Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

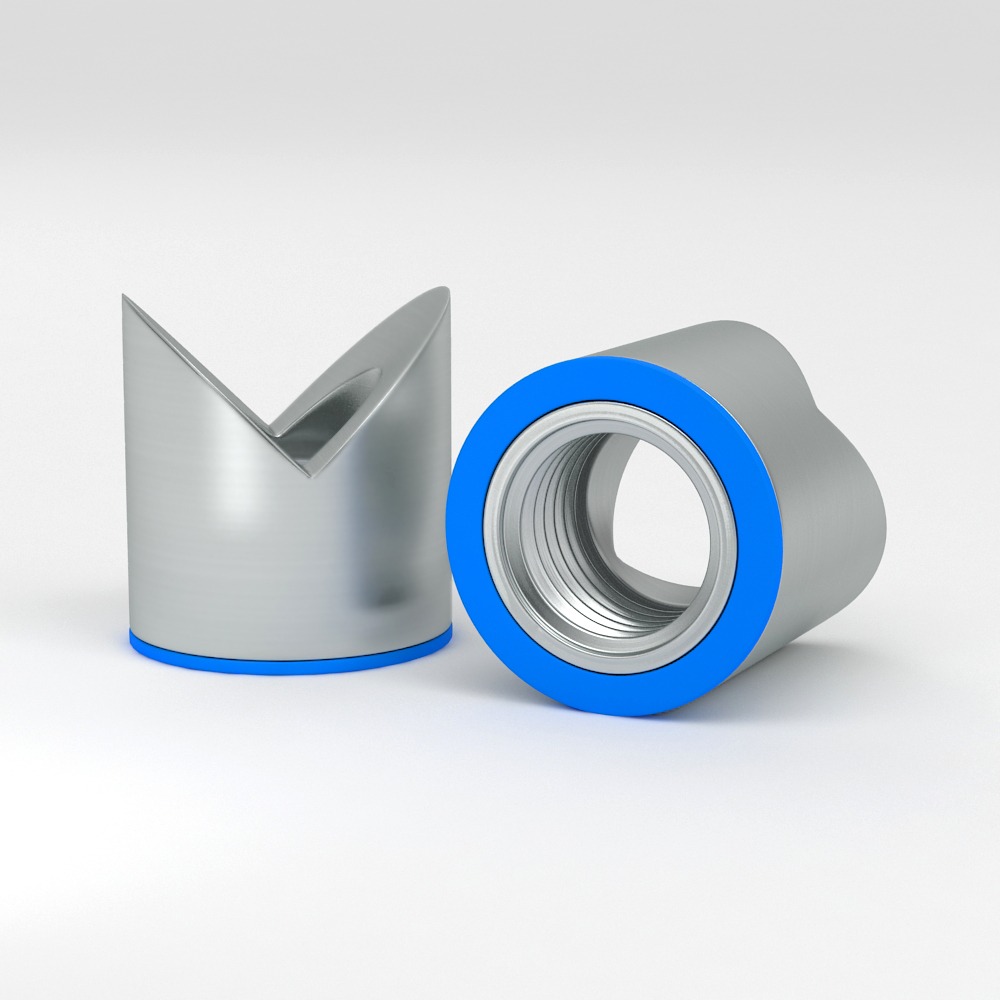

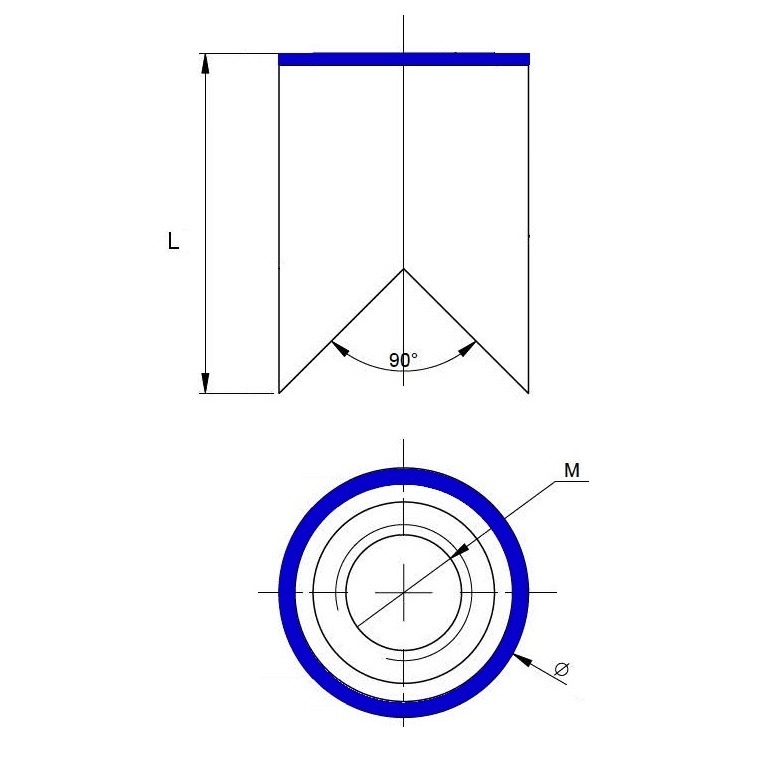

EHEDG-certified corner nut

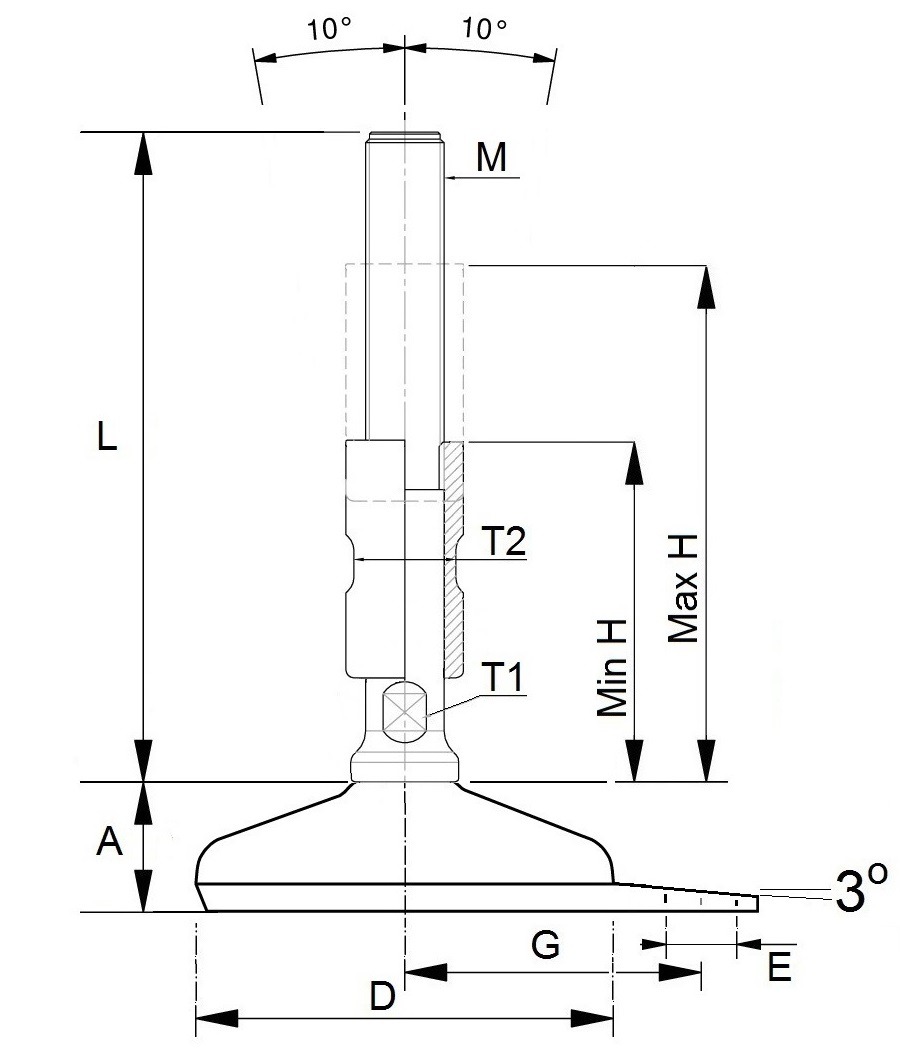

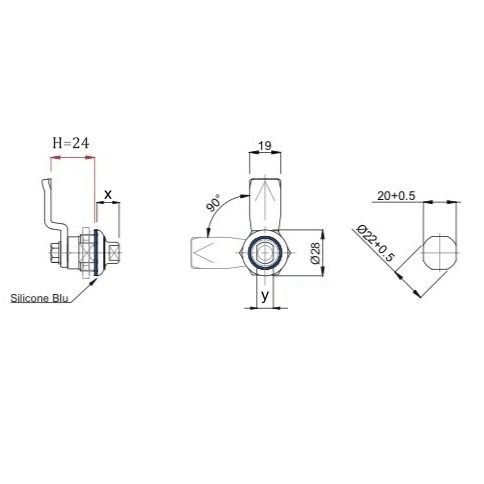

Ensuring Hygiene and Durability

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic Corner Nut

3A CN M5-L15 Ø12

3A CN M5-L25 Ø12

3A CN M6-L15 Ø12

3A CN M6-L25 Ø12

3A CN M8-L15 Ø15

3A CN M8-L25 Ø15

3A CN M10-L20 Ø20

3A CN M10-L30 Ø20

3A CN M12-L20 Ø22

3A CN M12-L30 Ø22

3A CN M16-L30 Ø28

3A CN M16-L40 Ø28

3A CN M20-L30 Ø32

3A CN M20-L40 Ø32

3A CN M24-L40 Ø36

3A CN M24-L50 Ø36

3A CN M30-L40 Ø46

3A CN M30-L50 Ø46

See our products for long-term cost savings here

Contact us for hygienic solution

What is an EHEDG Hygienic Corner Nut?

In industries where hygiene and safety are paramount, such as food processing and pharmaceuticals, the use of certified components is a must. The EHEDG Hygienic corner nut in stainless steel is a specialized fastening component designed to meet stringent hygienic standards. Certified by the EHEDG (European Hygienic Engineering & Design Group) and Sanitary Standards, these corner nuts play a crucial role in maintaining the integrity and cleanliness of equipment used in food and pharmaceutical processing environments.

Key Features and Benefits of EHEDG Hygienic Corner Nuts

- Hygienic Design:

The EHEDG Hygienic corner nuts are specifically engineered to ensure that no contaminants can accumulate in hard-to-reach areas. Their smooth, crevice-free surface prevents bacteria growth and allows for easy cleaning, making them ideal for hygienic environments. - Durability and Corrosion Resistance:

Manufactured from high-quality stainless steel, these corner nuts offer exceptional corrosion resistance, ensuring longevity even under harsh conditions. Stainless steel also provides resistance to common chemicals used in cleaning and sanitizing processes, ensuring that the nuts maintain their strength and hygiene properties over time. - Certifications:

These corner nuts are certified under both EHEDG and Sanitary Standards, offering assurance that they meet or exceed the hygiene and safety requirements set for food and pharmaceutical industries. The EHEDG certification guarantees that the components adhere to best practices in hygienic engineering, while the Sanitary Standards certification provides an additional layer of trust, especially for the U.S. market. - Versatility in Applications:

The EHEDG corner nuts are versatile and can be used in a variety of applications within food and pharmaceutical processing, such as on machinery, equipment frames, and piping systems. Whether in the dairy, beverage, or pharmaceutical industry, these corner nuts ensure that equipment is easily accessible for cleaning, maintenance, and sanitation.

Applications in Food Processing and Pharmaceutical Industries

- Food Processing:

In food processing plants, hygiene is critical to prevent contamination. The EHEDG Hygienic corner nuts are used to secure equipment parts such as conveyor systems, mixing machines, and filling lines. Their ability to withstand high-pressure washdowns and exposure to aggressive cleaning agents makes them perfect for food manufacturing environments where cleanliness is non-negotiable. - Pharmaceutical Manufacturing:

The pharmaceutical industry also demands high hygiene standards. Equipment used in this sector must be designed to minimize the risk of contamination, especially in the production of medicines, vaccines, and dietary supplements. The hygienic properties of the EHEDG corner nuts make them ideal for securing components of pharmaceutical manufacturing equipment, such as filtration systems and reactors. - Dairy and Beverage Processing:

Dairy and beverage plants benefit from the use of EHEDG Hygienic corner nuts due to their ability to maintain the necessary sanitary conditions. In these industries, where products like milk, yogurt, juices, and soft drinks are processed and packaged, the corner nuts prevent the accumulation of bacteria, helping manufacturers comply with food safety regulations.

Advantages Over Traditional Fasteners

Traditional fasteners often have gaps, threads, or crevices where dirt and bacteria can accumulate. These hard-to-reach areas pose a significant risk of contamination, especially in sanitary applications. In contrast, EHEDG Hygienic corner nuts are designed with smooth surfaces and fewer crevices, minimizing the chances of contamination.

The corrosion resistance and durability of stainless steel ensure that these fasteners maintain their structural integrity, even in extreme cleaning cycles. The added bonus is their long lifespan, meaning fewer replacements are needed, resulting in cost savings over time.

The Importance of EHEDG Hygienic Corner Nuts in Stainless Steel

For Food, Pharmaceutical and other hygiene-sensitive industries

The EHEDG Hygienic corner nut in stainless steel is an essential component for ensuring hygiene, safety, and durability in food processing, pharmaceutical, and other hygienic environments. By meeting stringent industry standards, these corner nuts offer manufacturers the peace of mind they need to comply with hygiene regulations while maintaining the longevity and efficiency of their equipment.

For industries prioritizing cleanliness and reliability, choosing EHEDG and Sanitary Standards certified components like the hygienic corner nut is a smart and necessary investment.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Ensuring Hygiene and Durability

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic Corner Nut

3A CN M5-L15 Ø12

3A CN M5-L25 Ø12

3A CN M6-L15 Ø12

3A CN M6-L25 Ø12

3A CN M8-L15 Ø15

3A CN M8-L25 Ø15

3A CN M10-L20 Ø20

3A CN M10-L30 Ø20

3A CN M12-L20 Ø22

3A CN M12-L30 Ø22

3A CN M16-L30 Ø28

3A CN M16-L40 Ø28

3A CN M20-L30 Ø32

3A CN M20-L40 Ø32

3A CN M24-L40 Ø36

3A CN M24-L50 Ø36

3A CN M30-L40 Ø46

3A CN M30-L50 Ø46

See our products for long-term cost savings here

Contact us for hygienic solution

What is an EHEDG Hygienic Corner Nut?

In industries where hygiene and safety are paramount, such as food processing and pharmaceuticals, the use of certified components is a must. The EHEDG Hygienic corner nut in stainless steel is a specialized fastening component designed to meet stringent hygienic standards. Certified by the EHEDG (European Hygienic Engineering & Design Group) and Sanitary Standards, these corner nuts play a crucial role in maintaining the integrity and cleanliness of equipment used in food and pharmaceutical processing environments.

Key Features and Benefits of EHEDG Hygienic Corner Nuts

- Hygienic Design:

The EHEDG Hygienic corner nuts are specifically engineered to ensure that no contaminants can accumulate in hard-to-reach areas. Their smooth, crevice-free surface prevents bacteria growth and allows for easy cleaning, making them ideal for hygienic environments. - Durability and Corrosion Resistance:

Manufactured from high-quality stainless steel, these corner nuts offer exceptional corrosion resistance, ensuring longevity even under harsh conditions. Stainless steel also provides resistance to common chemicals used in cleaning and sanitizing processes, ensuring that the nuts maintain their strength and hygiene properties over time. - Certifications:

These corner nuts are certified under both EHEDG and Sanitary Standards, offering assurance that they meet or exceed the hygiene and safety requirements set for food and pharmaceutical industries. The EHEDG certification guarantees that the components adhere to best practices in hygienic engineering, while the Sanitary Standards certification provides an additional layer of trust, especially for the U.S. market. - Versatility in Applications:

The EHEDG corner nuts are versatile and can be used in a variety of applications within food and pharmaceutical processing, such as on machinery, equipment frames, and piping systems. Whether in the dairy, beverage, or pharmaceutical industry, these corner nuts ensure that equipment is easily accessible for cleaning, maintenance, and sanitation.

Applications in Food Processing and Pharmaceutical Industries

- Food Processing:

In food processing plants, hygiene is critical to prevent contamination. The EHEDG Hygienic corner nuts are used to secure equipment parts such as conveyor systems, mixing machines, and filling lines. Their ability to withstand high-pressure washdowns and exposure to aggressive cleaning agents makes them perfect for food manufacturing environments where cleanliness is non-negotiable. - Pharmaceutical Manufacturing:

The pharmaceutical industry also demands high hygiene standards. Equipment used in this sector must be designed to minimize the risk of contamination, especially in the production of medicines, vaccines, and dietary supplements. The hygienic properties of the EHEDG corner nuts make them ideal for securing components of pharmaceutical manufacturing equipment, such as filtration systems and reactors. - Dairy and Beverage Processing:

Dairy and beverage plants benefit from the use of EHEDG Hygienic corner nuts due to their ability to maintain the necessary sanitary conditions. In these industries, where products like milk, yogurt, juices, and soft drinks are processed and packaged, the corner nuts prevent the accumulation of bacteria, helping manufacturers comply with food safety regulations.

Advantages Over Traditional Fasteners

Traditional fasteners often have gaps, threads, or crevices where dirt and bacteria can accumulate. These hard-to-reach areas pose a significant risk of contamination, especially in sanitary applications. In contrast, EHEDG Hygienic corner nuts are designed with smooth surfaces and fewer crevices, minimizing the chances of contamination.

The corrosion resistance and durability of stainless steel ensure that these fasteners maintain their structural integrity, even in extreme cleaning cycles. The added bonus is their long lifespan, meaning fewer replacements are needed, resulting in cost savings over time.

The Importance of EHEDG Hygienic Corner Nuts in Stainless Steel

For Food, Pharmaceutical and other hygiene-sensitive industries

The EHEDG Hygienic corner nut in stainless steel is an essential component for ensuring hygiene, safety, and durability in food processing, pharmaceutical, and other hygienic environments. By meeting stringent industry standards, these corner nuts offer manufacturers the peace of mind they need to comply with hygiene regulations while maintaining the longevity and efficiency of their equipment.

For industries prioritizing cleanliness and reliability, choosing EHEDG and Sanitary Standards certified components like the hygienic corner nut is a smart and necessary investment.

Ensuring Hygiene and Durability

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic Corner Nut

3A CN M5-L15 Ø12

3A CN M5-L25 Ø12

3A CN M6-L15 Ø12

3A CN M6-L25 Ø12

3A CN M8-L15 Ø15

3A CN M8-L25 Ø15

3A CN M10-L20 Ø20

3A CN M10-L30 Ø20

3A CN M12-L20 Ø22

3A CN M12-L30 Ø22

3A CN M16-L30 Ø28

3A CN M16-L40 Ø28

3A CN M20-L30 Ø32

3A CN M20-L40 Ø32

3A CN M24-L40 Ø36

3A CN M24-L50 Ø36

3A CN M30-L40 Ø46

3A CN M30-L50 Ø46

See our products for long-term cost savings here

Contact us for hygienic solution

What is an EHEDG Hygienic Corner Nut?

In industries where hygiene and safety are paramount, such as food processing and pharmaceuticals, the use of certified components is a must. The EHEDG Hygienic corner nut in stainless steel is a specialized fastening component designed to meet stringent hygienic standards. Certified by the EHEDG (European Hygienic Engineering & Design Group) and Sanitary Standards, these corner nuts play a crucial role in maintaining the integrity and cleanliness of equipment used in food and pharmaceutical processing environments.

Key Features and Benefits of EHEDG Hygienic Corner Nuts

- Hygienic Design:

The EHEDG Hygienic corner nuts are specifically engineered to ensure that no contaminants can accumulate in hard-to-reach areas. Their smooth, crevice-free surface prevents bacteria growth and allows for easy cleaning, making them ideal for hygienic environments. - Durability and Corrosion Resistance:

Manufactured from high-quality stainless steel, these corner nuts offer exceptional corrosion resistance, ensuring longevity even under harsh conditions. Stainless steel also provides resistance to common chemicals used in cleaning and sanitizing processes, ensuring that the nuts maintain their strength and hygiene properties over time. - Certifications:

These corner nuts are certified under both EHEDG and Sanitary Standards, offering assurance that they meet or exceed the hygiene and safety requirements set for food and pharmaceutical industries. The EHEDG certification guarantees that the components adhere to best practices in hygienic engineering, while the Sanitary Standards certification provides an additional layer of trust, especially for the U.S. market. - Versatility in Applications:

The EHEDG corner nuts are versatile and can be used in a variety of applications within food and pharmaceutical processing, such as on machinery, equipment frames, and piping systems. Whether in the dairy, beverage, or pharmaceutical industry, these corner nuts ensure that equipment is easily accessible for cleaning, maintenance, and sanitation.

Applications in Food Processing and Pharmaceutical Industries

- Food Processing:

In food processing plants, hygiene is critical to prevent contamination. The EHEDG Hygienic corner nuts are used to secure equipment parts such as conveyor systems, mixing machines, and filling lines. Their ability to withstand high-pressure washdowns and exposure to aggressive cleaning agents makes them perfect for food manufacturing environments where cleanliness is non-negotiable. - Pharmaceutical Manufacturing:

The pharmaceutical industry also demands high hygiene standards. Equipment used in this sector must be designed to minimize the risk of contamination, especially in the production of medicines, vaccines, and dietary supplements. The hygienic properties of the EHEDG corner nuts make them ideal for securing components of pharmaceutical manufacturing equipment, such as filtration systems and reactors. - Dairy and Beverage Processing:

Dairy and beverage plants benefit from the use of EHEDG Hygienic corner nuts due to their ability to maintain the necessary sanitary conditions. In these industries, where products like milk, yogurt, juices, and soft drinks are processed and packaged, the corner nuts prevent the accumulation of bacteria, helping manufacturers comply with food safety regulations.

Advantages Over Traditional Fasteners

Traditional fasteners often have gaps, threads, or crevices where dirt and bacteria can accumulate. These hard-to-reach areas pose a significant risk of contamination, especially in sanitary applications. In contrast, EHEDG Hygienic corner nuts are designed with smooth surfaces and fewer crevices, minimizing the chances of contamination.

The corrosion resistance and durability of stainless steel ensure that these fasteners maintain their structural integrity, even in extreme cleaning cycles. The added bonus is their long lifespan, meaning fewer replacements are needed, resulting in cost savings over time.

The Importance of EHEDG Hygienic Corner Nuts in Stainless Steel

For Food, Pharmaceutical and other hygiene-sensitive industries

The EHEDG Hygienic corner nut in stainless steel is an essential component for ensuring hygiene, safety, and durability in food processing, pharmaceutical, and other hygienic environments. By meeting stringent industry standards, these corner nuts offer manufacturers the peace of mind they need to comply with hygiene regulations while maintaining the longevity and efficiency of their equipment.

For industries prioritizing cleanliness and reliability, choosing EHEDG and Sanitary Standards certified components like the hygienic corner nut is a smart and necessary investment.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.