Contact us

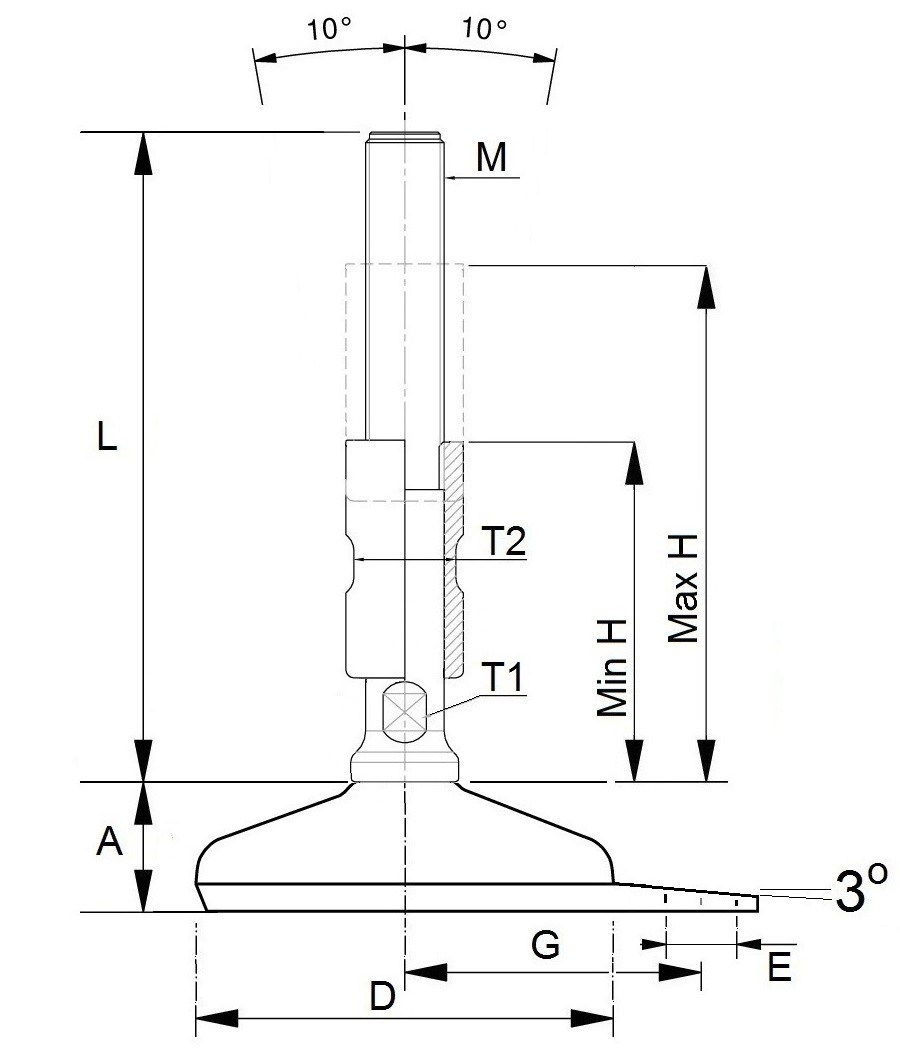

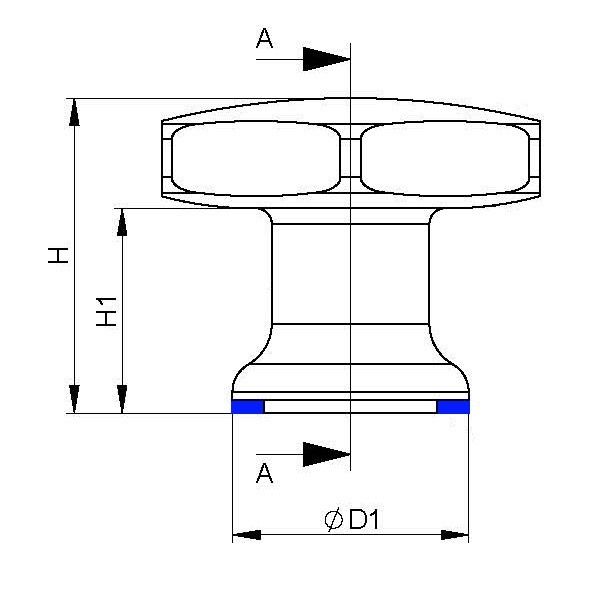

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

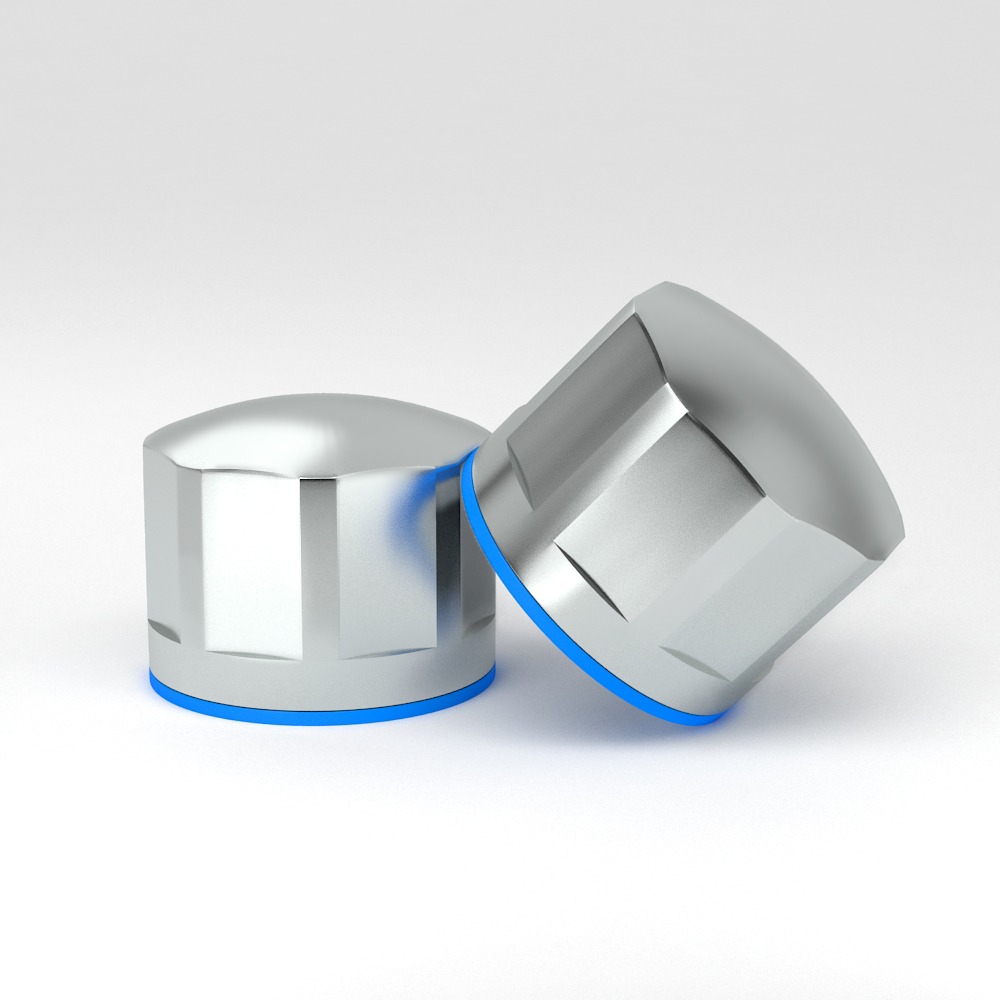

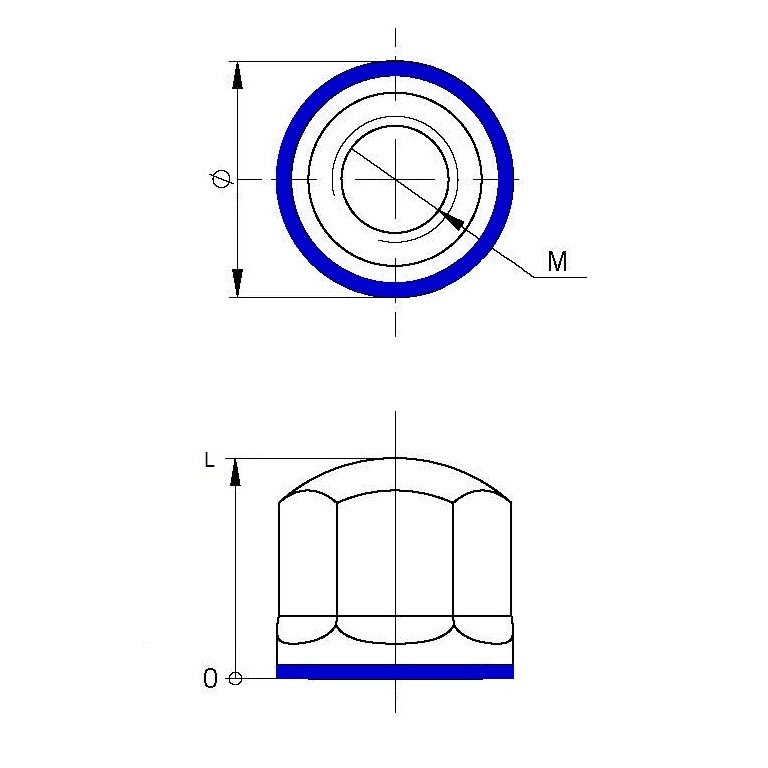

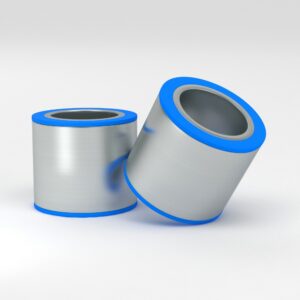

EHEDG-certified nut

A Must-Have for Hygienic Equipment

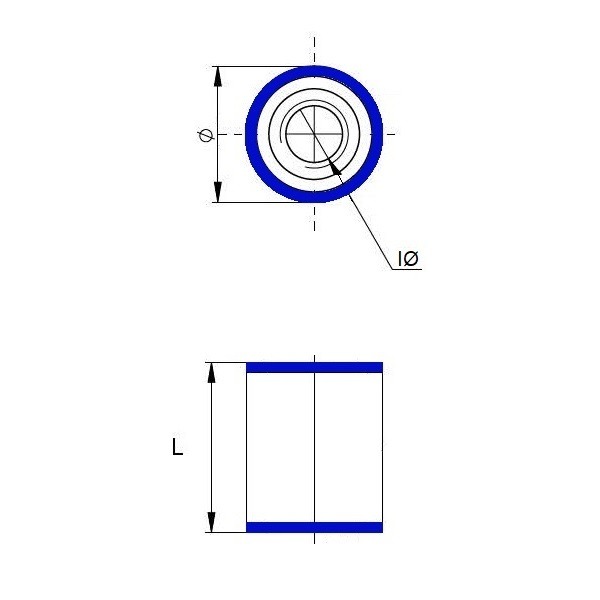

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

The design of the nuts does not deviate from the sizes of current standard nuts. Therefore, wrench sizes, thread heights etc. all remains the same making it very easy to upgrade and replace standard nuts. This is the right choice of nuts to be used on all machinery in all certified hygienic wash-down environments.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic nut

3A HN M5-L12 Ø12

3A HN M5-L18 Ø12

3A HN M6-L12 Ø12

3A HN M6-L18 Ø12

3A HN M8-L14 Ø15

3A HN M8-L21 Ø15

3A HN M10-L16 Ø20

3A HN M10-L24 Ø20

3A HN M12-L18 Ø22

3A HN M12-L27 Ø22

3A HN M16-L20 Ø28

3A HN M16-L30 Ø28

3A HN M20-L22 Ø32

3A HN M20-L33 Ø32

3A HN M24-L24 Ø36

3A HN M24-L36 Ø36

3A HN M30-L26 Ø46

3A HN M30-L39 Ø46

See our product line here | NHK Machinery Parts

Contact us for hygienic solution

EHEDG Hygienic Nut in Stainless Steel:

Ensuring Hygiene and Durability in Food and Pharmaceutical Processing

In industries where hygiene is a priority, such as food processing, pharmaceuticals, and biotechnology, the quality of each component plays a vital role. One such critical component is the EHEDG hygienic nut in stainless steel, which ensures both the structural integrity and hygiene compliance of equipment used in these industries. This article will dive into the unique features and advantages of this essential part and how it contributes to optimizing machinery design and maintenance.

What is an EHEDG Hygienic Nut?

The EHEDG hygienic nut is a specialized fastening component crafted from high-quality stainless steel. It is designed to meet the stringent hygiene and safety standards required in food, beverage, and pharmaceutical manufacturing. This type of nut is certified by organizations like the European Hygienic Engineering and Design Group (EHEDG) and Sanitary Standards, which focus on promoting the highest standards of cleanliness and food safety in processing equipment.

EHEDG hygienic nuts are part of a broader set of guidelines aimed at preventing contamination and ensuring that food and pharmaceutical products are safe for consumption and use. These nuts are engineered to prevent dirt, bacteria, and other contaminants from accumulating in hard-to-clean areas, which is a common issue with standard fastening components.

Key Features of EHEDG Hygienic Nuts

1. Corrosion Resistance

One of the primary benefits of using stainless steel EHEDG hygienic nuts is their excellent resistance to corrosion. Stainless steel, particularly grades such as AISI 304 or 316, is highly resistant to oxidation and staining. This makes these nuts ideal for environments that experience frequent washing, exposure to moisture, or interaction with aggressive cleaning agents used in hygienic applications.

2. Easy to Clean and Maintain

The design of the EHEDG hygienic nut ensures that it is smooth, non-porous, and free of threads that could trap contaminants. This makes them easy to clean, which is a critical feature in industries where hygiene is paramount. The absence of crevices or grooves ensures that cleaning agents can easily reach every surface, preventing the buildup of bacteria, mold, or other harmful agents.

3. High Durability and Longevity

EHEDG hygienic nuts are designed for high performance in demanding environments. They are capable of withstanding extreme temperatures and pressure variations, which are common in processing equipment. The durability of these nuts reduces the frequency of replacements and helps to ensure the continuous operation of machinery without costly downtime.

4. Precision Engineering

EHEDG hygienic nuts are manufactured with precision to meet specific requirements. This ensures that each nut fits securely and tightly, reducing the risk of machinery malfunctions or product contamination. Their standardized design also ensures compatibility with a wide range of equipment, making them a versatile choice for manufacturers.

5. Compliance with Hygienic Standards

The EHEDG certification standard ensures that these nuts comply with international safety and hygiene regulations. Whether used in the food and beverage industry or the pharmaceutical sector, these components meet the critical criteria for sanitation, preventing cross-contamination in production processes.

Applications of EHEDG Hygienic Nuts

EHEDG hygienic nuts are used in a variety of applications across multiple industries. Some notable uses include:

- Food Processing: In food production facilities, hygienic nuts are used to secure equipment such as pasteurizers, mixers, and conveyors, all of which require regular cleaning.

- Pharmaceutical Manufacturing: These nuts are commonly used in pharmaceutical processing equipment, including mixers, reactors, and filling machines, where cleanliness and precision are paramount.

- Biotechnology: In biotech facilities, these nuts are often employed in fermentation tanks, reactors, and filtration systems, where strict hygienic conditions must be maintained.

Why Choose EHEDG Hygienic Nuts?

In industries where hygiene is non-negotiable, EHEDG hygienic nuts in stainless steel offer the perfect solution to meet high standards of cleanliness, durability, and functionality. Their corrosion resistance, easy-to-clean design, and compatibility with various types of hygienic equipment make them indispensable for the food, pharmaceutical, and biotechnology industries. Whether you are designing new equipment or upgrading existing machinery, incorporating EHEDG certified components ensures your operations remain compliant, efficient, and safe.

By choosing EHEDG hygienic nuts, you are investing in a component that not only enhances the reliability and longevity of your equipment but also contributes to a cleaner and safer manufacturing environment.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

A Must-Have for Hygienic Equipment

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

The design of the nuts does not deviate from the sizes of current standard nuts. Therefore, wrench sizes, thread heights etc. all remains the same making it very easy to upgrade and replace standard nuts. This is the right choice of nuts to be used on all machinery in all certified hygienic wash-down environments.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic nut

3A HN M5-L12 Ø12

3A HN M5-L18 Ø12

3A HN M6-L12 Ø12

3A HN M6-L18 Ø12

3A HN M8-L14 Ø15

3A HN M8-L21 Ø15

3A HN M10-L16 Ø20

3A HN M10-L24 Ø20

3A HN M12-L18 Ø22

3A HN M12-L27 Ø22

3A HN M16-L20 Ø28

3A HN M16-L30 Ø28

3A HN M20-L22 Ø32

3A HN M20-L33 Ø32

3A HN M24-L24 Ø36

3A HN M24-L36 Ø36

3A HN M30-L26 Ø46

3A HN M30-L39 Ø46

See our product line here | NHK Machinery Parts

Contact us for hygienic solution

EHEDG Hygienic Nut in Stainless Steel:

Ensuring Hygiene and Durability in Food and Pharmaceutical Processing

In industries where hygiene is a priority, such as food processing, pharmaceuticals, and biotechnology, the quality of each component plays a vital role. One such critical component is the EHEDG hygienic nut in stainless steel, which ensures both the structural integrity and hygiene compliance of equipment used in these industries. This article will dive into the unique features and advantages of this essential part and how it contributes to optimizing machinery design and maintenance.

What is an EHEDG Hygienic Nut?

The EHEDG hygienic nut is a specialized fastening component crafted from high-quality stainless steel. It is designed to meet the stringent hygiene and safety standards required in food, beverage, and pharmaceutical manufacturing. This type of nut is certified by organizations like the European Hygienic Engineering and Design Group (EHEDG) and Sanitary Standards, which focus on promoting the highest standards of cleanliness and food safety in processing equipment.

EHEDG hygienic nuts are part of a broader set of guidelines aimed at preventing contamination and ensuring that food and pharmaceutical products are safe for consumption and use. These nuts are engineered to prevent dirt, bacteria, and other contaminants from accumulating in hard-to-clean areas, which is a common issue with standard fastening components.

Key Features of EHEDG Hygienic Nuts

1. Corrosion Resistance

One of the primary benefits of using stainless steel EHEDG hygienic nuts is their excellent resistance to corrosion. Stainless steel, particularly grades such as AISI 304 or 316, is highly resistant to oxidation and staining. This makes these nuts ideal for environments that experience frequent washing, exposure to moisture, or interaction with aggressive cleaning agents used in hygienic applications.

2. Easy to Clean and Maintain

The design of the EHEDG hygienic nut ensures that it is smooth, non-porous, and free of threads that could trap contaminants. This makes them easy to clean, which is a critical feature in industries where hygiene is paramount. The absence of crevices or grooves ensures that cleaning agents can easily reach every surface, preventing the buildup of bacteria, mold, or other harmful agents.

3. High Durability and Longevity

EHEDG hygienic nuts are designed for high performance in demanding environments. They are capable of withstanding extreme temperatures and pressure variations, which are common in processing equipment. The durability of these nuts reduces the frequency of replacements and helps to ensure the continuous operation of machinery without costly downtime.

4. Precision Engineering

EHEDG hygienic nuts are manufactured with precision to meet specific requirements. This ensures that each nut fits securely and tightly, reducing the risk of machinery malfunctions or product contamination. Their standardized design also ensures compatibility with a wide range of equipment, making them a versatile choice for manufacturers.

5. Compliance with Hygienic Standards

The EHEDG certification standard ensures that these nuts comply with international safety and hygiene regulations. Whether used in the food and beverage industry or the pharmaceutical sector, these components meet the critical criteria for sanitation, preventing cross-contamination in production processes.

Applications of EHEDG Hygienic Nuts

EHEDG hygienic nuts are used in a variety of applications across multiple industries. Some notable uses include:

- Food Processing: In food production facilities, hygienic nuts are used to secure equipment such as pasteurizers, mixers, and conveyors, all of which require regular cleaning.

- Pharmaceutical Manufacturing: These nuts are commonly used in pharmaceutical processing equipment, including mixers, reactors, and filling machines, where cleanliness and precision are paramount.

- Biotechnology: In biotech facilities, these nuts are often employed in fermentation tanks, reactors, and filtration systems, where strict hygienic conditions must be maintained.

Why Choose EHEDG Hygienic Nuts?

In industries where hygiene is non-negotiable, EHEDG hygienic nuts in stainless steel offer the perfect solution to meet high standards of cleanliness, durability, and functionality. Their corrosion resistance, easy-to-clean design, and compatibility with various types of hygienic equipment make them indispensable for the food, pharmaceutical, and biotechnology industries. Whether you are designing new equipment or upgrading existing machinery, incorporating EHEDG certified components ensures your operations remain compliant, efficient, and safe.

By choosing EHEDG hygienic nuts, you are investing in a component that not only enhances the reliability and longevity of your equipment but also contributes to a cleaner and safer manufacturing environment.

A Must-Have for Hygienic Equipment

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

The design of the nuts does not deviate from the sizes of current standard nuts. Therefore, wrench sizes, thread heights etc. all remains the same making it very easy to upgrade and replace standard nuts. This is the right choice of nuts to be used on all machinery in all certified hygienic wash-down environments.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic nut

3A HN M5-L12 Ø12

3A HN M5-L18 Ø12

3A HN M6-L12 Ø12

3A HN M6-L18 Ø12

3A HN M8-L14 Ø15

3A HN M8-L21 Ø15

3A HN M10-L16 Ø20

3A HN M10-L24 Ø20

3A HN M12-L18 Ø22

3A HN M12-L27 Ø22

3A HN M16-L20 Ø28

3A HN M16-L30 Ø28

3A HN M20-L22 Ø32

3A HN M20-L33 Ø32

3A HN M24-L24 Ø36

3A HN M24-L36 Ø36

3A HN M30-L26 Ø46

3A HN M30-L39 Ø46

See our product line here | NHK Machinery Parts

Contact us for hygienic solution

EHEDG Hygienic Nut in Stainless Steel:

Ensuring Hygiene and Durability in Food and Pharmaceutical Processing

In industries where hygiene is a priority, such as food processing, pharmaceuticals, and biotechnology, the quality of each component plays a vital role. One such critical component is the EHEDG hygienic nut in stainless steel, which ensures both the structural integrity and hygiene compliance of equipment used in these industries. This article will dive into the unique features and advantages of this essential part and how it contributes to optimizing machinery design and maintenance.

What is an EHEDG Hygienic Nut?

The EHEDG hygienic nut is a specialized fastening component crafted from high-quality stainless steel. It is designed to meet the stringent hygiene and safety standards required in food, beverage, and pharmaceutical manufacturing. This type of nut is certified by organizations like the European Hygienic Engineering and Design Group (EHEDG) and Sanitary Standards, which focus on promoting the highest standards of cleanliness and food safety in processing equipment.

EHEDG hygienic nuts are part of a broader set of guidelines aimed at preventing contamination and ensuring that food and pharmaceutical products are safe for consumption and use. These nuts are engineered to prevent dirt, bacteria, and other contaminants from accumulating in hard-to-clean areas, which is a common issue with standard fastening components.

Key Features of EHEDG Hygienic Nuts

1. Corrosion Resistance

One of the primary benefits of using stainless steel EHEDG hygienic nuts is their excellent resistance to corrosion. Stainless steel, particularly grades such as AISI 304 or 316, is highly resistant to oxidation and staining. This makes these nuts ideal for environments that experience frequent washing, exposure to moisture, or interaction with aggressive cleaning agents used in hygienic applications.

2. Easy to Clean and Maintain

The design of the EHEDG hygienic nut ensures that it is smooth, non-porous, and free of threads that could trap contaminants. This makes them easy to clean, which is a critical feature in industries where hygiene is paramount. The absence of crevices or grooves ensures that cleaning agents can easily reach every surface, preventing the buildup of bacteria, mold, or other harmful agents.

3. High Durability and Longevity

EHEDG hygienic nuts are designed for high performance in demanding environments. They are capable of withstanding extreme temperatures and pressure variations, which are common in processing equipment. The durability of these nuts reduces the frequency of replacements and helps to ensure the continuous operation of machinery without costly downtime.

4. Precision Engineering

EHEDG hygienic nuts are manufactured with precision to meet specific requirements. This ensures that each nut fits securely and tightly, reducing the risk of machinery malfunctions or product contamination. Their standardized design also ensures compatibility with a wide range of equipment, making them a versatile choice for manufacturers.

5. Compliance with Hygienic Standards

The EHEDG certification standard ensures that these nuts comply with international safety and hygiene regulations. Whether used in the food and beverage industry or the pharmaceutical sector, these components meet the critical criteria for sanitation, preventing cross-contamination in production processes.

Applications of EHEDG Hygienic Nuts

EHEDG hygienic nuts are used in a variety of applications across multiple industries. Some notable uses include:

- Food Processing: In food production facilities, hygienic nuts are used to secure equipment such as pasteurizers, mixers, and conveyors, all of which require regular cleaning.

- Pharmaceutical Manufacturing: These nuts are commonly used in pharmaceutical processing equipment, including mixers, reactors, and filling machines, where cleanliness and precision are paramount.

- Biotechnology: In biotech facilities, these nuts are often employed in fermentation tanks, reactors, and filtration systems, where strict hygienic conditions must be maintained.

Why Choose EHEDG Hygienic Nuts?

In industries where hygiene is non-negotiable, EHEDG hygienic nuts in stainless steel offer the perfect solution to meet high standards of cleanliness, durability, and functionality. Their corrosion resistance, easy-to-clean design, and compatibility with various types of hygienic equipment make them indispensable for the food, pharmaceutical, and biotechnology industries. Whether you are designing new equipment or upgrading existing machinery, incorporating EHEDG certified components ensures your operations remain compliant, efficient, and safe.

By choosing EHEDG hygienic nuts, you are investing in a component that not only enhances the reliability and longevity of your equipment but also contributes to a cleaner and safer manufacturing environment.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.