Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

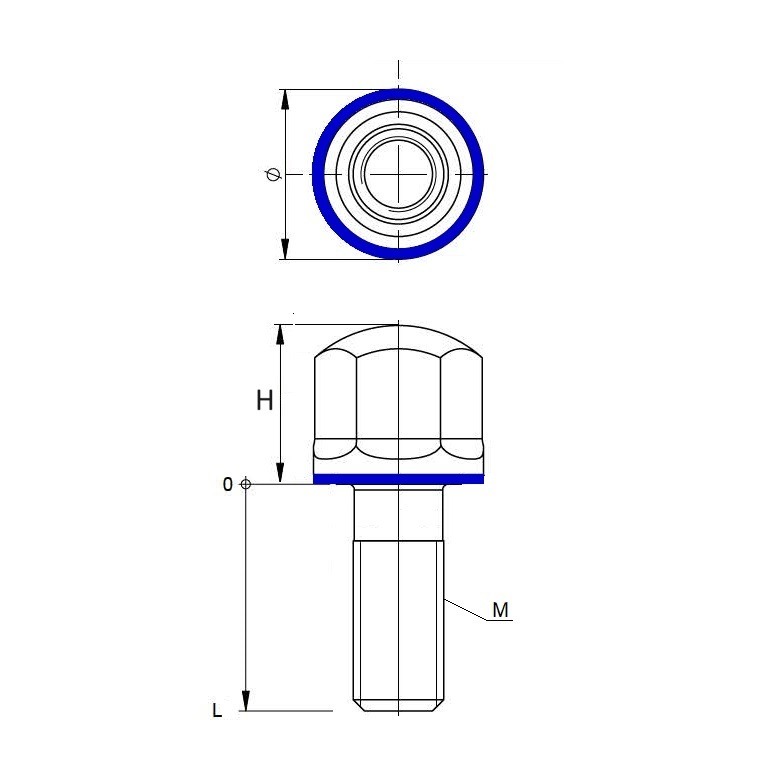

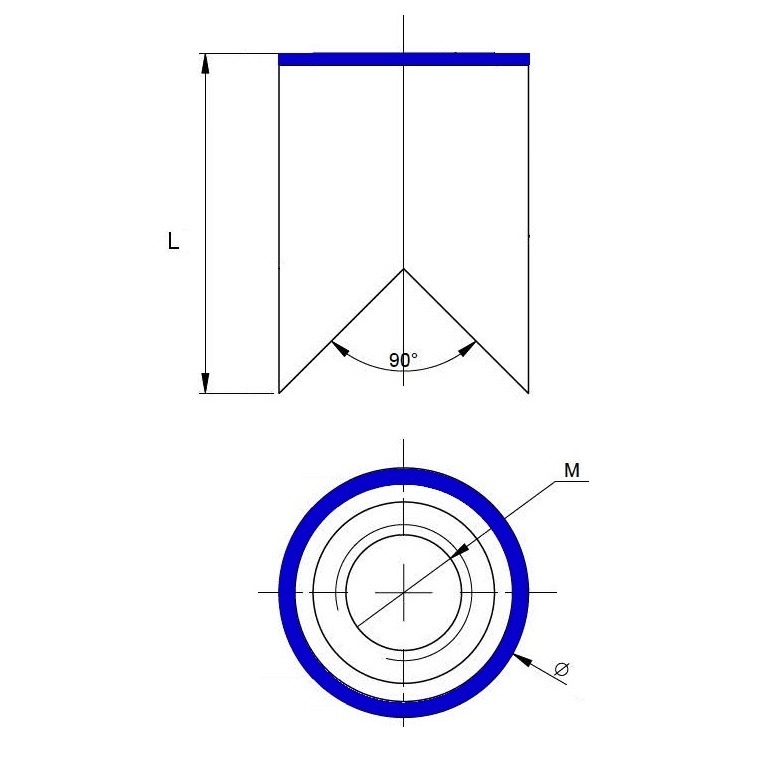

EHEDG-certified bolt M5 to M30

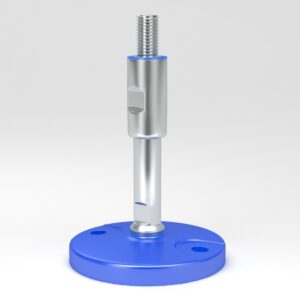

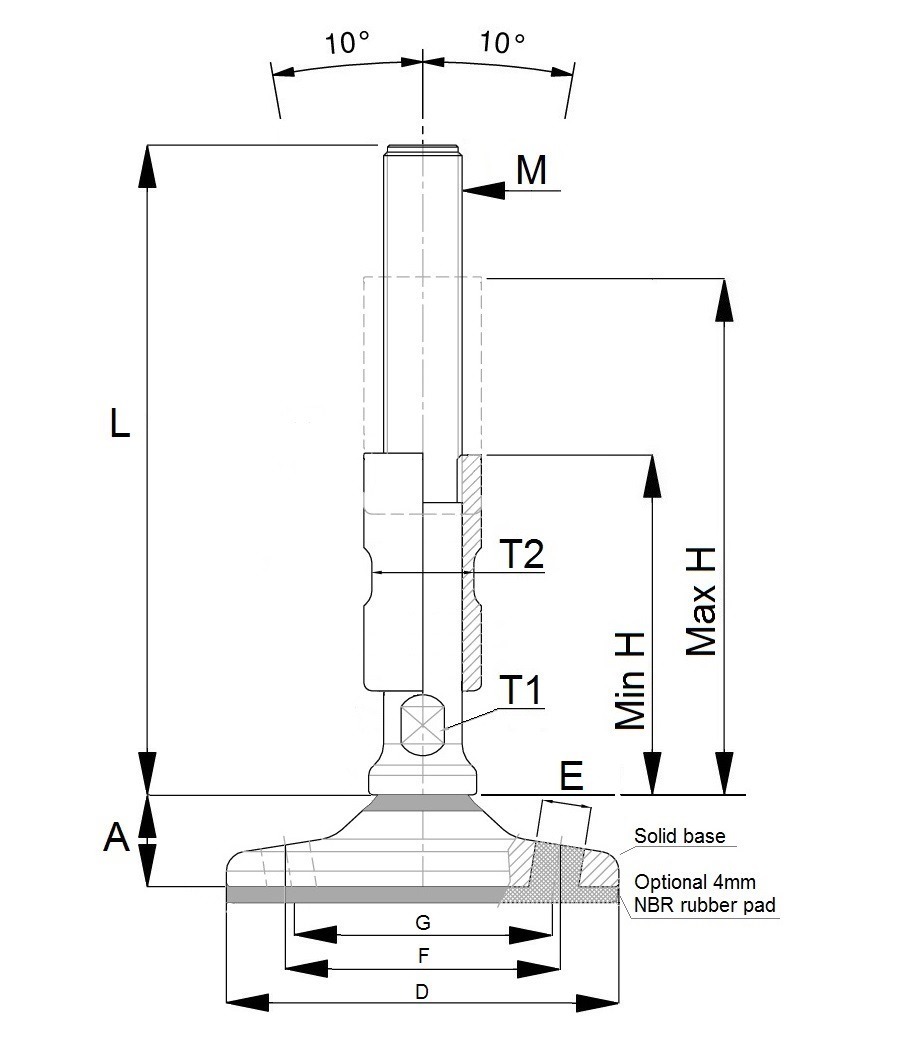

The Ideal Solution for Hygienic and Sanitary Applications

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

The design of the bolts does not deviate from the sizes of current standard bolts. Therefore, wrench sizes, thread heights etc. all remains the same making it very easy to upgrade and replace standard bolts. This is the right choice of bolts to be used on all machinery in all certified hygienic wash-down environments.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic bolt

3A HB M5-L10 Ø12 H=12

3A HB M5-L12 Ø12 H=12

3A HB M5-L16 Ø12 H=12

3A HB M5-L20 Ø12 H=12

3A HB M5-L25 Ø12 H=12

3A HB M5-L30 Ø12 H=12

3A HB M5-L35 Ø12 H=12

3A HB M6-L10 Ø12 H=12

3A HB M6-L12 Ø12 H=12

3A HB M6-L16 Ø12 H=12

3A HB M6-L20 Ø12 H=12

3A HB M6-L25 Ø12 H=12

3A HB M6-L30 Ø12 H=12

3A HB M6-L35 Ø12 H=12

3A HB M6-L40 Ø12 H=12

3A HB M6-L50 Ø12 H=12

3A HB M6-L60 Ø12 H=12

3A HB M6-L80 Ø12 H=12

3A HB M6-L100 Ø12 H=12

3A HB M8-L10 Ø15 H=14

3A HB M8-L12 Ø15 H=14

3A HB M8-L16 Ø15 H=14

3A HB M8-L20 Ø15 H=14

3A HB M8-L25 Ø15 H=14

3A HB M8-L30 Ø15 H=14

3A HB M8-L35 Ø15 H=14

3A HB M8-L40 Ø15 H=14

3A HB M8-L50 Ø15 H=14

3A HB M8-L60 Ø15 H=14

3A HB M8-L80 Ø15 H=14

3A HB M8-L100 Ø15 H=14

3A HB M10-L10 Ø20 H=16

3A HB M10-L12 Ø20 H=16

3A HB M10-L16 Ø20 H=16

3A HB M10-L20 Ø20 H=16

3A HB M10-L25 Ø20 H=16

3A HB M10-L30 Ø20 H=16

3A HB M10-L35 Ø20 H=16

3A HB M10-L40 Ø20 H=16

3A HB M10-L50 Ø20 H=16

3A HB M10-L60 Ø20 H=16

3A HB M10-L80 Ø20 H=16

3A HB M10-L100 Ø20 H=16

3A HB M12-L12 Ø22 H=18

3A HB M12-L16 Ø22 H=18

3A HB M12-L20 Ø22 H=18

3A HB M12-L25 Ø22 H=18

3A HB M12-L30 Ø22 H=18

3A HB M12-L35 Ø22 H=18

3A HB M12-L40 Ø22 H=18

3A HB M12-L50 Ø22 H=18

3A HB M12-L60 Ø22 H=18

3A HB M12-L80 Ø22 H=18

3A HB M12-L100 Ø22 H=18

3A HB M12-L120 Ø22 H=18

3A HB M16-L16 Ø28 H=20

3A HB M16-L20 Ø28 H=20

3A HB M16-L25 Ø28 H=20

3A HB M16-L30 Ø28 H=20

3A HB M16-L35 Ø28 H=20

3A HB M16-L40 Ø28 H=20

3A HB M16-L50 Ø28 H=20

3A HB M16-L60 Ø28 H=20

3A HB M16-L80 Ø28 H=20

3A HB M16-L100 Ø28 H=20

3A HB M16-L120 Ø28 H=20

3A HB M16-L150 Ø28 H=20

3A HB M20-L20 Ø32 H=22

3A HB M20-L25 Ø32 H=22

3A HB M20-L30 Ø32 H=22

3A HB M20-L35 Ø32 H=22

3A HB M20-L40 Ø32 H=22

3A HB M20-L50 Ø32 H=22

3A HB M20-L60 Ø32 H=22

3A HB M20-L80 Ø32 H=22

3A HB M20-L100 Ø32 H=22

3A HB M20-L120 Ø32 H=22

3A HB M20-L150 Ø32 H=22

3A HB M24-L25 Ø36 H=24

3A HB M24-L30 Ø36 H=24

3A HB M24-L35 Ø36 H=24

3A HB M24-L40 Ø36 H=24

3A HB M24-L50 Ø36 H=24

3A HB M24-L60 Ø36 H=24

3A HB M24-L80 Ø36 H=24

3A HB M24-L100 Ø36 H=24

3A HB M24-L120 Ø36 H=24

3A HB M24-L150 Ø36 H=24

3A HB M30-L30 Ø46 H=26

3A HB M30-L35 Ø46 H=26

3A HB M30-L40 Ø46 H=26

3A HB M30-L50 Ø46 H=26

3A HB M30-L60 Ø46 H=26

3A HB M30-L80 Ø46 H=26

3A HB M30-L100 Ø46 H=26

3A HB M30-L120 Ø46 H=26

3A HB M30-L150 Ø46 H=26

See our components which ensures product safety

Contact us for hygienic solution

What Are EHEDG Hygienic Bolts?

EHEDG (European Hygienic Engineering & Design Group) and Sanitary Standard are two internationally recognized standards that focus on hygienic design and performance, ensuring equipment components meet rigorous cleanliness requirements. The EHEDG Hygienic Bolts M5 to M30 in stainless steel are a prime example of high-quality components designed to meet these exacting standards. These bolts are commonly used in industries where hygiene and cleanliness are of paramount importance, including food processing, pharmaceuticals, and biotechnology.

Manufactured in stainless steel, these bolts are designed for use in environments that demand high levels of sterility. The M5 to M30 range ensures versatility, with bolts available in a variety of sizes to suit different equipment and machinery configurations.

The Importance of Hygienic Bolts in Sanitary Industries

In industries such as food processing and pharmaceuticals, equipment components like bolts are often exposed to harsh cleaning agents, high-pressure washing, and extreme temperatures. If these bolts are not designed with hygiene in mind, they can become breeding grounds for bacteria, mold, and other contaminants. The EHEDG Hygienic Bolts M5 to M30 are specifically engineered to prevent such risks, providing a solution that enhances overall equipment hygiene and reduces the chance of contamination.

These hygienic bolts are also designed to be corrosion-resistant, which makes them ideal for use in environments with high humidity or in systems exposed to chemicals, moisture, and steam. By maintaining their integrity over time, they ensure that your equipment runs efficiently and safely, with minimal risk of bacterial growth or contamination.

Features of EHEDG Hygienic Bolts M5 to M30

Several key features make the EHEDG Hygienic Bolts M5 to M30 a top choice for industries where hygiene is critical:

- Stainless Steel Construction: The stainless steel material ensures the bolts are durable, corrosion-resistant, and easy to clean, all of which are crucial for maintaining a sterile environment.

- EHEDG & Sanitary Standard Certified: These bolts meet the strict hygienic design standards set by EHEDG and Sanitary Standard, ensuring they comply with the highest industry standards for sanitation.

- Versatility in Sizes: With a size range from M5 to M30, these bolts can be used in various applications, providing flexibility for different equipment and machinery designs.

- Smooth Surface: The smooth surface of the bolts helps prevent the buildup of dirt, bacteria, and other contaminants, making them easy to clean and maintain.

- Resistance to Extreme Conditions: EHEDG Hygienic Bolts are designed to withstand high-pressure washing, heat, and exposure to cleaning chemicals, making them perfect for environments that require frequent sanitization.

Applications of EHEDG Hygienic Bolts M5 to M30

The versatility and hygienic design of these bolts make them suitable for a wide range of applications across various industries:

- Food Processing: In food production, these hygienic bolts ensure that processing equipment is safe, clean, and efficient. From mixers to conveyors, any equipment in direct contact with food must be designed to meet stringent hygiene regulations.

- Pharmaceutical Manufacturing: In pharmaceutical facilities, hygiene and safety are critical to producing high-quality medicines. These bolts are used to fasten equipment in areas where sterility must be maintained, such as in filling lines, mixers, and reactors.

- Biotechnology: In biotechnology research and development, these bolts provide the necessary hygienic performance required for sterilized equipment, ensuring no contamination interferes with the research or product development process.

- Chemical Manufacturing: The bolts are also suitable for use in the chemical industry, where harsh chemicals are often present, and hygiene must be maintained to prevent cross-contamination.

Why Choose EHEDG Hygienic Bolts?

Choosing EHEDG Hygienic Bolts M5 to M30 offers a host of benefits for companies across various industries:

- Compliance with Hygienic Standards: Meeting the EHEDG and Sanitary Standards guarantees that the bolts are compliant with industry regulations, which is essential for passing audits and maintaining certifications.

- Enhanced Equipment Longevity: With corrosion-resistant properties and durability, these bolts help extend the life of your equipment, reducing the need for frequent replacements and maintenance.

- Improved Operational Efficiency: The use of hygienic components, such as these bolts, helps prevent equipment breakdowns caused by contamination, improving the overall efficiency of your operations.

- Ease of Maintenance: The smooth, non-porous surface of the bolts simplifies cleaning, ensuring that maintenance time is minimized and sanitary conditions are upheld.

EHEDG Hygienic Bolts M5 to M30 in Stainless Steel

Ensuring Hygiene and Durability for Critical Industries

The EHEDG Hygienic Bolts M5 to M30 in stainless steel are essential components for industries where hygiene and safety are top priorities. Their durable construction, resistance to harsh cleaning conditions, and compliance with stringent hygiene standards make them an excellent choice for applications in food processing, pharmaceuticals, biotechnology, and other sanitary environments. By choosing these bolts, businesses can improve the safety, efficiency, and longevity of their equipment while ensuring compliance with health and safety regulations.

See our components which ensures product safety

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

The Ideal Solution for Hygienic and Sanitary Applications

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

The design of the bolts does not deviate from the sizes of current standard bolts. Therefore, wrench sizes, thread heights etc. all remains the same making it very easy to upgrade and replace standard bolts. This is the right choice of bolts to be used on all machinery in all certified hygienic wash-down environments.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic bolt

3A HB M5-L10 Ø12 H=12

3A HB M5-L12 Ø12 H=12

3A HB M5-L16 Ø12 H=12

3A HB M5-L20 Ø12 H=12

3A HB M5-L25 Ø12 H=12

3A HB M5-L30 Ø12 H=12

3A HB M5-L35 Ø12 H=12

3A HB M6-L10 Ø12 H=12

3A HB M6-L12 Ø12 H=12

3A HB M6-L16 Ø12 H=12

3A HB M6-L20 Ø12 H=12

3A HB M6-L25 Ø12 H=12

3A HB M6-L30 Ø12 H=12

3A HB M6-L35 Ø12 H=12

3A HB M6-L40 Ø12 H=12

3A HB M6-L50 Ø12 H=12

3A HB M6-L60 Ø12 H=12

3A HB M6-L80 Ø12 H=12

3A HB M6-L100 Ø12 H=12

3A HB M8-L10 Ø15 H=14

3A HB M8-L12 Ø15 H=14

3A HB M8-L16 Ø15 H=14

3A HB M8-L20 Ø15 H=14

3A HB M8-L25 Ø15 H=14

3A HB M8-L30 Ø15 H=14

3A HB M8-L35 Ø15 H=14

3A HB M8-L40 Ø15 H=14

3A HB M8-L50 Ø15 H=14

3A HB M8-L60 Ø15 H=14

3A HB M8-L80 Ø15 H=14

3A HB M8-L100 Ø15 H=14

3A HB M10-L10 Ø20 H=16

3A HB M10-L12 Ø20 H=16

3A HB M10-L16 Ø20 H=16

3A HB M10-L20 Ø20 H=16

3A HB M10-L25 Ø20 H=16

3A HB M10-L30 Ø20 H=16

3A HB M10-L35 Ø20 H=16

3A HB M10-L40 Ø20 H=16

3A HB M10-L50 Ø20 H=16

3A HB M10-L60 Ø20 H=16

3A HB M10-L80 Ø20 H=16

3A HB M10-L100 Ø20 H=16

3A HB M12-L12 Ø22 H=18

3A HB M12-L16 Ø22 H=18

3A HB M12-L20 Ø22 H=18

3A HB M12-L25 Ø22 H=18

3A HB M12-L30 Ø22 H=18

3A HB M12-L35 Ø22 H=18

3A HB M12-L40 Ø22 H=18

3A HB M12-L50 Ø22 H=18

3A HB M12-L60 Ø22 H=18

3A HB M12-L80 Ø22 H=18

3A HB M12-L100 Ø22 H=18

3A HB M12-L120 Ø22 H=18

3A HB M16-L16 Ø28 H=20

3A HB M16-L20 Ø28 H=20

3A HB M16-L25 Ø28 H=20

3A HB M16-L30 Ø28 H=20

3A HB M16-L35 Ø28 H=20

3A HB M16-L40 Ø28 H=20

3A HB M16-L50 Ø28 H=20

3A HB M16-L60 Ø28 H=20

3A HB M16-L80 Ø28 H=20

3A HB M16-L100 Ø28 H=20

3A HB M16-L120 Ø28 H=20

3A HB M16-L150 Ø28 H=20

3A HB M20-L20 Ø32 H=22

3A HB M20-L25 Ø32 H=22

3A HB M20-L30 Ø32 H=22

3A HB M20-L35 Ø32 H=22

3A HB M20-L40 Ø32 H=22

3A HB M20-L50 Ø32 H=22

3A HB M20-L60 Ø32 H=22

3A HB M20-L80 Ø32 H=22

3A HB M20-L100 Ø32 H=22

3A HB M20-L120 Ø32 H=22

3A HB M20-L150 Ø32 H=22

3A HB M24-L25 Ø36 H=24

3A HB M24-L30 Ø36 H=24

3A HB M24-L35 Ø36 H=24

3A HB M24-L40 Ø36 H=24

3A HB M24-L50 Ø36 H=24

3A HB M24-L60 Ø36 H=24

3A HB M24-L80 Ø36 H=24

3A HB M24-L100 Ø36 H=24

3A HB M24-L120 Ø36 H=24

3A HB M24-L150 Ø36 H=24

3A HB M30-L30 Ø46 H=26

3A HB M30-L35 Ø46 H=26

3A HB M30-L40 Ø46 H=26

3A HB M30-L50 Ø46 H=26

3A HB M30-L60 Ø46 H=26

3A HB M30-L80 Ø46 H=26

3A HB M30-L100 Ø46 H=26

3A HB M30-L120 Ø46 H=26

3A HB M30-L150 Ø46 H=26

See our components which ensures product safety

Contact us for hygienic solution

What Are EHEDG Hygienic Bolts?

EHEDG (European Hygienic Engineering & Design Group) and Sanitary Standard are two internationally recognized standards that focus on hygienic design and performance, ensuring equipment components meet rigorous cleanliness requirements. The EHEDG Hygienic Bolts M5 to M30 in stainless steel are a prime example of high-quality components designed to meet these exacting standards. These bolts are commonly used in industries where hygiene and cleanliness are of paramount importance, including food processing, pharmaceuticals, and biotechnology.

Manufactured in stainless steel, these bolts are designed for use in environments that demand high levels of sterility. The M5 to M30 range ensures versatility, with bolts available in a variety of sizes to suit different equipment and machinery configurations.

The Importance of Hygienic Bolts in Sanitary Industries

In industries such as food processing and pharmaceuticals, equipment components like bolts are often exposed to harsh cleaning agents, high-pressure washing, and extreme temperatures. If these bolts are not designed with hygiene in mind, they can become breeding grounds for bacteria, mold, and other contaminants. The EHEDG Hygienic Bolts M5 to M30 are specifically engineered to prevent such risks, providing a solution that enhances overall equipment hygiene and reduces the chance of contamination.

These hygienic bolts are also designed to be corrosion-resistant, which makes them ideal for use in environments with high humidity or in systems exposed to chemicals, moisture, and steam. By maintaining their integrity over time, they ensure that your equipment runs efficiently and safely, with minimal risk of bacterial growth or contamination.

Features of EHEDG Hygienic Bolts M5 to M30

Several key features make the EHEDG Hygienic Bolts M5 to M30 a top choice for industries where hygiene is critical:

- Stainless Steel Construction: The stainless steel material ensures the bolts are durable, corrosion-resistant, and easy to clean, all of which are crucial for maintaining a sterile environment.

- EHEDG & Sanitary Standard Certified: These bolts meet the strict hygienic design standards set by EHEDG and Sanitary Standard, ensuring they comply with the highest industry standards for sanitation.

- Versatility in Sizes: With a size range from M5 to M30, these bolts can be used in various applications, providing flexibility for different equipment and machinery designs.

- Smooth Surface: The smooth surface of the bolts helps prevent the buildup of dirt, bacteria, and other contaminants, making them easy to clean and maintain.

- Resistance to Extreme Conditions: EHEDG Hygienic Bolts are designed to withstand high-pressure washing, heat, and exposure to cleaning chemicals, making them perfect for environments that require frequent sanitization.

Applications of EHEDG Hygienic Bolts M5 to M30

The versatility and hygienic design of these bolts make them suitable for a wide range of applications across various industries:

- Food Processing: In food production, these hygienic bolts ensure that processing equipment is safe, clean, and efficient. From mixers to conveyors, any equipment in direct contact with food must be designed to meet stringent hygiene regulations.

- Pharmaceutical Manufacturing: In pharmaceutical facilities, hygiene and safety are critical to producing high-quality medicines. These bolts are used to fasten equipment in areas where sterility must be maintained, such as in filling lines, mixers, and reactors.

- Biotechnology: In biotechnology research and development, these bolts provide the necessary hygienic performance required for sterilized equipment, ensuring no contamination interferes with the research or product development process.

- Chemical Manufacturing: The bolts are also suitable for use in the chemical industry, where harsh chemicals are often present, and hygiene must be maintained to prevent cross-contamination.

Why Choose EHEDG Hygienic Bolts?

Choosing EHEDG Hygienic Bolts M5 to M30 offers a host of benefits for companies across various industries:

- Compliance with Hygienic Standards: Meeting the EHEDG and Sanitary Standards guarantees that the bolts are compliant with industry regulations, which is essential for passing audits and maintaining certifications.

- Enhanced Equipment Longevity: With corrosion-resistant properties and durability, these bolts help extend the life of your equipment, reducing the need for frequent replacements and maintenance.

- Improved Operational Efficiency: The use of hygienic components, such as these bolts, helps prevent equipment breakdowns caused by contamination, improving the overall efficiency of your operations.

- Ease of Maintenance: The smooth, non-porous surface of the bolts simplifies cleaning, ensuring that maintenance time is minimized and sanitary conditions are upheld.

EHEDG Hygienic Bolts M5 to M30 in Stainless Steel

Ensuring Hygiene and Durability for Critical Industries

The EHEDG Hygienic Bolts M5 to M30 in stainless steel are essential components for industries where hygiene and safety are top priorities. Their durable construction, resistance to harsh cleaning conditions, and compliance with stringent hygiene standards make them an excellent choice for applications in food processing, pharmaceuticals, biotechnology, and other sanitary environments. By choosing these bolts, businesses can improve the safety, efficiency, and longevity of their equipment while ensuring compliance with health and safety regulations.

See our components which ensures product safety

The Ideal Solution for Hygienic and Sanitary Applications

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

The design of the bolts does not deviate from the sizes of current standard bolts. Therefore, wrench sizes, thread heights etc. all remains the same making it very easy to upgrade and replace standard bolts. This is the right choice of bolts to be used on all machinery in all certified hygienic wash-down environments.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Material Stainless steel 1.4301 and silicon sealing.

EHEDG Hygienic bolt

3A HB M5-L10 Ø12 H=12

3A HB M5-L12 Ø12 H=12

3A HB M5-L16 Ø12 H=12

3A HB M5-L20 Ø12 H=12

3A HB M5-L25 Ø12 H=12

3A HB M5-L30 Ø12 H=12

3A HB M5-L35 Ø12 H=12

3A HB M6-L10 Ø12 H=12

3A HB M6-L12 Ø12 H=12

3A HB M6-L16 Ø12 H=12

3A HB M6-L20 Ø12 H=12

3A HB M6-L25 Ø12 H=12

3A HB M6-L30 Ø12 H=12

3A HB M6-L35 Ø12 H=12

3A HB M6-L40 Ø12 H=12

3A HB M6-L50 Ø12 H=12

3A HB M6-L60 Ø12 H=12

3A HB M6-L80 Ø12 H=12

3A HB M6-L100 Ø12 H=12

3A HB M8-L10 Ø15 H=14

3A HB M8-L12 Ø15 H=14

3A HB M8-L16 Ø15 H=14

3A HB M8-L20 Ø15 H=14

3A HB M8-L25 Ø15 H=14

3A HB M8-L30 Ø15 H=14

3A HB M8-L35 Ø15 H=14

3A HB M8-L40 Ø15 H=14

3A HB M8-L50 Ø15 H=14

3A HB M8-L60 Ø15 H=14

3A HB M8-L80 Ø15 H=14

3A HB M8-L100 Ø15 H=14

3A HB M10-L10 Ø20 H=16

3A HB M10-L12 Ø20 H=16

3A HB M10-L16 Ø20 H=16

3A HB M10-L20 Ø20 H=16

3A HB M10-L25 Ø20 H=16

3A HB M10-L30 Ø20 H=16

3A HB M10-L35 Ø20 H=16

3A HB M10-L40 Ø20 H=16

3A HB M10-L50 Ø20 H=16

3A HB M10-L60 Ø20 H=16

3A HB M10-L80 Ø20 H=16

3A HB M10-L100 Ø20 H=16

3A HB M12-L12 Ø22 H=18

3A HB M12-L16 Ø22 H=18

3A HB M12-L20 Ø22 H=18

3A HB M12-L25 Ø22 H=18

3A HB M12-L30 Ø22 H=18

3A HB M12-L35 Ø22 H=18

3A HB M12-L40 Ø22 H=18

3A HB M12-L50 Ø22 H=18

3A HB M12-L60 Ø22 H=18

3A HB M12-L80 Ø22 H=18

3A HB M12-L100 Ø22 H=18

3A HB M12-L120 Ø22 H=18

3A HB M16-L16 Ø28 H=20

3A HB M16-L20 Ø28 H=20

3A HB M16-L25 Ø28 H=20

3A HB M16-L30 Ø28 H=20

3A HB M16-L35 Ø28 H=20

3A HB M16-L40 Ø28 H=20

3A HB M16-L50 Ø28 H=20

3A HB M16-L60 Ø28 H=20

3A HB M16-L80 Ø28 H=20

3A HB M16-L100 Ø28 H=20

3A HB M16-L120 Ø28 H=20

3A HB M16-L150 Ø28 H=20

3A HB M20-L20 Ø32 H=22

3A HB M20-L25 Ø32 H=22

3A HB M20-L30 Ø32 H=22

3A HB M20-L35 Ø32 H=22

3A HB M20-L40 Ø32 H=22

3A HB M20-L50 Ø32 H=22

3A HB M20-L60 Ø32 H=22

3A HB M20-L80 Ø32 H=22

3A HB M20-L100 Ø32 H=22

3A HB M20-L120 Ø32 H=22

3A HB M20-L150 Ø32 H=22

3A HB M24-L25 Ø36 H=24

3A HB M24-L30 Ø36 H=24

3A HB M24-L35 Ø36 H=24

3A HB M24-L40 Ø36 H=24

3A HB M24-L50 Ø36 H=24

3A HB M24-L60 Ø36 H=24

3A HB M24-L80 Ø36 H=24

3A HB M24-L100 Ø36 H=24

3A HB M24-L120 Ø36 H=24

3A HB M24-L150 Ø36 H=24

3A HB M30-L30 Ø46 H=26

3A HB M30-L35 Ø46 H=26

3A HB M30-L40 Ø46 H=26

3A HB M30-L50 Ø46 H=26

3A HB M30-L60 Ø46 H=26

3A HB M30-L80 Ø46 H=26

3A HB M30-L100 Ø46 H=26

3A HB M30-L120 Ø46 H=26

3A HB M30-L150 Ø46 H=26

See our components which ensures product safety

Contact us for hygienic solution

What Are EHEDG Hygienic Bolts?

EHEDG (European Hygienic Engineering & Design Group) and Sanitary Standard are two internationally recognized standards that focus on hygienic design and performance, ensuring equipment components meet rigorous cleanliness requirements. The EHEDG Hygienic Bolts M5 to M30 in stainless steel are a prime example of high-quality components designed to meet these exacting standards. These bolts are commonly used in industries where hygiene and cleanliness are of paramount importance, including food processing, pharmaceuticals, and biotechnology.

Manufactured in stainless steel, these bolts are designed for use in environments that demand high levels of sterility. The M5 to M30 range ensures versatility, with bolts available in a variety of sizes to suit different equipment and machinery configurations.

The Importance of Hygienic Bolts in Sanitary Industries

In industries such as food processing and pharmaceuticals, equipment components like bolts are often exposed to harsh cleaning agents, high-pressure washing, and extreme temperatures. If these bolts are not designed with hygiene in mind, they can become breeding grounds for bacteria, mold, and other contaminants. The EHEDG Hygienic Bolts M5 to M30 are specifically engineered to prevent such risks, providing a solution that enhances overall equipment hygiene and reduces the chance of contamination.

These hygienic bolts are also designed to be corrosion-resistant, which makes them ideal for use in environments with high humidity or in systems exposed to chemicals, moisture, and steam. By maintaining their integrity over time, they ensure that your equipment runs efficiently and safely, with minimal risk of bacterial growth or contamination.

Features of EHEDG Hygienic Bolts M5 to M30

Several key features make the EHEDG Hygienic Bolts M5 to M30 a top choice for industries where hygiene is critical:

- Stainless Steel Construction: The stainless steel material ensures the bolts are durable, corrosion-resistant, and easy to clean, all of which are crucial for maintaining a sterile environment.

- EHEDG & Sanitary Standard Certified: These bolts meet the strict hygienic design standards set by EHEDG and Sanitary Standard, ensuring they comply with the highest industry standards for sanitation.

- Versatility in Sizes: With a size range from M5 to M30, these bolts can be used in various applications, providing flexibility for different equipment and machinery designs.

- Smooth Surface: The smooth surface of the bolts helps prevent the buildup of dirt, bacteria, and other contaminants, making them easy to clean and maintain.

- Resistance to Extreme Conditions: EHEDG Hygienic Bolts are designed to withstand high-pressure washing, heat, and exposure to cleaning chemicals, making them perfect for environments that require frequent sanitization.

Applications of EHEDG Hygienic Bolts M5 to M30

The versatility and hygienic design of these bolts make them suitable for a wide range of applications across various industries:

- Food Processing: In food production, these hygienic bolts ensure that processing equipment is safe, clean, and efficient. From mixers to conveyors, any equipment in direct contact with food must be designed to meet stringent hygiene regulations.

- Pharmaceutical Manufacturing: In pharmaceutical facilities, hygiene and safety are critical to producing high-quality medicines. These bolts are used to fasten equipment in areas where sterility must be maintained, such as in filling lines, mixers, and reactors.

- Biotechnology: In biotechnology research and development, these bolts provide the necessary hygienic performance required for sterilized equipment, ensuring no contamination interferes with the research or product development process.

- Chemical Manufacturing: The bolts are also suitable for use in the chemical industry, where harsh chemicals are often present, and hygiene must be maintained to prevent cross-contamination.

Why Choose EHEDG Hygienic Bolts?

Choosing EHEDG Hygienic Bolts M5 to M30 offers a host of benefits for companies across various industries:

- Compliance with Hygienic Standards: Meeting the EHEDG and Sanitary Standards guarantees that the bolts are compliant with industry regulations, which is essential for passing audits and maintaining certifications.

- Enhanced Equipment Longevity: With corrosion-resistant properties and durability, these bolts help extend the life of your equipment, reducing the need for frequent replacements and maintenance.

- Improved Operational Efficiency: The use of hygienic components, such as these bolts, helps prevent equipment breakdowns caused by contamination, improving the overall efficiency of your operations.

- Ease of Maintenance: The smooth, non-porous surface of the bolts simplifies cleaning, ensuring that maintenance time is minimized and sanitary conditions are upheld.

EHEDG Hygienic Bolts M5 to M30 in Stainless Steel

Ensuring Hygiene and Durability for Critical Industries

The EHEDG Hygienic Bolts M5 to M30 in stainless steel are essential components for industries where hygiene and safety are top priorities. Their durable construction, resistance to harsh cleaning conditions, and compliance with stringent hygiene standards make them an excellent choice for applications in food processing, pharmaceuticals, biotechnology, and other sanitary environments. By choosing these bolts, businesses can improve the safety, efficiency, and longevity of their equipment while ensuring compliance with health and safety regulations.

See our components which ensures product safety

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.