Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

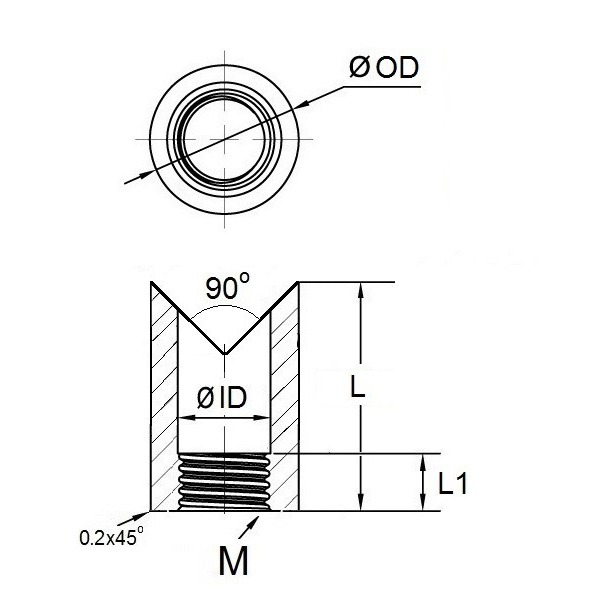

Sanitary corner nut in stainless steel

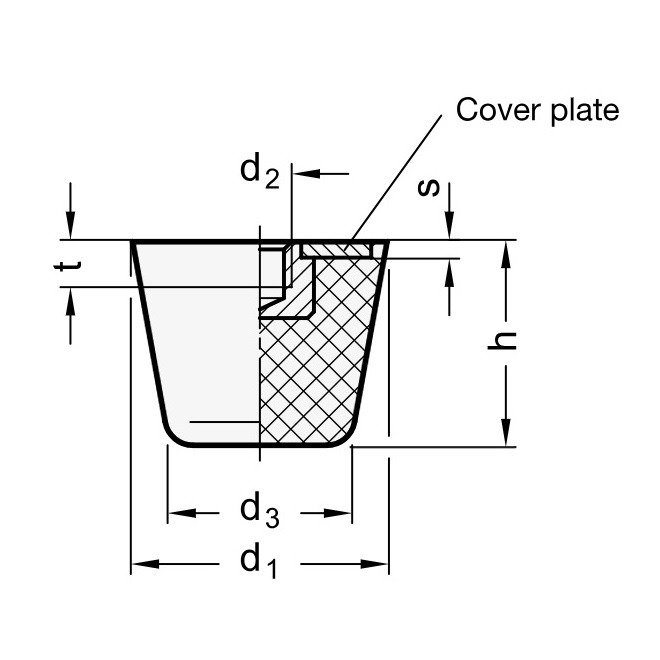

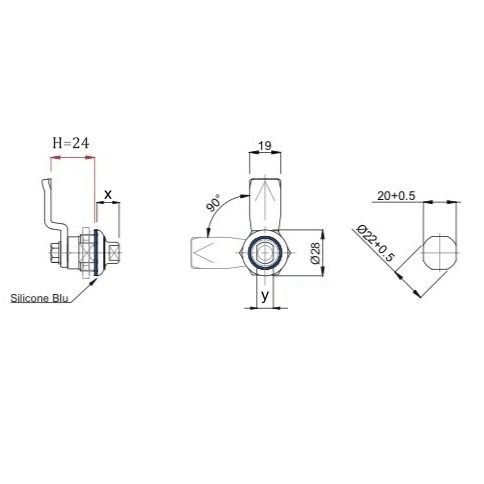

Corner nut

Our corner nut and spacer series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: medical equipment, food & pharmaceutical processing equipment, packaging machinery, 3A design-meat & poultry processing equipment, dairy processing machines.

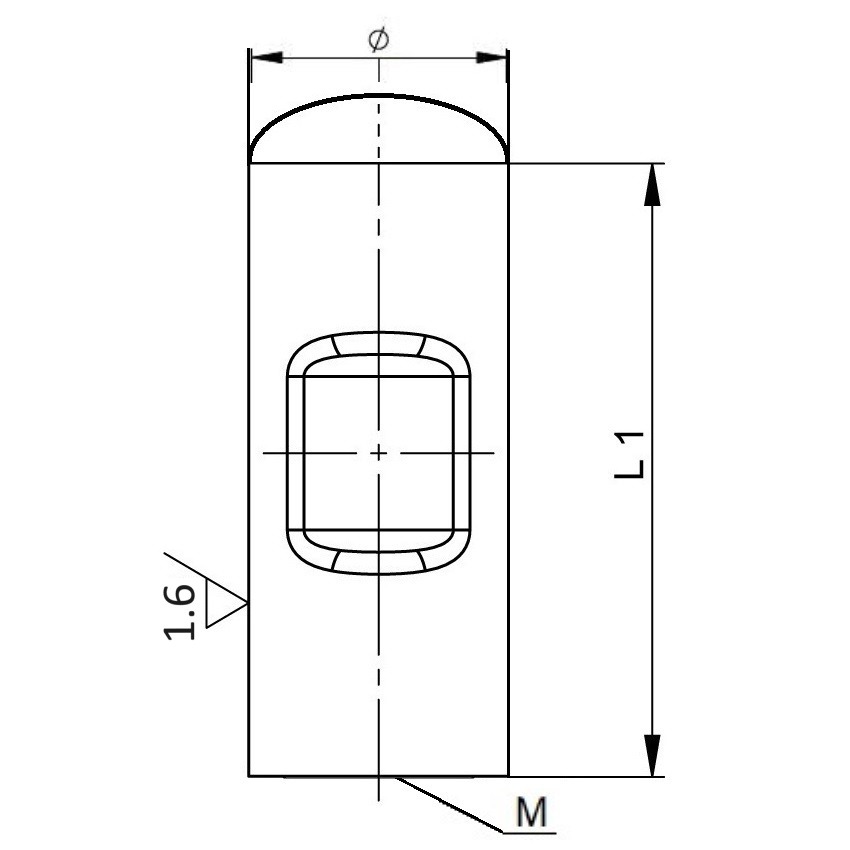

Threaded stainless steel corner nut (Aisi 1.4301)

Corner nut in stainless steel (Aisi 1.4301)

Corner nut M8-16-15 – ID=8.2 – OD=16.0 – L=15 – L1=6

Corner nut M8-16-20 – ID=8.2 – OD=16.0 – L=20 – L1=6

Corner nut M8-16-25 – ID=8.2 – OD=16.0 – L=25 – L1=10

Corner nut M10-18-15 – ID=10.2 – OD=18.0 – L=15 – L1=6

Corner nut M10-18-25 – ID=10.2 – OD=18.0 – L=25 – L1=10

Corner nut M12-22-15 – ID=12.2 – OD=22.0 – L=15 – L1=6

Corner nut M12-22-25 – ID=12.2 – OD=22.0 – L=25 – L1=10

Corner nut M16-26-15 – ID=16.2 – OD=26.0 – L=15 – L1=6

Corner nut M16-26-25 – ID=16.2 – OD=26.0 – L=25 – L1=10

Corner spacer in stainless steel (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Corner spacer 6.8-16-15 – ID=6.8 – OD=16.0 – L=15

Corner spacer 6.8-16-25 – ID=6.8 – OD=16.0 – L=25

Corner spacer 8.5-18-15 – ID=8.5 – OD=18.0 – L=15

Corner spacer 8.5-18-25 – ID=8.5 – OD=18.0 – L=25

Corner spacer 10.2-22-15 – ID=10.2 – OD=22.0 – L=15

Corner spacer 10.2-22-25 – ID=10.2 – OD=22.0 – L=25

Corner spacer 14.0-26-15 – ID=14.0 – OD=26.0 – L=15

Corner spacer 14.0-26-25 – ID=14.0 – OD=26.0 – L=25

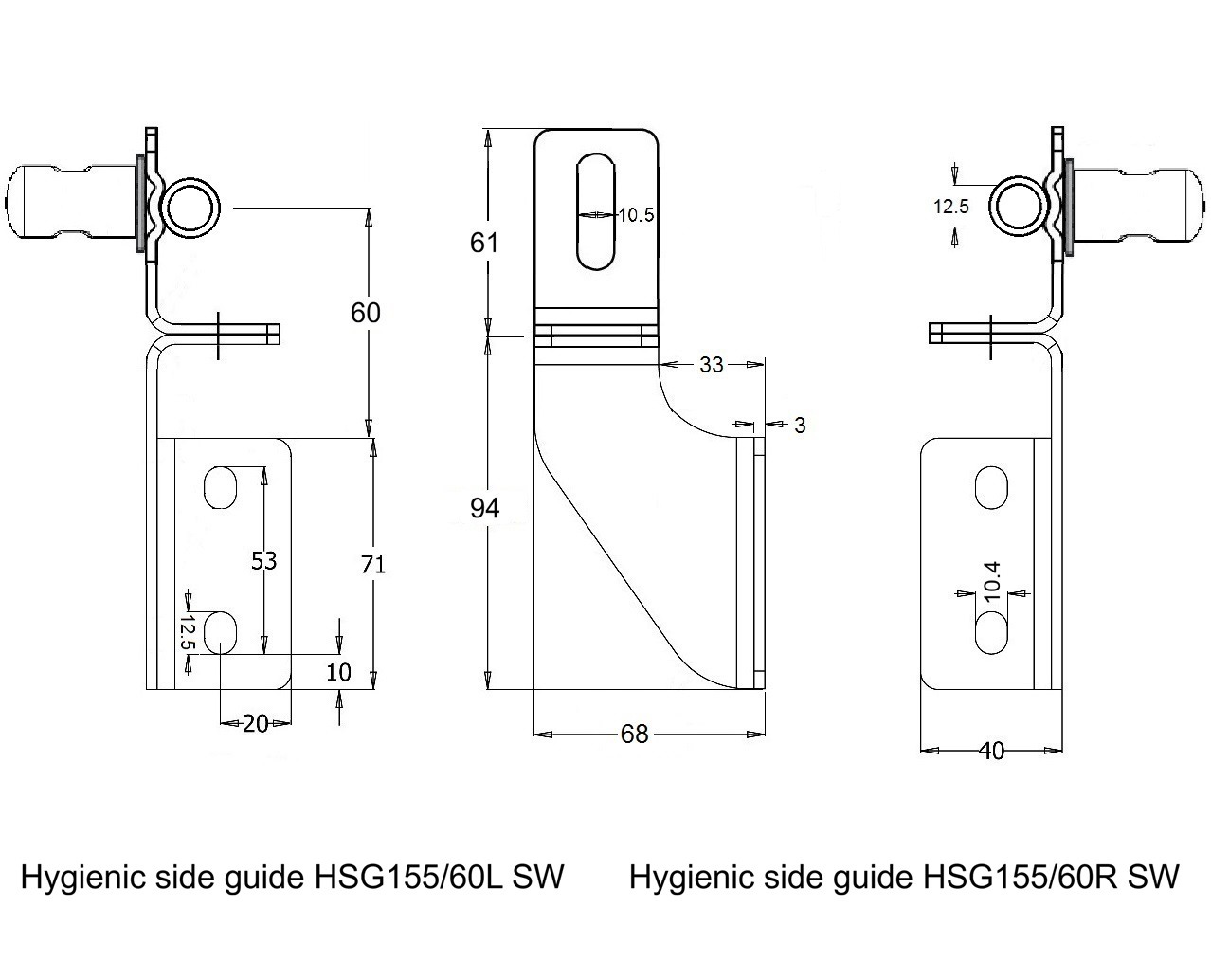

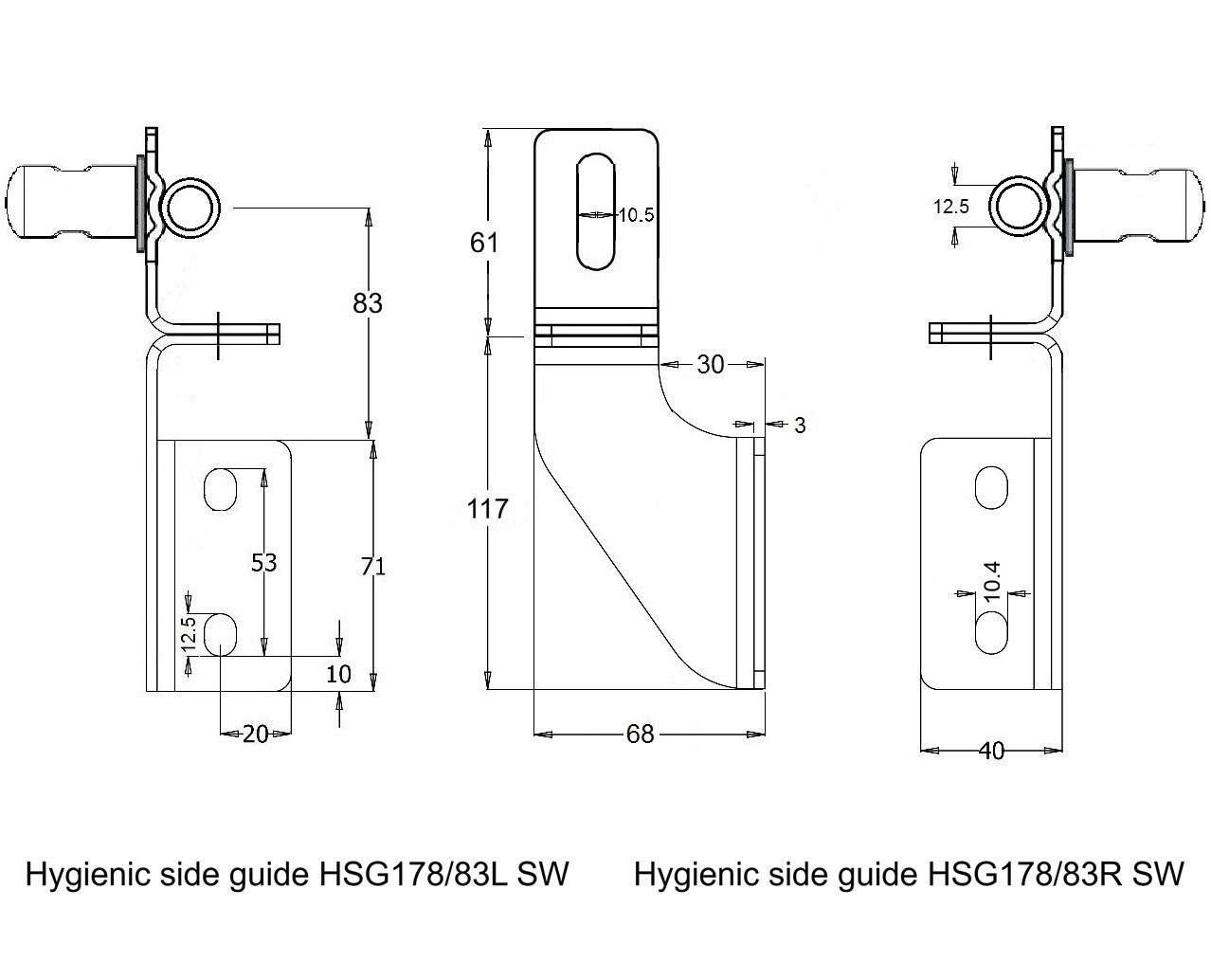

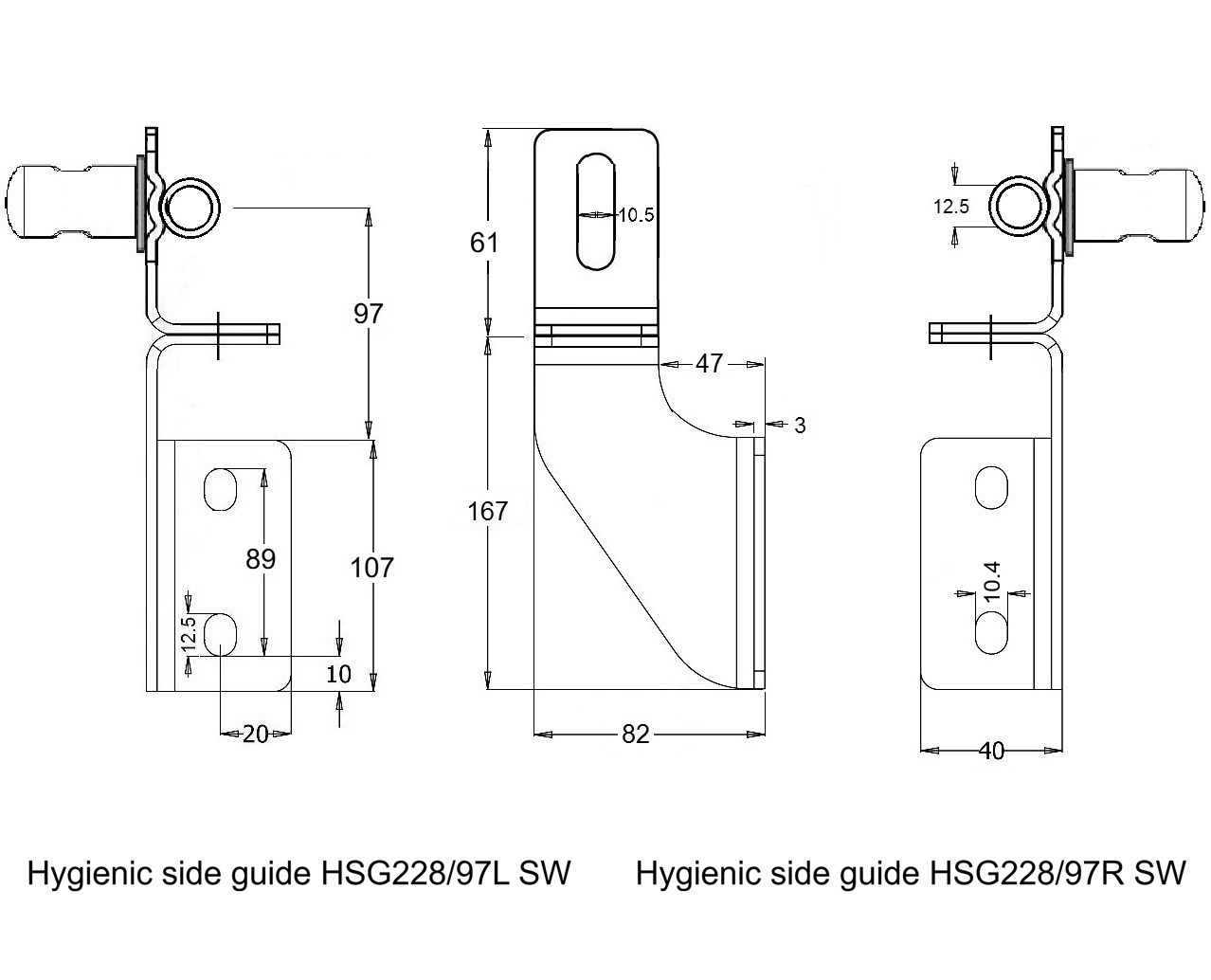

Conveyor components in hygienic design

For other size, please contact us.

Sanitary Corner Nut in Stainless Steel

Reduce Water and Cleaning Detergent Usage

In industries where hygiene is paramount, such as food processing, pharmaceuticals, and biotechnology, reducing resource consumption is a critical objective. Stainless steel sanitary corner nuts are an essential component in achieving this goal. These precision-engineered fasteners not only meet stringent cleanliness standards but also significantly reduce water and cleaning detergent usage during sanitation processes.

Hygiene Meets Sustainability

What Are Sanitary Corner Nuts?

Sanitary corner nuts are specialized fasteners designed for applications requiring impeccable hygiene. Typically made from stainless steel, these components are corrosion-resistant, durable, and easy to clean. Their unique design minimizes areas where contaminants can accumulate, ensuring compliance with rigorous hygiene standards such as EHEDG and 3-A certifications.

Reducing Cleaning Resource Usage

Traditional fasteners often have crevices and rough surfaces where dirt and bacteria can harbor, necessitating extensive cleaning procedures. Sanitary corner nuts, with their smooth, crevice-free design, require less water and cleaning detergent for effective sanitation. By optimizing cleaning processes, these components help facilities achieve sustainability goals without compromising on hygiene.

Key Benefits of Stainless Steel Sanitary Corner Nuts

1. Durability and Corrosion Resistance

Manufactured from high-grade stainless steel, these nuts withstand harsh cleaning agents and exposure to moisture. This ensures a long service life, reducing the need for frequent replacements and contributing to cost savings.

2. Ease of Cleaning

The smooth surfaces and hygienic design eliminate the risk of debris accumulation, allowing for quick and efficient cleaning. This feature reduces downtime and increases operational productivity.

3. Compliance with Industry Standards

Sanitary corner nuts meet industry certifications like EHEDG and 3-A, ensuring adherence to global hygiene standards. Their use demonstrates a commitment to quality and safety in processing environments.

4. Environmental Impact Reduction

By reducing water and detergent usage, these components contribute to more sustainable operations. Facilities can lower their environmental footprint while maintaining high sanitation standards.

Applications of Sanitary Corner Nuts

Sanitary corner nuts are indispensable in industries where cleanliness is non-negotiable.

Food and Beverage Processing

Used in conveyors, mixing equipment, and filling systems, these nuts prevent contamination and ensure product safety.

Pharmaceutical and Biotechnology Sectors

In sterile environments, stainless steel corner nuts maintain hygiene without introducing contaminants. Their easy-to-clean design supports strict compliance protocols.

Dairy Industry

From milk processing to cheese production, these components are vital for maintaining the integrity of hygienic systems.

Best Practices for Using Sanitary Corner Nuts

Regular Inspections

Conduct regular checks to ensure nuts remain intact and free from wear.

Appropriate Cleaning Methods

Use recommended cleaning agents and follow manufacturer guidelines to maximize the lifespan of the components.

Integration with Hygienic Systems

Combine sanitary corner nuts with other hygienic components for an all-encompassing approach to cleanliness and sustainability.

Choosing the Right Sanitary Corner Nuts

When selecting sanitary corner nuts, prioritize:

- Material Quality: Look for premium stainless steel options.

- Certifications: Ensure compliance with industry standards.

- Design Features: Opt for smooth surfaces and crevice-free designs to simplify cleaning.

A Small Component with Big Impacts: Sustainable Hygiene Solution

Stainless steel sanitary corner nuts may seem like a small part of hygienic systems, but their contribution to reducing water and cleaning detergent usage is substantial. By integrating these components into your operations, you can enhance efficiency, meet hygiene standards, and contribute to a more sustainable future.

Investing in such innovative solutions not only bolsters operational excellence but also underscores a commitment to environmental responsibility.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Corner nut

Our corner nut and spacer series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: medical equipment, food & pharmaceutical processing equipment, packaging machinery, 3A design-meat & poultry processing equipment, dairy processing machines.

Threaded stainless steel corner nut (Aisi 1.4301)

Corner nut in stainless steel (Aisi 1.4301)

Corner nut M8-16-15 – ID=8.2 – OD=16.0 – L=15 – L1=6

Corner nut M8-16-20 – ID=8.2 – OD=16.0 – L=20 – L1=6

Corner nut M8-16-25 – ID=8.2 – OD=16.0 – L=25 – L1=10

Corner nut M10-18-15 – ID=10.2 – OD=18.0 – L=15 – L1=6

Corner nut M10-18-25 – ID=10.2 – OD=18.0 – L=25 – L1=10

Corner nut M12-22-15 – ID=12.2 – OD=22.0 – L=15 – L1=6

Corner nut M12-22-25 – ID=12.2 – OD=22.0 – L=25 – L1=10

Corner nut M16-26-15 – ID=16.2 – OD=26.0 – L=15 – L1=6

Corner nut M16-26-25 – ID=16.2 – OD=26.0 – L=25 – L1=10

Corner spacer in stainless steel (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Corner spacer 6.8-16-15 – ID=6.8 – OD=16.0 – L=15

Corner spacer 6.8-16-25 – ID=6.8 – OD=16.0 – L=25

Corner spacer 8.5-18-15 – ID=8.5 – OD=18.0 – L=15

Corner spacer 8.5-18-25 – ID=8.5 – OD=18.0 – L=25

Corner spacer 10.2-22-15 – ID=10.2 – OD=22.0 – L=15

Corner spacer 10.2-22-25 – ID=10.2 – OD=22.0 – L=25

Corner spacer 14.0-26-15 – ID=14.0 – OD=26.0 – L=15

Corner spacer 14.0-26-25 – ID=14.0 – OD=26.0 – L=25

Conveyor components in hygienic design

For other size, please contact us.

Sanitary Corner Nut in Stainless Steel

Reduce Water and Cleaning Detergent Usage

In industries where hygiene is paramount, such as food processing, pharmaceuticals, and biotechnology, reducing resource consumption is a critical objective. Stainless steel sanitary corner nuts are an essential component in achieving this goal. These precision-engineered fasteners not only meet stringent cleanliness standards but also significantly reduce water and cleaning detergent usage during sanitation processes.

Hygiene Meets Sustainability

What Are Sanitary Corner Nuts?

Sanitary corner nuts are specialized fasteners designed for applications requiring impeccable hygiene. Typically made from stainless steel, these components are corrosion-resistant, durable, and easy to clean. Their unique design minimizes areas where contaminants can accumulate, ensuring compliance with rigorous hygiene standards such as EHEDG and 3-A certifications.

Reducing Cleaning Resource Usage

Traditional fasteners often have crevices and rough surfaces where dirt and bacteria can harbor, necessitating extensive cleaning procedures. Sanitary corner nuts, with their smooth, crevice-free design, require less water and cleaning detergent for effective sanitation. By optimizing cleaning processes, these components help facilities achieve sustainability goals without compromising on hygiene.

Key Benefits of Stainless Steel Sanitary Corner Nuts

1. Durability and Corrosion Resistance

Manufactured from high-grade stainless steel, these nuts withstand harsh cleaning agents and exposure to moisture. This ensures a long service life, reducing the need for frequent replacements and contributing to cost savings.

2. Ease of Cleaning

The smooth surfaces and hygienic design eliminate the risk of debris accumulation, allowing for quick and efficient cleaning. This feature reduces downtime and increases operational productivity.

3. Compliance with Industry Standards

Sanitary corner nuts meet industry certifications like EHEDG and 3-A, ensuring adherence to global hygiene standards. Their use demonstrates a commitment to quality and safety in processing environments.

4. Environmental Impact Reduction

By reducing water and detergent usage, these components contribute to more sustainable operations. Facilities can lower their environmental footprint while maintaining high sanitation standards.

Applications of Sanitary Corner Nuts

Sanitary corner nuts are indispensable in industries where cleanliness is non-negotiable.

Food and Beverage Processing

Used in conveyors, mixing equipment, and filling systems, these nuts prevent contamination and ensure product safety.

Pharmaceutical and Biotechnology Sectors

In sterile environments, stainless steel corner nuts maintain hygiene without introducing contaminants. Their easy-to-clean design supports strict compliance protocols.

Dairy Industry

From milk processing to cheese production, these components are vital for maintaining the integrity of hygienic systems.

Best Practices for Using Sanitary Corner Nuts

Regular Inspections

Conduct regular checks to ensure nuts remain intact and free from wear.

Appropriate Cleaning Methods

Use recommended cleaning agents and follow manufacturer guidelines to maximize the lifespan of the components.

Integration with Hygienic Systems

Combine sanitary corner nuts with other hygienic components for an all-encompassing approach to cleanliness and sustainability.

Choosing the Right Sanitary Corner Nuts

When selecting sanitary corner nuts, prioritize:

- Material Quality: Look for premium stainless steel options.

- Certifications: Ensure compliance with industry standards.

- Design Features: Opt for smooth surfaces and crevice-free designs to simplify cleaning.

A Small Component with Big Impacts: Sustainable Hygiene Solution

Stainless steel sanitary corner nuts may seem like a small part of hygienic systems, but their contribution to reducing water and cleaning detergent usage is substantial. By integrating these components into your operations, you can enhance efficiency, meet hygiene standards, and contribute to a more sustainable future.

Investing in such innovative solutions not only bolsters operational excellence but also underscores a commitment to environmental responsibility.

Corner nut

Our corner nut and spacer series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: medical equipment, food & pharmaceutical processing equipment, packaging machinery, 3A design-meat & poultry processing equipment, dairy processing machines.

Threaded stainless steel corner nut (Aisi 1.4301)

Corner nut in stainless steel (Aisi 1.4301)

Corner nut M8-16-15 – ID=8.2 – OD=16.0 – L=15 – L1=6

Corner nut M8-16-20 – ID=8.2 – OD=16.0 – L=20 – L1=6

Corner nut M8-16-25 – ID=8.2 – OD=16.0 – L=25 – L1=10

Corner nut M10-18-15 – ID=10.2 – OD=18.0 – L=15 – L1=6

Corner nut M10-18-25 – ID=10.2 – OD=18.0 – L=25 – L1=10

Corner nut M12-22-15 – ID=12.2 – OD=22.0 – L=15 – L1=6

Corner nut M12-22-25 – ID=12.2 – OD=22.0 – L=25 – L1=10

Corner nut M16-26-15 – ID=16.2 – OD=26.0 – L=15 – L1=6

Corner nut M16-26-25 – ID=16.2 – OD=26.0 – L=25 – L1=10

Corner spacer in stainless steel (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Corner spacer 6.8-16-15 – ID=6.8 – OD=16.0 – L=15

Corner spacer 6.8-16-25 – ID=6.8 – OD=16.0 – L=25

Corner spacer 8.5-18-15 – ID=8.5 – OD=18.0 – L=15

Corner spacer 8.5-18-25 – ID=8.5 – OD=18.0 – L=25

Corner spacer 10.2-22-15 – ID=10.2 – OD=22.0 – L=15

Corner spacer 10.2-22-25 – ID=10.2 – OD=22.0 – L=25

Corner spacer 14.0-26-15 – ID=14.0 – OD=26.0 – L=15

Corner spacer 14.0-26-25 – ID=14.0 – OD=26.0 – L=25

Conveyor components in hygienic design

For other size, please contact us.

Sanitary Corner Nut in Stainless Steel

Reduce Water and Cleaning Detergent Usage

In industries where hygiene is paramount, such as food processing, pharmaceuticals, and biotechnology, reducing resource consumption is a critical objective. Stainless steel sanitary corner nuts are an essential component in achieving this goal. These precision-engineered fasteners not only meet stringent cleanliness standards but also significantly reduce water and cleaning detergent usage during sanitation processes.

Hygiene Meets Sustainability

What Are Sanitary Corner Nuts?

Sanitary corner nuts are specialized fasteners designed for applications requiring impeccable hygiene. Typically made from stainless steel, these components are corrosion-resistant, durable, and easy to clean. Their unique design minimizes areas where contaminants can accumulate, ensuring compliance with rigorous hygiene standards such as EHEDG and 3-A certifications.

Reducing Cleaning Resource Usage

Traditional fasteners often have crevices and rough surfaces where dirt and bacteria can harbor, necessitating extensive cleaning procedures. Sanitary corner nuts, with their smooth, crevice-free design, require less water and cleaning detergent for effective sanitation. By optimizing cleaning processes, these components help facilities achieve sustainability goals without compromising on hygiene.

Key Benefits of Stainless Steel Sanitary Corner Nuts

1. Durability and Corrosion Resistance

Manufactured from high-grade stainless steel, these nuts withstand harsh cleaning agents and exposure to moisture. This ensures a long service life, reducing the need for frequent replacements and contributing to cost savings.

2. Ease of Cleaning

The smooth surfaces and hygienic design eliminate the risk of debris accumulation, allowing for quick and efficient cleaning. This feature reduces downtime and increases operational productivity.

3. Compliance with Industry Standards

Sanitary corner nuts meet industry certifications like EHEDG and 3-A, ensuring adherence to global hygiene standards. Their use demonstrates a commitment to quality and safety in processing environments.

4. Environmental Impact Reduction

By reducing water and detergent usage, these components contribute to more sustainable operations. Facilities can lower their environmental footprint while maintaining high sanitation standards.

Applications of Sanitary Corner Nuts

Sanitary corner nuts are indispensable in industries where cleanliness is non-negotiable.

Food and Beverage Processing

Used in conveyors, mixing equipment, and filling systems, these nuts prevent contamination and ensure product safety.

Pharmaceutical and Biotechnology Sectors

In sterile environments, stainless steel corner nuts maintain hygiene without introducing contaminants. Their easy-to-clean design supports strict compliance protocols.

Dairy Industry

From milk processing to cheese production, these components are vital for maintaining the integrity of hygienic systems.

Best Practices for Using Sanitary Corner Nuts

Regular Inspections

Conduct regular checks to ensure nuts remain intact and free from wear.

Appropriate Cleaning Methods

Use recommended cleaning agents and follow manufacturer guidelines to maximize the lifespan of the components.

Integration with Hygienic Systems

Combine sanitary corner nuts with other hygienic components for an all-encompassing approach to cleanliness and sustainability.

Choosing the Right Sanitary Corner Nuts

When selecting sanitary corner nuts, prioritize:

- Material Quality: Look for premium stainless steel options.

- Certifications: Ensure compliance with industry standards.

- Design Features: Opt for smooth surfaces and crevice-free designs to simplify cleaning.

A Small Component with Big Impacts: Sustainable Hygiene Solution

Stainless steel sanitary corner nuts may seem like a small part of hygienic systems, but their contribution to reducing water and cleaning detergent usage is substantial. By integrating these components into your operations, you can enhance efficiency, meet hygiene standards, and contribute to a more sustainable future.

Investing in such innovative solutions not only bolsters operational excellence but also underscores a commitment to environmental responsibility.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.