functional integrity, reducing the need for frequent replacements and thus improving operational efficiency.

5. Compliance with Industry Standards

EHEDG and Sanitary Standards certifications signify that these spacers meet the rigorous hygiene standards required in critical industries. These certifications ensure that the spacer not only complies with regulations but also contributes to a safer and more efficient operation by preventing contamination risks.

Applications of EHEDG Hygienic Spacers

1. Food Processing

In food manufacturing, the prevention of contamination is a top priority. EHEDG hygienic spacers are used in various food processing applications, including dairy, meat, beverage, and snack food production. These spacers are integral to ensuring that equipment remains clean and safe for food contact, adhering to stringent hygiene requirements.

2. Pharmaceutical Manufacturing

The pharmaceutical industry has some of the highest hygiene standards in the world. EHEDG hygienic spacers help ensure that pharmaceutical production lines meet these requirements, preventing cross-contamination and ensuring the integrity of the end products. They are commonly used in processes like tablet production, liquid filling, and aseptic manufacturing.

3. Biotechnology

In biotechnology, where contamination could compromise valuable research or medical products, EHEDG hygienic spacers play a vital role in maintaining a contamination-free environment. These spacers ensure that machinery used in sensitive processes, such as the production of vaccines or biologics, operates under stringent sanitary conditions.

Why Choose EHEDG Hygienic Stainless Steel Spacers?

Choosing EHEDG hygienic spacers in stainless steel offers several benefits, especially for industries where contamination could have serious consequences. These spacers enhance the safety, efficiency, and reliability of operations while reducing the risk of non-compliance with hygiene regulations.

Additionally, the durability of stainless steel ensures that these spacers provide a long-lasting solution for preventing contamination, ultimately leading to cost savings in the long run. For companies looking to meet both local and international hygiene standards, EHEDG hygienic spacers are a wise investment.

Enhancing Efficiency with EHEDG Hygienic Spacers in Stainless Steel

The EHEDG hygienic spacer in stainless steel is a crucial component for businesses that prioritize hygiene and safety. Its corrosion resistance, ease of cleaning, and compliance with industry standards make it an essential choice for food processing, pharmaceuticals, and biotechnology industries. By incorporating these spacers into production lines, companies can ensure a higher level of hygiene, reduce contamination risks, and improve operational efficiency.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

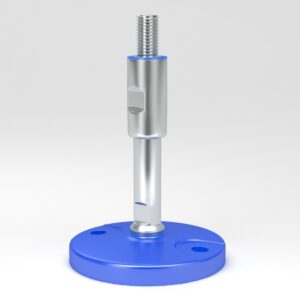

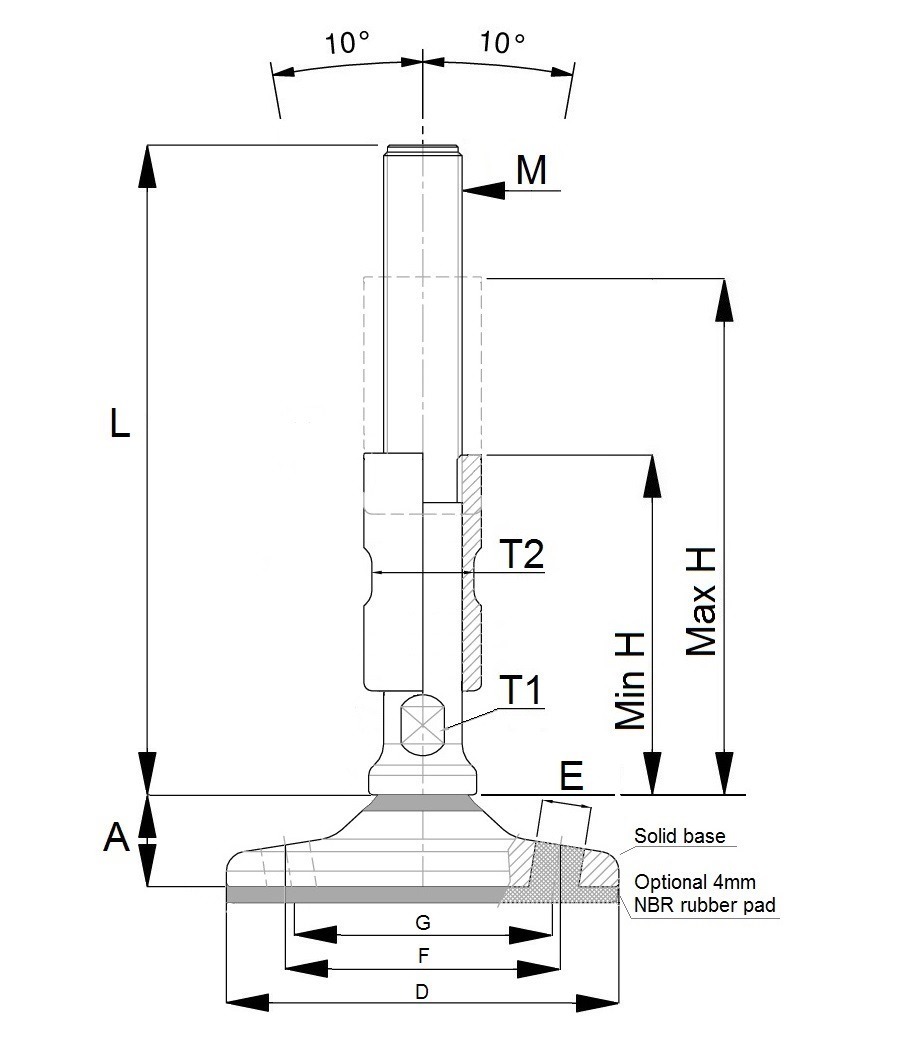

A Vital Component for Hygiene and Performance

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic Spacer

3A SB IØ5-L10 Ø12

3A SB IØ5-L20 Ø12

3A SB IØ5-L30 Ø12

3A SB IØ6-L10 Ø12

3A SB IØ6-L20 Ø12

3A SB IØ6-L30 Ø12

3A SB IØ8-L10 Ø15

3A SB IØ8-L20 Ø15

3A SB IØ8-L30 Ø15

3A SB IØ10-L10 Ø20

3A SB IØ10-L20 Ø20

3A SB IØ10-L30 Ø20

3A SB IØ12-L10 Ø22

3A SB IØ12-L20 Ø22

3A SB IØ12-L30 Ø22

3A SB IØ16-L10 Ø28

3A SB IØ16-L20 Ø28

3A SB IØ16-L30 Ø28

3A SB IØ20-L10 Ø32

3A SB IØ20-L20 Ø32

3A SB IØ20-L30 Ø32

3A SB IØ24-L20 Ø36

3A SB IØ24-L30 Ø36

3A SB IØ24-L40 Ø36

3A SB IØ30-L20 Ø46

3A SB IØ30-L30 Ø46

3A SB IØ30-L40 Ø46

See our products which reduces maintenance costs here

Contact us for hygienic solution

EHEDG Hygienic Spacer in Stainless Steel

Ensuring Hygiene and Performance

In industries where hygiene is paramount, particularly in food processing, pharmaceuticals, and biotechnology, the use of certified components is crucial. The EHEDG hygienic spacer in stainless steel stands out as a key component in achieving the highest standards of cleanliness, safety, and performance. This article explores the essential role of these spacers, their features, and the industries that benefit from their use.

What is an EHEDG Hygienic Spacer?

An EHEDG hygienic spacer is a high-quality component made of stainless steel designed to meet the strict hygiene standards set by both the EHEDG (European Hygienic Engineering & Design Group) and Sanitary Standards. These spacers are engineered to ensure that machinery and equipment remain free of contaminants, preventing the buildup of dirt, bacteria, or other harmful substances that can compromise product quality or safety.

The spacer’s design focuses on smooth surfaces, easy-to-clean edges, and non-porous materials that prevent the accumulation of contaminants. By using stainless steel, which is resistant to corrosion, the spacer provides durability and reliability in harsh working environments.

Features and Benefits of EHEDG Hygienic Spacers

1. Corrosion Resistance

Stainless steel is renowned for its resistance to corrosion, making it ideal for use in environments where cleaning agents, moisture, and extreme temperatures are common. Whether used in the food processing industry or the pharmaceutical sector, these spacers retain their integrity over time, ensuring consistent performance.

2. Easy to Clean

One of the most significant advantages of the EHEDG hygienic spacer is its ease of cleaning. The smooth surface eliminates crevices or grooves where dirt or bacteria could accumulate, making the spacer suitable for industries that require frequent and rigorous cleaning protocols.

3. Hygienic Design

The spacer’s hygienic design is compliant with both EHEDG and Sanitary Standards, which are globally recognized certifications for hygienic equipment used in food and beverage processing, as well as pharmaceuticals. This ensures that the spacer contributes to overall sanitation and safety during manufacturing processes.

4. Durability

The stainless steel construction of the EHEDG spacer ensures durability under tough working conditions. Resistant to wear, mechanical stress, and high temperatures, the spacer maintains its functional integrity, reducing the need for frequent replacements and thus improving operational efficiency.

5. Compliance with Industry Standards

EHEDG and Sanitary Standards certifications signify that these spacers meet the rigorous hygiene standards required in critical industries. These certifications ensure that the spacer not only complies with regulations but also contributes to a safer and more efficient operation by preventing contamination risks.

Applications of EHEDG Hygienic Spacers

1. Food Processing

In food manufacturing, the prevention of contamination is a top priority. EHEDG hygienic spacers are used in various food processing applications, including dairy, meat, beverage, and snack food production. These spacers are integral to ensuring that equipment remains clean and safe for food contact, adhering to stringent hygiene requirements.

2. Pharmaceutical Manufacturing

The pharmaceutical industry has some of the highest hygiene standards in the world. EHEDG hygienic spacers help ensure that pharmaceutical production lines meet these requirements, preventing cross-contamination and ensuring the integrity of the end products. They are commonly used in processes like tablet production, liquid filling, and aseptic manufacturing.

3. Biotechnology

In biotechnology, where contamination could compromise valuable research or medical products, EHEDG hygienic spacers play a vital role in maintaining a contamination-free environment. These spacers ensure that machinery used in sensitive processes, such as the production of vaccines or biologics, operates under stringent sanitary conditions.

Why Choose EHEDG Hygienic Stainless Steel Spacers?

Choosing EHEDG hygienic spacers in stainless steel offers several benefits, especially for industries where contamination could have serious consequences. These spacers enhance the safety, efficiency, and reliability of operations while reducing the risk of non-compliance with hygiene regulations.

Additionally, the durability of stainless steel ensures that these spacers provide a long-lasting solution for preventing contamination, ultimately leading to cost savings in the long run. For companies looking to meet both local and international hygiene standards, EHEDG hygienic spacers are a wise investment.

Enhancing Efficiency with EHEDG Hygienic Spacers in Stainless Steel

The EHEDG hygienic spacer in stainless steel is a crucial component for businesses that prioritize hygiene and safety. Its corrosion resistance, ease of cleaning, and compliance with industry standards make it an essential choice for food processing, pharmaceuticals, and biotechnology industries. By incorporating these spacers into production lines, companies can ensure a higher level of hygiene, reduce contamination risks, and improve operational efficiency.

A Vital Component for Hygiene and Performance

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic Spacer

3A SB IØ5-L10 Ø12

3A SB IØ5-L20 Ø12

3A SB IØ5-L30 Ø12

3A SB IØ6-L10 Ø12

3A SB IØ6-L20 Ø12

3A SB IØ6-L30 Ø12

3A SB IØ8-L10 Ø15

3A SB IØ8-L20 Ø15

3A SB IØ8-L30 Ø15

3A SB IØ10-L10 Ø20

3A SB IØ10-L20 Ø20

3A SB IØ10-L30 Ø20

3A SB IØ12-L10 Ø22

3A SB IØ12-L20 Ø22

3A SB IØ12-L30 Ø22

3A SB IØ16-L10 Ø28

3A SB IØ16-L20 Ø28

3A SB IØ16-L30 Ø28

3A SB IØ20-L10 Ø32

3A SB IØ20-L20 Ø32

3A SB IØ20-L30 Ø32

3A SB IØ24-L20 Ø36

3A SB IØ24-L30 Ø36

3A SB IØ24-L40 Ø36

3A SB IØ30-L20 Ø46

3A SB IØ30-L30 Ø46

3A SB IØ30-L40 Ø46

See our products which reduces maintenance costs here

Contact us for hygienic solution

EHEDG Hygienic Spacer in Stainless Steel

Ensuring Hygiene and Performance

In industries where hygiene is paramount, particularly in food processing, pharmaceuticals, and biotechnology, the use of certified components is crucial. The EHEDG hygienic spacer in stainless steel stands out as a key component in achieving the highest standards of cleanliness, safety, and performance. This article explores the essential role of these spacers, their features, and the industries that benefit from their use.

What is an EHEDG Hygienic Spacer?

An EHEDG hygienic spacer is a high-quality component made of stainless steel designed to meet the strict hygiene standards set by both the EHEDG (European Hygienic Engineering & Design Group) and Sanitary Standards. These spacers are engineered to ensure that machinery and equipment remain free of contaminants, preventing the buildup of dirt, bacteria, or other harmful substances that can compromise product quality or safety.

The spacer’s design focuses on smooth surfaces, easy-to-clean edges, and non-porous materials that prevent the accumulation of contaminants. By using stainless steel, which is resistant to corrosion, the spacer provides durability and reliability in harsh working environments.

Features and Benefits of EHEDG Hygienic Spacers

1. Corrosion Resistance

Stainless steel is renowned for its resistance to corrosion, making it ideal for use in environments where cleaning agents, moisture, and extreme temperatures are common. Whether used in the food processing industry or the pharmaceutical sector, these spacers retain their integrity over time, ensuring consistent performance.

2. Easy to Clean

One of the most significant advantages of the EHEDG hygienic spacer is its ease of cleaning. The smooth surface eliminates crevices or grooves where dirt or bacteria could accumulate, making the spacer suitable for industries that require frequent and rigorous cleaning protocols.

3. Hygienic Design

The spacer’s hygienic design is compliant with both EHEDG and Sanitary Standards, which are globally recognized certifications for hygienic equipment used in food and beverage processing, as well as pharmaceuticals. This ensures that the spacer contributes to overall sanitation and safety during manufacturing processes.

4. Durability

The stainless steel construction of the EHEDG spacer ensures durability under tough working conditions. Resistant to wear, mechanical stress, and high temperatures, the spacer maintains its functional integrity, reducing the need for frequent replacements and thus improving operational efficiency.

5. Compliance with Industry Standards

EHEDG and Sanitary Standards certifications signify that these spacers meet the rigorous hygiene standards required in critical industries. These certifications ensure that the spacer not only complies with regulations but also contributes to a safer and more efficient operation by preventing contamination risks.

Applications of EHEDG Hygienic Spacers

1. Food Processing

In food manufacturing, the prevention of contamination is a top priority. EHEDG hygienic spacers are used in various food processing applications, including dairy, meat, beverage, and snack food production. These spacers are integral to ensuring that equipment remains clean and safe for food contact, adhering to stringent hygiene requirements.

2. Pharmaceutical Manufacturing

The pharmaceutical industry has some of the highest hygiene standards in the world. EHEDG hygienic spacers help ensure that pharmaceutical production lines meet these requirements, preventing cross-contamination and ensuring the integrity of the end products. They are commonly used in processes like tablet production, liquid filling, and aseptic manufacturing.

3. Biotechnology

In biotechnology, where contamination could compromise valuable research or medical products, EHEDG hygienic spacers play a vital role in maintaining a contamination-free environment. These spacers ensure that machinery used in sensitive processes, such as the production of vaccines or biologics, operates under stringent sanitary conditions.

Why Choose EHEDG Hygienic Stainless Steel Spacers?

Choosing EHEDG hygienic spacers in stainless steel offers several benefits, especially for industries where contamination could have serious consequences. These spacers enhance the safety, efficiency, and reliability of operations while reducing the risk of non-compliance with hygiene regulations.

Additionally, the durability of stainless steel ensures that these spacers provide a long-lasting solution for preventing contamination, ultimately leading to cost savings in the long run. For companies looking to meet both local and international hygiene standards, EHEDG hygienic spacers are a wise investment.

Enhancing Efficiency with EHEDG Hygienic Spacers in Stainless Steel

The EHEDG hygienic spacer in stainless steel is a crucial component for businesses that prioritize hygiene and safety. Its corrosion resistance, ease of cleaning, and compliance with industry standards make it an essential choice for food processing, pharmaceuticals, and biotechnology industries. By incorporating these spacers into production lines, companies can ensure a higher level of hygiene, reduce contamination risks, and improve operational efficiency.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.