Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

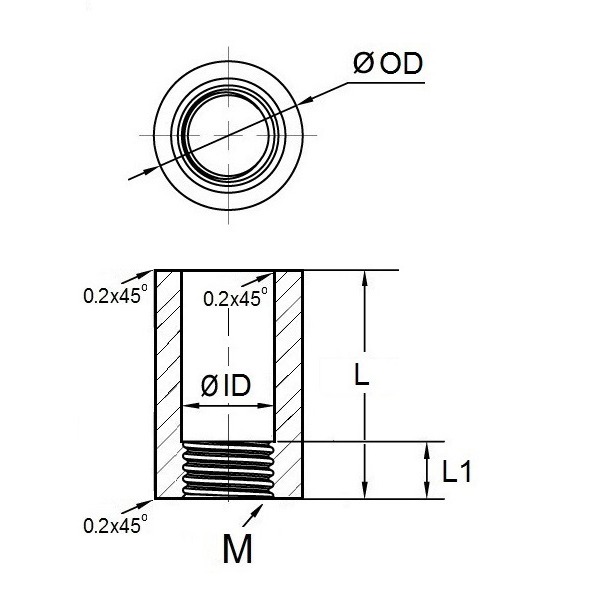

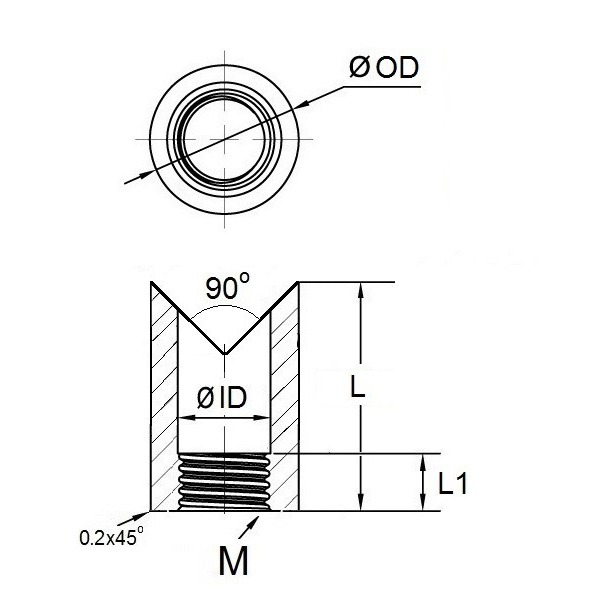

Hygienic nuts in stainless steel

Hygienic nuts in stainless steel

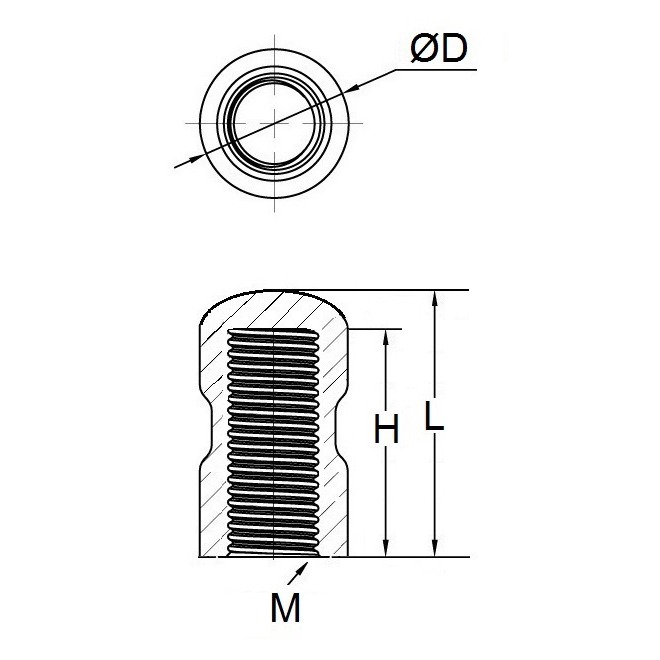

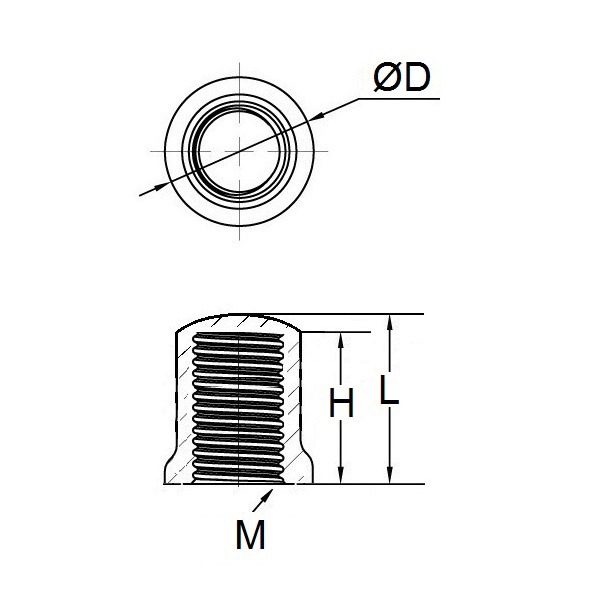

Hygienic nut in stainless steel (Aisi 1.4301)

Hygienic nut M10-L25 – M=M10 – L=25.0 – H=20 – ØD=20

Hygienic nut M10-L35 – M=M10 – L=35.0 – H=30 – ØD=20

In addition to our standard nuts, we also supply customized nuts.

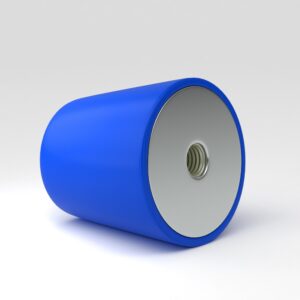

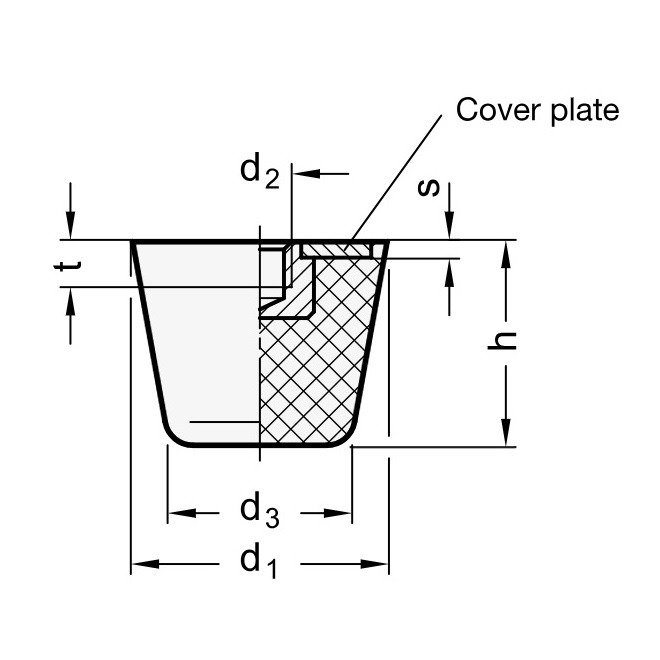

Machinery components in hygienic design

For other size, please contact us.

Hygienic Nuts in Stainless Steel

Enhancing Sanitary Standards in Industrial Applications

In industries like food processing, pharmaceuticals, and biotechnology, maintaining high hygiene standards is non-negotiable. Hygienic nuts in stainless steel are vital components designed to meet the stringent sanitary requirements of these industries. Their innovative design minimizes contamination risks while ensuring mechanical reliability in challenging environments.

Why Stainless Steel for Hygienic Nuts?

Corrosion Resistance and Longevity

Stainless steel is renowned for its superior corrosion resistance, making it an ideal material for hygienic nuts. These nuts are designed to withstand harsh cleaning agents, high-pressure washdowns, and extreme temperatures without degrading. This durability reduces maintenance costs and ensures long-term performance.

Smooth Surface Design

The smooth surface finish of stainless steel hygienic nuts prevents the accumulation of dirt, bacteria, and other contaminants. This feature is critical in environments where cleanliness is paramount, such as food processing plants and pharmaceutical facilities.

Compliance with Industry Standards

Hygienic nuts are often manufactured to comply with international hygiene standards, including EHEDG and 3-A certifications. These certifications ensure the nuts meet rigorous sanitation requirements, providing peace of mind for industries that prioritize safety and cleanliness.

Applications of Hygienic Nuts in Stainless Steel

Food and Beverage Processing

Hygienic nuts are extensively used in food and beverage processing equipment, such as conveyors, mixers, and packaging machines. Their ability to withstand corrosive substances like salt, sugar, and acidic ingredients makes them indispensable.

Pharmaceutical and Biotechnology Industries

In pharmaceutical and biotech applications, where sterility is critical, hygienic nuts play a crucial role. They are commonly used in machinery for tablet production, liquid filling, and vaccine manufacturing, ensuring contamination-free operations.

Chemical and Cosmetics Manufacturing

Hygienic nuts are also valuable in chemical and cosmetics manufacturing, where frequent cleaning and exposure to aggressive chemicals are routine. Their resistance to chemical corrosion ensures both safety and durability.

Advantages of Hygienic Nuts in Stainless Steel

Enhanced Cleanability

Hygienic nuts are designed with rounded edges and smooth surfaces, allowing for easy cleaning and preventing bacterial growth. This feature is particularly beneficial in CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems.

High Strength and Load-Bearing Capacity

Stainless steel hygienic nuts are engineered for high mechanical strength, making them suitable for heavy-duty applications. They provide reliable fastening solutions without compromising hygiene.

Eco-Friendly and Recyclable

Stainless steel is an environmentally friendly material, as it is fully recyclable. Hygienic nuts made from stainless steel contribute to sustainable practices by reducing waste and environmental impact.

Key Considerations When Selecting Hygienic Nuts

- Material Grade: Choose the appropriate stainless steel grade, such as 304 or 316, depending on the application. 316 stainless steel offers enhanced resistance to chlorides and is ideal for harsh environments.

- Certifications: Ensure the nuts comply with relevant hygiene standards, such as EHEDG or FDA guidelines.

- Surface Finish: Opt for a polished or electropolished finish for superior cleanability and reduced contamination risk.

- Size and Compatibility: Select nuts that fit seamlessly with your existing machinery and components.

Elevate Hygiene Standards with Stainless Steel Hygienic Nuts

Hygienic nuts in stainless steel are an essential component in industries where cleanliness, durability, and safety are top priorities. By investing in these high-quality fasteners, businesses can enhance their operational efficiency, comply with stringent hygiene regulations, and ensure product integrity. Whether in food processing, pharmaceuticals, or cosmetics, stainless steel hygienic nuts are a reliable choice for maintaining the highest sanitary standards.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Hygienic nuts in stainless steel

Hygienic nut in stainless steel (Aisi 1.4301)

Hygienic nut M10-L25 – M=M10 – L=25.0 – H=20 – ØD=20

Hygienic nut M10-L35 – M=M10 – L=35.0 – H=30 – ØD=20

In addition to our standard nuts, we also supply customized nuts.

Machinery components in hygienic design

For other size, please contact us.

Hygienic Nuts in Stainless Steel

Enhancing Sanitary Standards in Industrial Applications

In industries like food processing, pharmaceuticals, and biotechnology, maintaining high hygiene standards is non-negotiable. Hygienic nuts in stainless steel are vital components designed to meet the stringent sanitary requirements of these industries. Their innovative design minimizes contamination risks while ensuring mechanical reliability in challenging environments.

Why Stainless Steel for Hygienic Nuts?

Corrosion Resistance and Longevity

Stainless steel is renowned for its superior corrosion resistance, making it an ideal material for hygienic nuts. These nuts are designed to withstand harsh cleaning agents, high-pressure washdowns, and extreme temperatures without degrading. This durability reduces maintenance costs and ensures long-term performance.

Smooth Surface Design

The smooth surface finish of stainless steel hygienic nuts prevents the accumulation of dirt, bacteria, and other contaminants. This feature is critical in environments where cleanliness is paramount, such as food processing plants and pharmaceutical facilities.

Compliance with Industry Standards

Hygienic nuts are often manufactured to comply with international hygiene standards, including EHEDG and 3-A certifications. These certifications ensure the nuts meet rigorous sanitation requirements, providing peace of mind for industries that prioritize safety and cleanliness.

Applications of Hygienic Nuts in Stainless Steel

Food and Beverage Processing

Hygienic nuts are extensively used in food and beverage processing equipment, such as conveyors, mixers, and packaging machines. Their ability to withstand corrosive substances like salt, sugar, and acidic ingredients makes them indispensable.

Pharmaceutical and Biotechnology Industries

In pharmaceutical and biotech applications, where sterility is critical, hygienic nuts play a crucial role. They are commonly used in machinery for tablet production, liquid filling, and vaccine manufacturing, ensuring contamination-free operations.

Chemical and Cosmetics Manufacturing

Hygienic nuts are also valuable in chemical and cosmetics manufacturing, where frequent cleaning and exposure to aggressive chemicals are routine. Their resistance to chemical corrosion ensures both safety and durability.

Advantages of Hygienic Nuts in Stainless Steel

Enhanced Cleanability

Hygienic nuts are designed with rounded edges and smooth surfaces, allowing for easy cleaning and preventing bacterial growth. This feature is particularly beneficial in CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems.

High Strength and Load-Bearing Capacity

Stainless steel hygienic nuts are engineered for high mechanical strength, making them suitable for heavy-duty applications. They provide reliable fastening solutions without compromising hygiene.

Eco-Friendly and Recyclable

Stainless steel is an environmentally friendly material, as it is fully recyclable. Hygienic nuts made from stainless steel contribute to sustainable practices by reducing waste and environmental impact.

Key Considerations When Selecting Hygienic Nuts

- Material Grade: Choose the appropriate stainless steel grade, such as 304 or 316, depending on the application. 316 stainless steel offers enhanced resistance to chlorides and is ideal for harsh environments.

- Certifications: Ensure the nuts comply with relevant hygiene standards, such as EHEDG or FDA guidelines.

- Surface Finish: Opt for a polished or electropolished finish for superior cleanability and reduced contamination risk.

- Size and Compatibility: Select nuts that fit seamlessly with your existing machinery and components.

Elevate Hygiene Standards with Stainless Steel Hygienic Nuts

Hygienic nuts in stainless steel are an essential component in industries where cleanliness, durability, and safety are top priorities. By investing in these high-quality fasteners, businesses can enhance their operational efficiency, comply with stringent hygiene regulations, and ensure product integrity. Whether in food processing, pharmaceuticals, or cosmetics, stainless steel hygienic nuts are a reliable choice for maintaining the highest sanitary standards.

Hygienic nuts in stainless steel

Hygienic nut in stainless steel (Aisi 1.4301)

Hygienic nut M10-L25 – M=M10 – L=25.0 – H=20 – ØD=20

Hygienic nut M10-L35 – M=M10 – L=35.0 – H=30 – ØD=20

In addition to our standard nuts, we also supply customized nuts.

Machinery components in hygienic design

For other size, please contact us.

Hygienic Nuts in Stainless Steel

Enhancing Sanitary Standards in Industrial Applications

In industries like food processing, pharmaceuticals, and biotechnology, maintaining high hygiene standards is non-negotiable. Hygienic nuts in stainless steel are vital components designed to meet the stringent sanitary requirements of these industries. Their innovative design minimizes contamination risks while ensuring mechanical reliability in challenging environments.

Why Stainless Steel for Hygienic Nuts?

Corrosion Resistance and Longevity

Stainless steel is renowned for its superior corrosion resistance, making it an ideal material for hygienic nuts. These nuts are designed to withstand harsh cleaning agents, high-pressure washdowns, and extreme temperatures without degrading. This durability reduces maintenance costs and ensures long-term performance.

Smooth Surface Design

The smooth surface finish of stainless steel hygienic nuts prevents the accumulation of dirt, bacteria, and other contaminants. This feature is critical in environments where cleanliness is paramount, such as food processing plants and pharmaceutical facilities.

Compliance with Industry Standards

Hygienic nuts are often manufactured to comply with international hygiene standards, including EHEDG and 3-A certifications. These certifications ensure the nuts meet rigorous sanitation requirements, providing peace of mind for industries that prioritize safety and cleanliness.

Applications of Hygienic Nuts in Stainless Steel

Food and Beverage Processing

Hygienic nuts are extensively used in food and beverage processing equipment, such as conveyors, mixers, and packaging machines. Their ability to withstand corrosive substances like salt, sugar, and acidic ingredients makes them indispensable.

Pharmaceutical and Biotechnology Industries

In pharmaceutical and biotech applications, where sterility is critical, hygienic nuts play a crucial role. They are commonly used in machinery for tablet production, liquid filling, and vaccine manufacturing, ensuring contamination-free operations.

Chemical and Cosmetics Manufacturing

Hygienic nuts are also valuable in chemical and cosmetics manufacturing, where frequent cleaning and exposure to aggressive chemicals are routine. Their resistance to chemical corrosion ensures both safety and durability.

Advantages of Hygienic Nuts in Stainless Steel

Enhanced Cleanability

Hygienic nuts are designed with rounded edges and smooth surfaces, allowing for easy cleaning and preventing bacterial growth. This feature is particularly beneficial in CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems.

High Strength and Load-Bearing Capacity

Stainless steel hygienic nuts are engineered for high mechanical strength, making them suitable for heavy-duty applications. They provide reliable fastening solutions without compromising hygiene.

Eco-Friendly and Recyclable

Stainless steel is an environmentally friendly material, as it is fully recyclable. Hygienic nuts made from stainless steel contribute to sustainable practices by reducing waste and environmental impact.

Key Considerations When Selecting Hygienic Nuts

- Material Grade: Choose the appropriate stainless steel grade, such as 304 or 316, depending on the application. 316 stainless steel offers enhanced resistance to chlorides and is ideal for harsh environments.

- Certifications: Ensure the nuts comply with relevant hygiene standards, such as EHEDG or FDA guidelines.

- Surface Finish: Opt for a polished or electropolished finish for superior cleanability and reduced contamination risk.

- Size and Compatibility: Select nuts that fit seamlessly with your existing machinery and components.

Elevate Hygiene Standards with Stainless Steel Hygienic Nuts

Hygienic nuts in stainless steel are an essential component in industries where cleanliness, durability, and safety are top priorities. By investing in these high-quality fasteners, businesses can enhance their operational efficiency, comply with stringent hygiene regulations, and ensure product integrity. Whether in food processing, pharmaceuticals, or cosmetics, stainless steel hygienic nuts are a reliable choice for maintaining the highest sanitary standards.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.